Patents

Literature

35results about How to "Without lowering productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

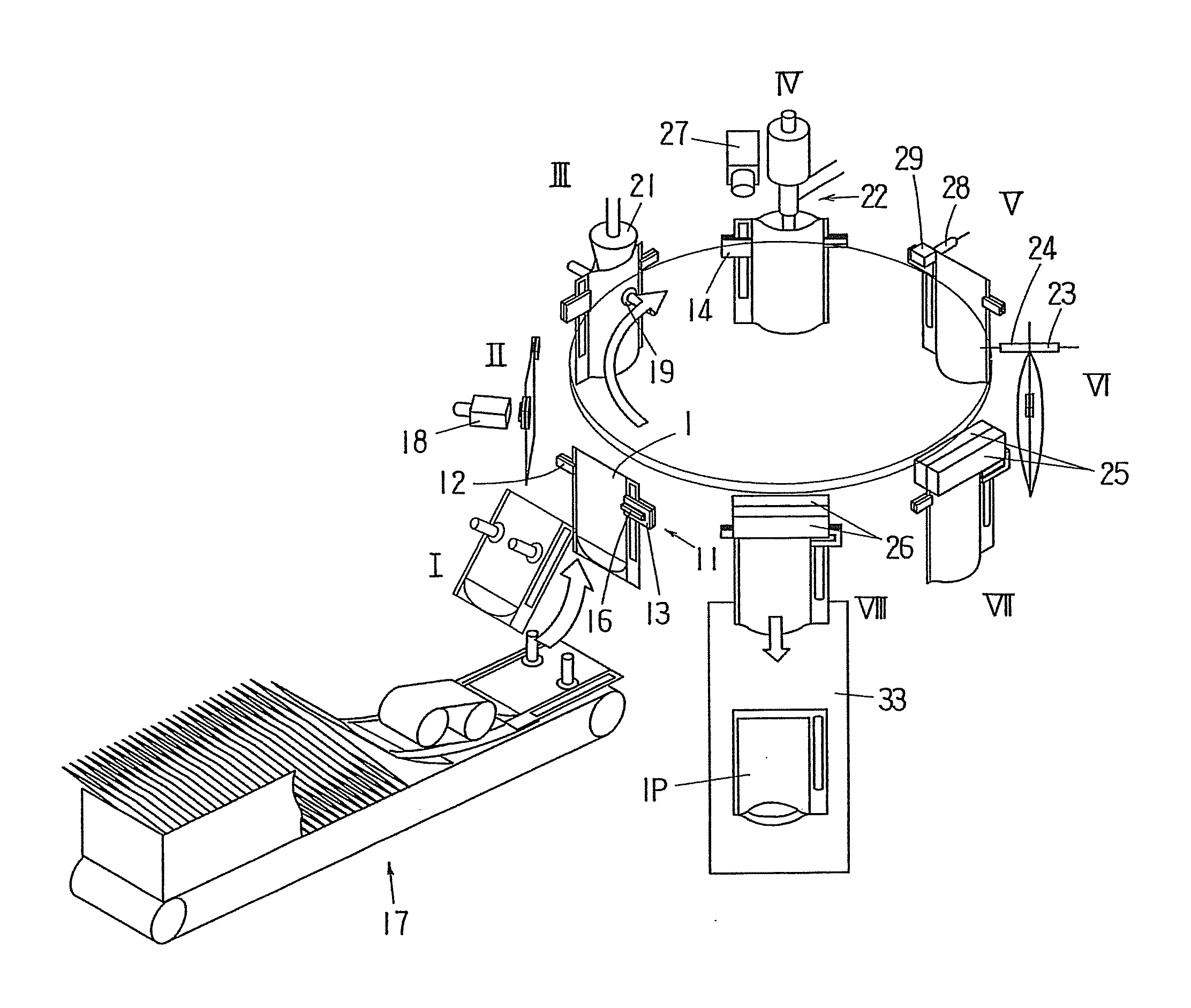

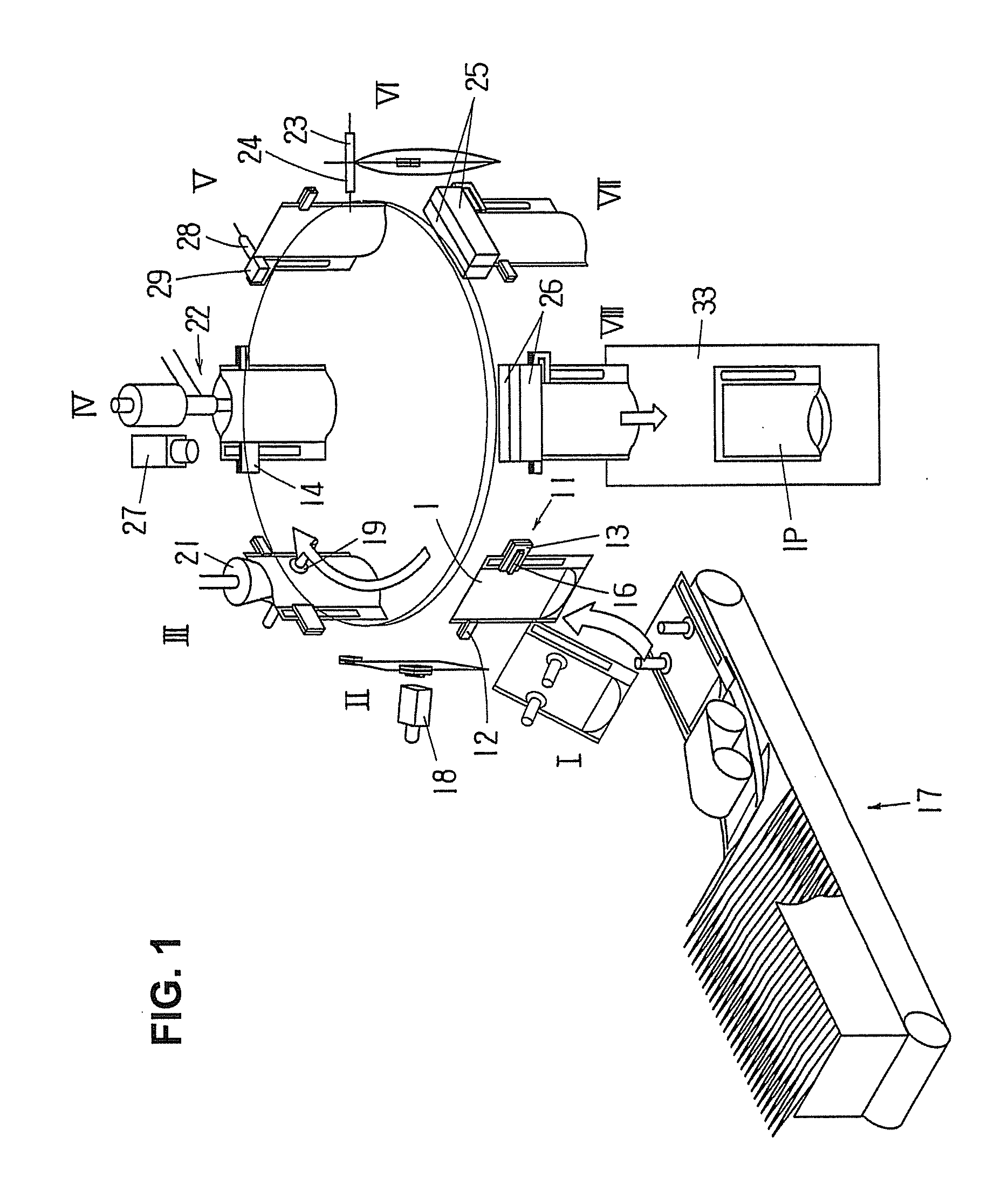

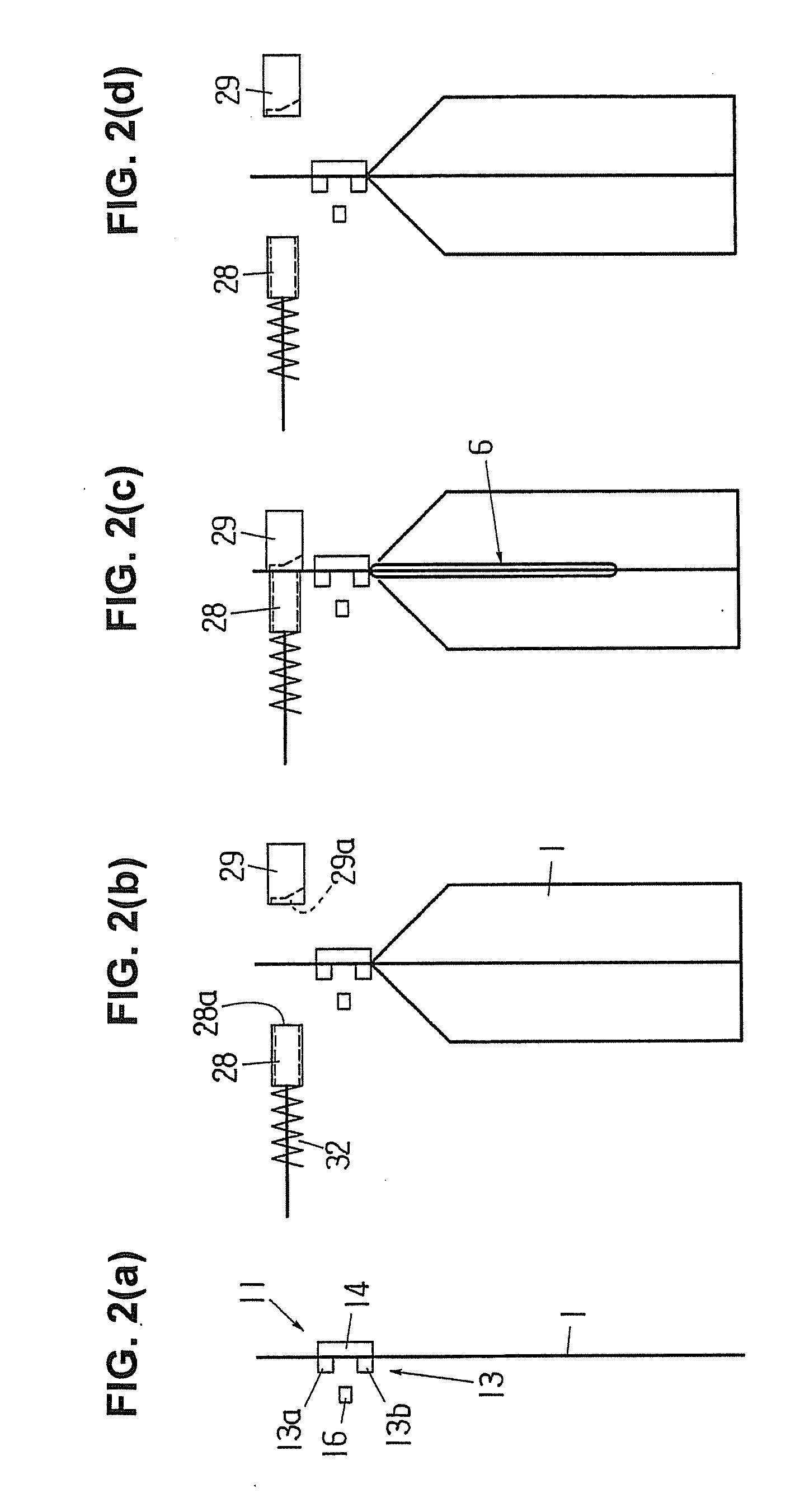

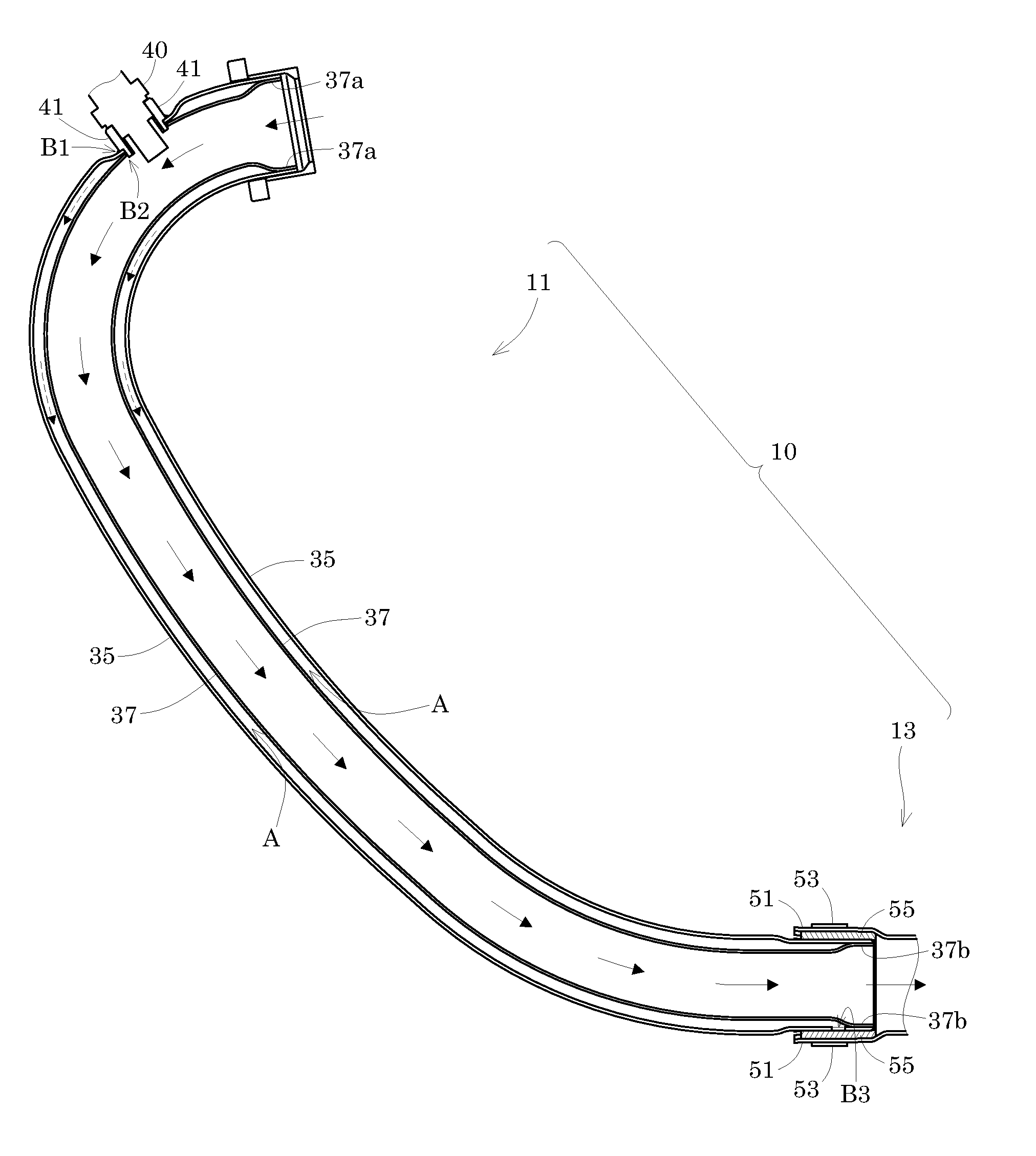

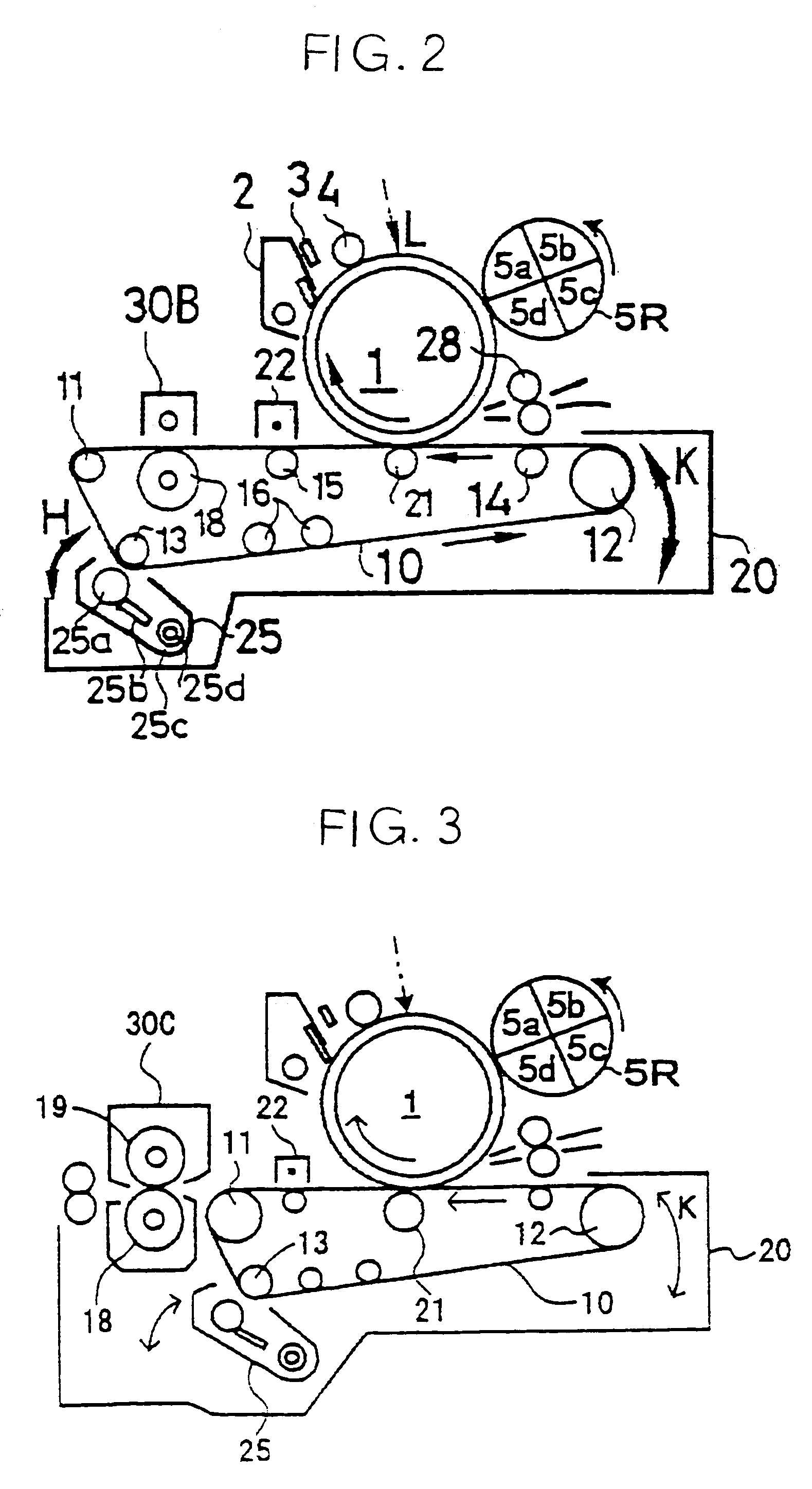

Gas Charging Method and Gas Charging Apparatus for Bag Equipped with Gas Compartment Portion

InactiveUS20140250834A1Evenly filledWithout loss of productivityCapsCap application using vaccuumEngineeringElectrical and Electronics engineering

In a method and apparatus for charging a gas into a gas compartment portion (6) of a bag (1), after a pre-heating step which is performed in stop position (IV) so that the gas compartment portion of the bag is heated by a heated gas-blowing nozzle (27), a preliminary gas injection step for injecting gas into the gas compartment portion is performed by a gas blowing nozzle (28) and a receiving member (29) in stop position (V). Then, a gas filling step is carried out in stop position (VI) by gas injection nozzles (23, 24), and the incision (9) in the gas compartment portion is sealed in stop position (VII). In the following pre-heating step, the front and rear film sheets (7, 8) of the gas compartment portion are softened, and in the preliminary gas injection step, the film sheets are separated and their adhesion is eliminated.

