Apparatus for forming inflated packaging cushions

a technology for packaging cushions and inflated cushions, which is applied in the field of conventional apparatuses for forming inflated packaging cushions, can solve the problems of large and complex machines, difficult installation of such apparatuses at manufacturing sites and other locations where packaging takes place, and gross inefficiency and cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

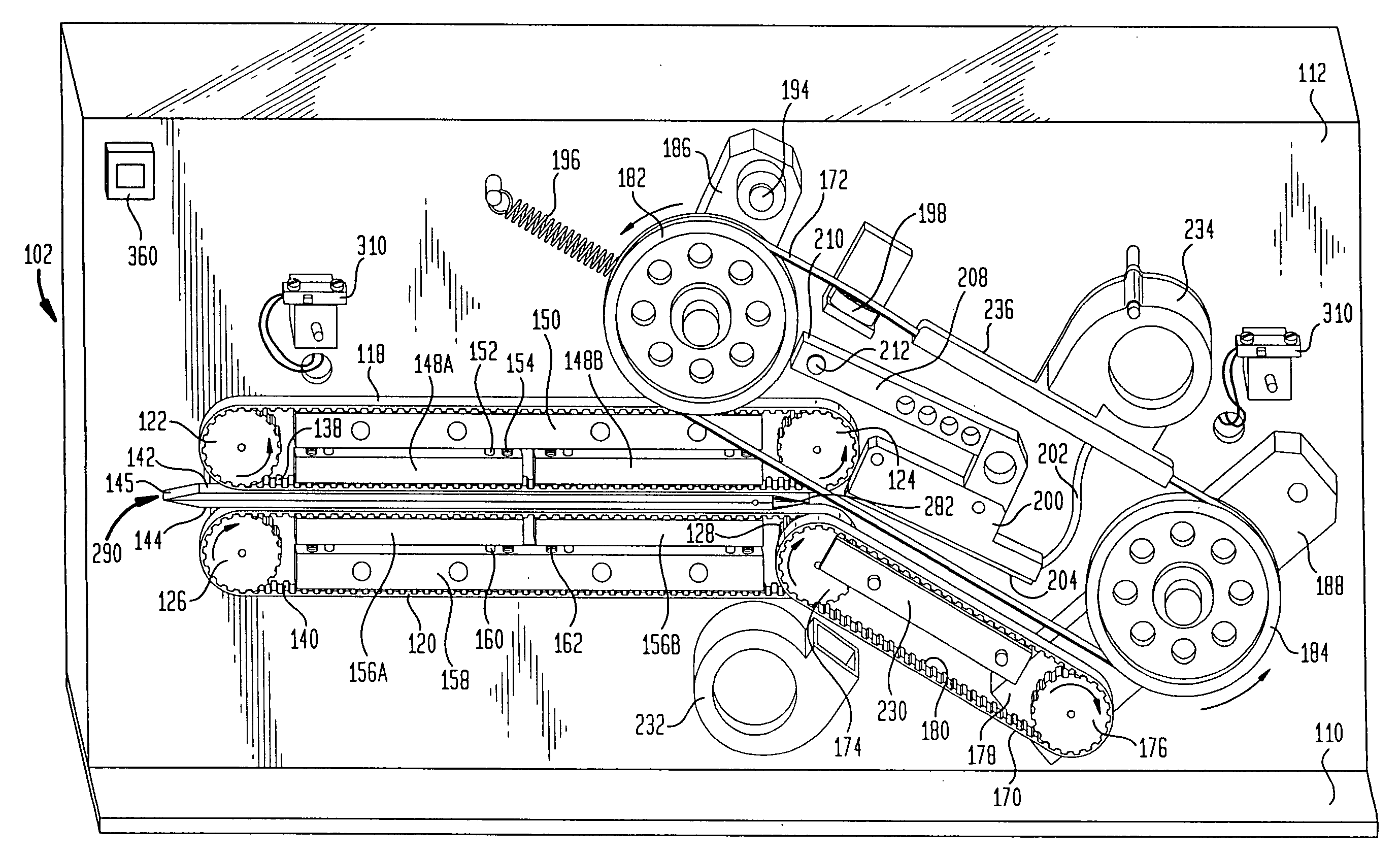

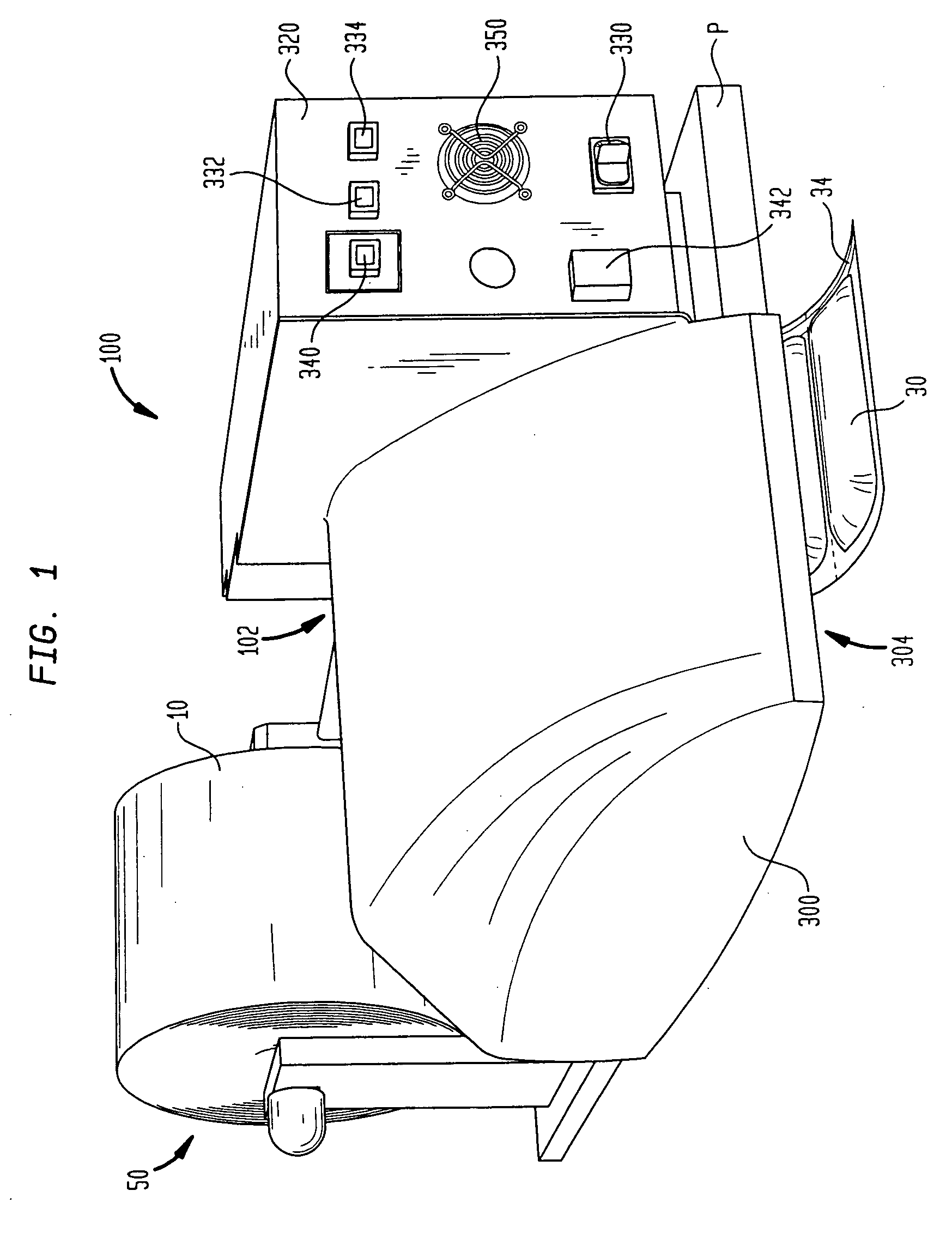

