Gas Charging Method and Gas Charging Apparatus for Bag Equipped with Gas Compartment Portion

a gas compartment and gas charging technology, which is applied in the direction of liquid handling, packaging goods, caps, etc., can solve the problems of difficult to improve productivity, gas compartment portion adhesion, front and rear film sheets that constitute, etc., and achieve the effect of smooth gas filling and no loss of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

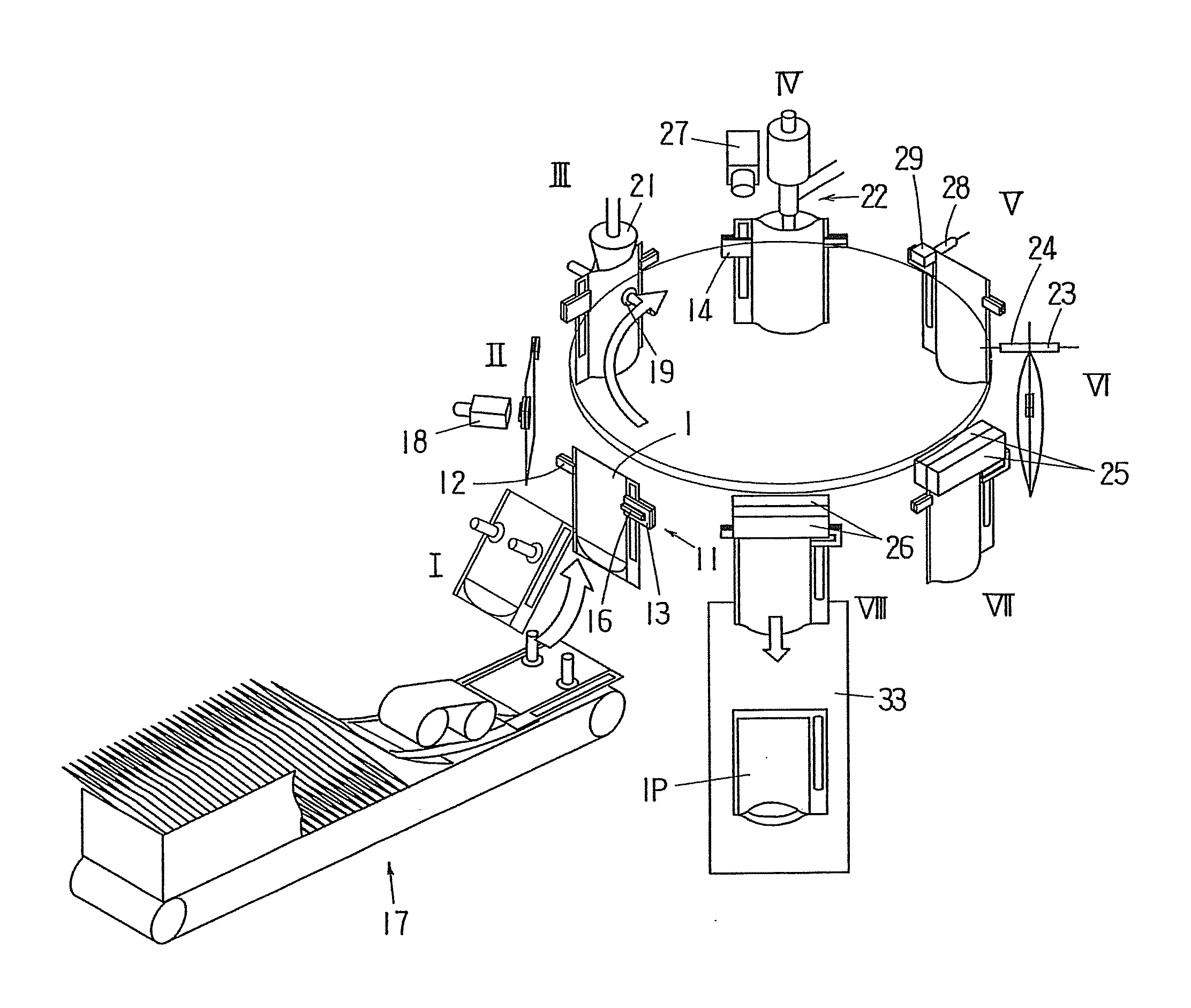

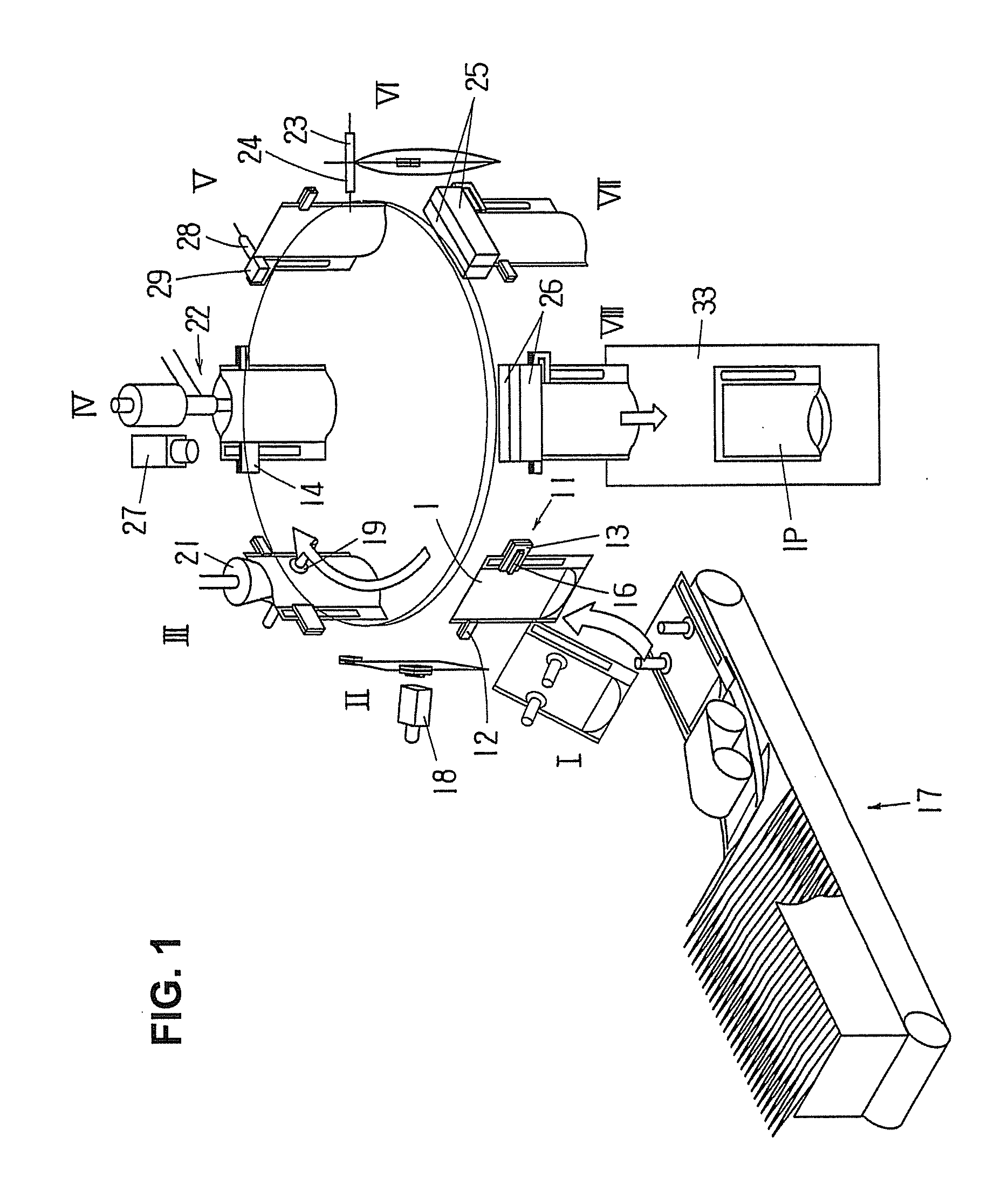

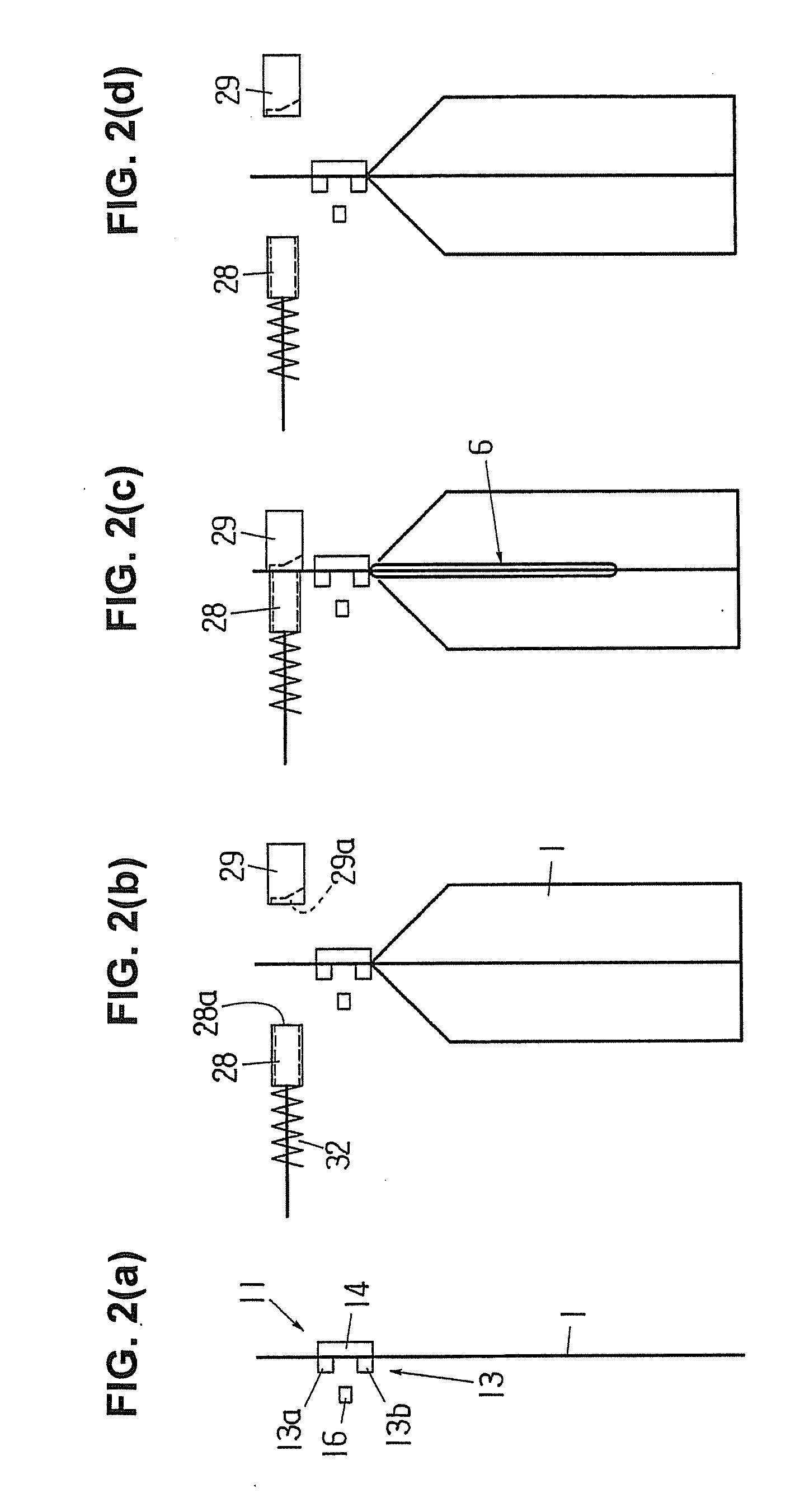

[0044]A gas charging method and apparatus of the present invention will be described below in more detail with reference to FIG. 1-FIG. 9(b).

[0045]FIGS. 5(a) and 5(b) show a bag 1 that is equipped with a gas compartment portion 6. The bag 1 is a bottom-gusseted self-supporting bag that is made up of front and rear film sheets, as well as a folded bottom film sheet. In the upper region X of the bag 1, the front and rear film sheets of the bag 1 are bonded together along the two lateral side edges, thereby forming seal portions 2, 3. At the upper edge, the front and rear film sheets are not bonded together, creating an open bag mouth 4. In the lower region Y of the bag 1, the front and rear film sheets are bonded along the two lateral side edges, thereby sandwiching the film sheet of the bottom portion, and, in addition, are bonded on the inside, where the film sheet of the bottom portion itself is folded inward. In the central portion, the front and rear film sheets are respectively ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| adhesion | aaaaa | aaaaa |

| shape retention | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com