Owner:TOYO JIDOKI CO LTD

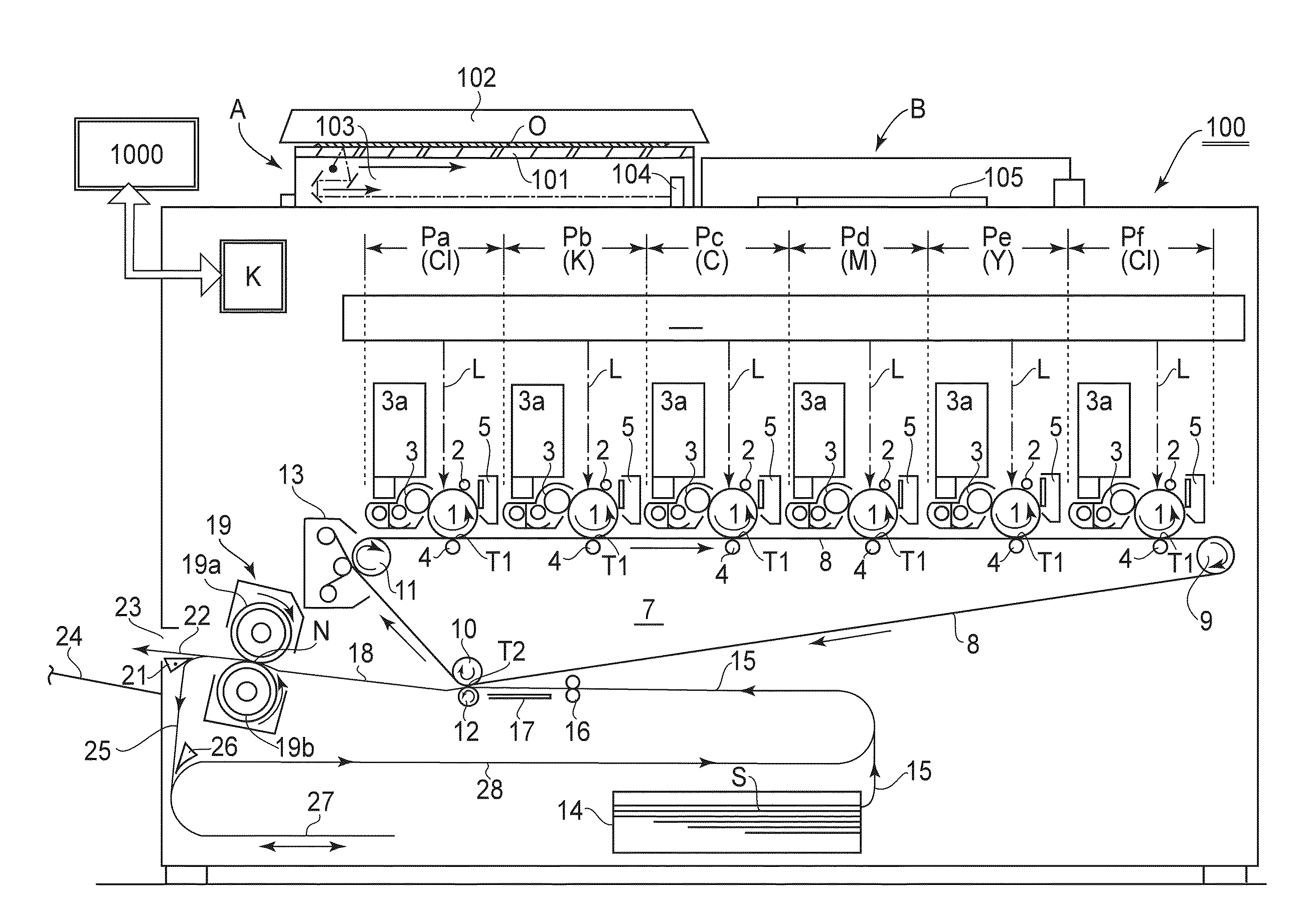

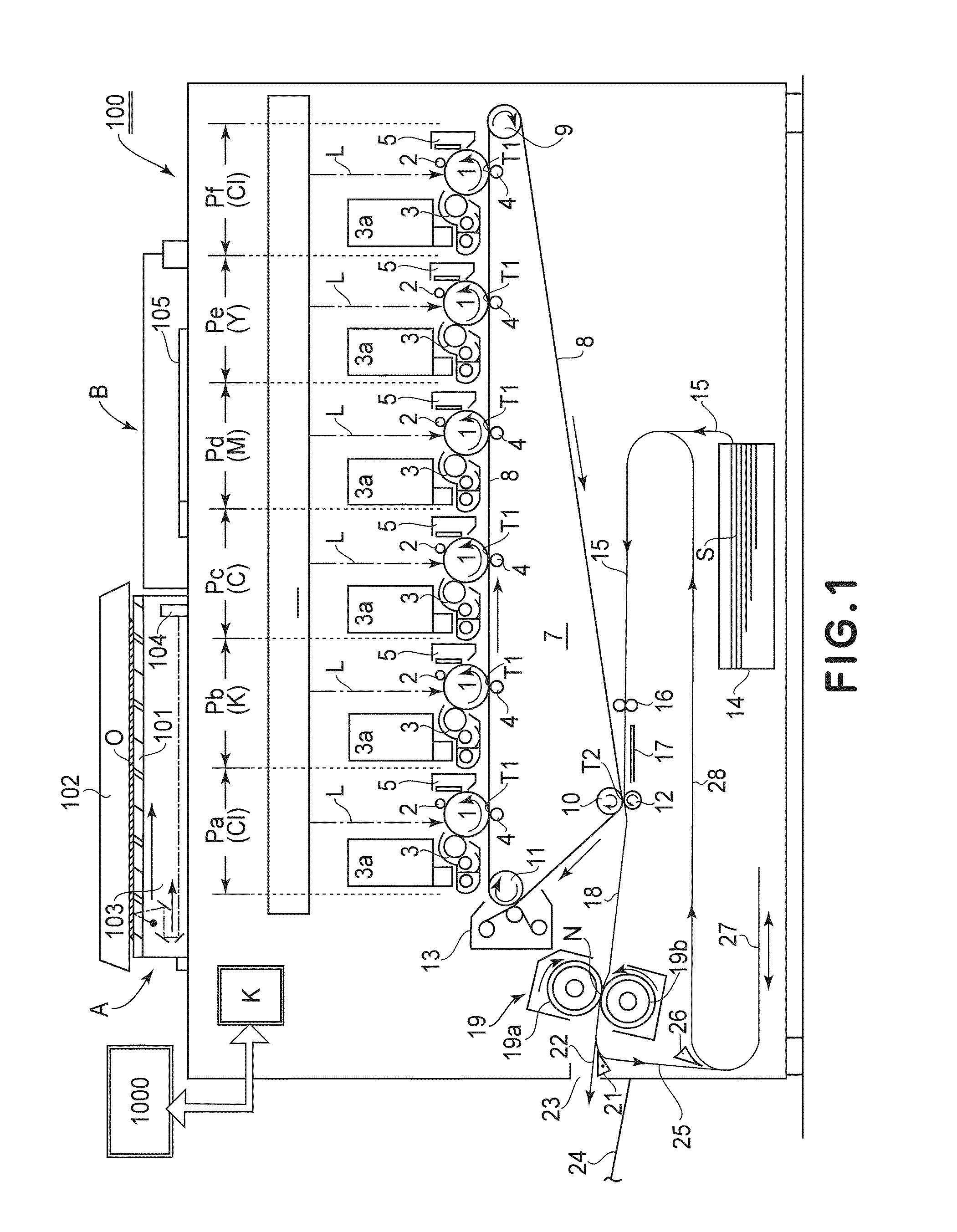

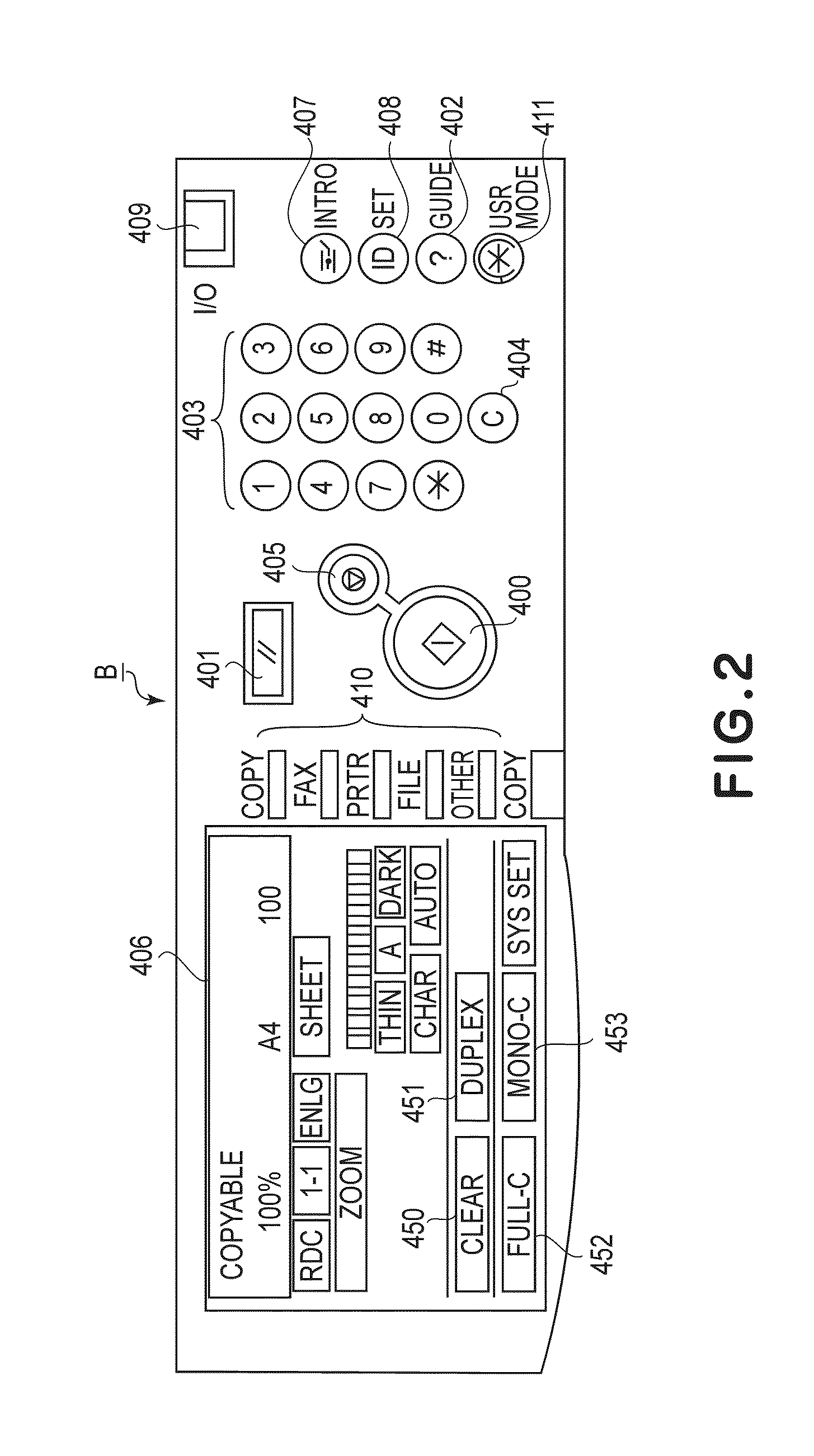

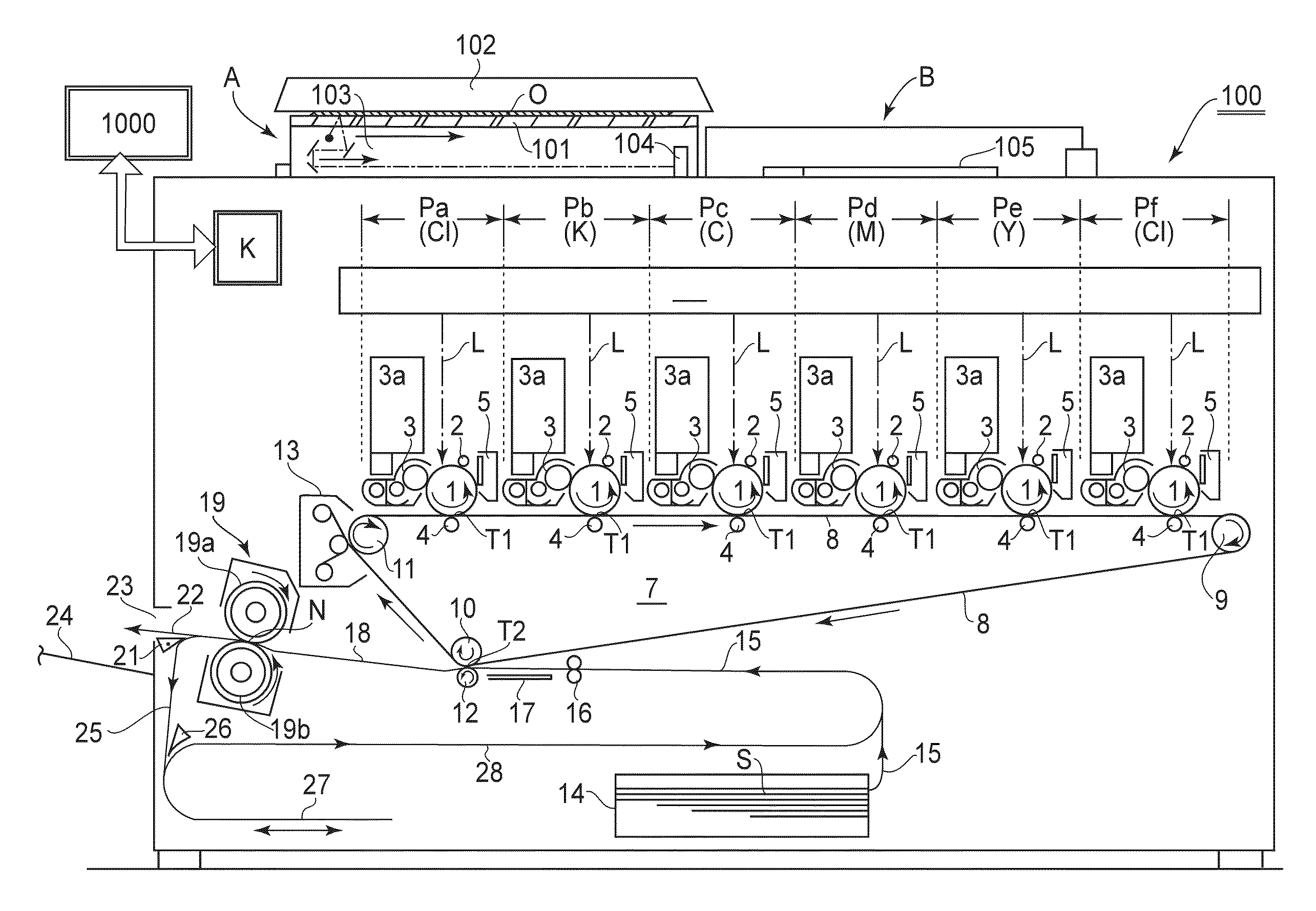

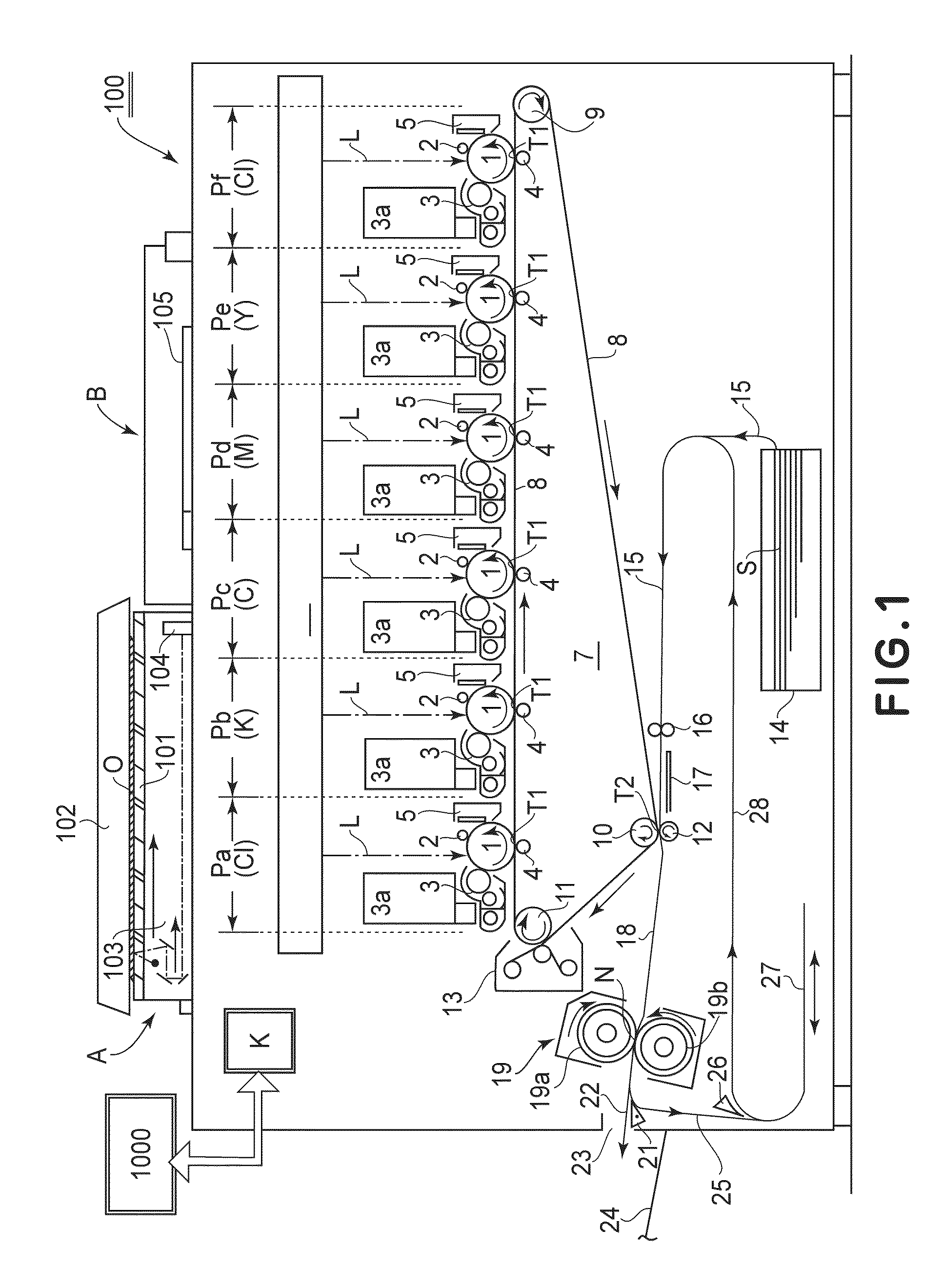

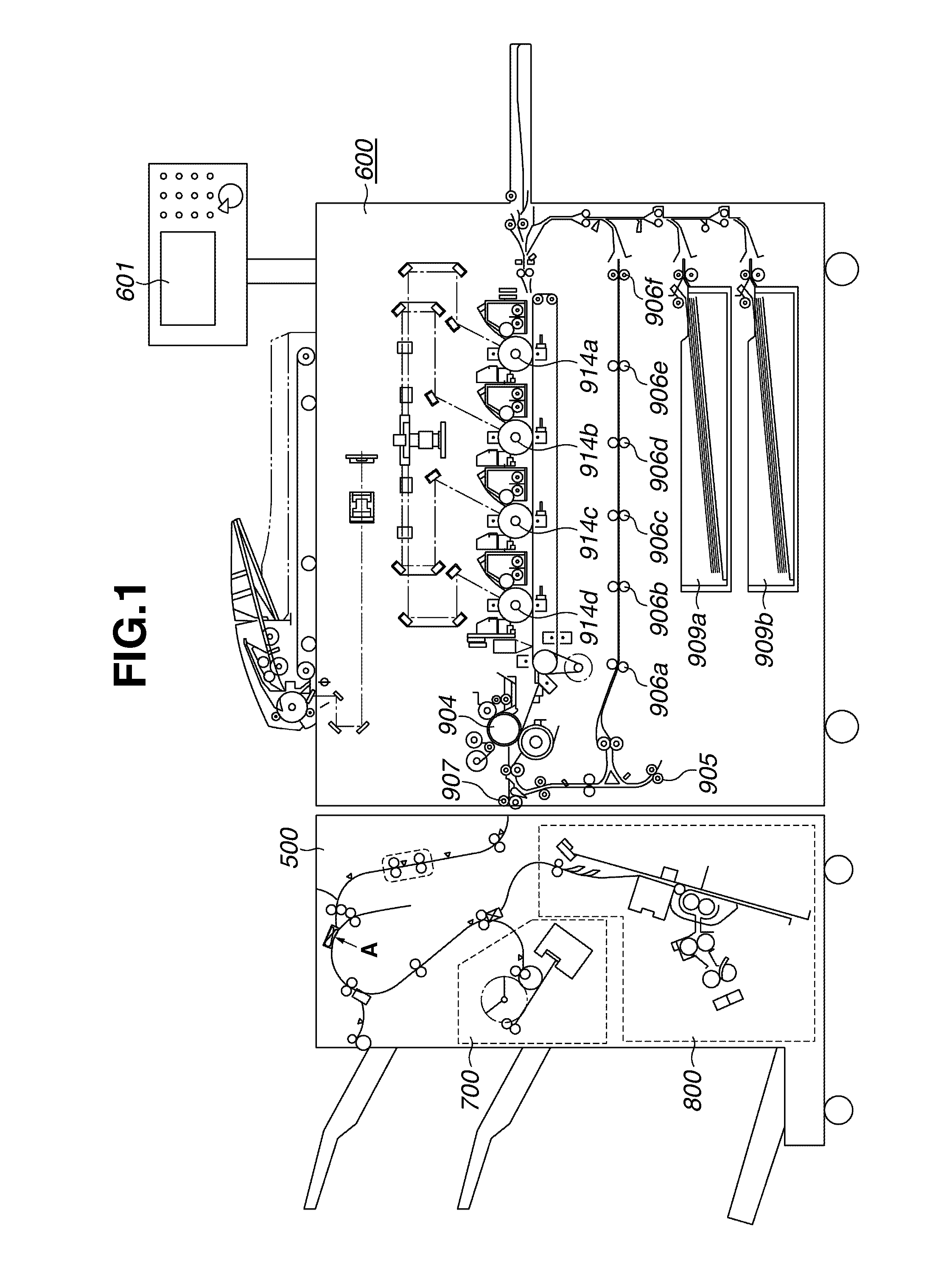

Image forming apparatus

InactiveUS20110182607A1Without lowering productivityWide glossiness controlElectrographic process apparatusImage formationEngineering

An image forming apparatus includes a color toner image forming portion for forming a toner image with a color toner on a recording material; a clear toner image forming portion for forming a toner image with a clear toner on the recording material, wherein the clear toner has a melt viscosity, at a fixing temperature, higher than that of the color toner; a fixing device for fixing the toner image formed on the recording material; an obtaining portion for obtaining information on an area in which designated glossiness is partly increased, partly decreased, or partly increased and decreased; and a control device for determining the order of formation of the toner image with the color toner and the toner image with the clear toner on the recording material depending on the information obtained by the obtaining portion.