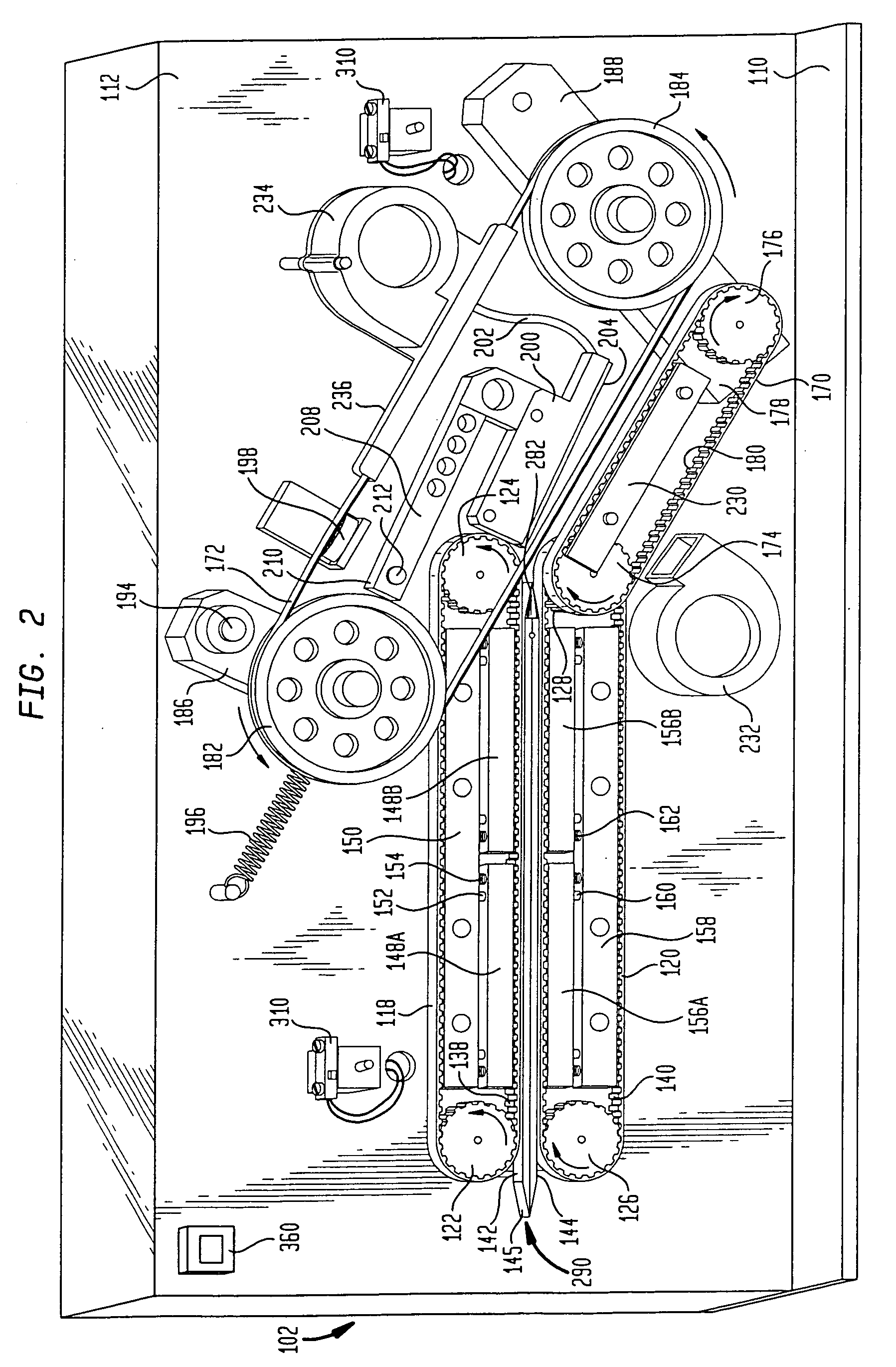

[0025] An apparatus 100 for forming inflated packaging cushions in accordance with the present invention is illustrated in FIG. 1. Generally speaking, apparatus 100 receives a film web 10 preformed with a plurality of open pockets, conveys the web past an inflation zone where the pockets are inflated with a gas, and then seals the pockets closed to entrap the gas therein. Each inflated pocket acts as a cushion for protecting an article packaged in an outer container.

[0026] Film web 10 may be formed from any flexible material that can be manipulated by apparatus 100 and retain a gas as described herein, including various thermoplastic materials, such as polyethylene homopolymer or copolymer, polypropylene homopolymer or copolymer, etc. Non-limiting examples of suitable thermoplastic polymers include polyethylene homopolymers, such as low density polyethylene (LDPE) and high density polyethylene (HDPE), and polyethylene copolymers such as ionomers, EVA, EMA, heterogeneous (Ziegler-Na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com