Owner:CANON KK

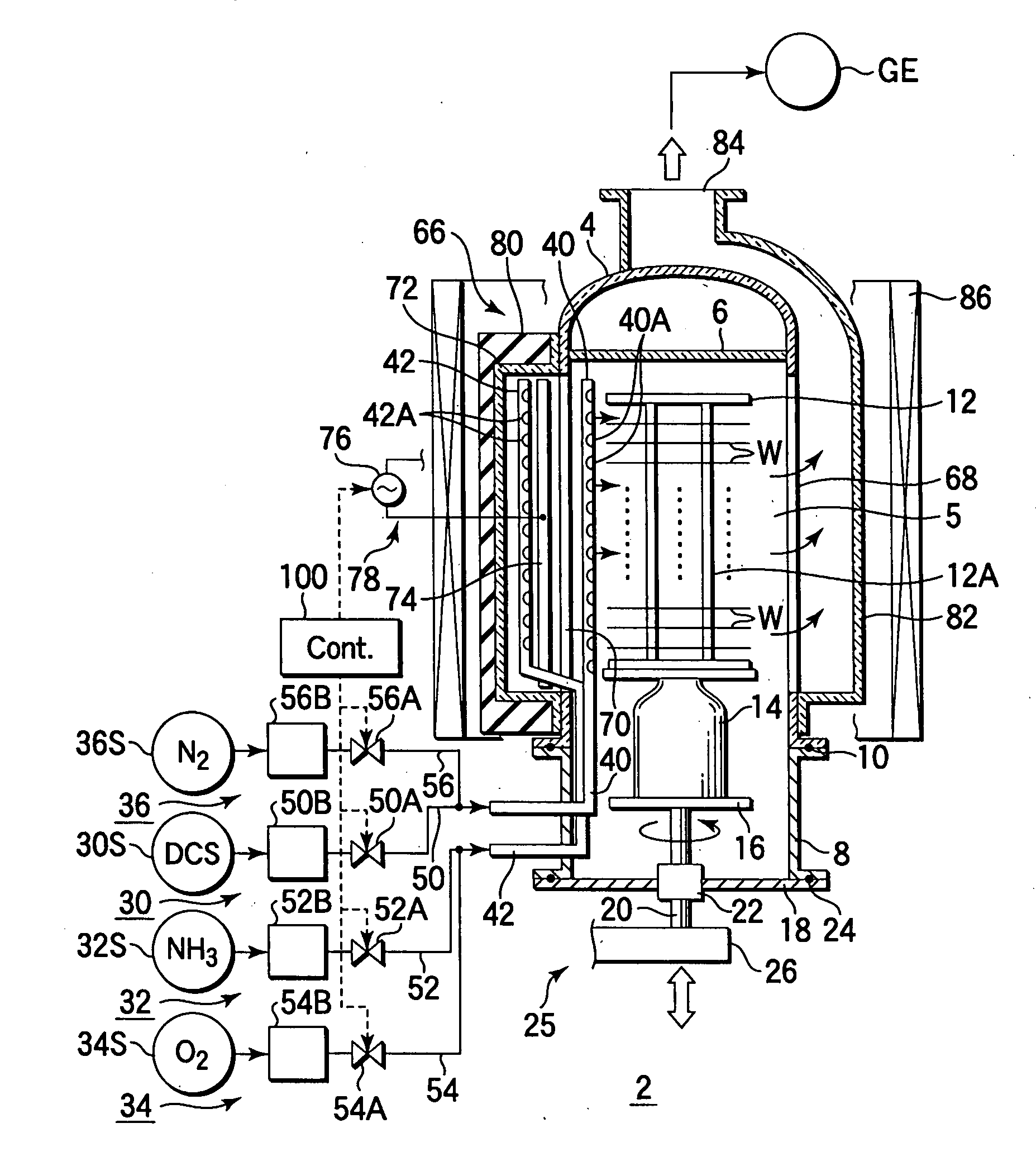

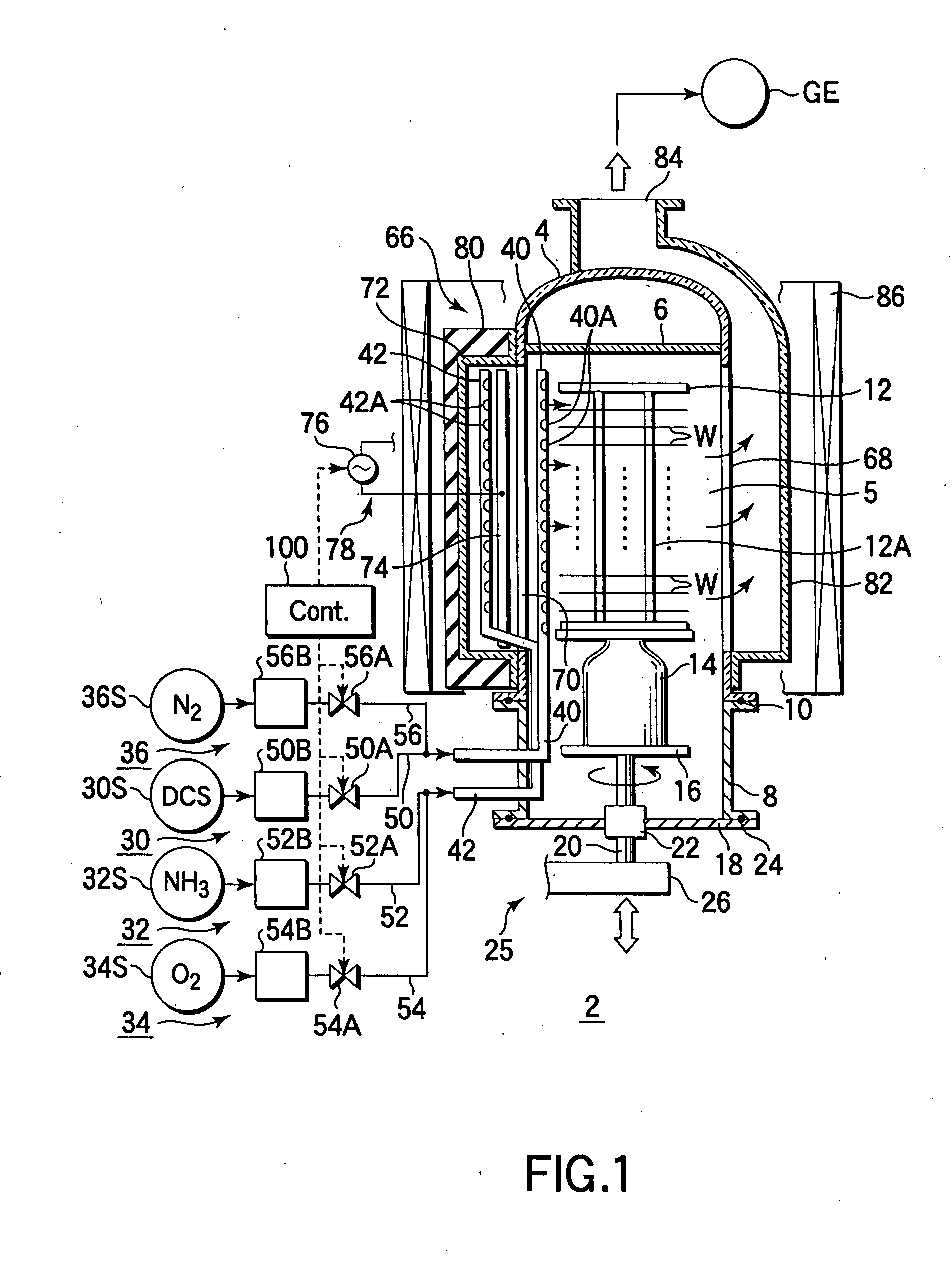

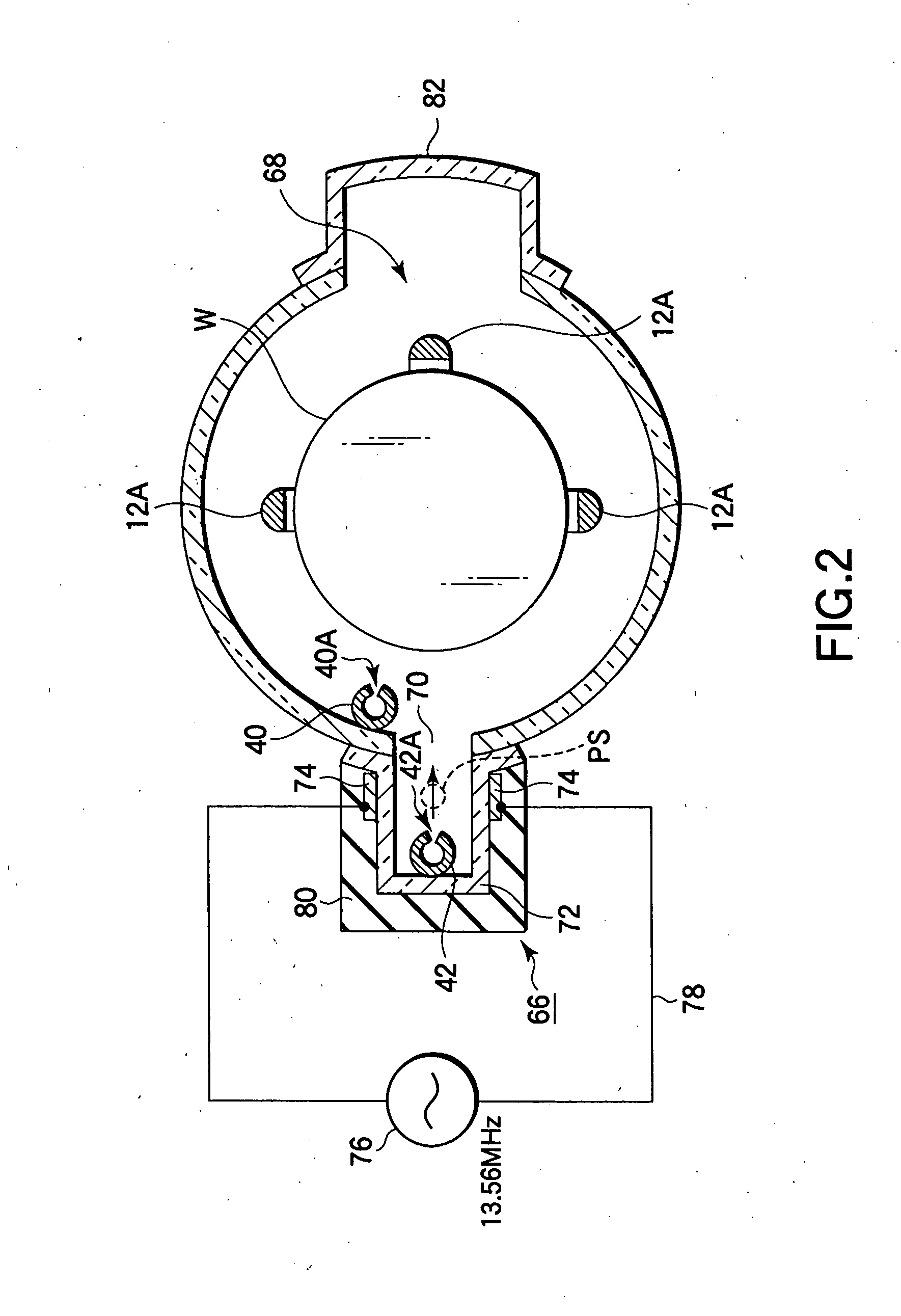

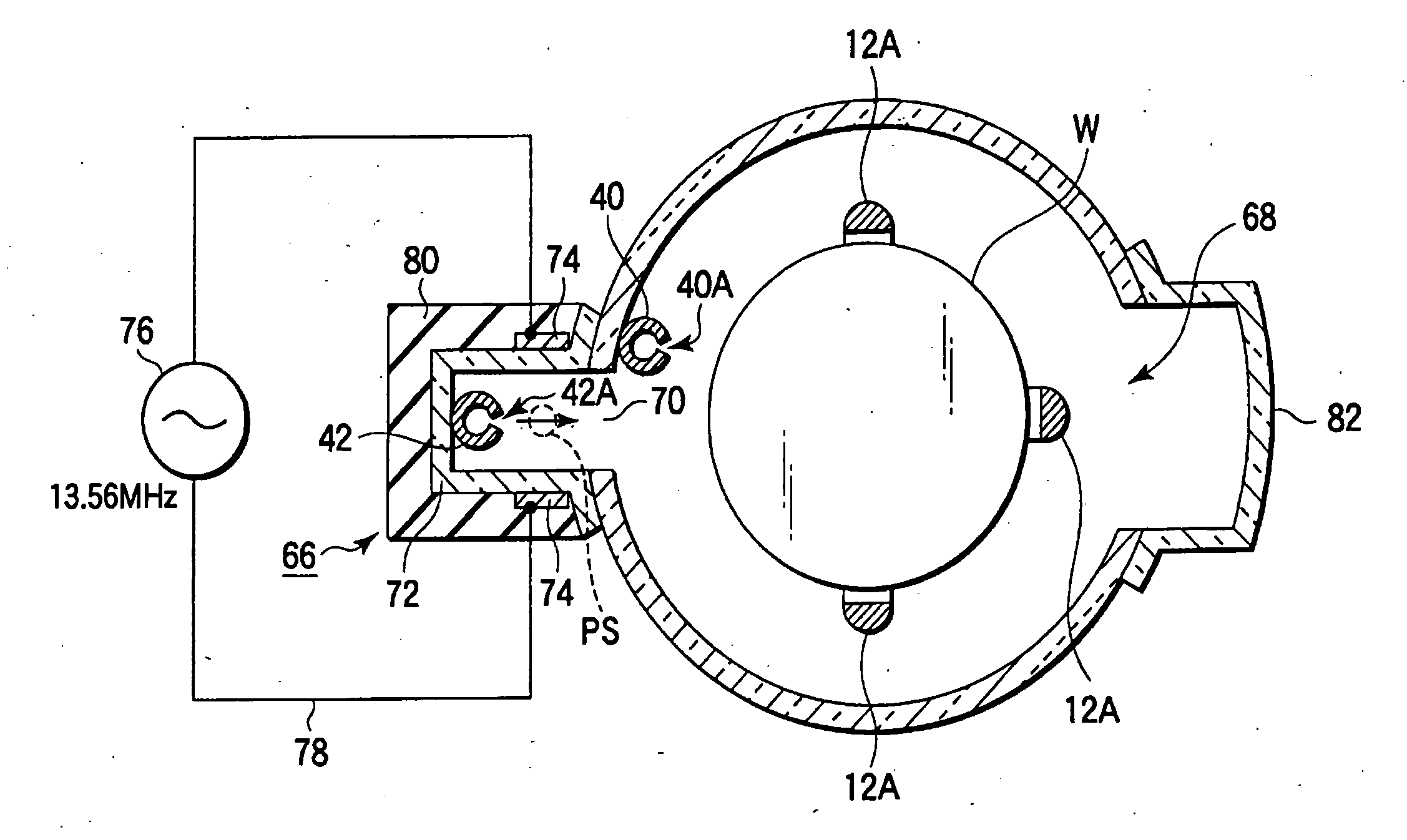

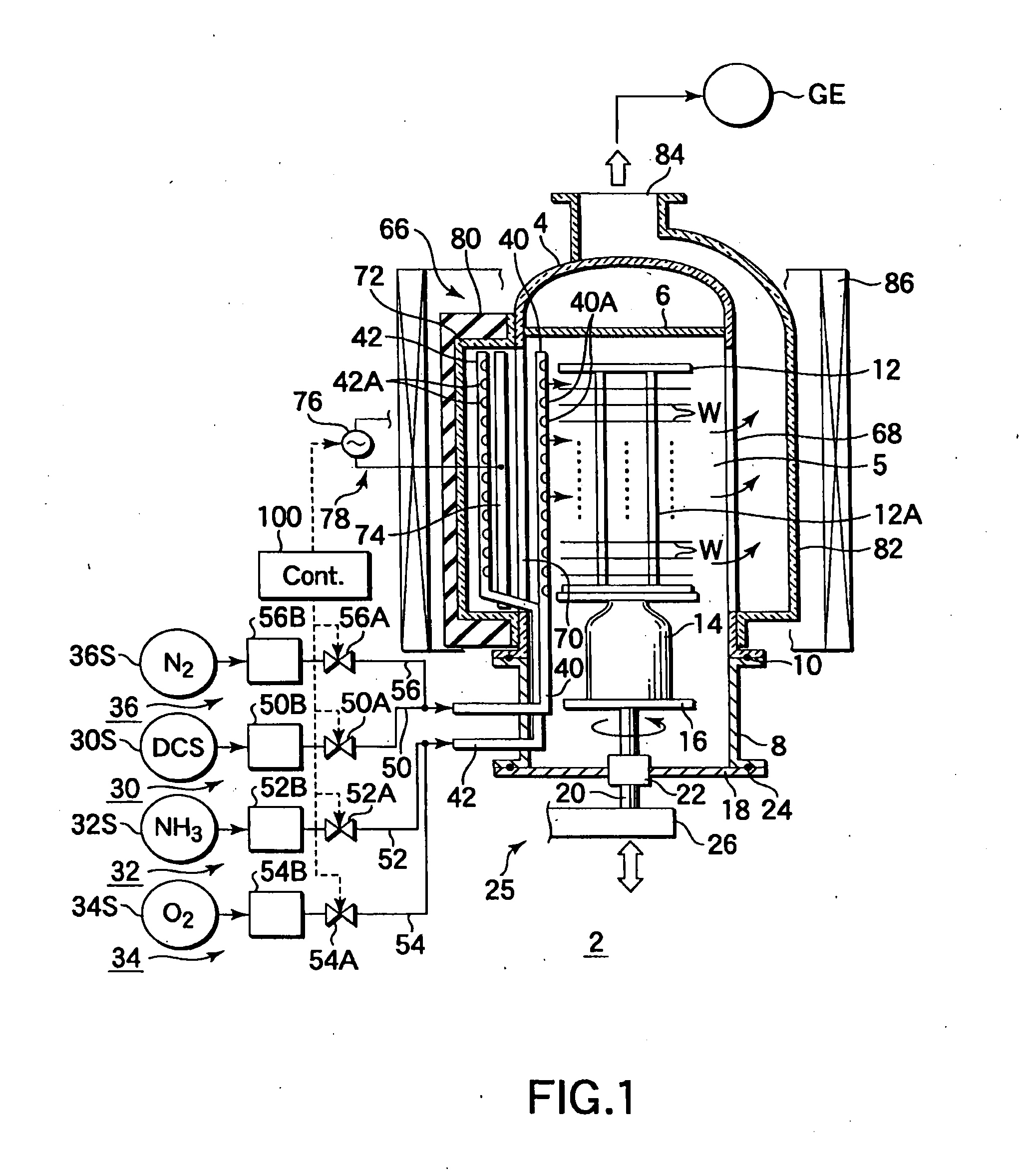

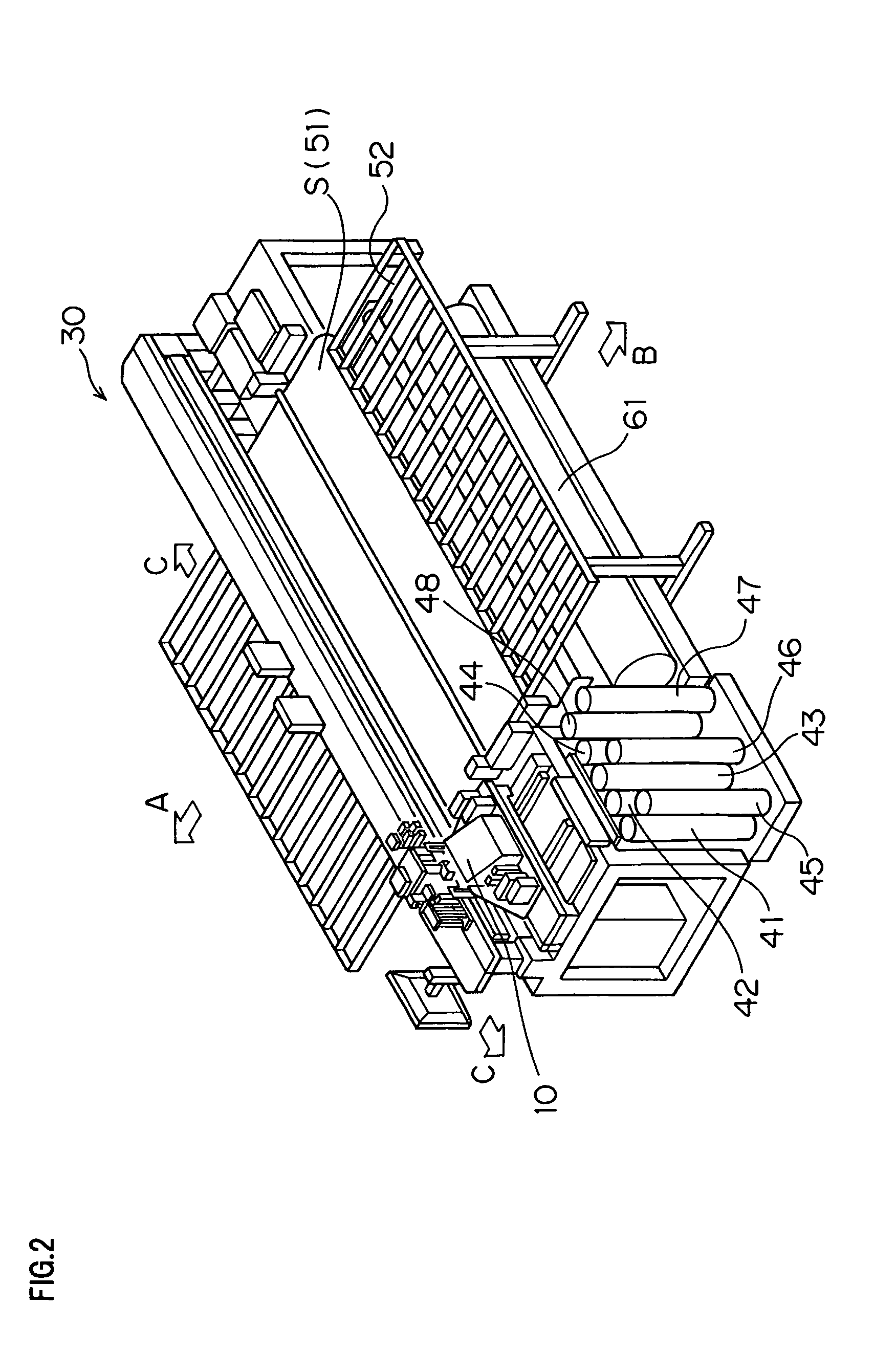

Film formation apparatus for semiconductor process and method for using the same

InactiveUS20080132083A1Without lowering productivityPrevent particle generationLiquid surface applicatorsElectric discharge tubesNitrogenProcess engineering

A method is provided for using a film formation apparatus including a process container having an inner surface, which contains as a main component a material selected from the group consisting of quartz and silicon carbide. The method includes performing a film formation process to form a silicon nitride film on a product target substrate inside the process container, and then, unloading the product target substrate from the process container. Thereafter, the method includes supplying an oxidizing gas into the process container with no product target substrate accommodated therein, thereby performing an oxidation process to change by-product films deposited on the inner surface of the process container into a composition richer in oxygen than nitrogen, at a part of the by-product films from a surface thereof to a predetermined depth.

Owner:TOKYO ELECTRON LTD

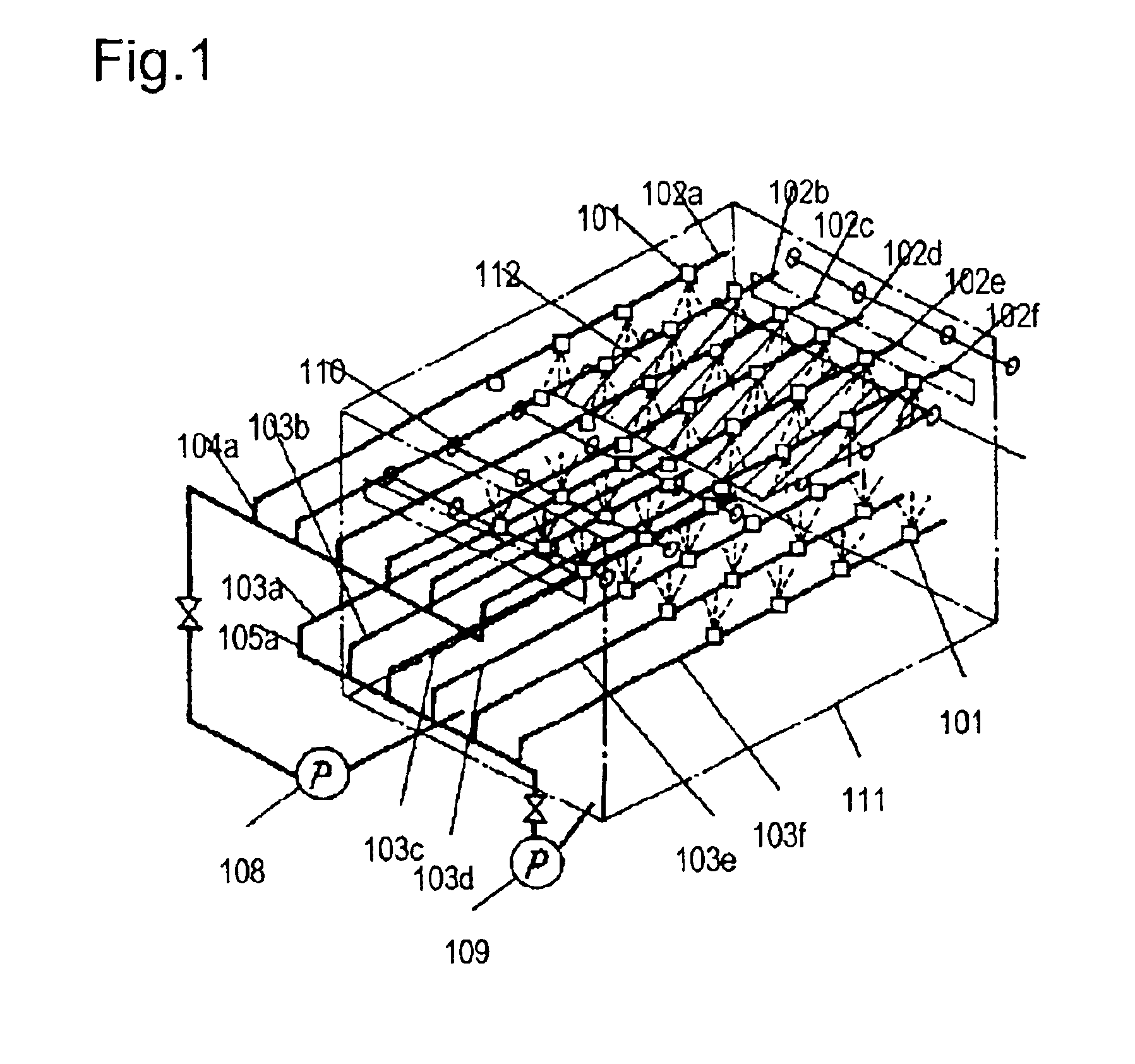

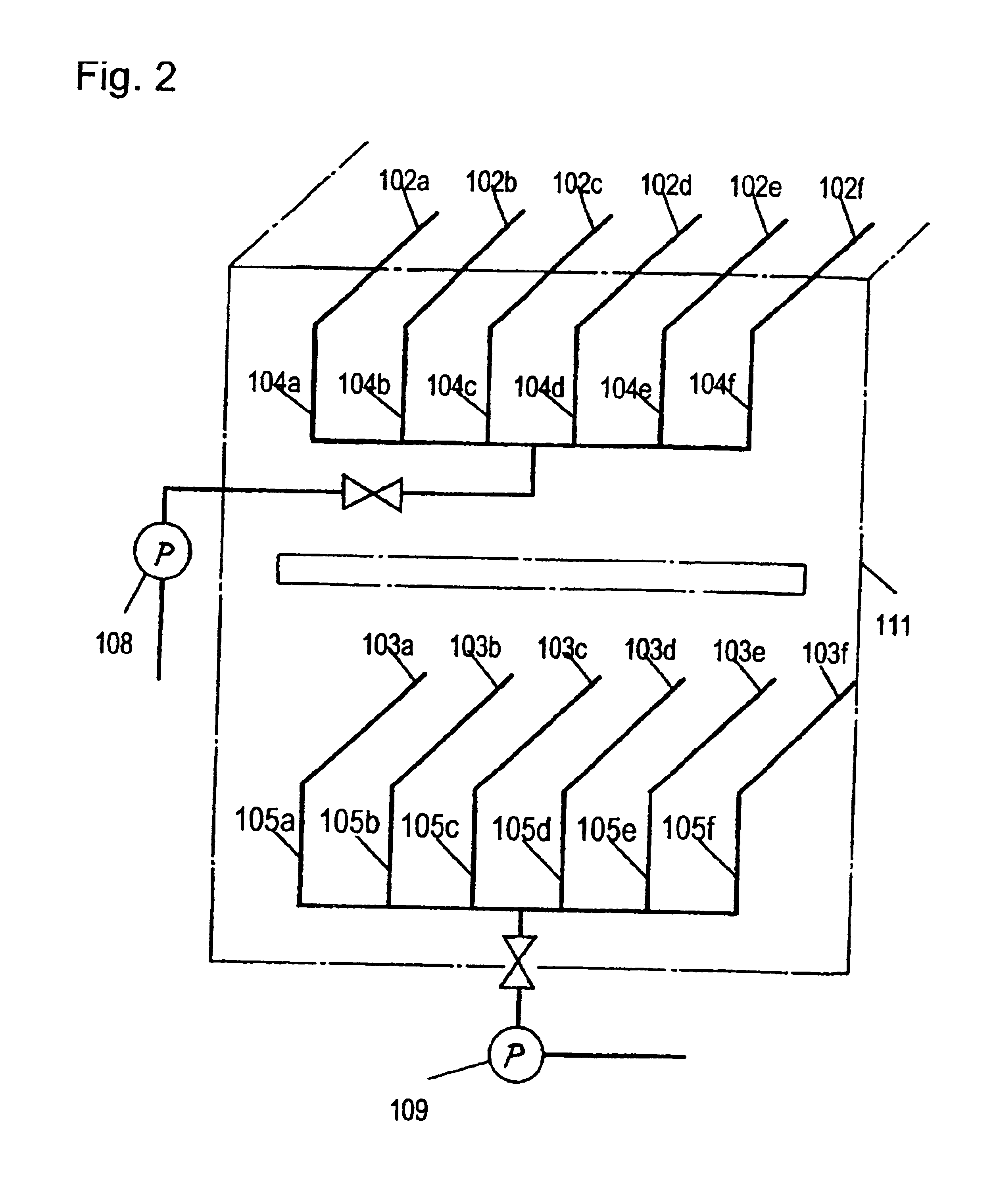

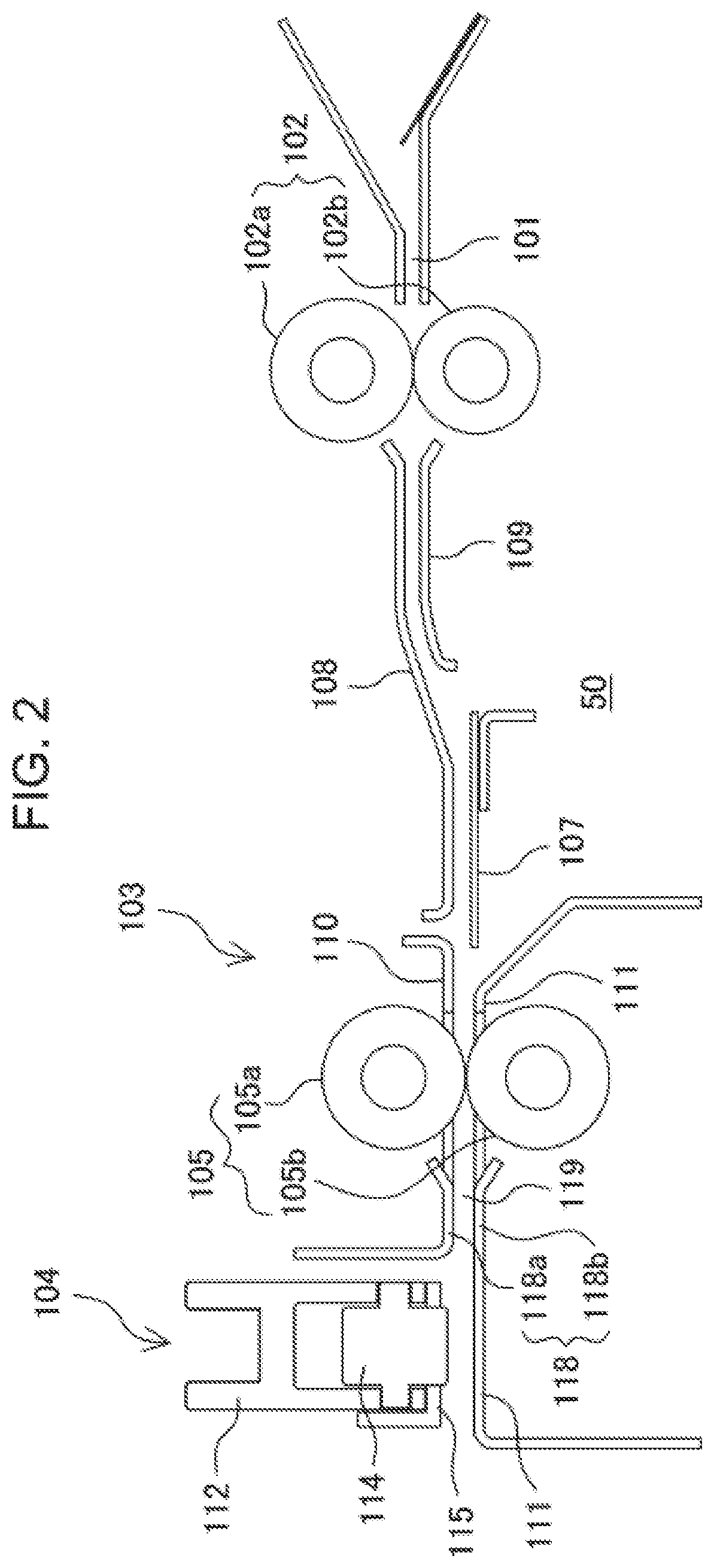

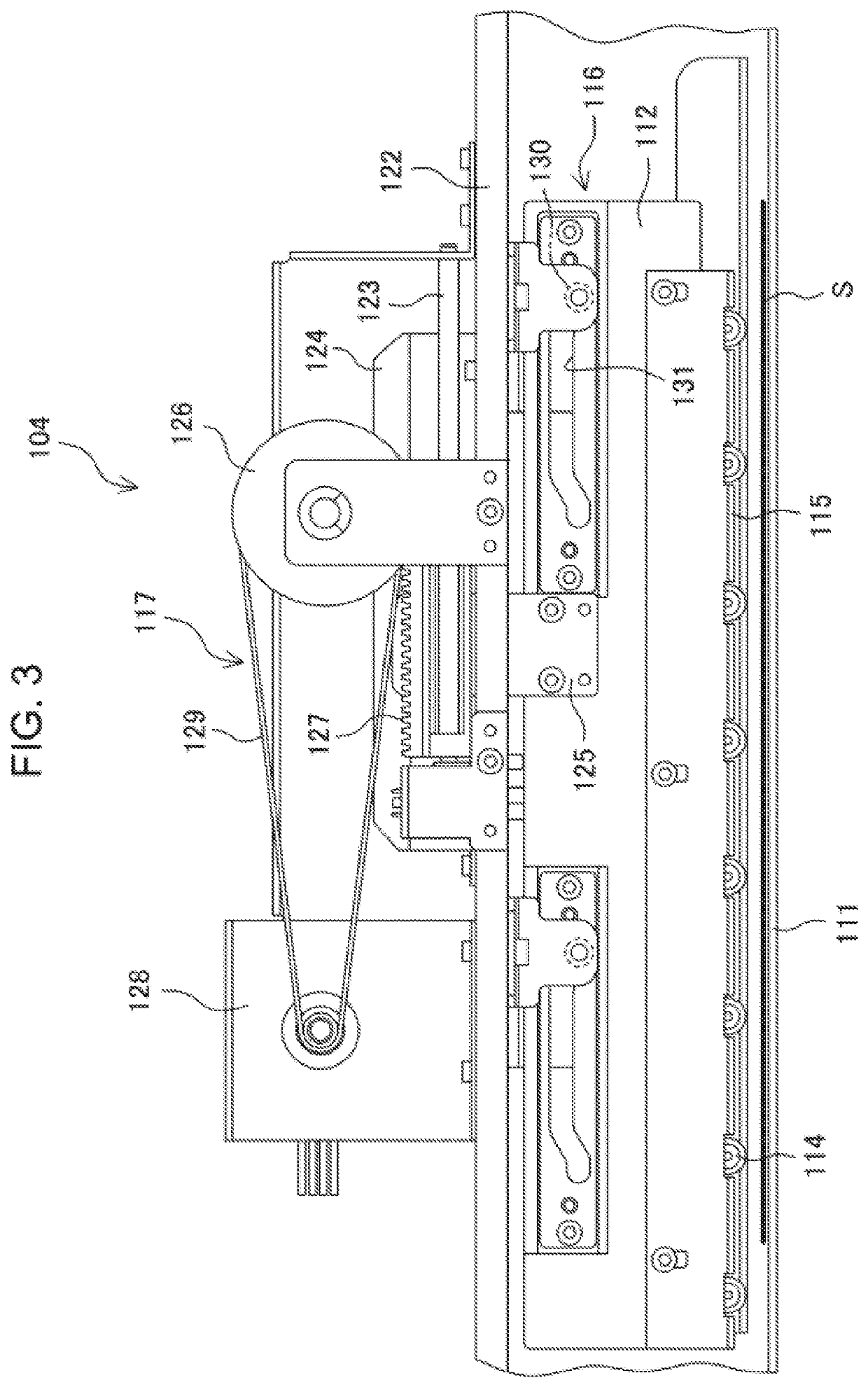

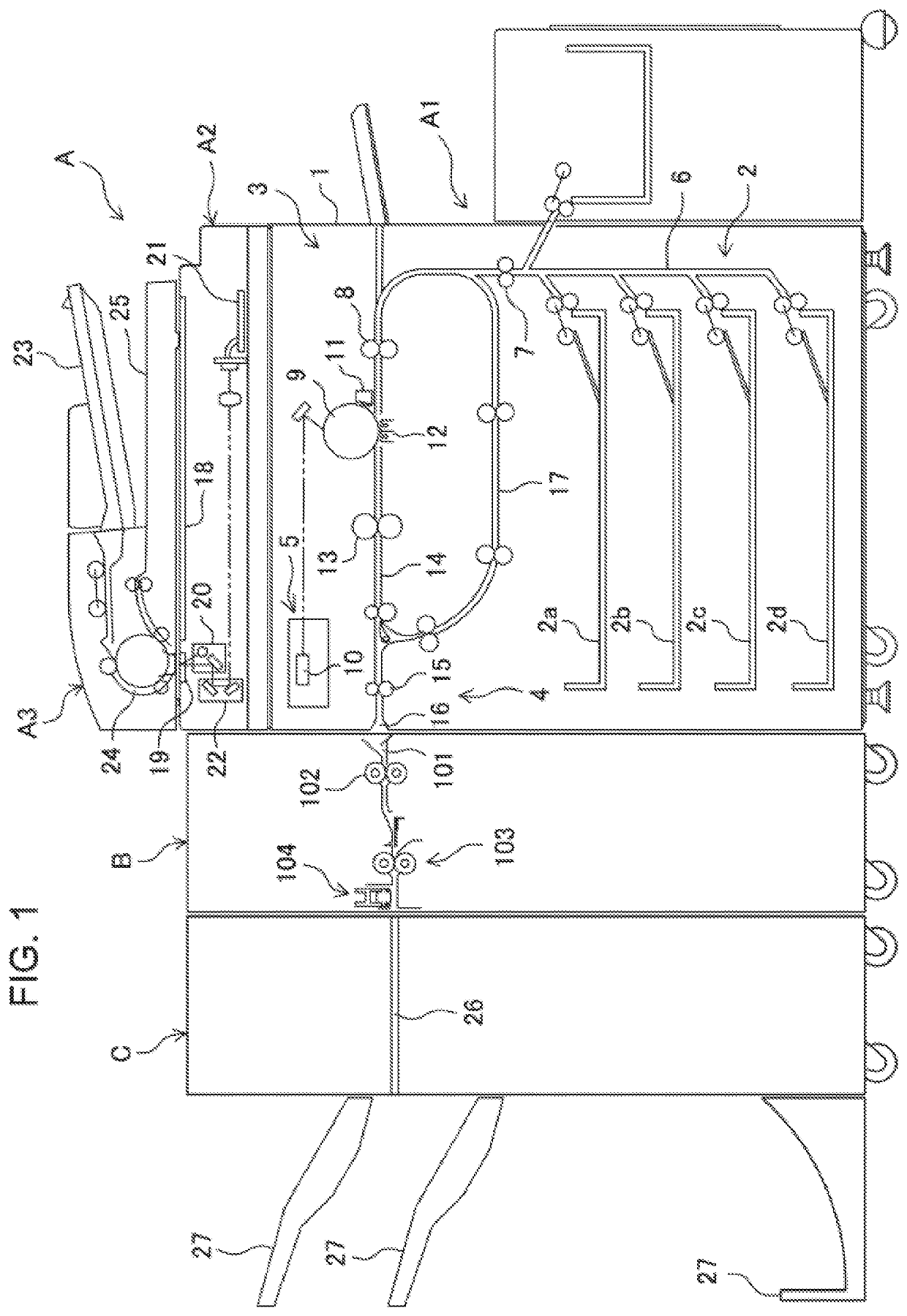

Apparatus for manufacturing printed wiring board and method for manufacturing printed wiring board using the same

InactiveUS6918989B2Increase pressureDecrease productivityFluid heatersSpraying apparatusEngineeringPiping

In a manufacturing apparatus of printed wiring board an aperture of a nozzle pipe located in a central position is larger than that at both sides, or the aperture of the piping to the nozzle pipe in the central position is larger than that of the piping at both sides. The mutual interval is narrower with the central nozzle pipes. The interval of the individual nozzle pipes is variable, and is also variable in the vertical direction. A pressure-proof flexible tube is provided between each nozzle pipe and the pump, and the interval of the individual nozzle pipes is variable, and is also variable in the vertical direction. Further, the spray pressure, oscillating angle, and oscillating speed can be set individually in each nozzle pipe, and such setting can be automated.

Owner:PANASONIC CORP

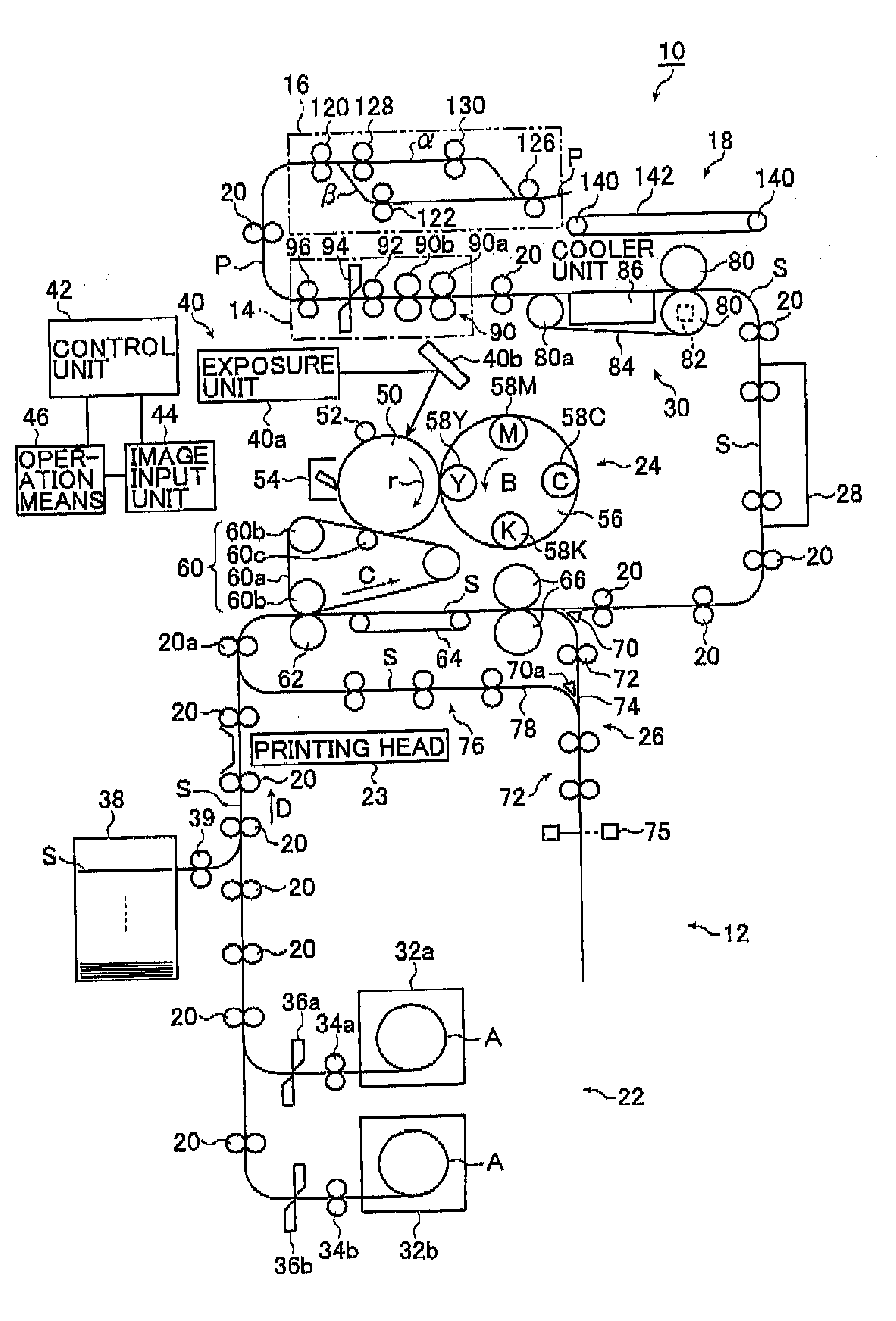

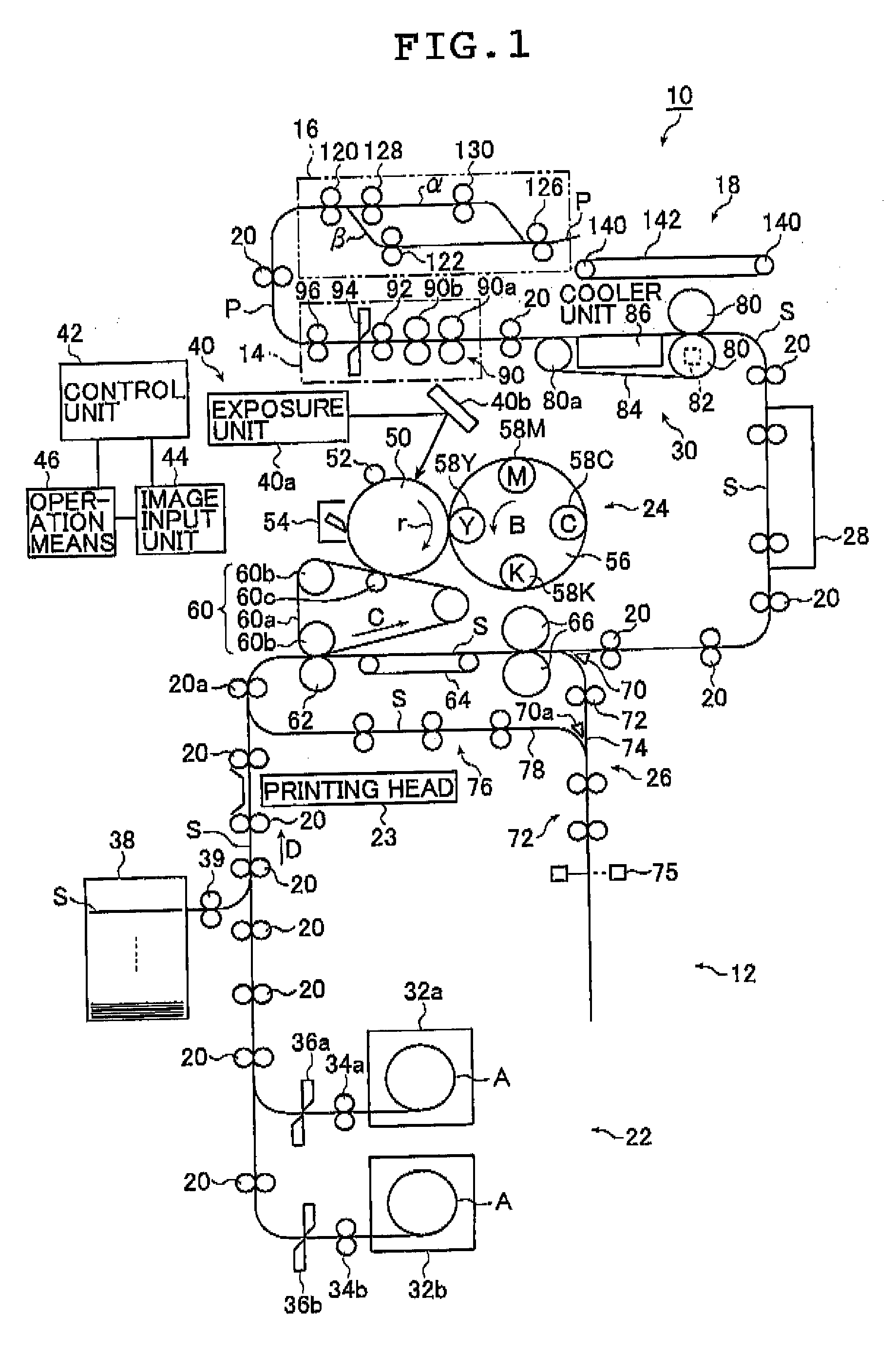

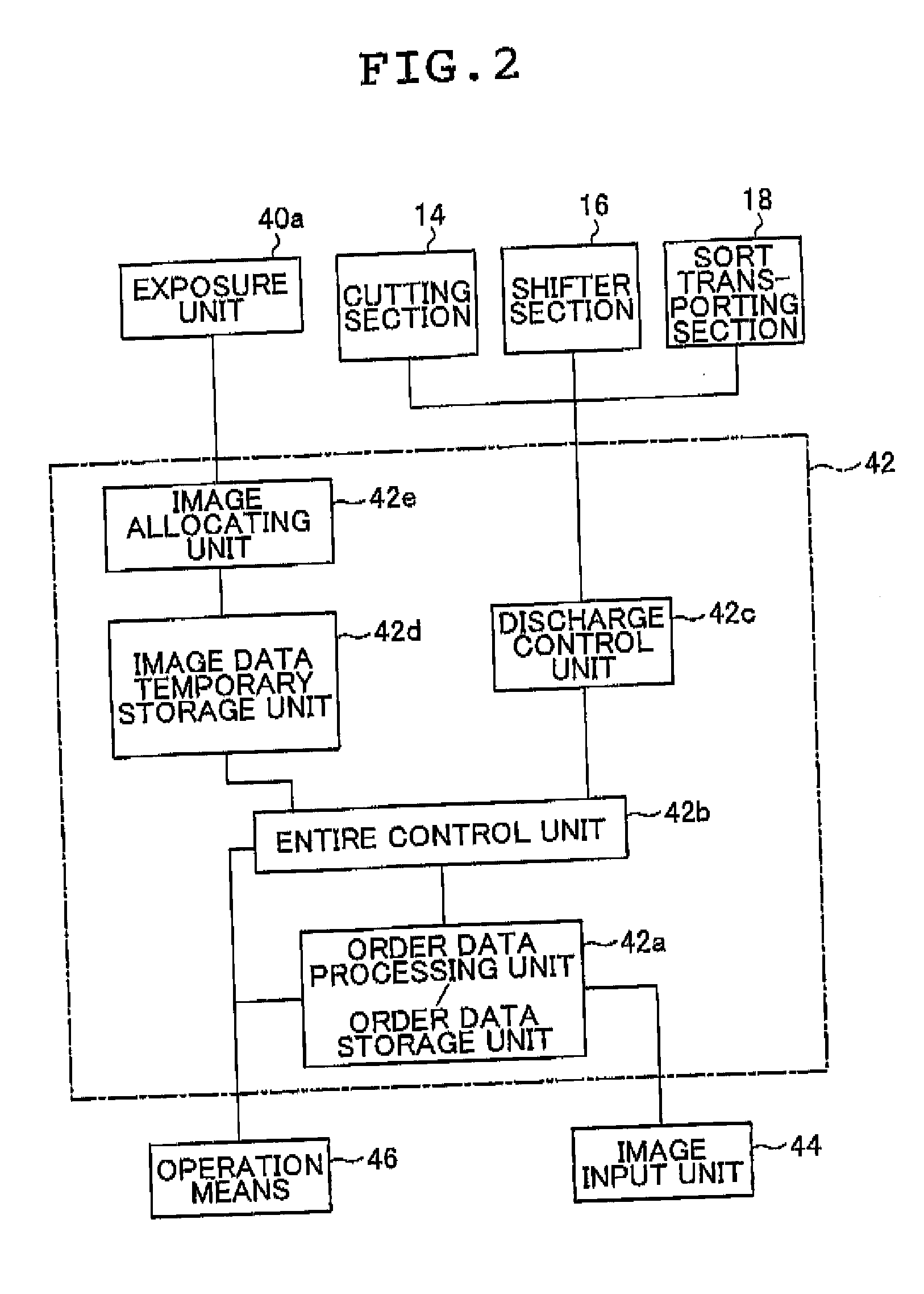

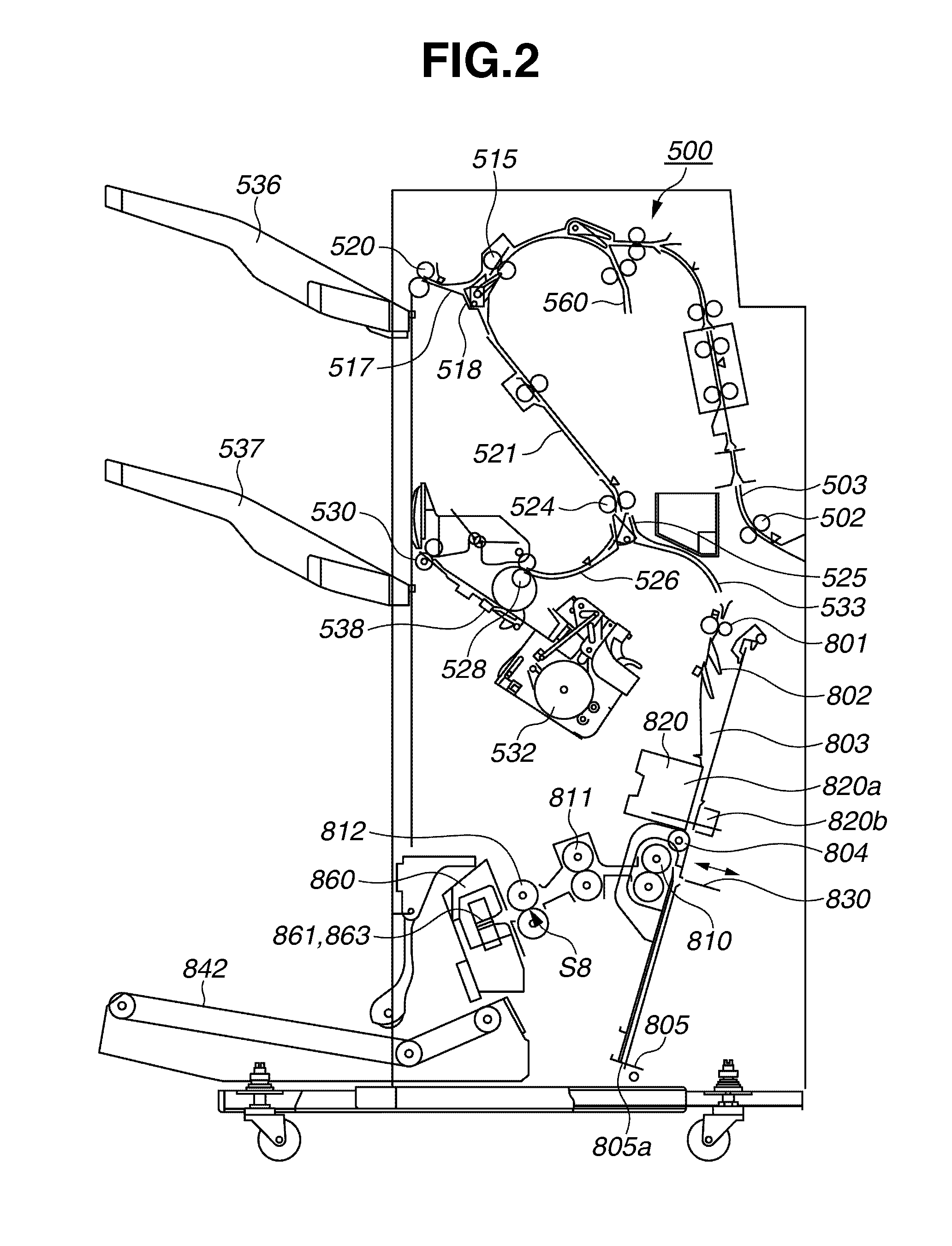

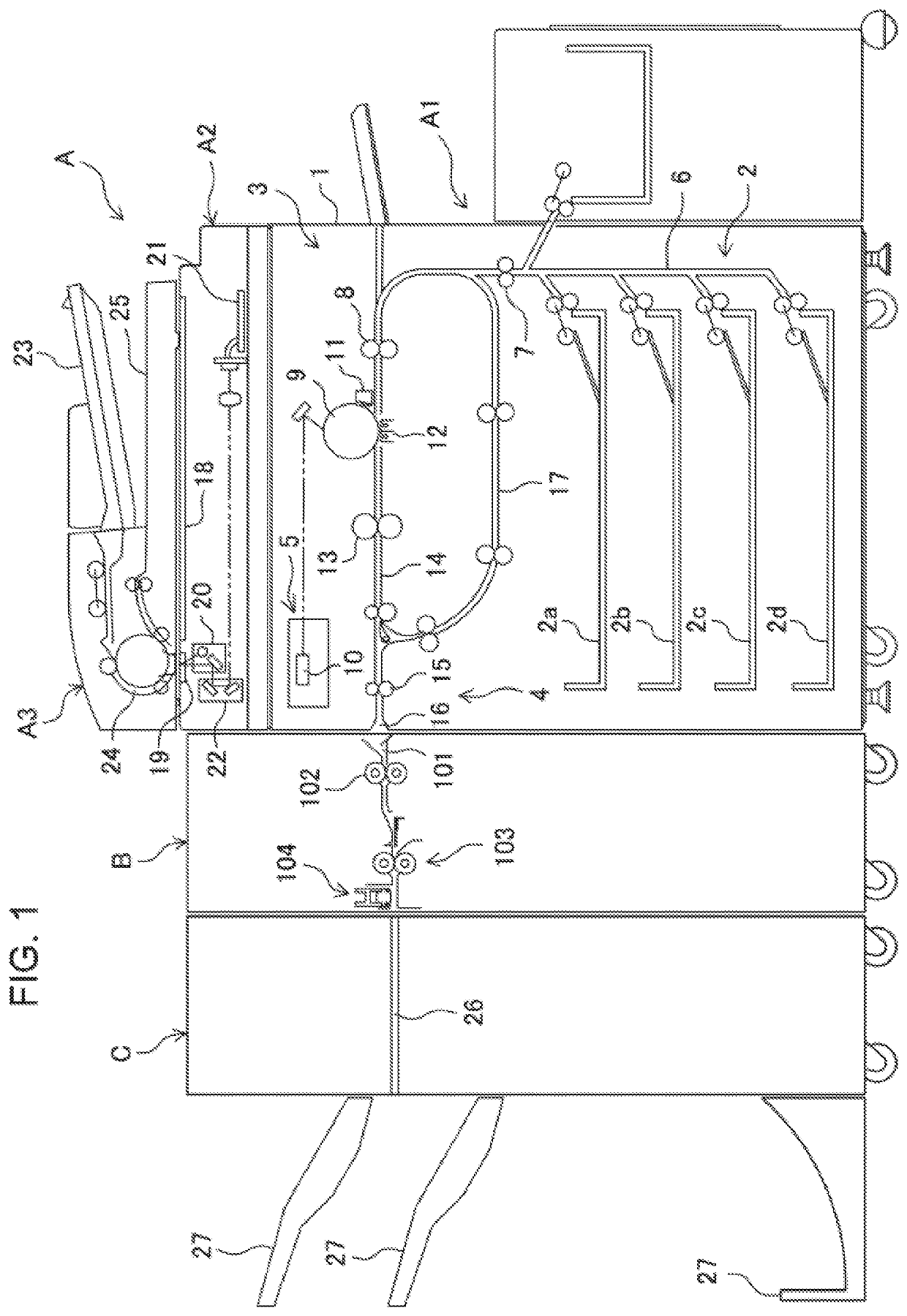

Image recording apparatus

InactiveUS20070071528A1Productivity be lowerEasily obtainElectrographic process apparatusImage recordingComputer hardware

The image recording apparatus includes an image allocating section allocating the plural images with respect to each recording medium, an image recording section recording the plural images on each recording medium, a cutting section cutting the one recording medium on which the plural images are recorded into the plural prints, a arranging section unifying the plural prints in a single line, a sort transporting section accumulating the plural prints, a discharge control section acquiring at least status information of the arranging section, and controls operations of the cutting section, the arranging section, and the sort transporting section, and an entire control section performing adjustment of allocating operations, or controls the operation of the arranging section, based upon at least one of an appointed delivery date of the plural prints and the status information.

Owner:FUJIFILM CORP

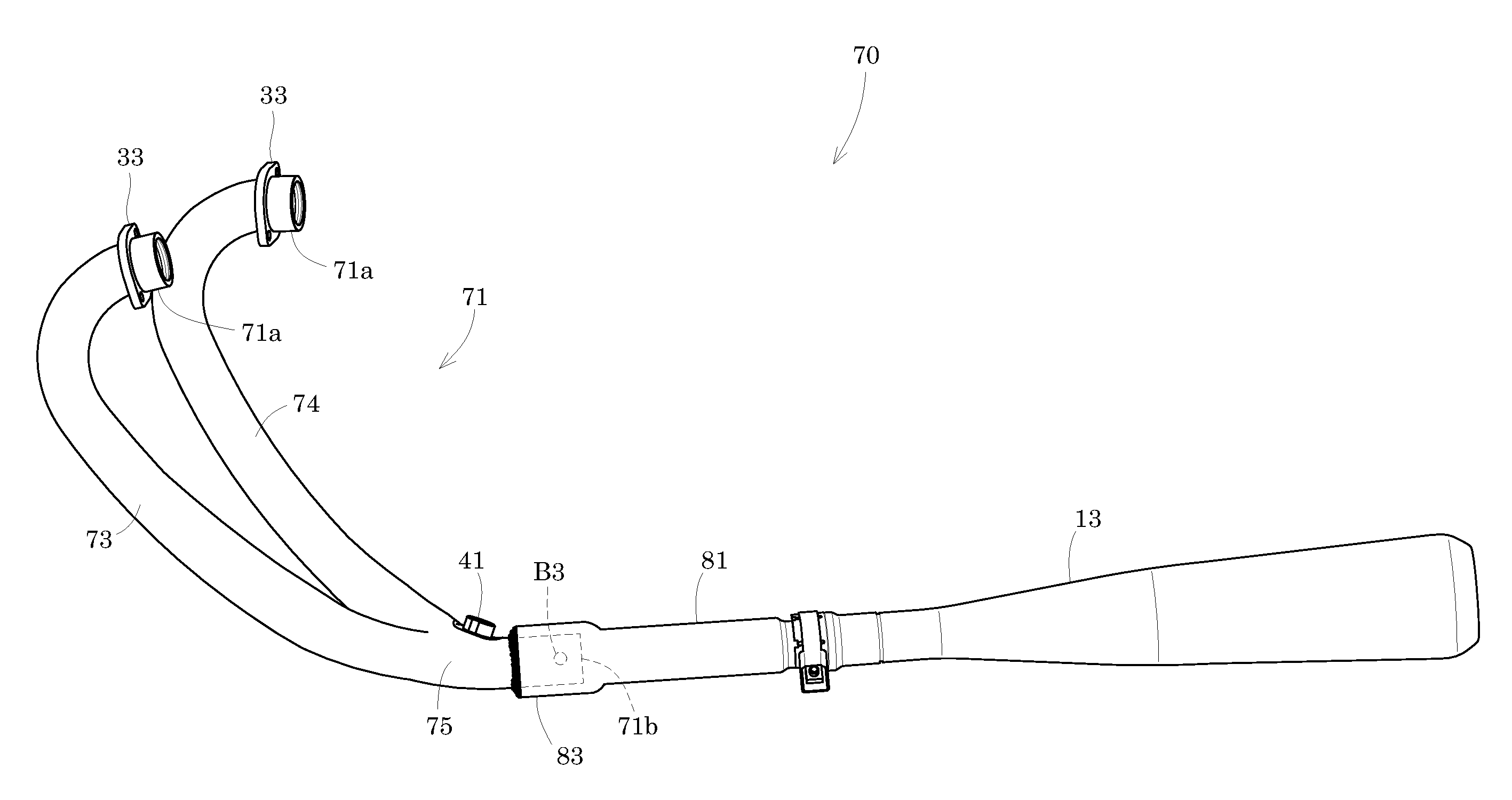

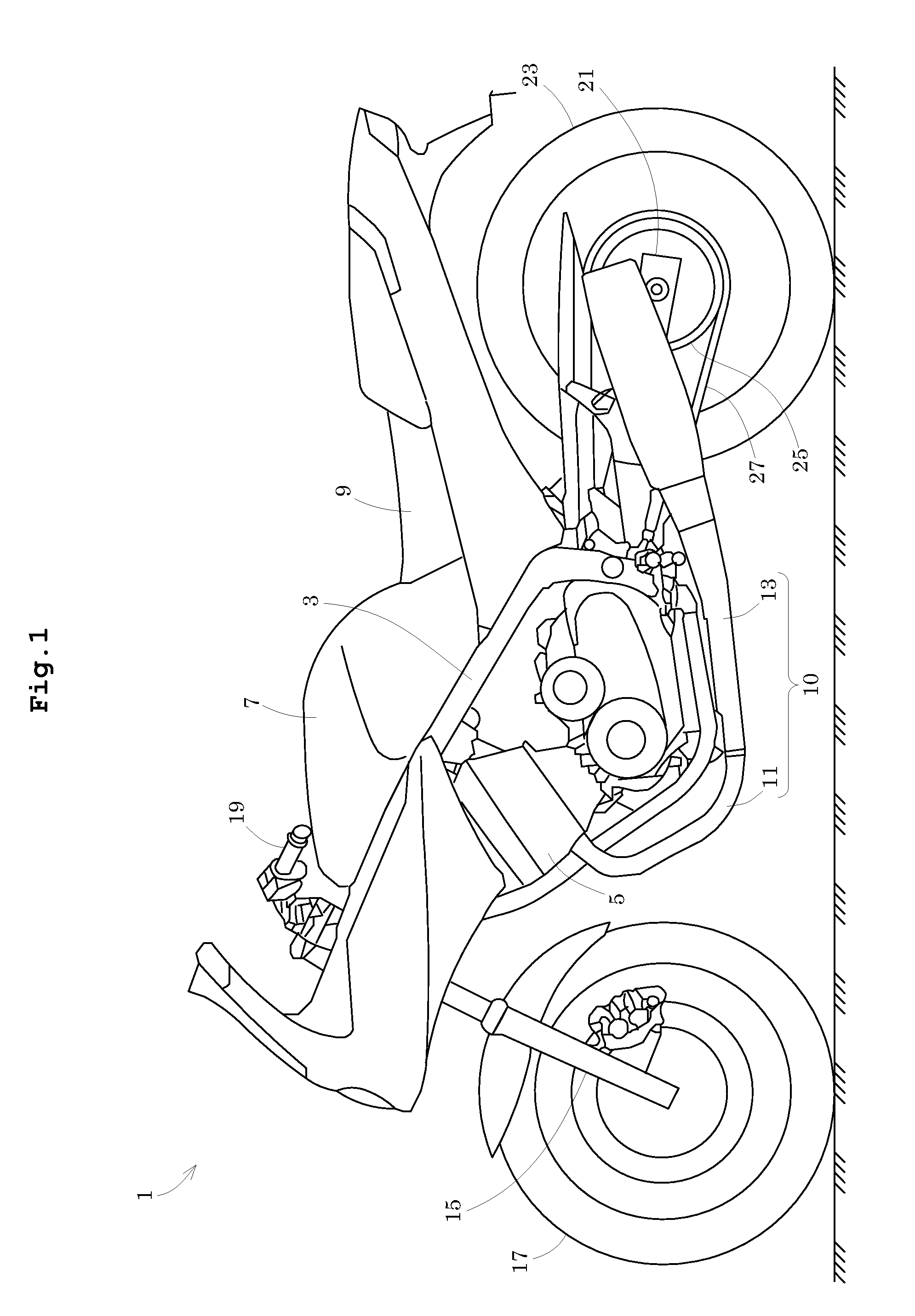

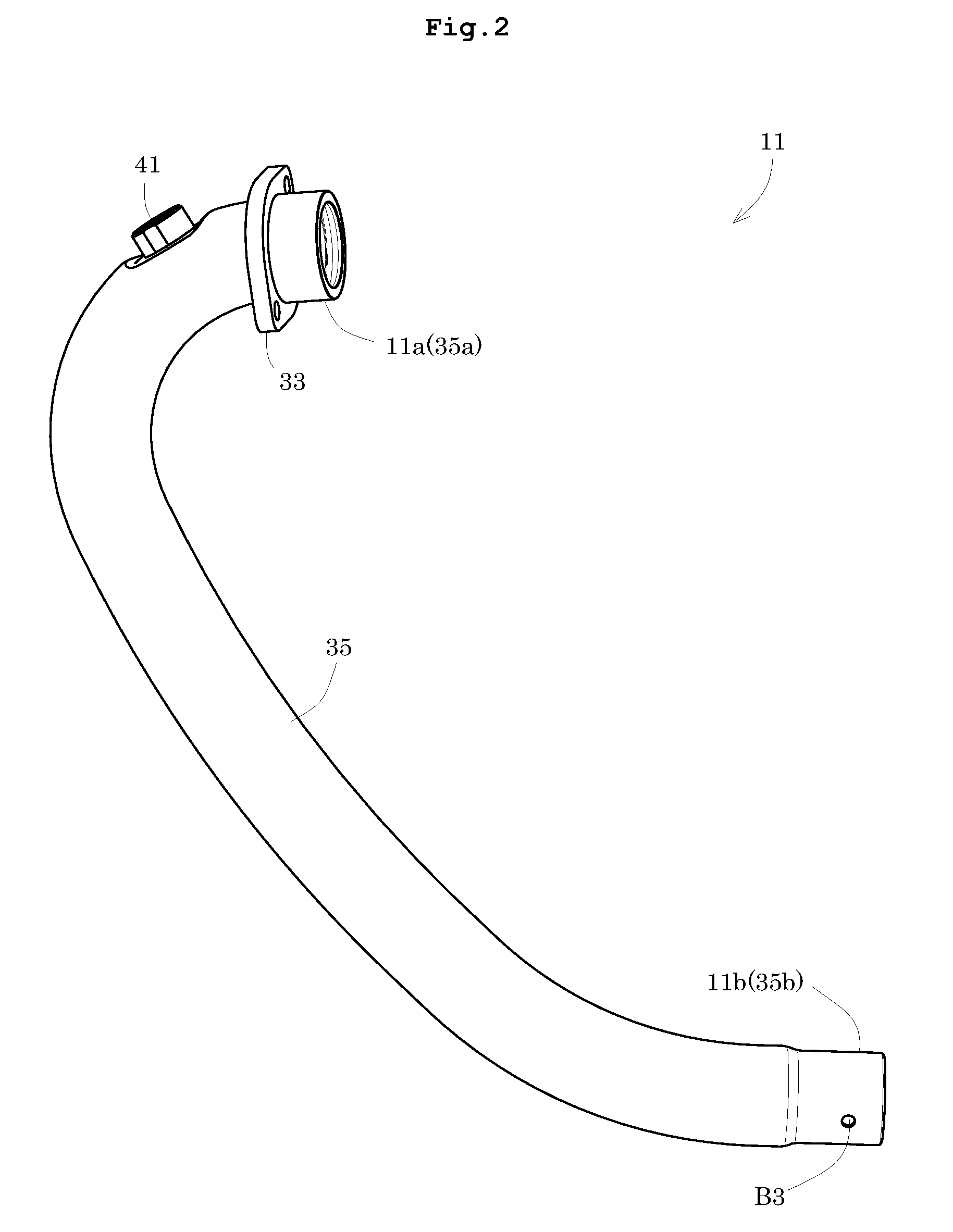

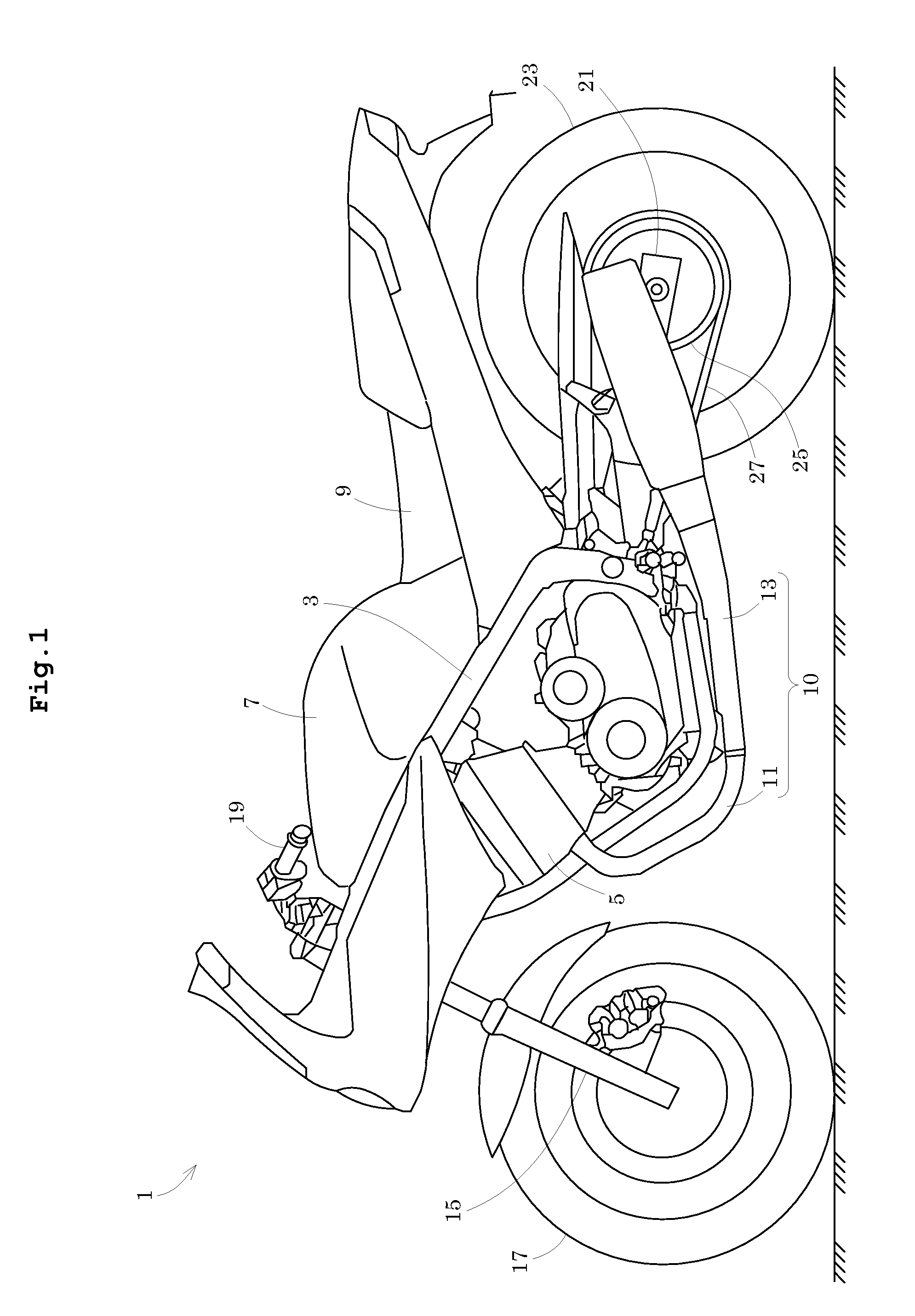

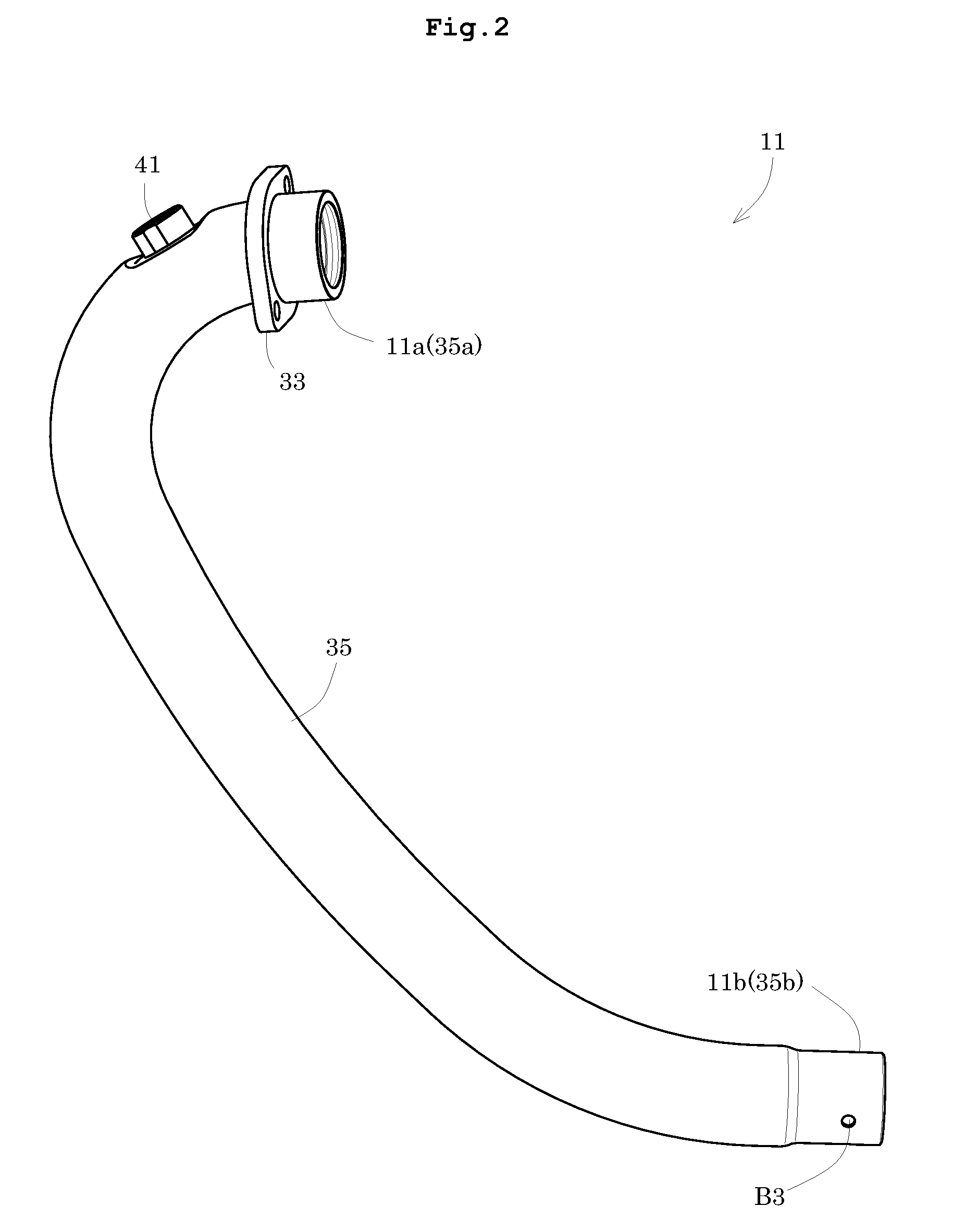

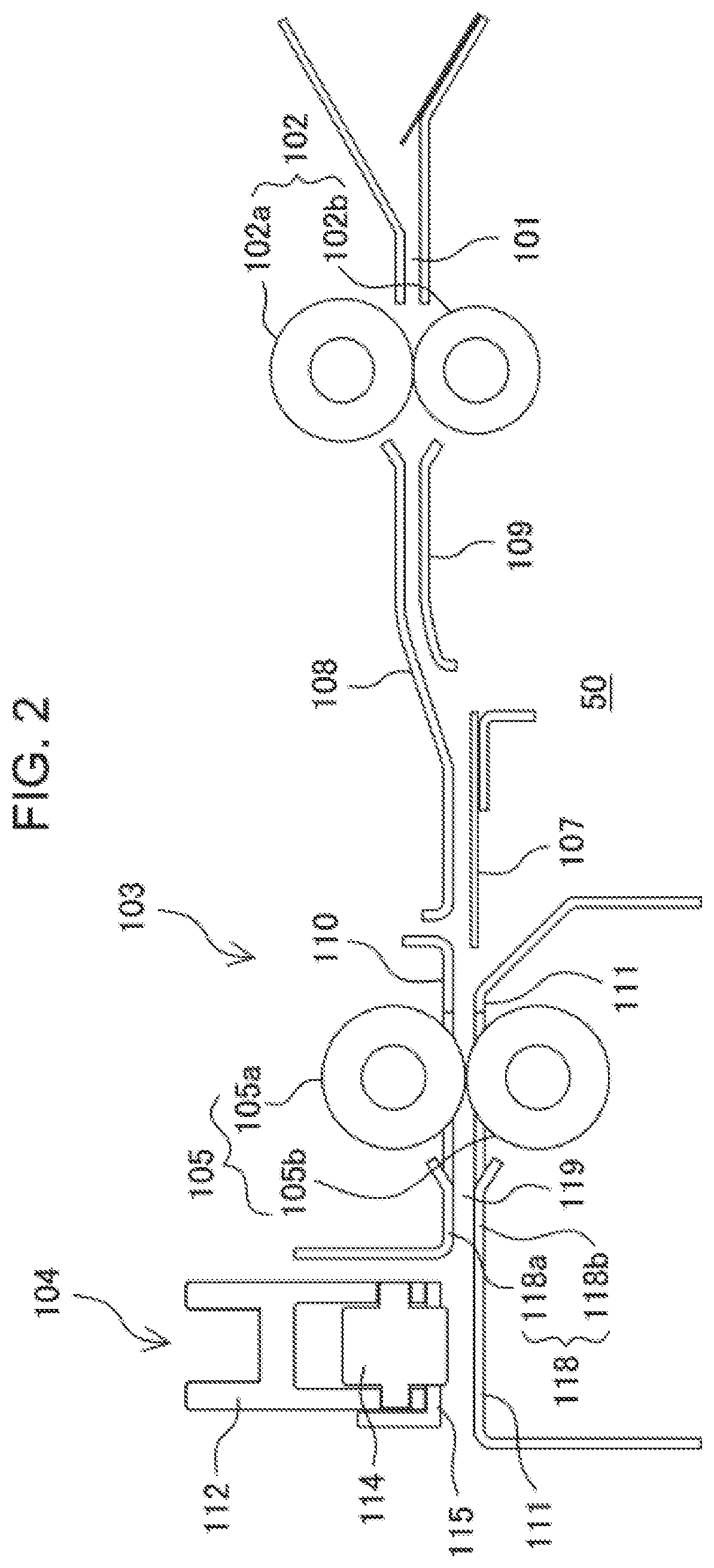

Exhaust system, a saddle riding type vehicle having the same, and a method of manufacturing and mounting an exhaust pipe

ActiveUS20110047998A1Firmly connectedImprove sealingSilencing apparatusMachines/enginesEngineeringExhaust pipe

An exhaust system includes an exhaust pipe. The exhaust pipe includes an outer pipe and an inner pipe. A first through-hole and a second through-hole are provided in a peripheral surface of the outer pipe and a peripheral surface of the inner pipe, respectively, to receive an exhaust gas detector. Third through-holes are provided in the peripheral surface of the outer pipe, at a different position than that of the first through-hole. Since the third through-holes are provided in the outer pipe, a liquid can be drained promptly from a space between the outer pipe and inner pipe. Exhaust gas can be prevented from being discharged to the atmosphere by sealing the third through-holes.

Owner:YAMAHA MOTOR CO LTD

Image forming apparatus including an image area glossiness control feature

InactiveUS8649696B2Without lowering productivityWide glossiness controlElectrographic process apparatusImage formationEngineering

Owner:CANON KK

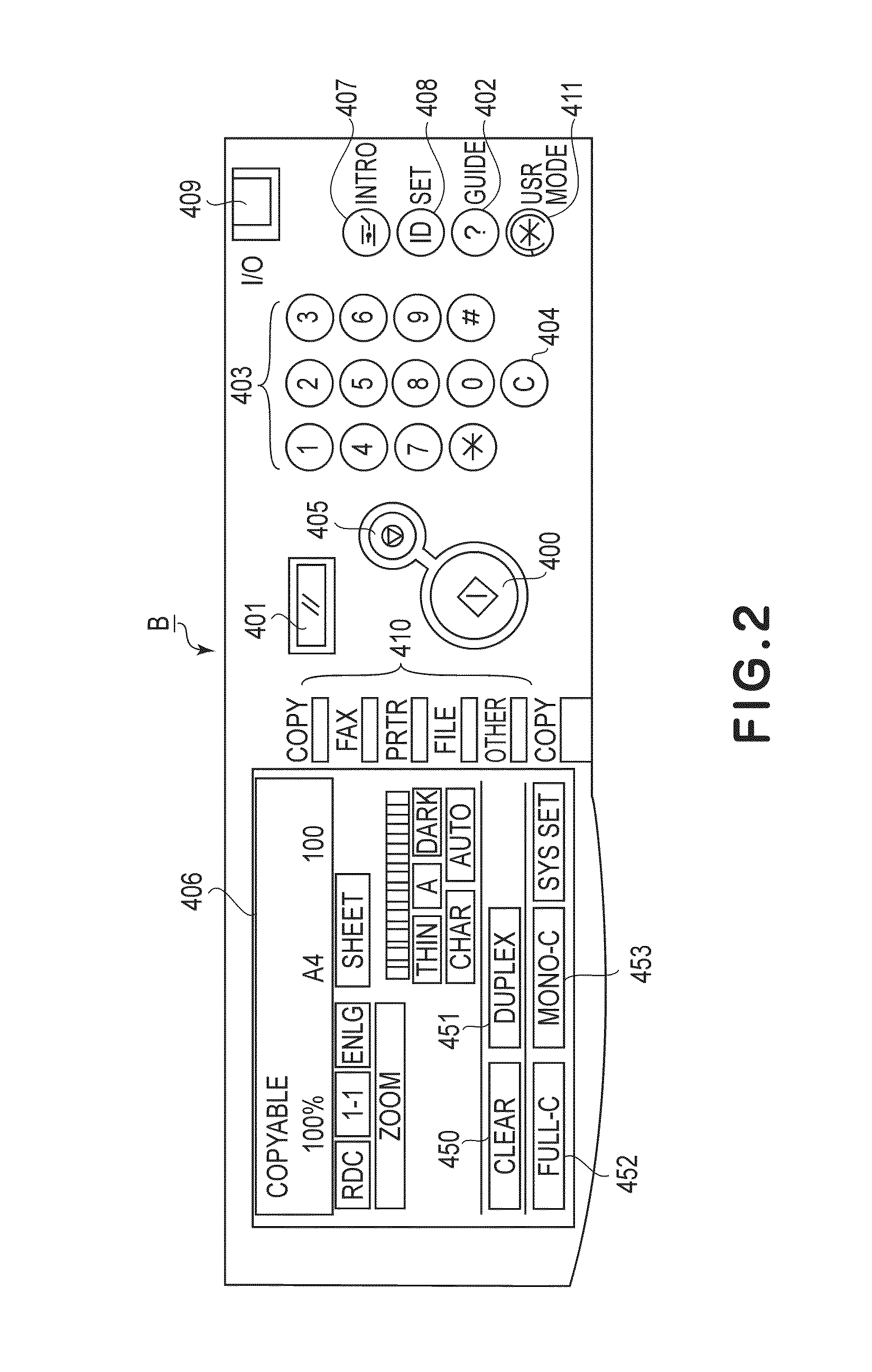

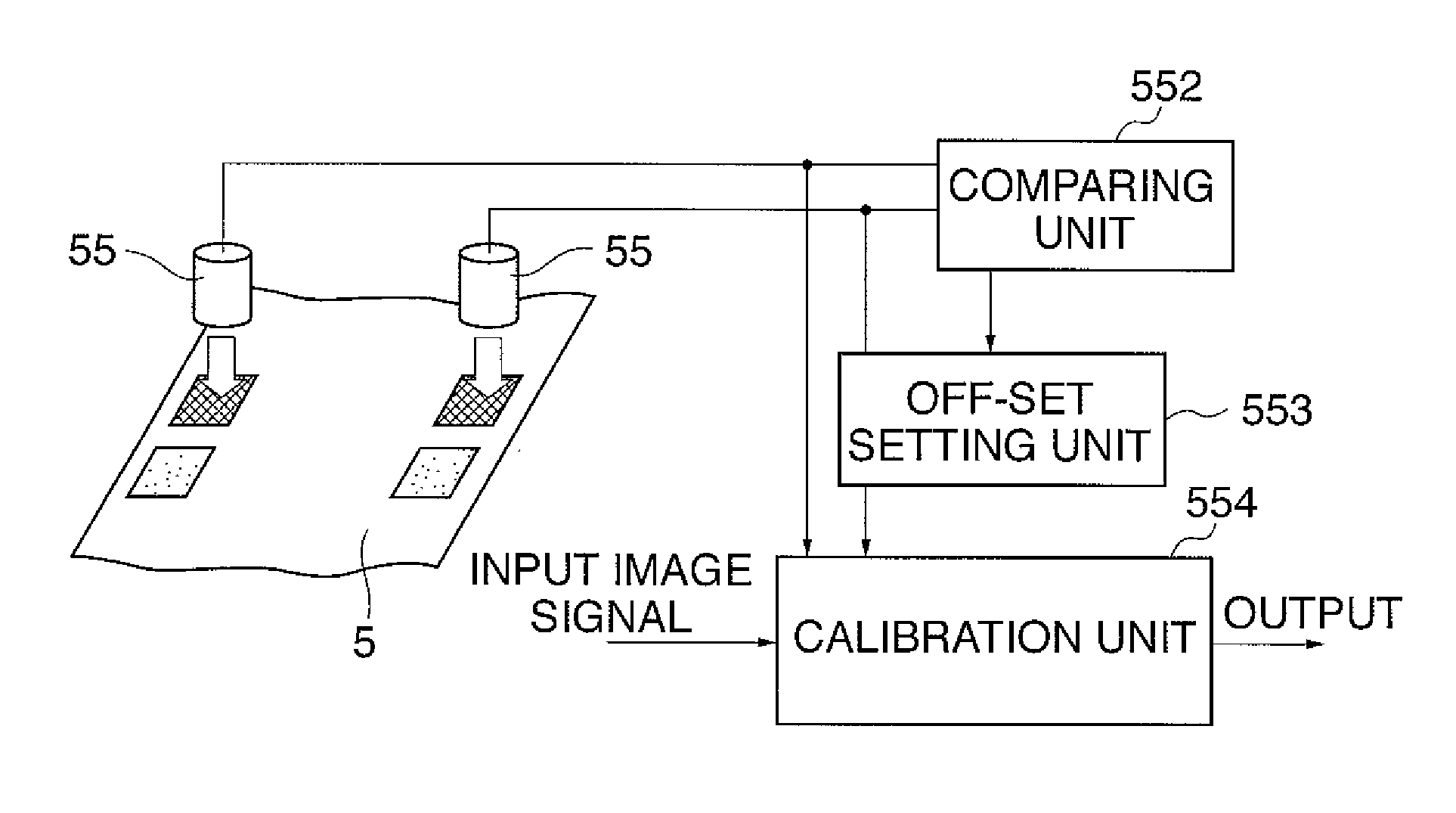

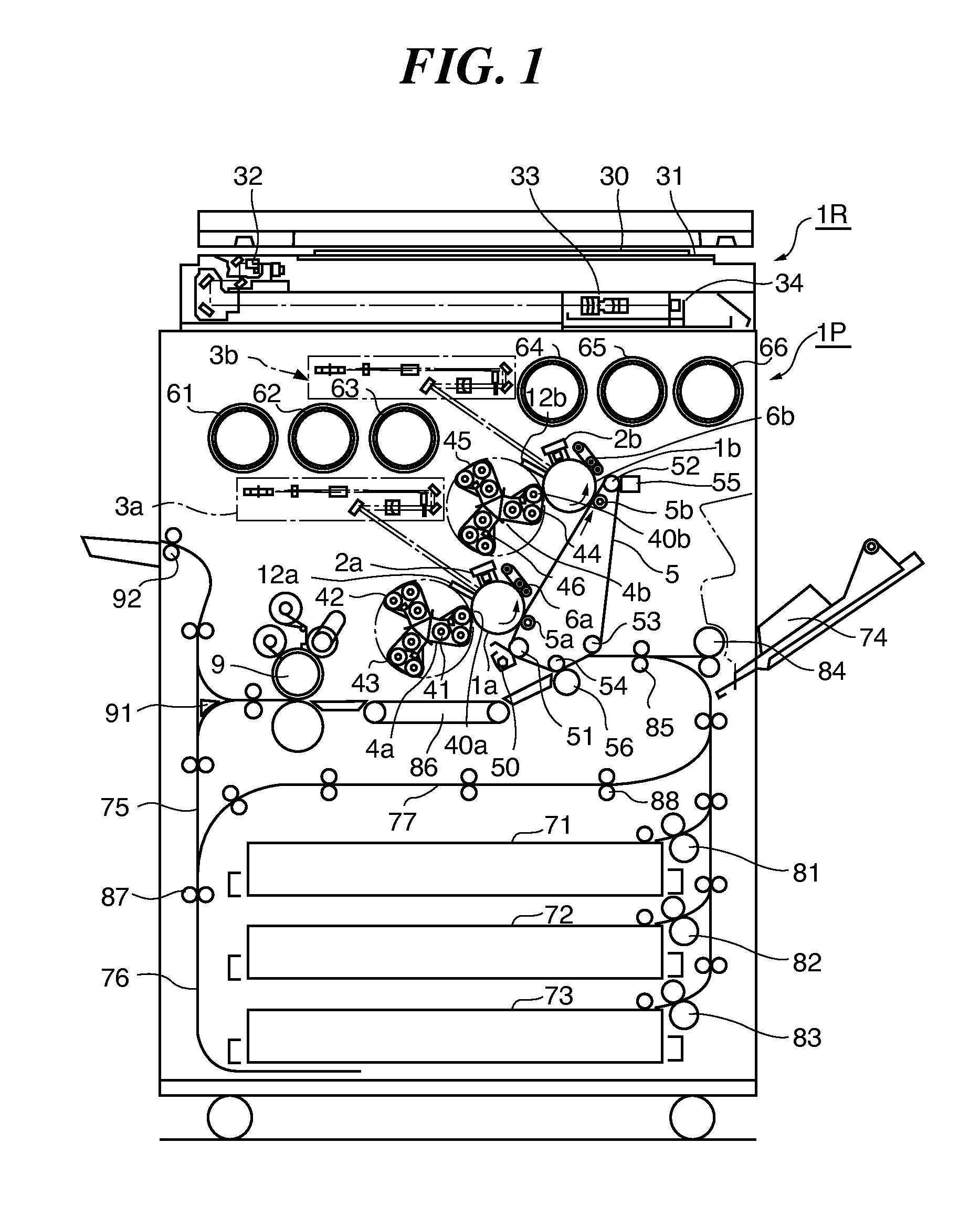

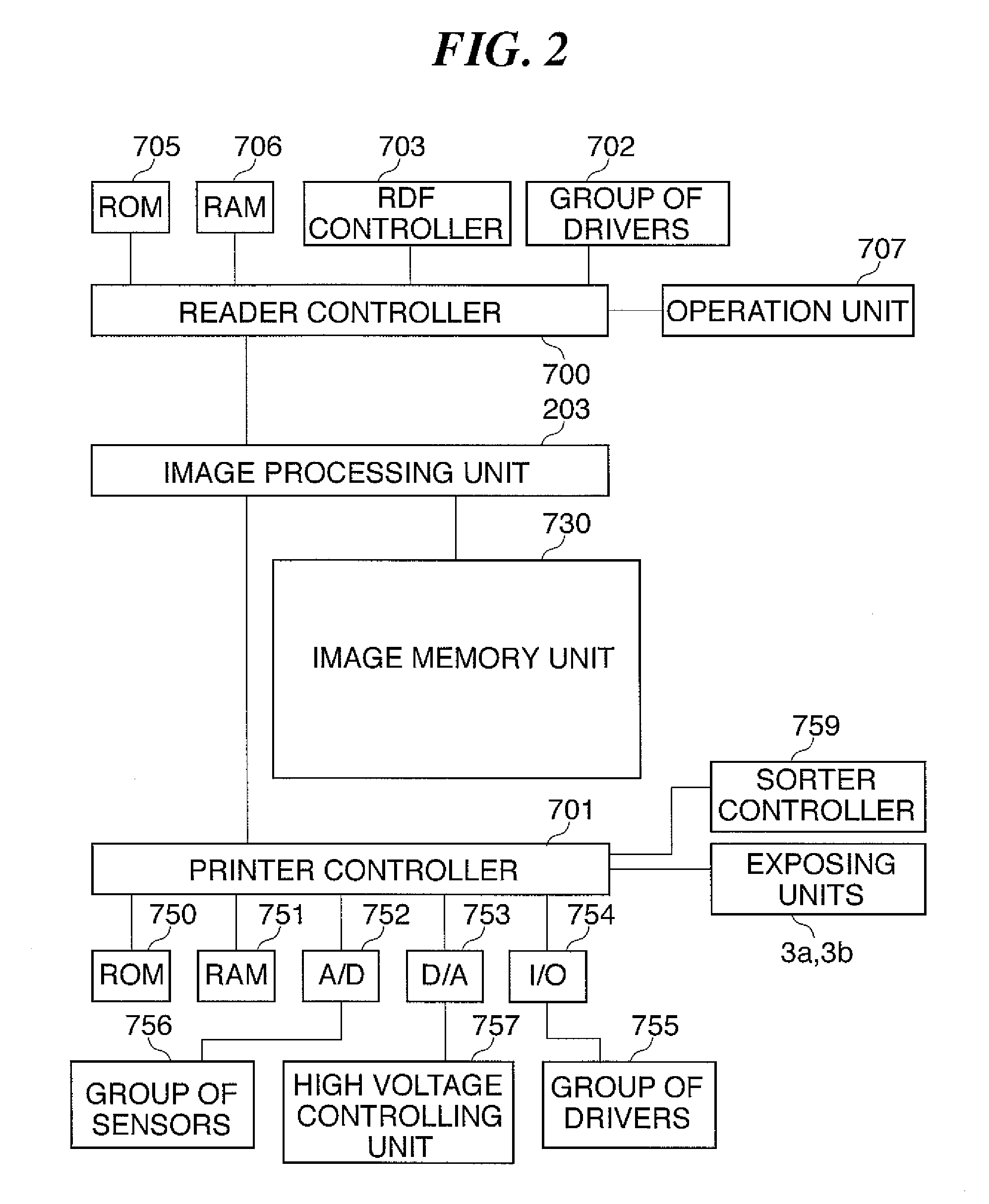

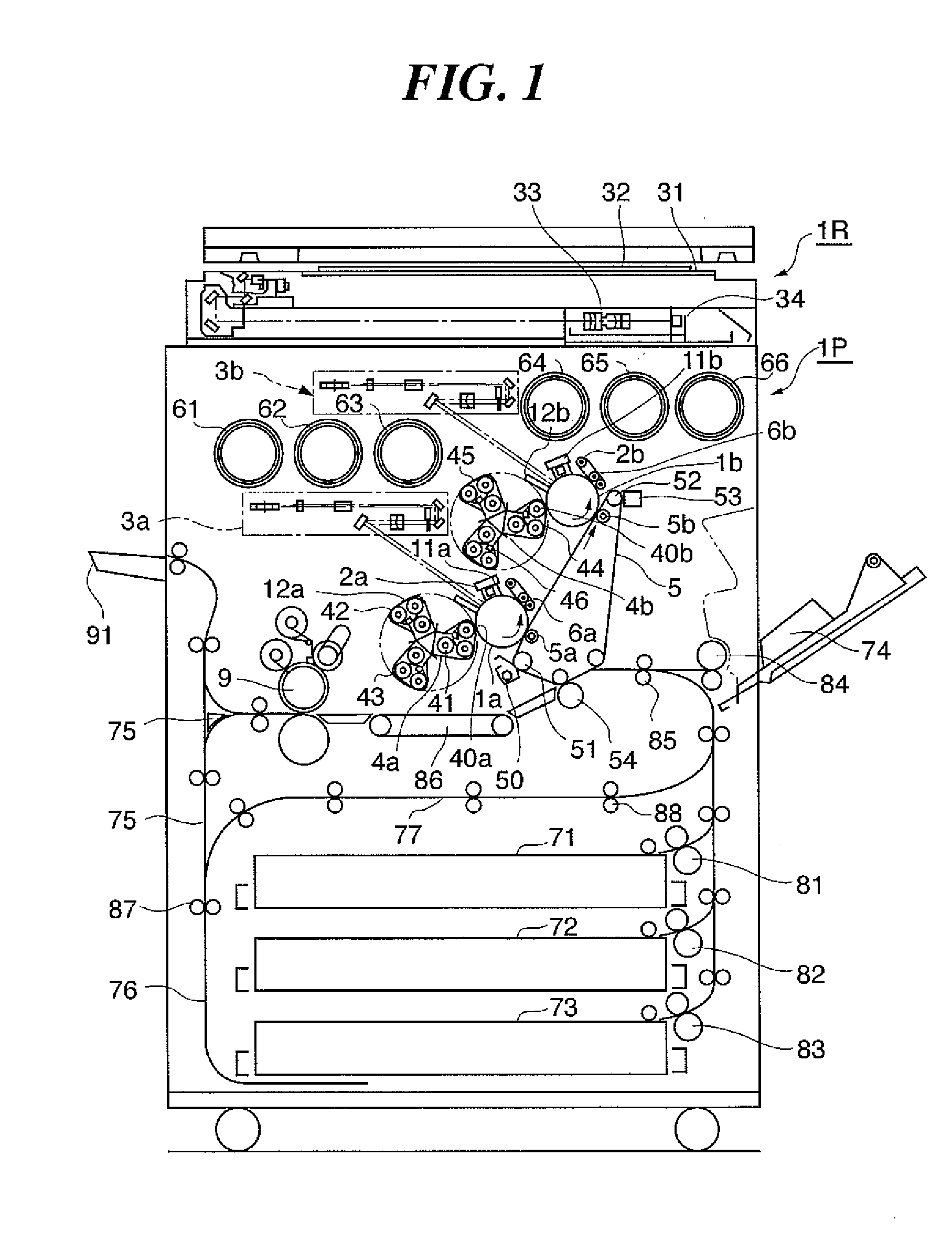

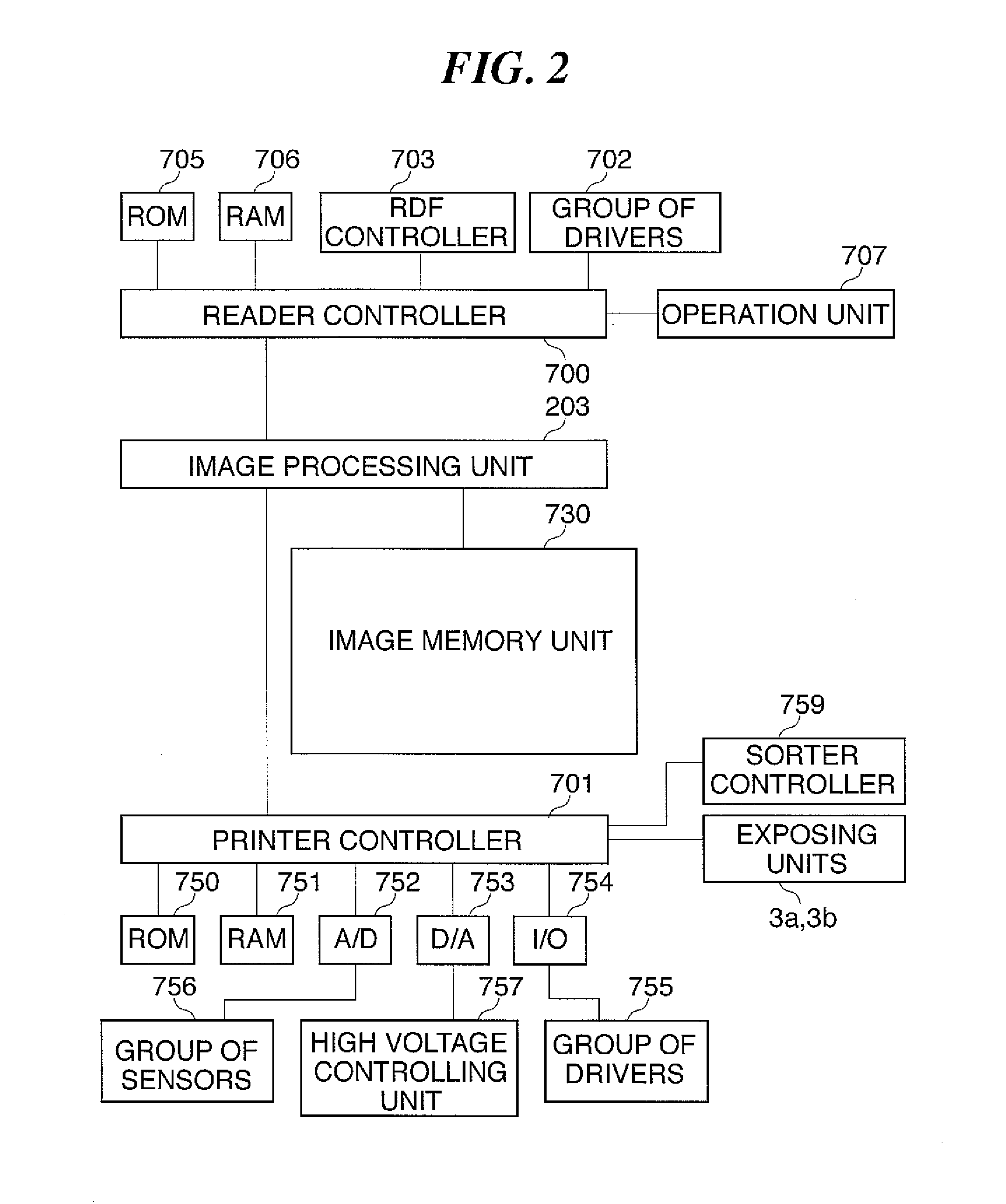

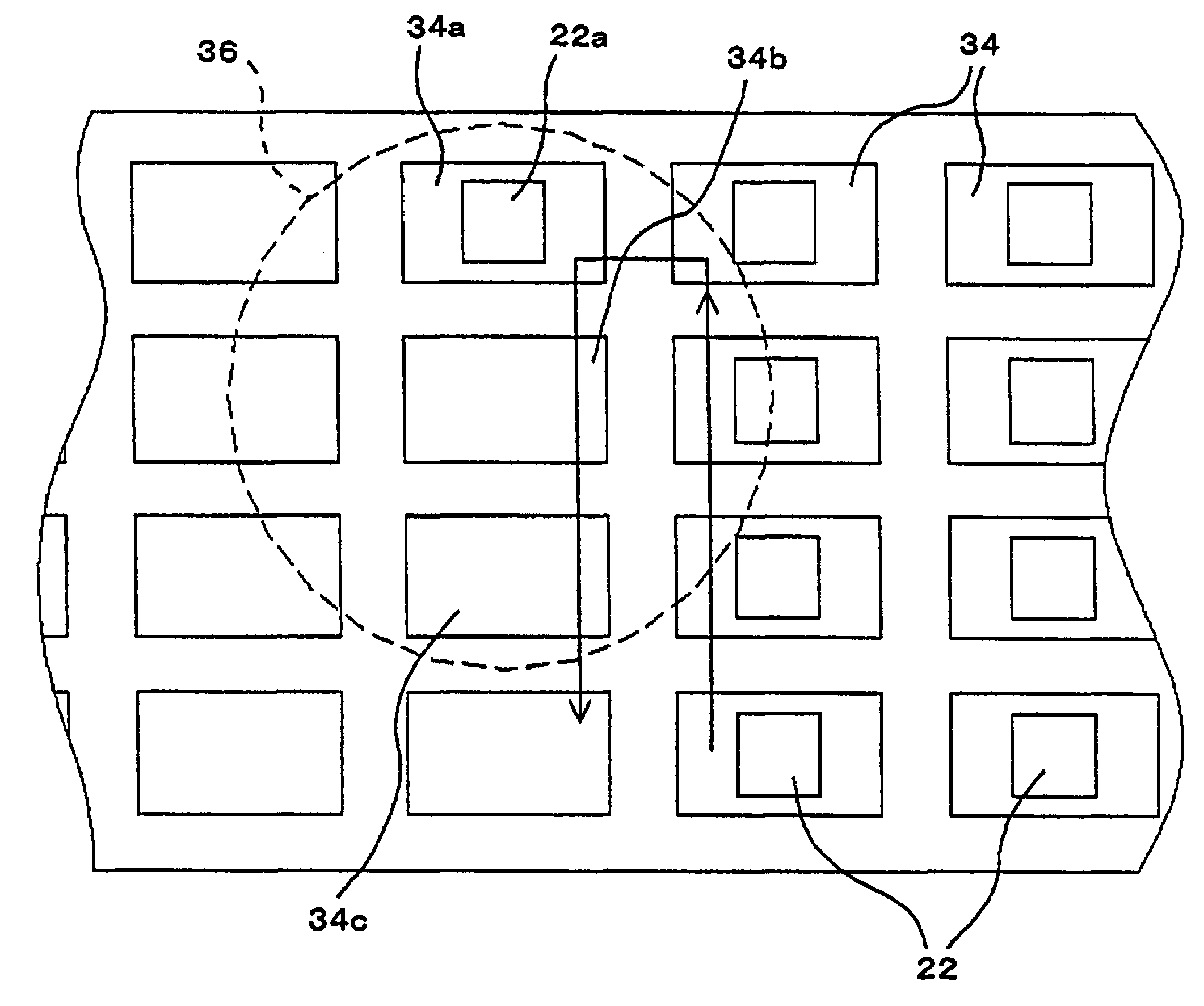

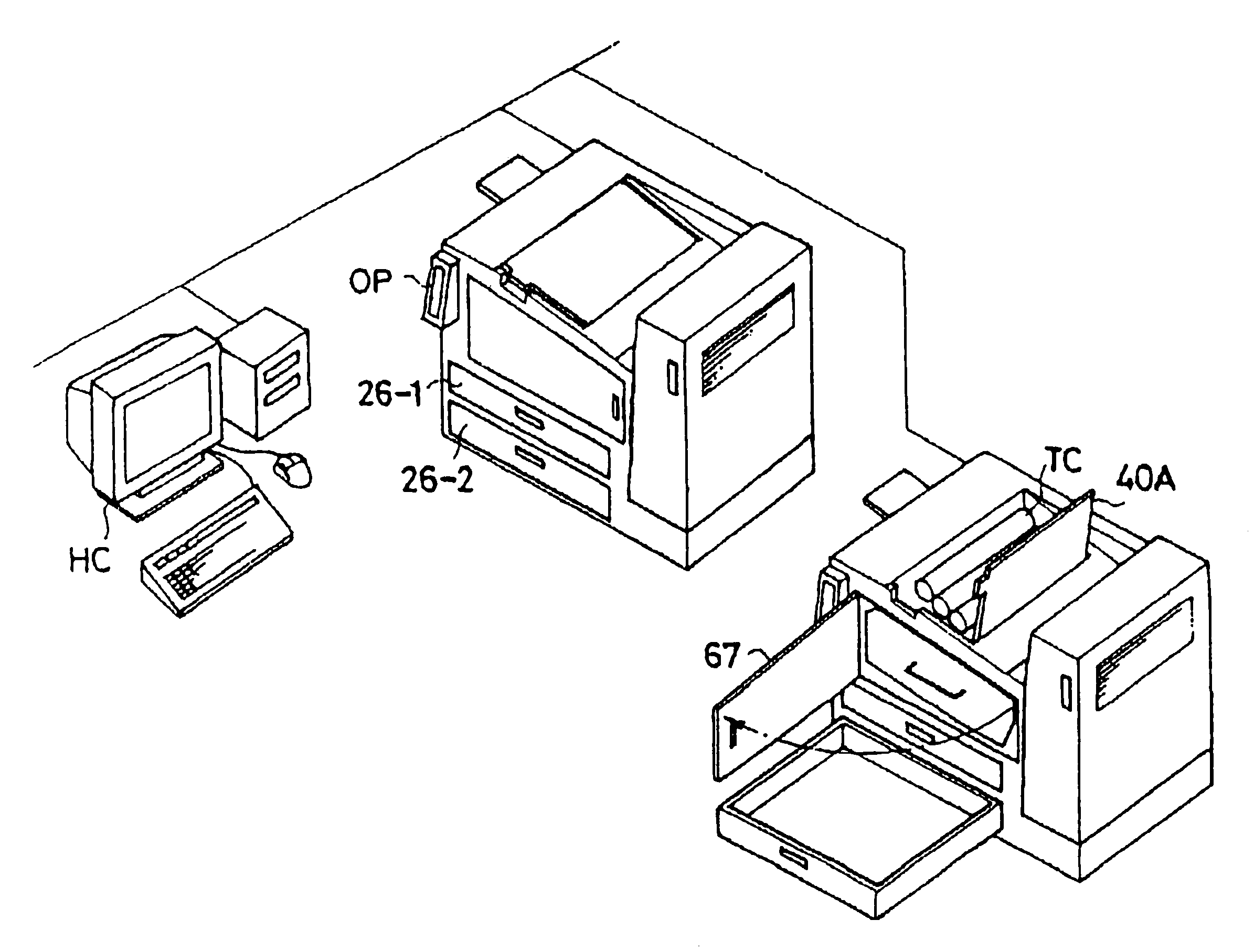

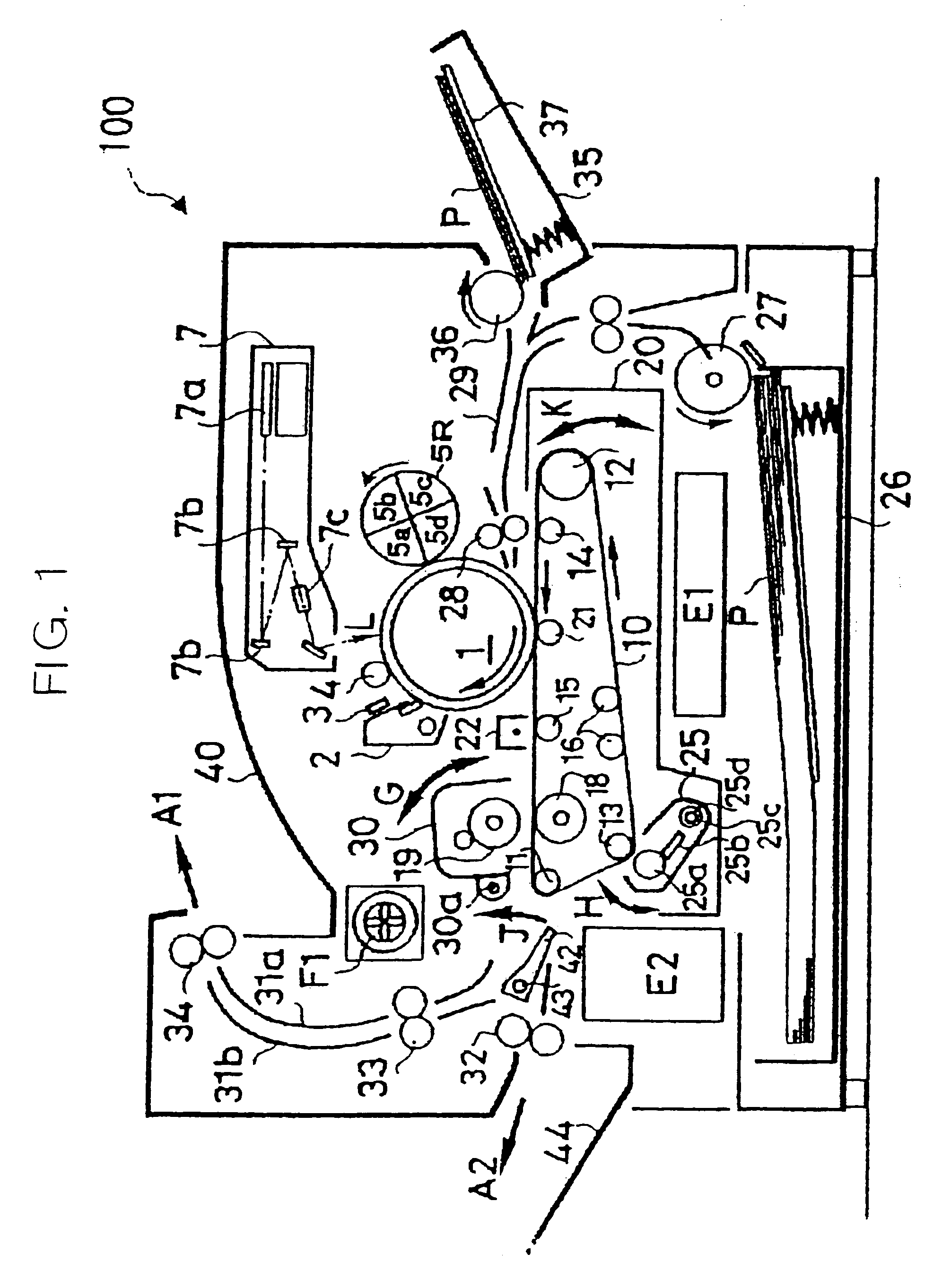

Image forming apparatus

InactiveUS7676166B2Without lowering productivityIncrease productivityElectrographic process apparatusProduction rateError processing

An image forming apparatus that can provide a quality image in a stable manner without lowering the productivity. A reference image forming unit forms reference images on a transfer member. A plurality of sensing units detect densities of the formed reference images. A control unit adjusts respective output values from the plurality of sensing units according to a difference between the output values from the plurality of sensing units. The control unit performs error processing according to the difference between the output values from the plurality of sensing units when the control unit adjusts the output values from the plurality of sensing units.

Owner:CANON KK

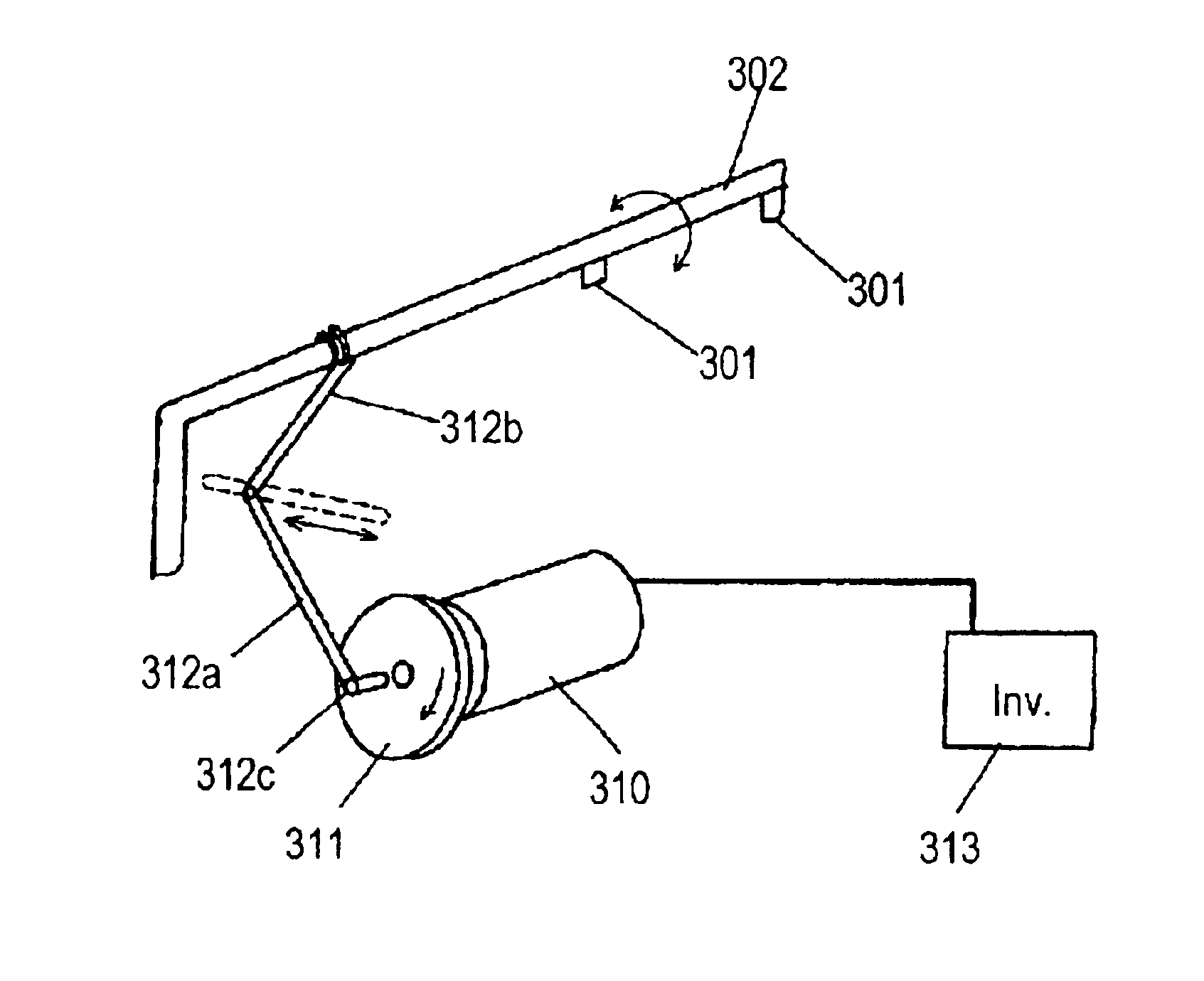

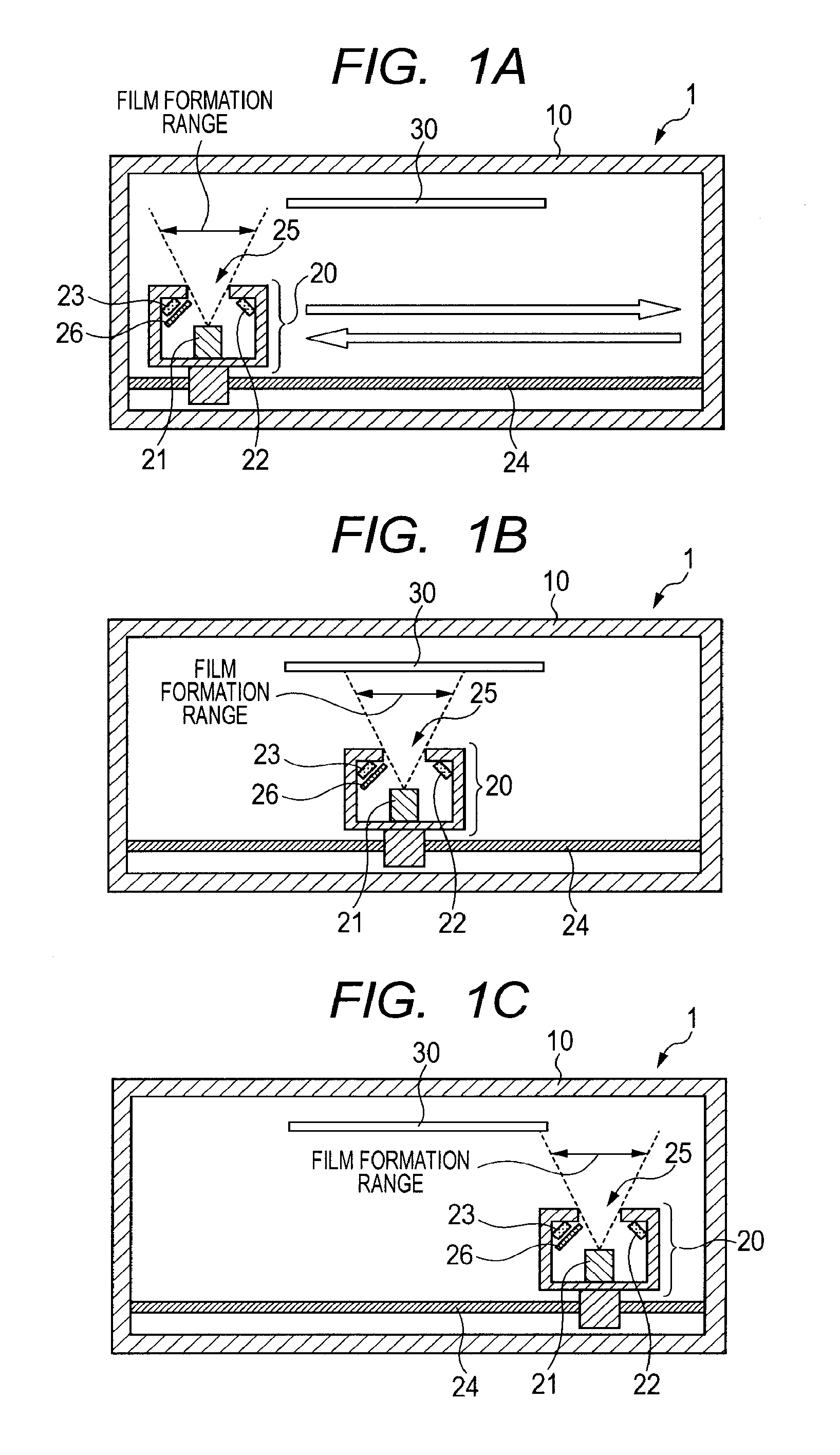

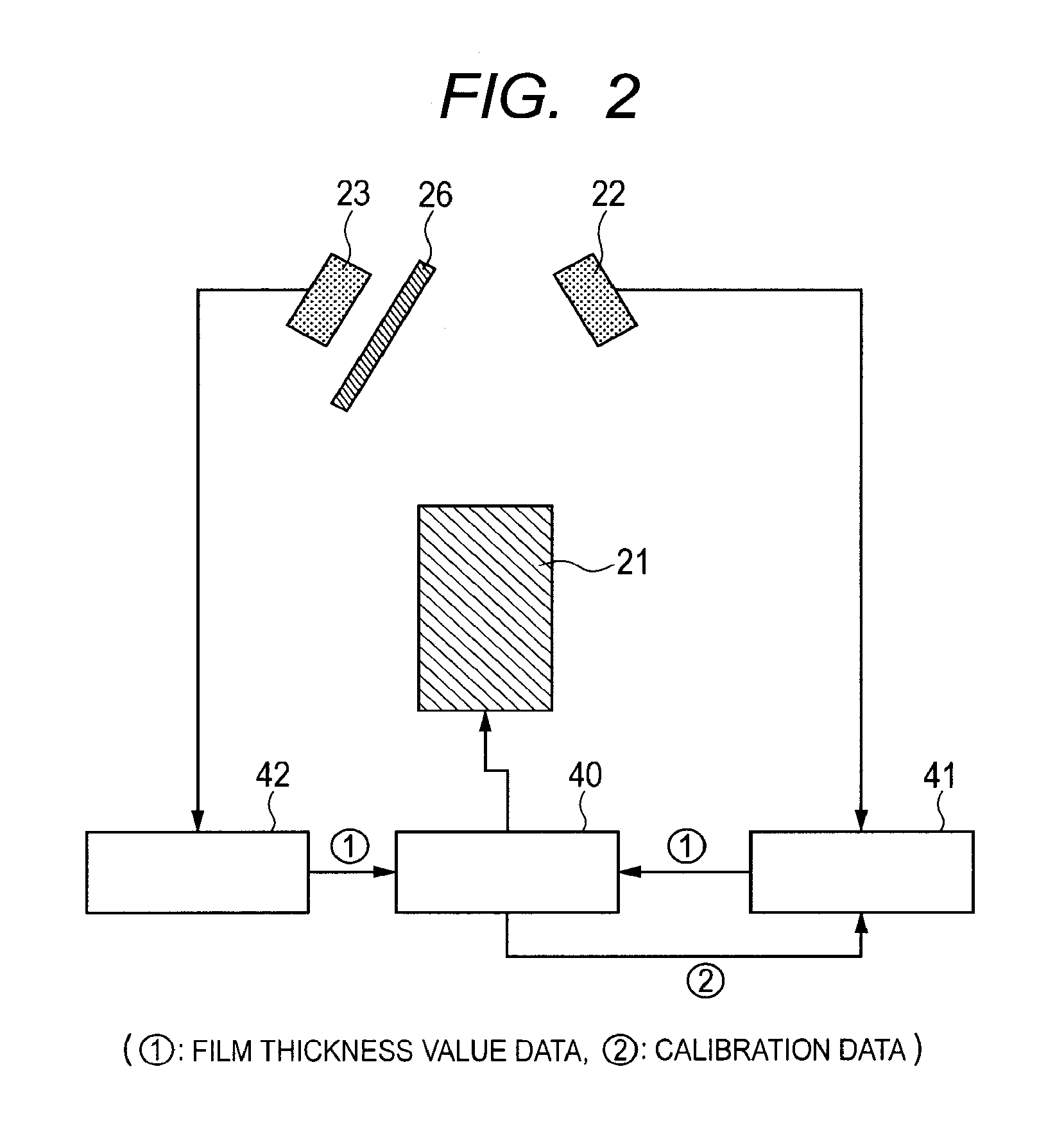

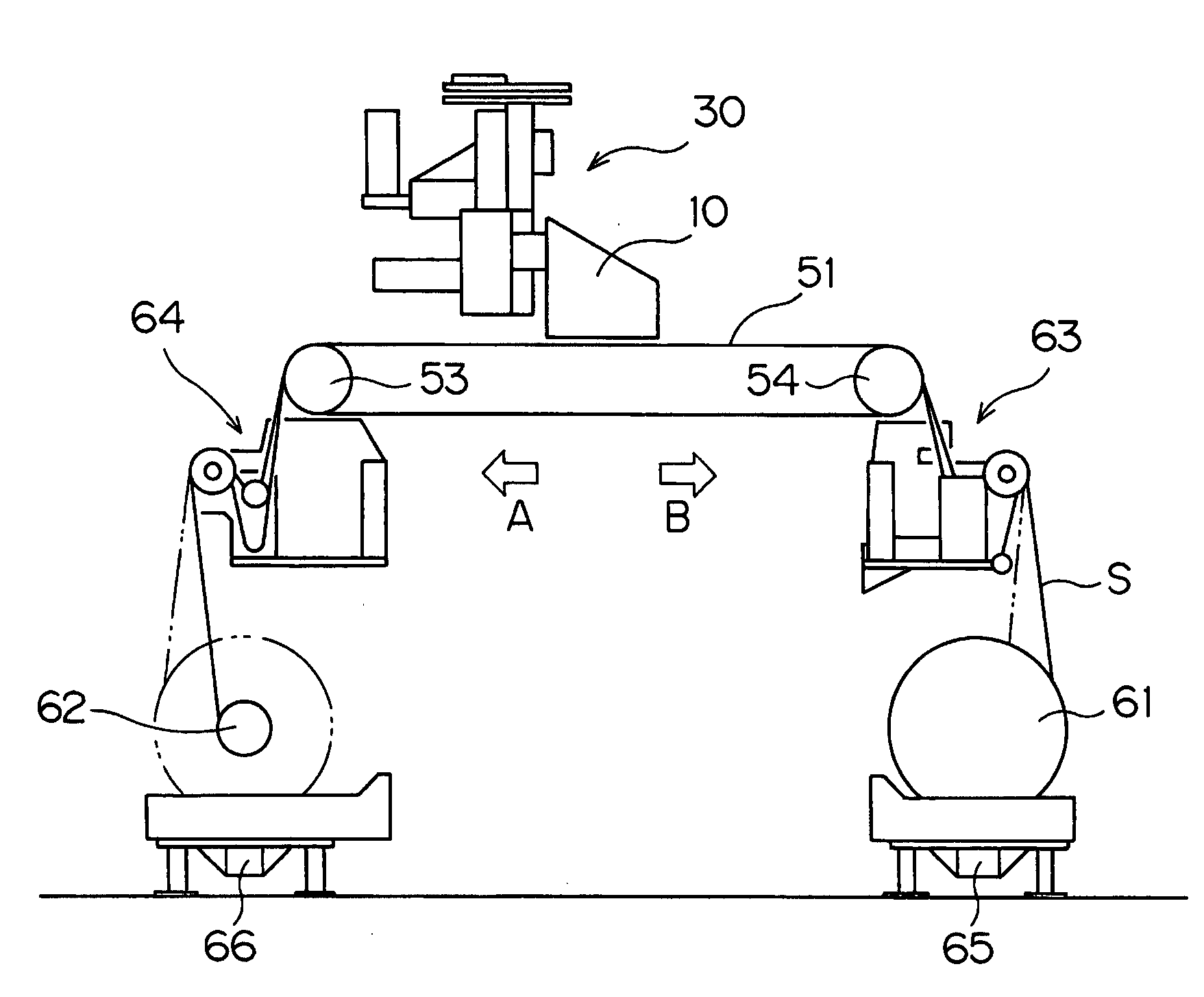

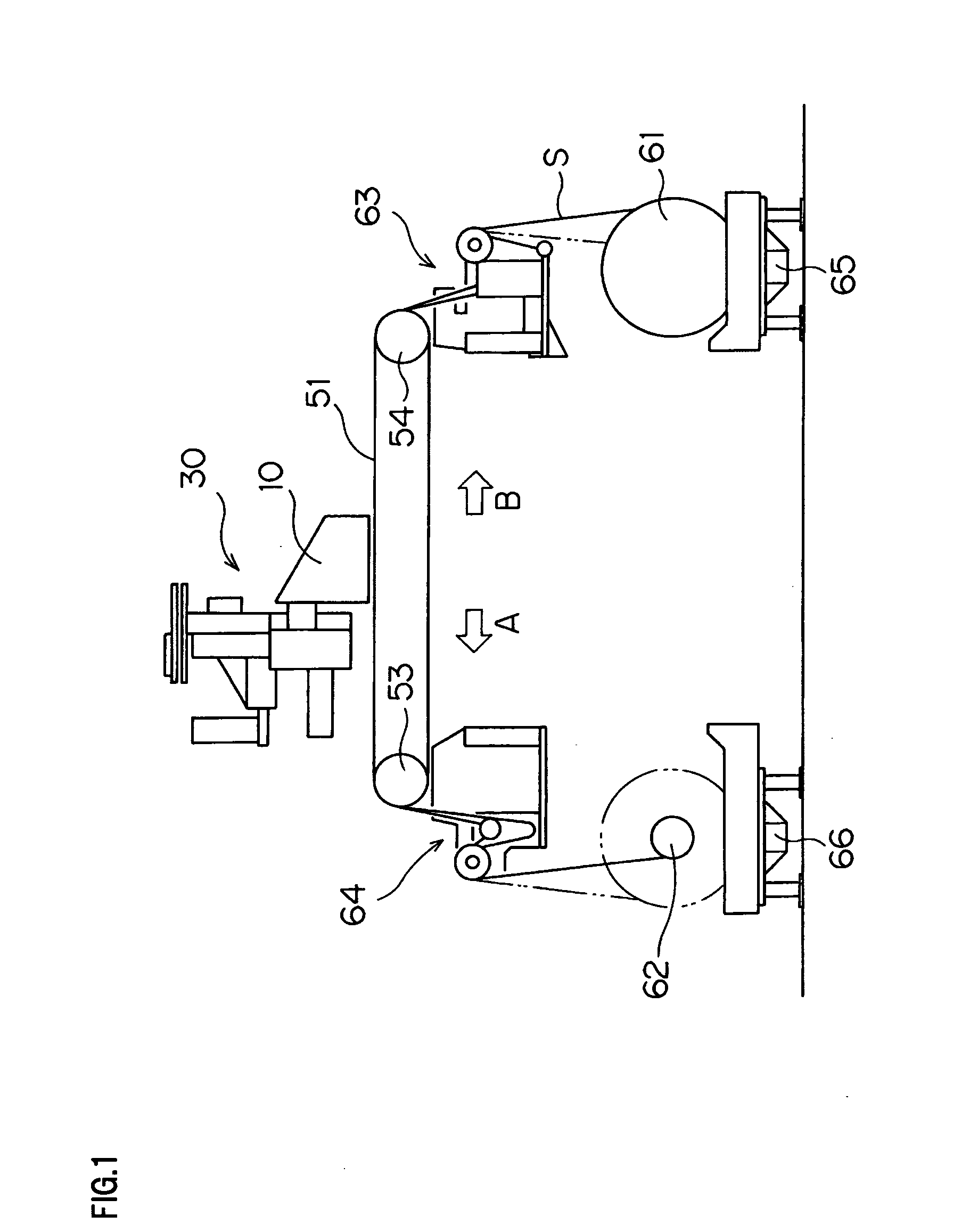

Film formation apparatus and film formation method

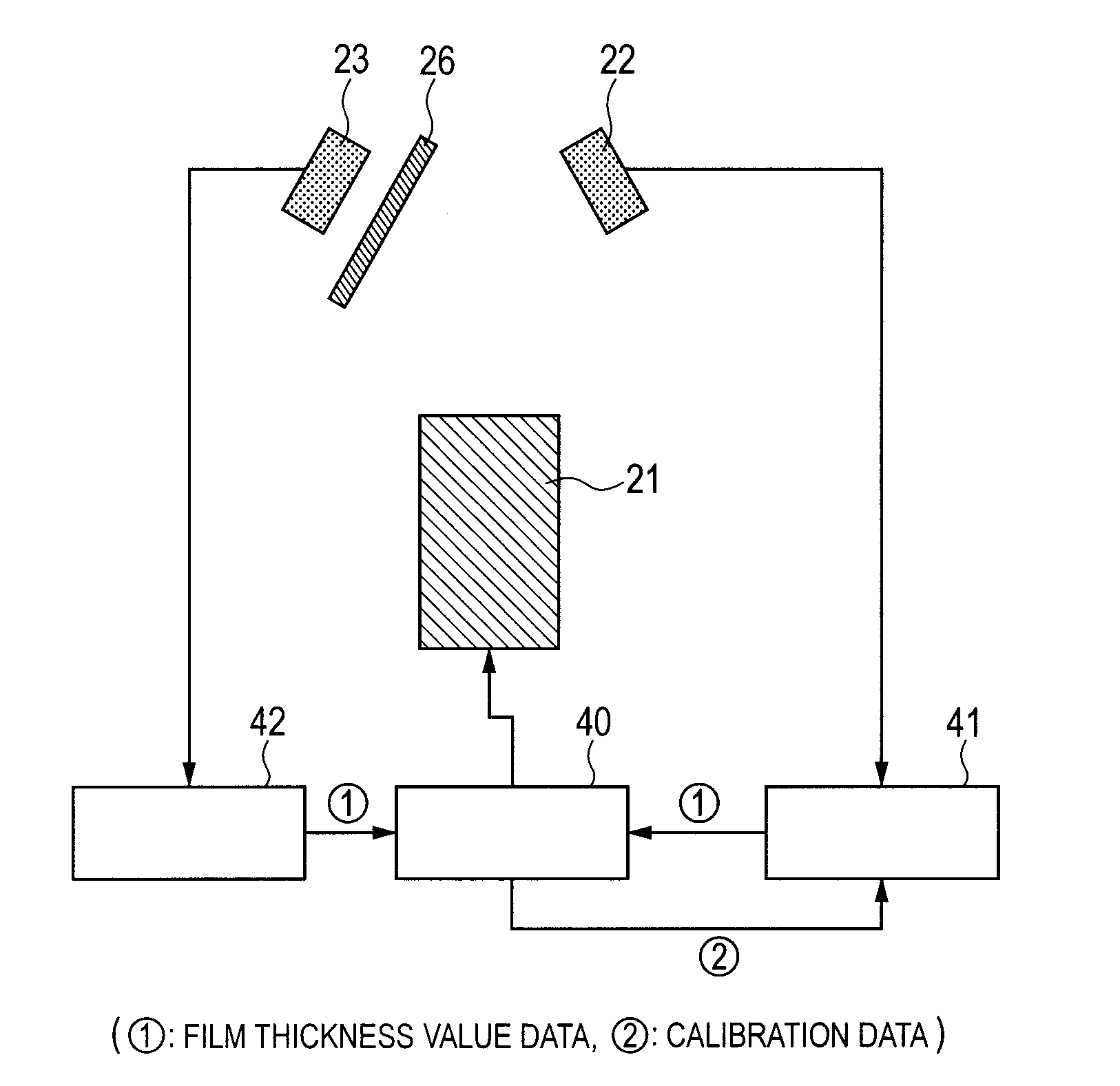

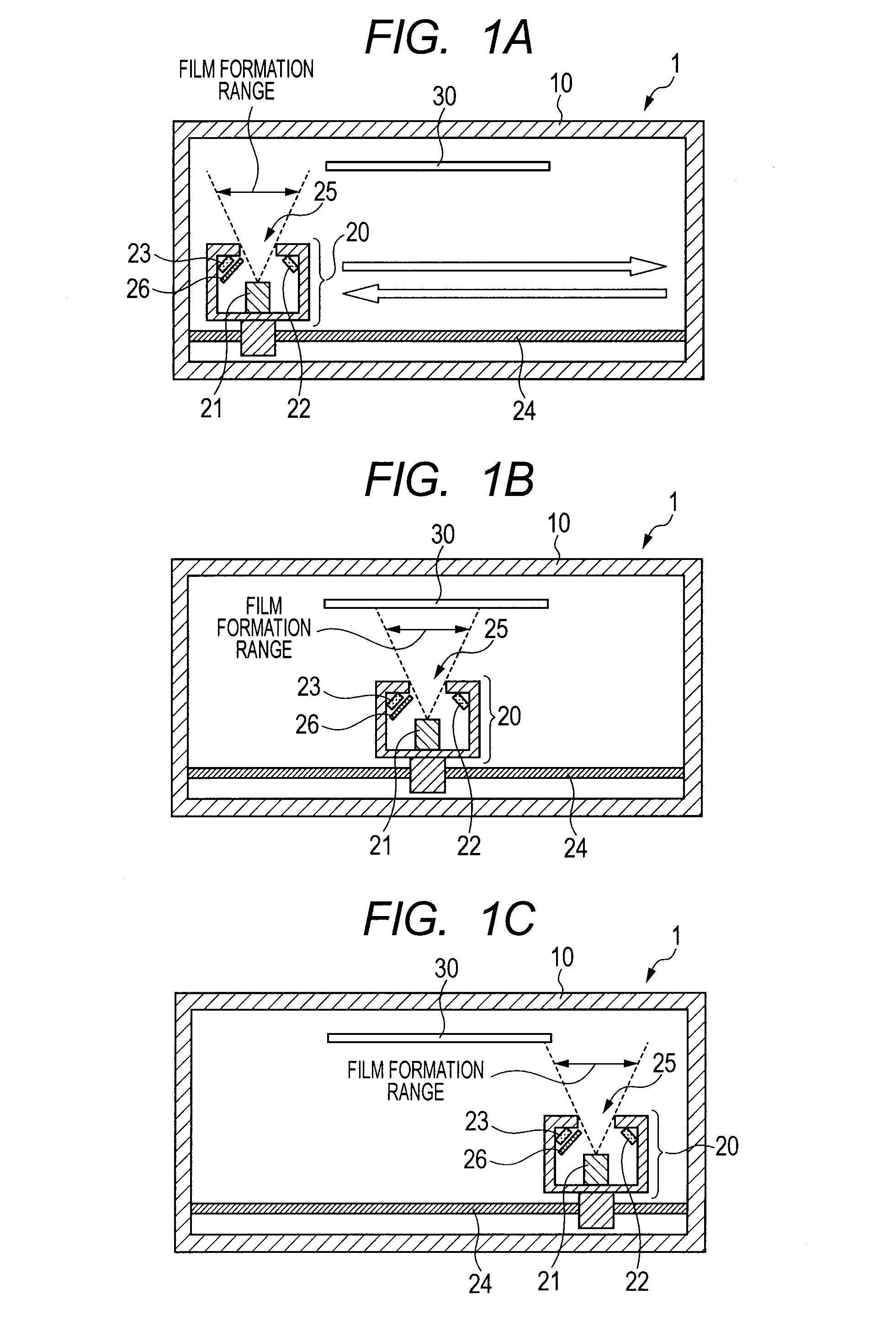

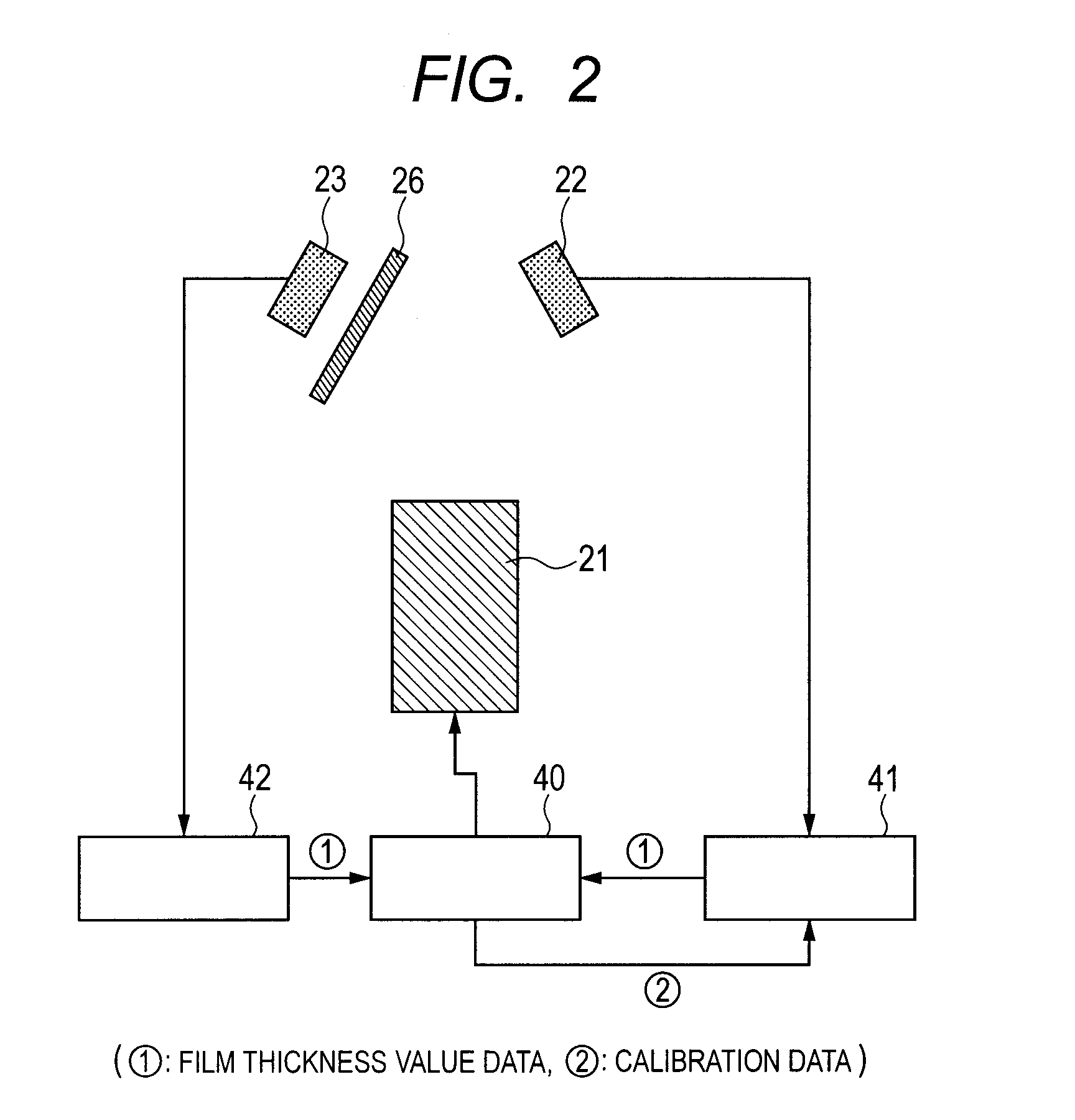

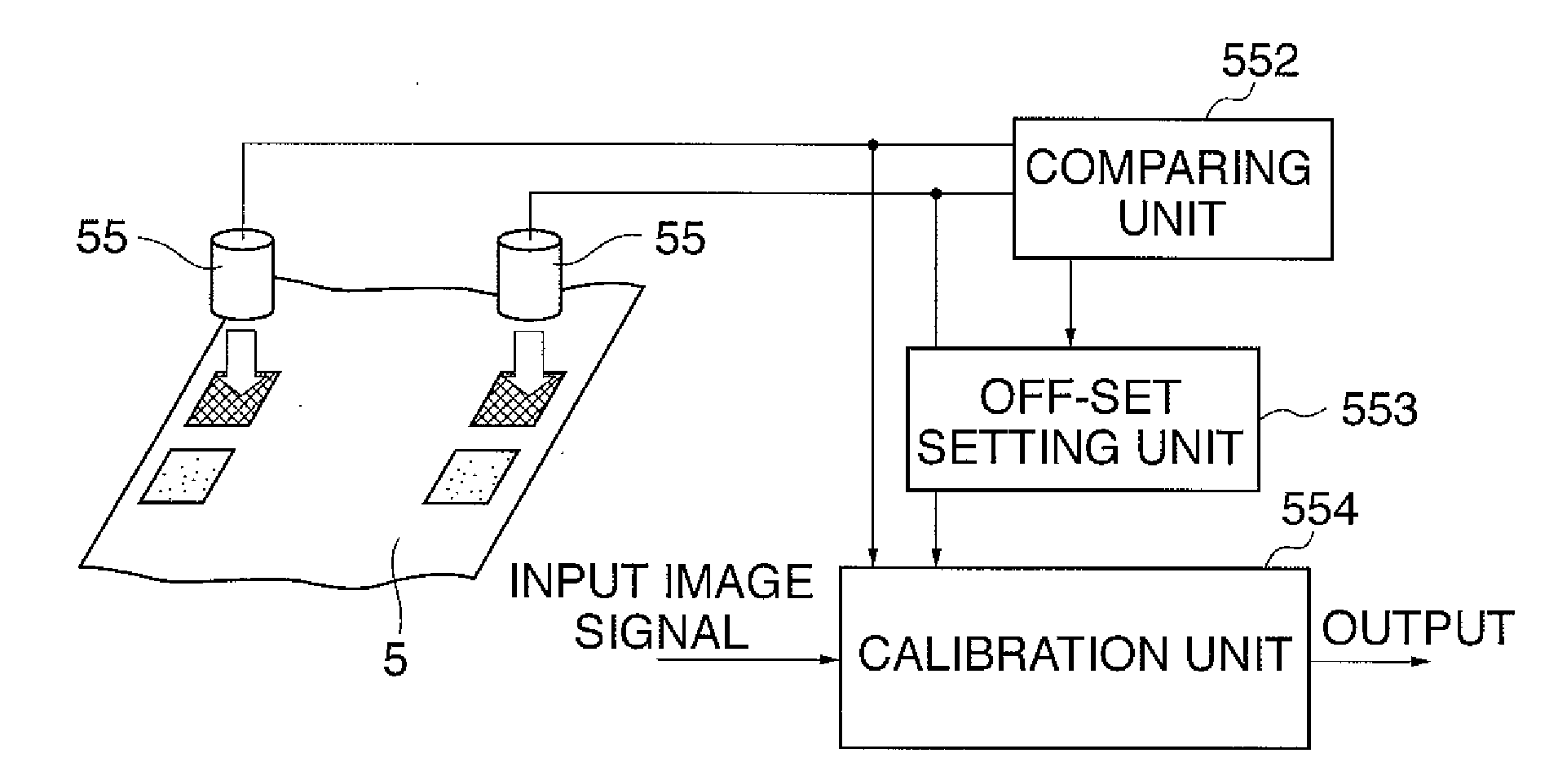

InactiveUS20120114837A1Lowering productivityWithout lowering productivityLiquid surface applicatorsVacuum evaporation coatingQuartzMoving parts

Provided are a film formation apparatus and a film formation method which may control with accuracy the thickness of a thin film formed on the film formation object. A film formation apparatus includes a moving part (film formation source unit) for moving a film formation source between a predetermined film formation waiting position and a predetermined film forming position is provided, and the moving part holds a quartz oscillator for measurement and a quartz oscillator for calibration so that their relative positions with respect to the film formation source are maintained. And a calibration step for calibrating a monitored value of the quartz oscillator for measurement, using a monitored value of the quartz oscillator for calibration, is performed in a middle of the film forming step of forming the film on the film formation object.

Owner:CANON KK

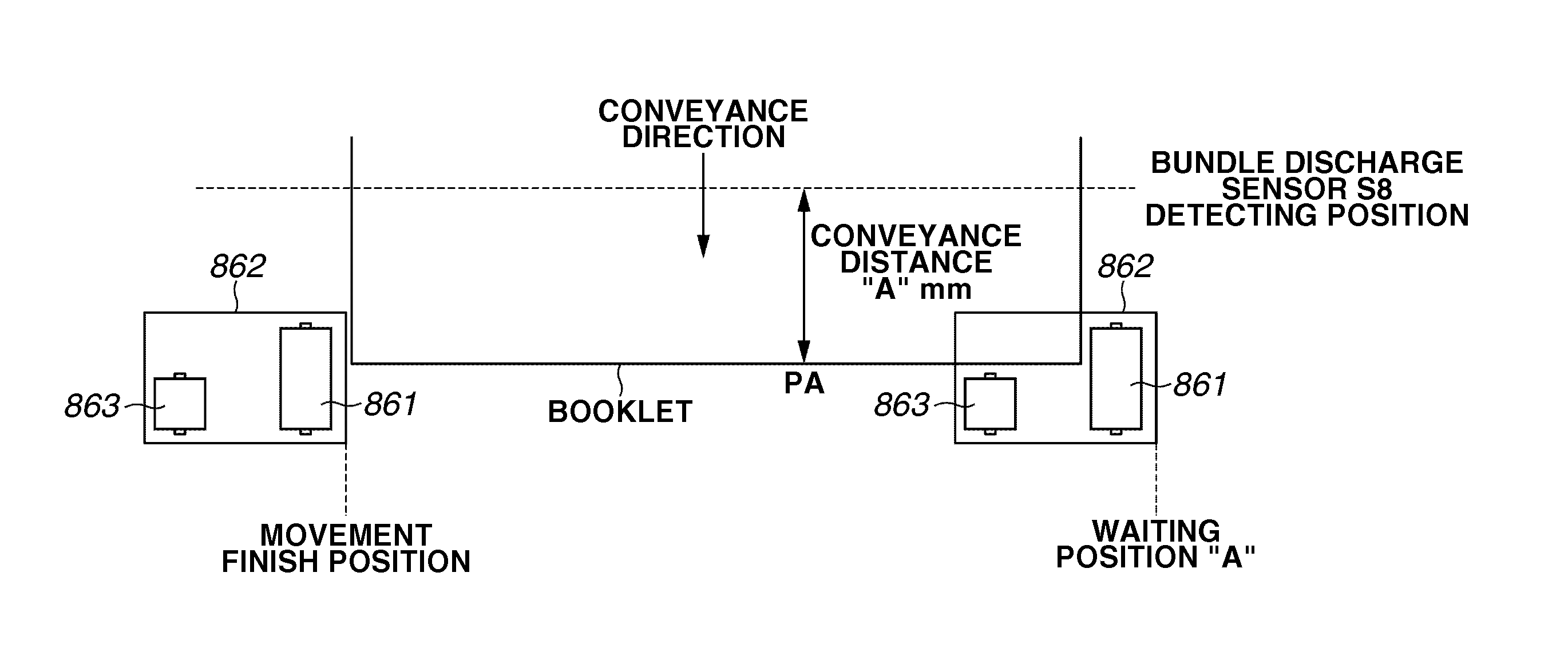

Sheet processing apparatus

InactiveUS8613435B2Without lowering productivityMechanical working/deformationFolding thin materialsEngineeringMechanical engineering

Owner:CANON KK

Exhaust system, a saddle riding type vehicle having the same, and a method of manufacturing and mounting an exhaust pipe

ActiveUS8678038B2Without lowering productivityPrevent leakageSilencing apparatusMachines/enginesEngineeringExhaust pipe

An exhaust system includes an exhaust pipe. The exhaust pipe includes an outer pipe and an inner pipe. A first through-hole and a second through-hole are provided in a peripheral surface of the outer pipe and a peripheral surface of the inner pipe, respectively, to receive an exhaust gas detector. Third through-holes are provided in the peripheral surface of the outer pipe, at a different position than that of the first through-hole. Since the third through-holes are provided in the outer pipe, a liquid can be drained promptly from a space between the outer pipe and inner pipe. Exhaust gas can be prevented from being discharged to the atmosphere by sealing the third through-holes.

Owner:YAMAHA MOTOR CO LTD

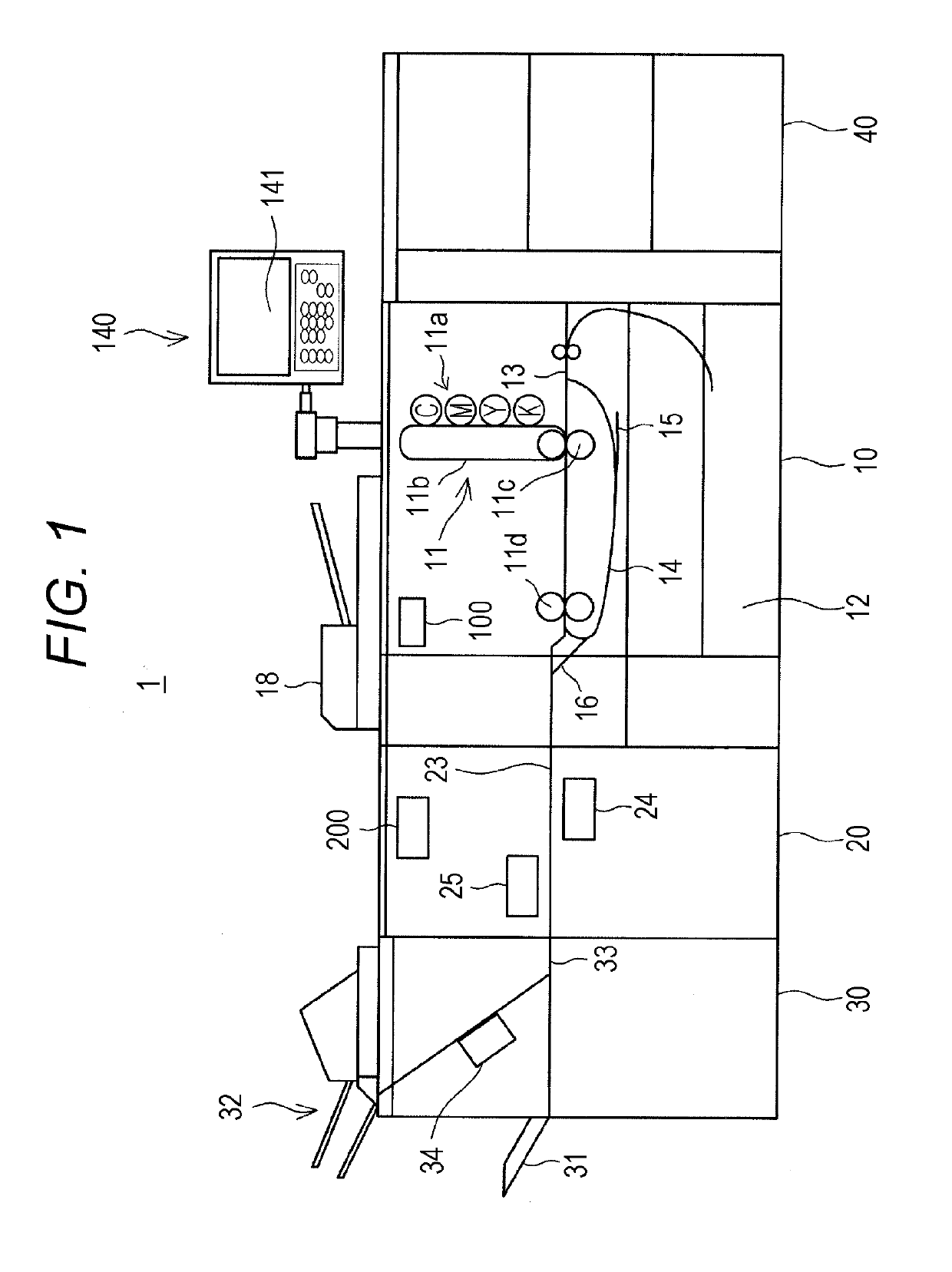

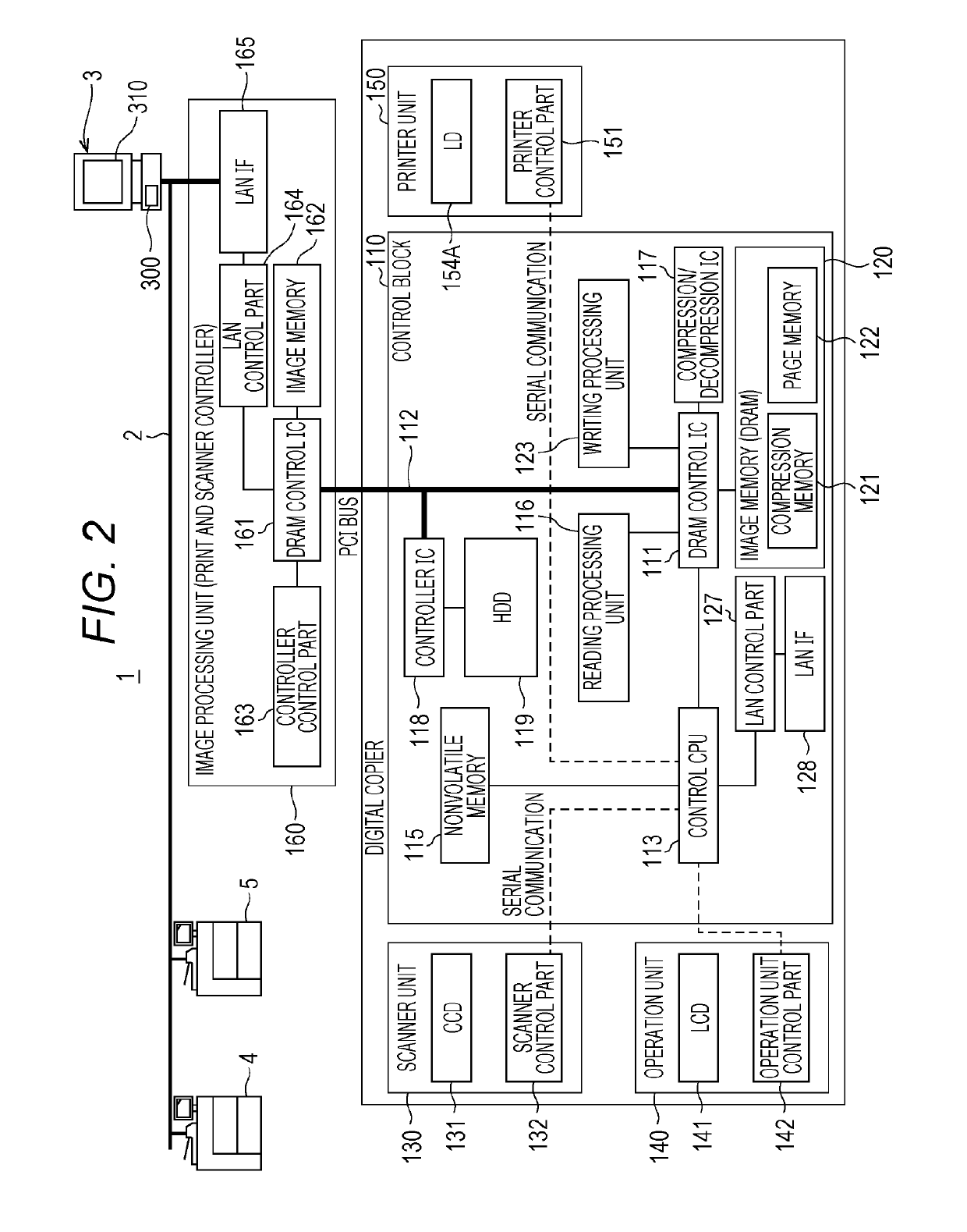

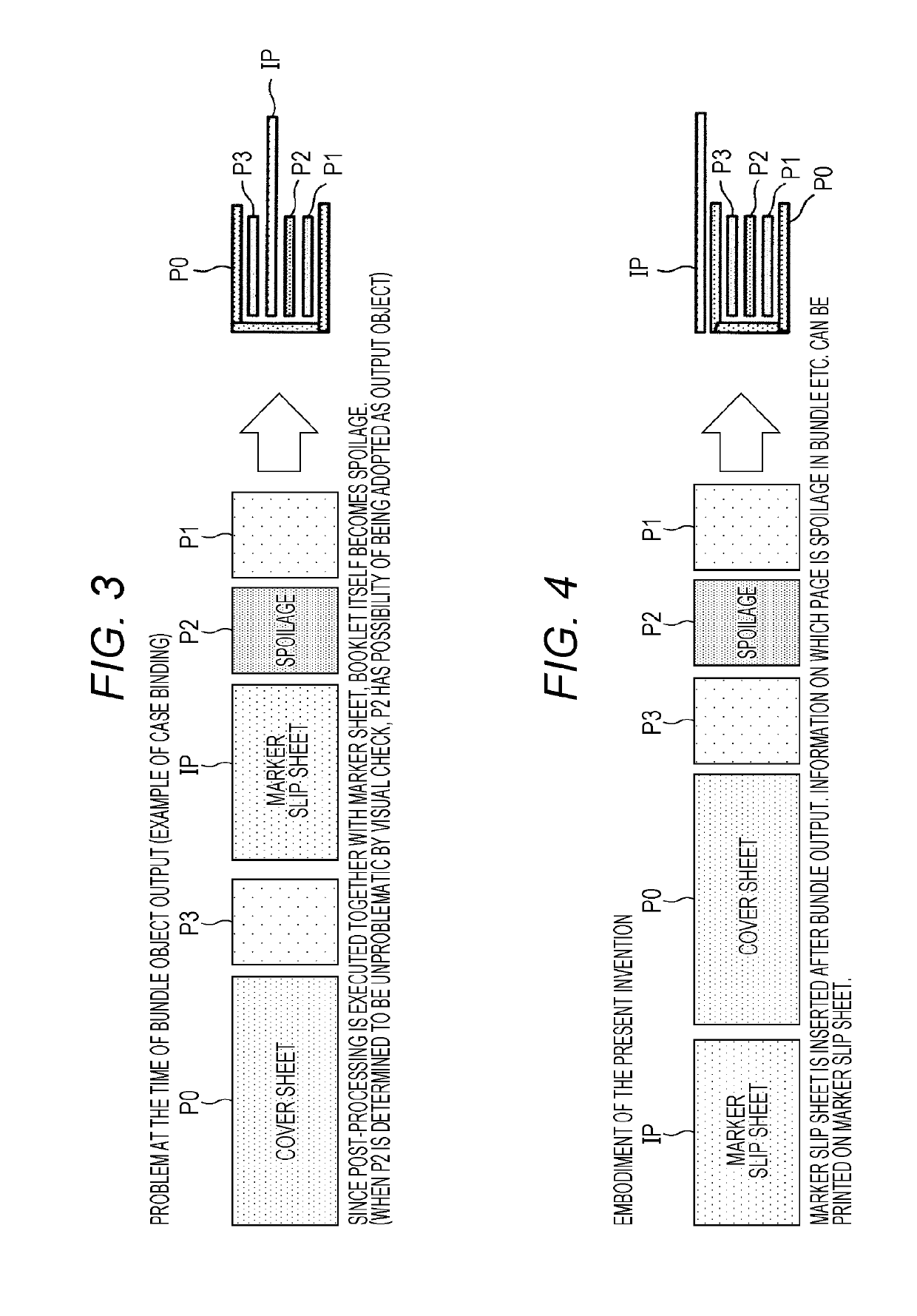

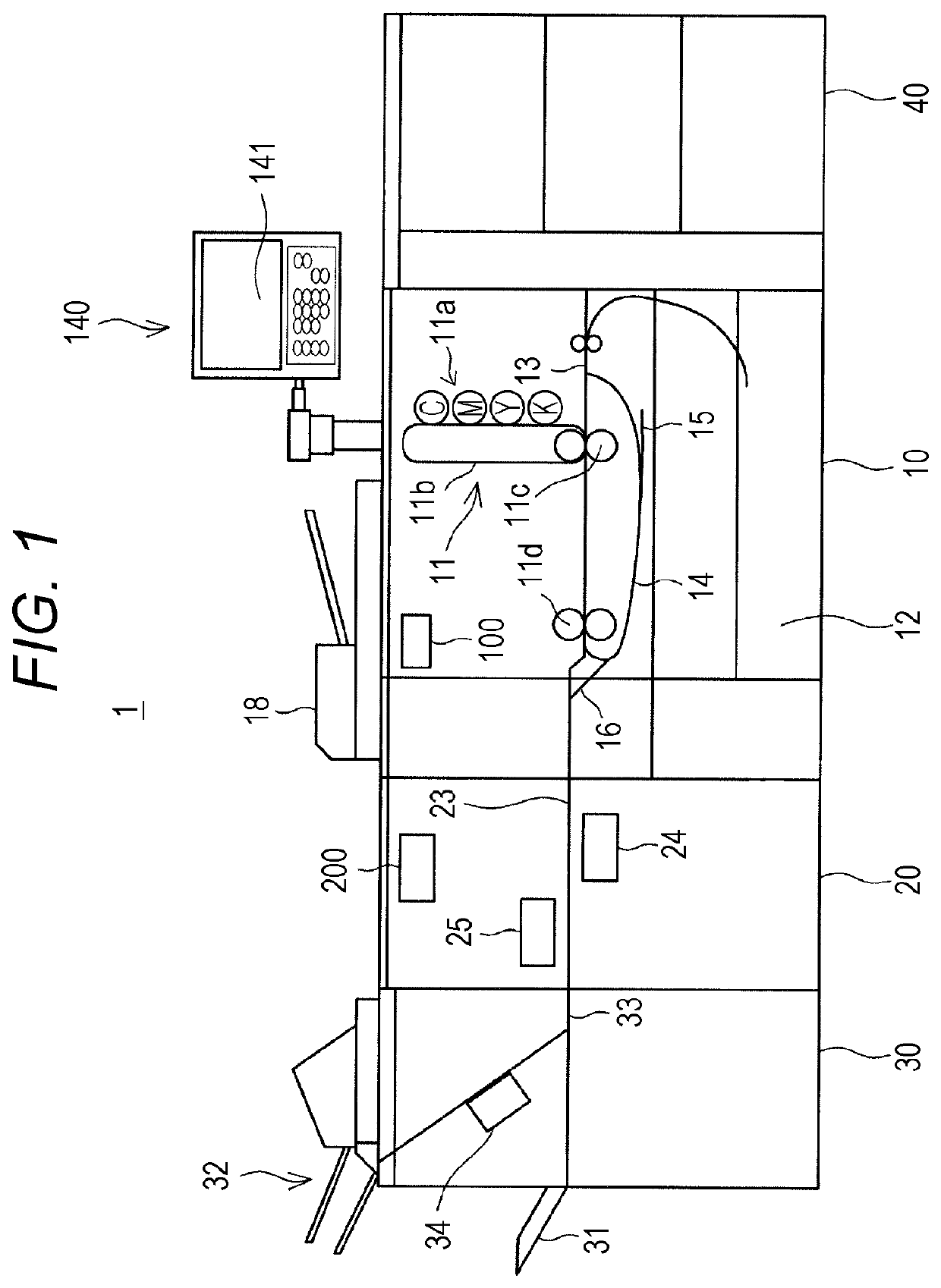

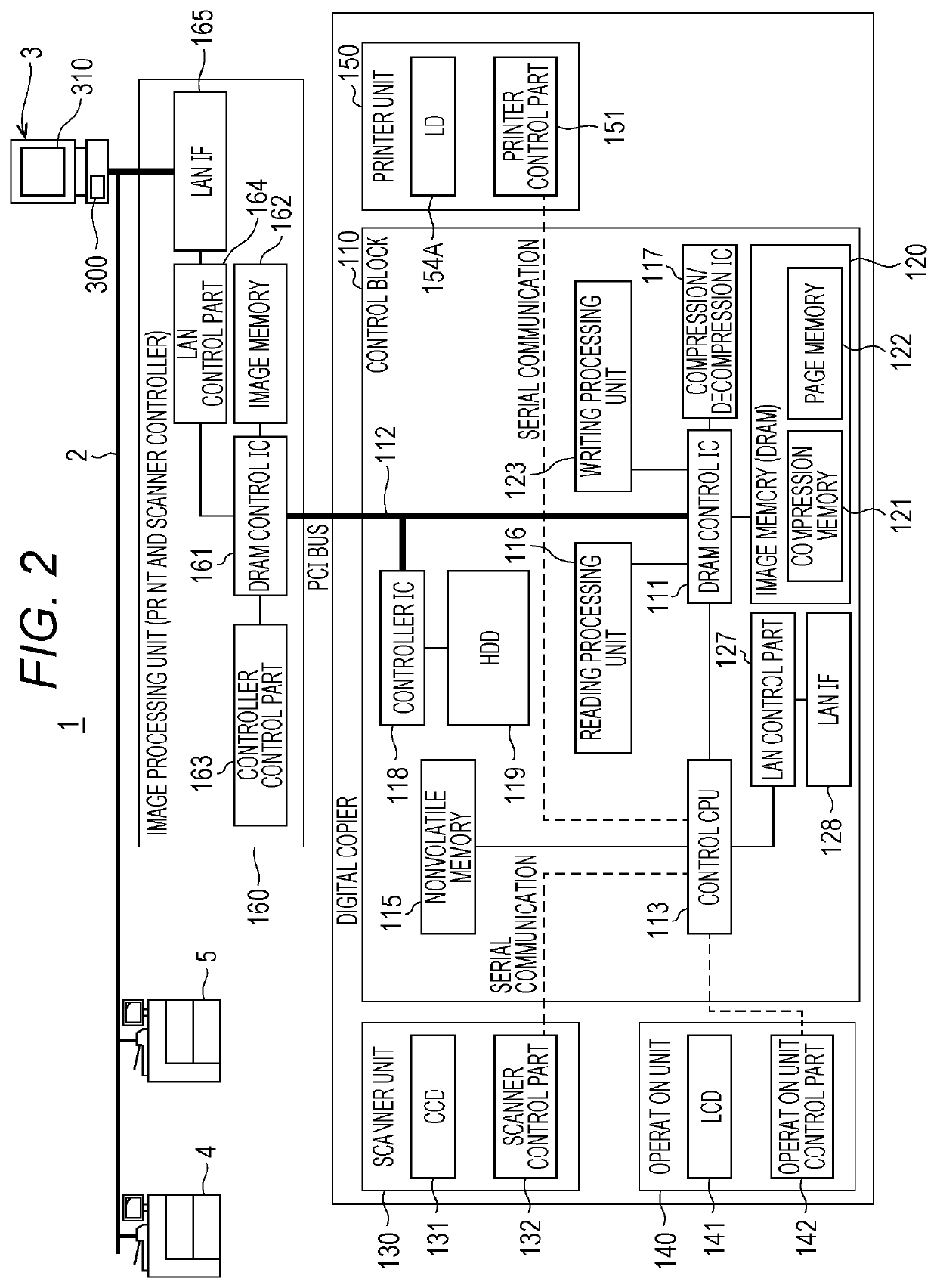

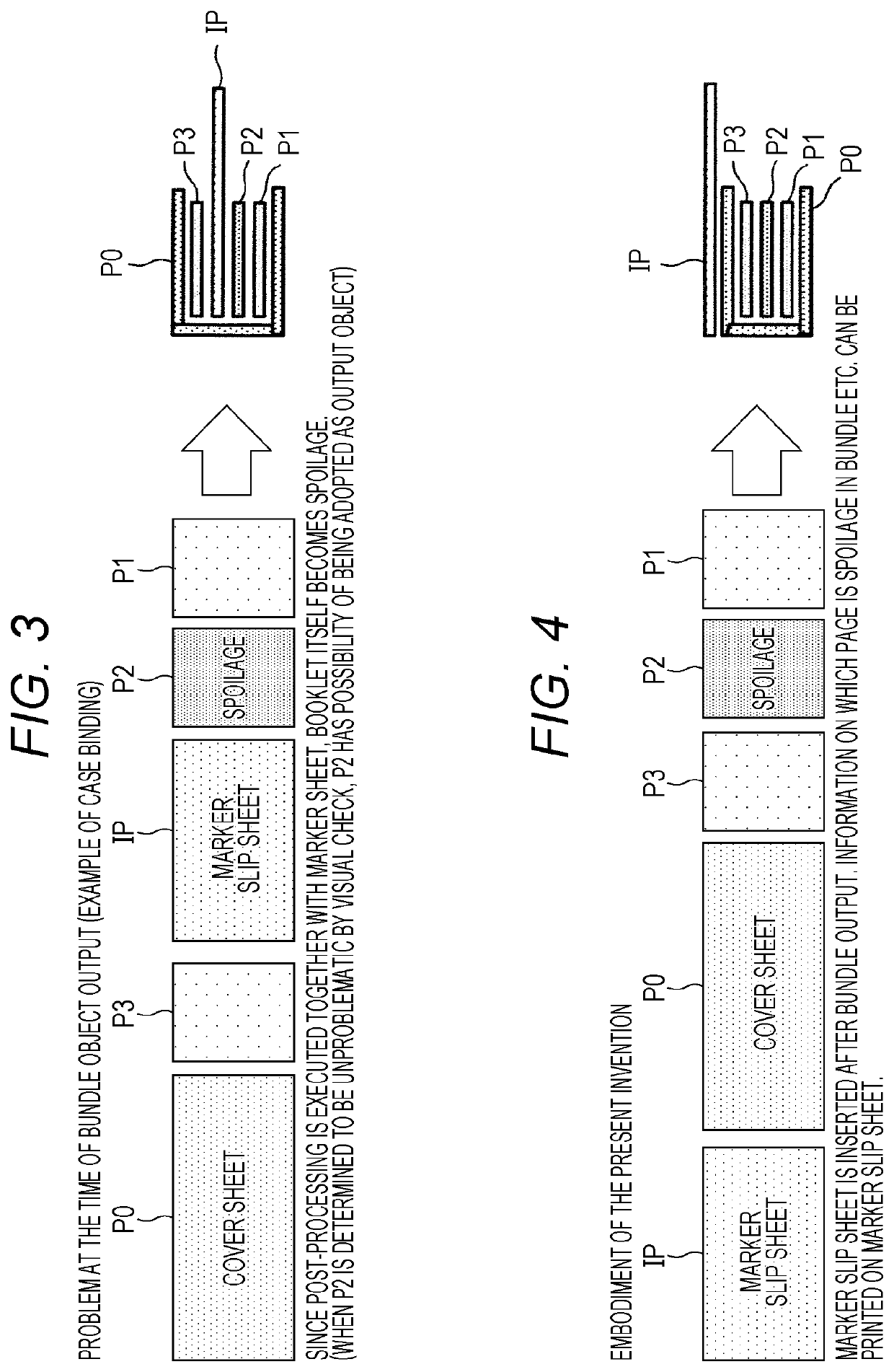

Image forming apparatus, image inspection apparatus, and program

ActiveUS20190281169A1Without low productivityEasily detectPictoral communicationExecution controlImage Inspection

An image forming apparatus includes: an image former that forms an image on a recording medium; a slip sheet inserter that inserts a slip sheet; and a hardware processor capable of controlling image formation, slip sheet insertion and post-processing, wherein the hardware processor acquires a read image obtained by reading the recording medium on which the image is formed and determines whether an abnormality is present in the image on the recording medium based on the read image, and when detecting the abnormality in the image on the recording medium of a page to which bundle post-processing to bundle recording media as one bundle is applied, the hardware processor performs control to discharge the slip sheet after producing a bundle including the recording medium by the bundle post-processing without inserting the slip sheet.

Owner:KONICA MINOLTA INC

Image forming apparatus

InactiveUS20080008486A1Without lowering productivityIncrease productivityElectrographic process apparatusProduction rateError processing

An image forming apparatus that can provide a quality image in a stable manner without lowering the productivity. A reference image forming unit forms reference images on a transfer member. A plurality of sensing units detect densities of the formed reference images. A control unit adjusts respective output values from the plurality of sensing units according to a difference between the output values from the plurality of sensing units. The control unit performs error processing according to the difference between the output values from the plurality of sensing units when the control unit adjusts the output values from the plurality of sensing units.

Owner:CANON KK

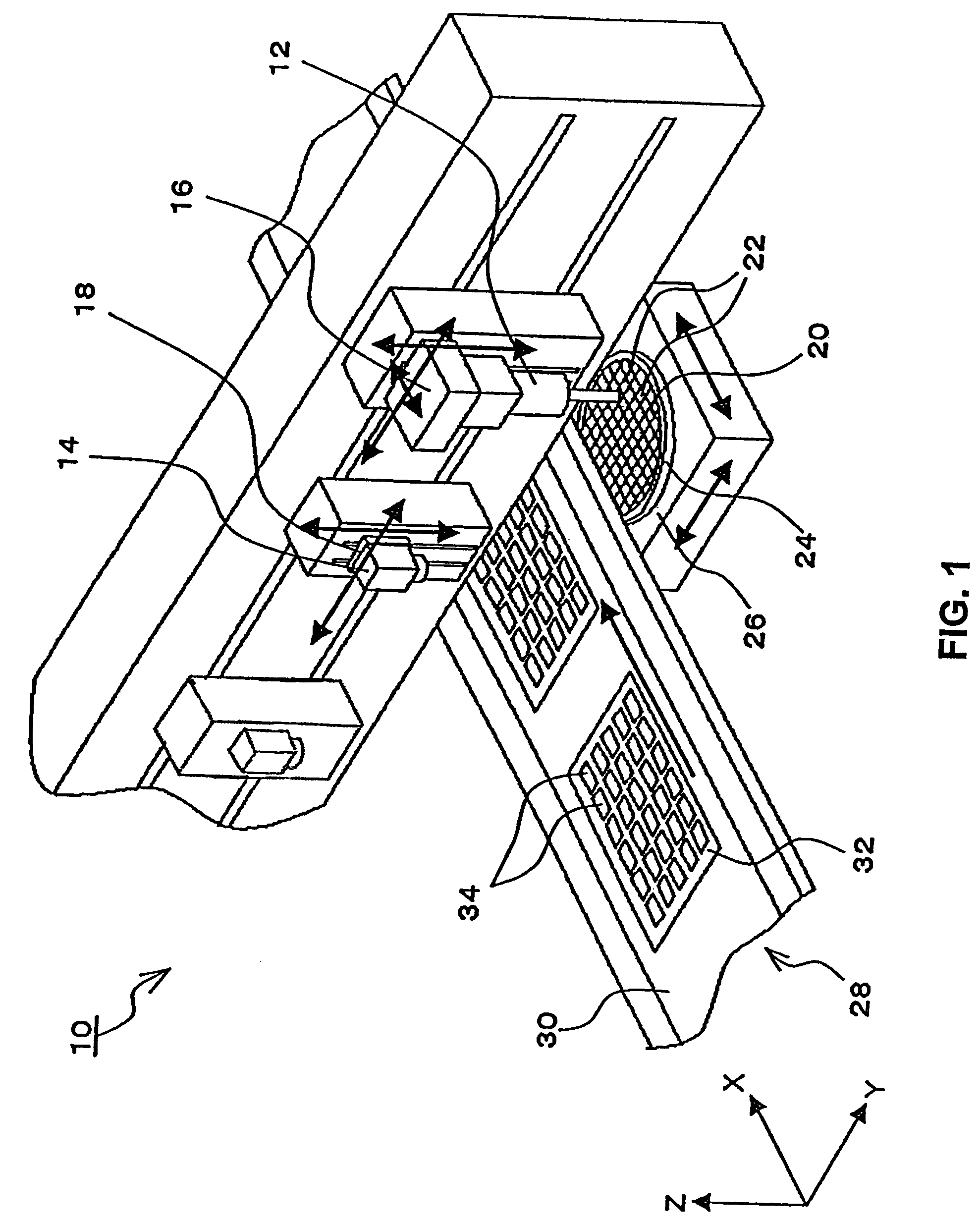

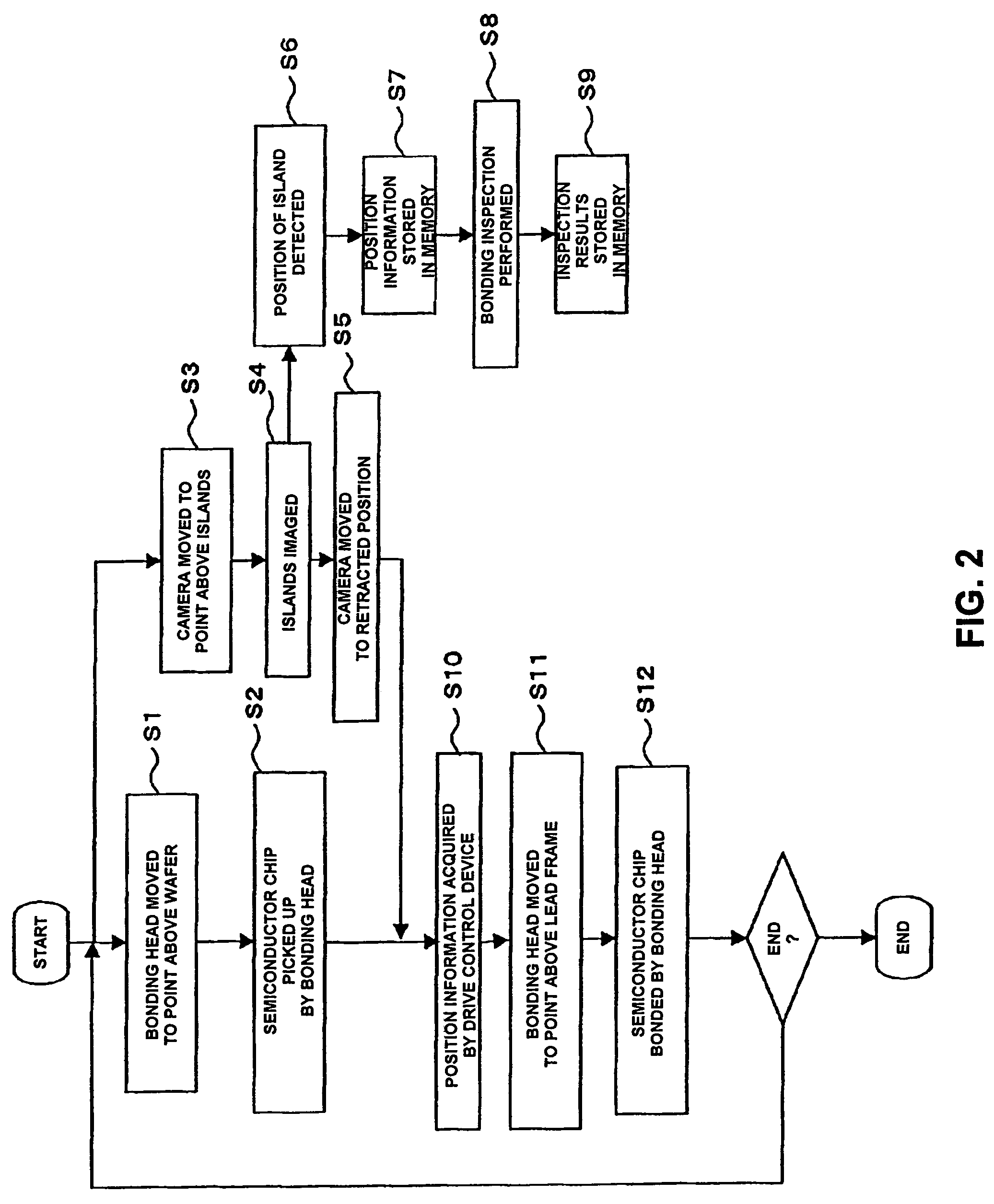

Die bonding method and apparatus

ActiveUS7087457B2Without lowering productivityWithout causing a productivity dropPrinted circuit assemblingSemiconductor/solid-state device manufacturingVisual field lossProduction rate

A die bonding method and apparatus that performs bonding position detection and bonding inspection without lowering the productivity, in which after a bonding head has bonded a semiconductor chip to an island, the bonding head is moved to a wafer to pick up a semiconductor chip and is returned to the island; and during this period, an island used for bonding inspection (that is the island on which bonding has just been performed) and an island used for position detection (that is the island on which bonding is to be done next) are imaged by a camera in the same visual field, and inspection of the bonding conditions of the island used for inspection and detection of the position of the island used for position detection are performed based on the acquired image data.

Owner:SHINKAWA CO LTD

Film formation apparatus for semiconductor process and method for using the same

ActiveUS20120263888A1Without lowering productivityLiquid surface applicatorsElectric discharge tubesNitrogenProcess engineering

A method is provided for using a film formation apparatus including a process container having an inner surface, which contains as a main component a material selected from the group consisting of quartz and silicon carbide. The method includes performing a film formation process to form a silicon nitride film on a product target substrate inside the process container, and then, unloading the product target substrate from the process container. Thereafter, the method includes supplying an oxidizing gas into the process container with no product target substrate accommodated therein, thereby performing an oxidation process to change by-product films deposited on the inner surface of the process container into a composition richer in oxygen than nitrogen, at a part of the by-product films from a surface thereof to a predetermined depth.

Owner:TOKYO ELECTRON LTD

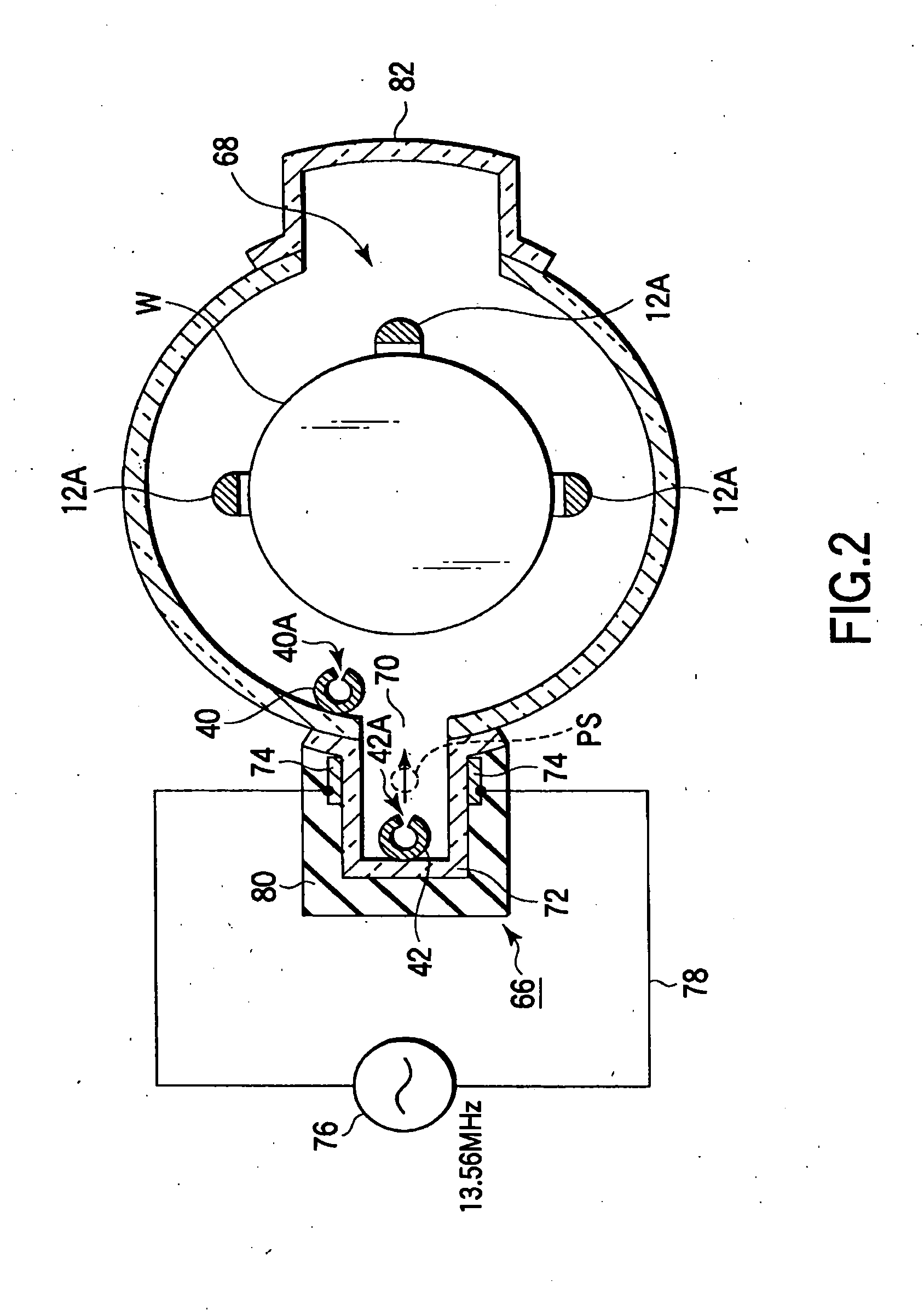

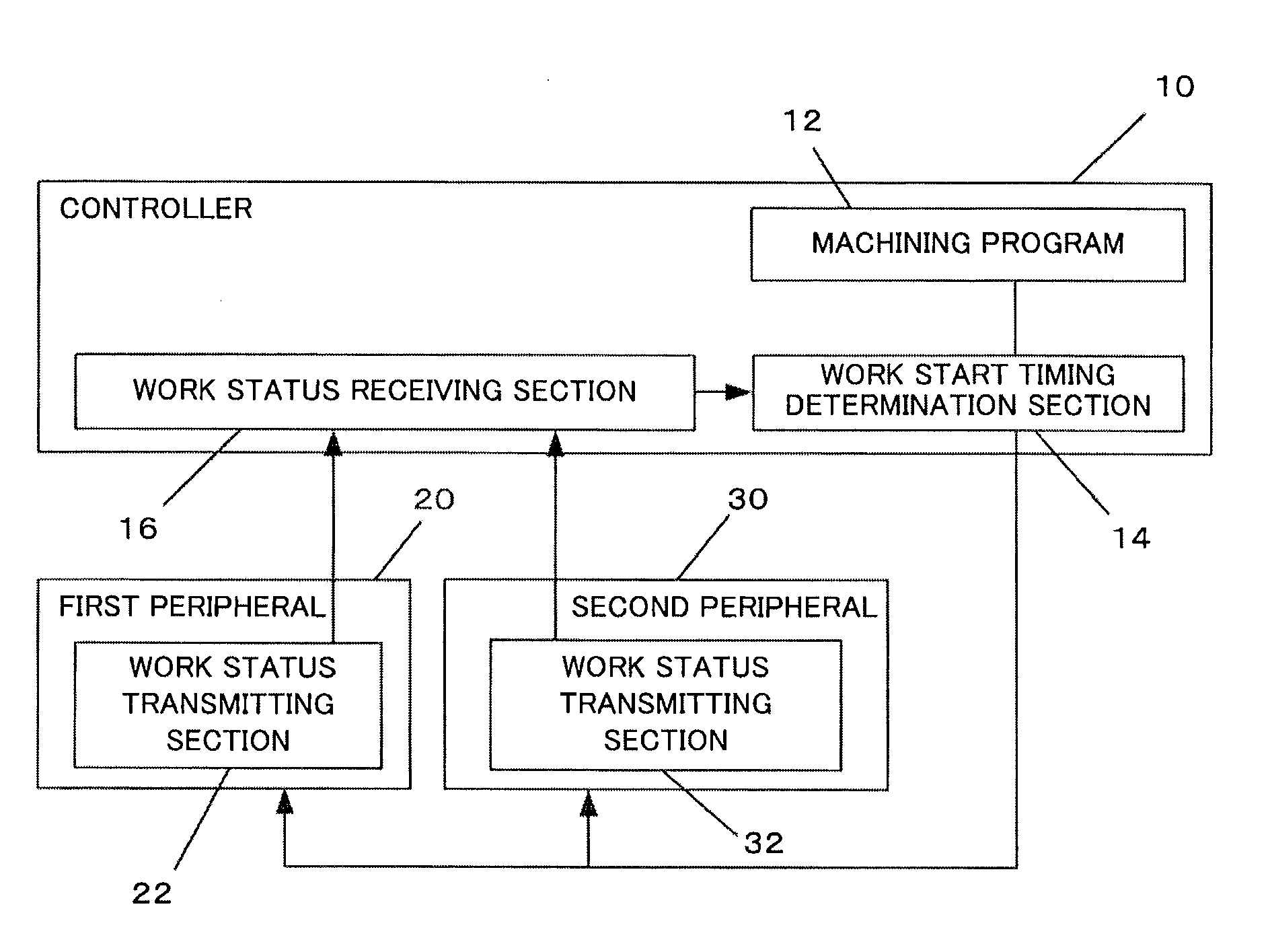

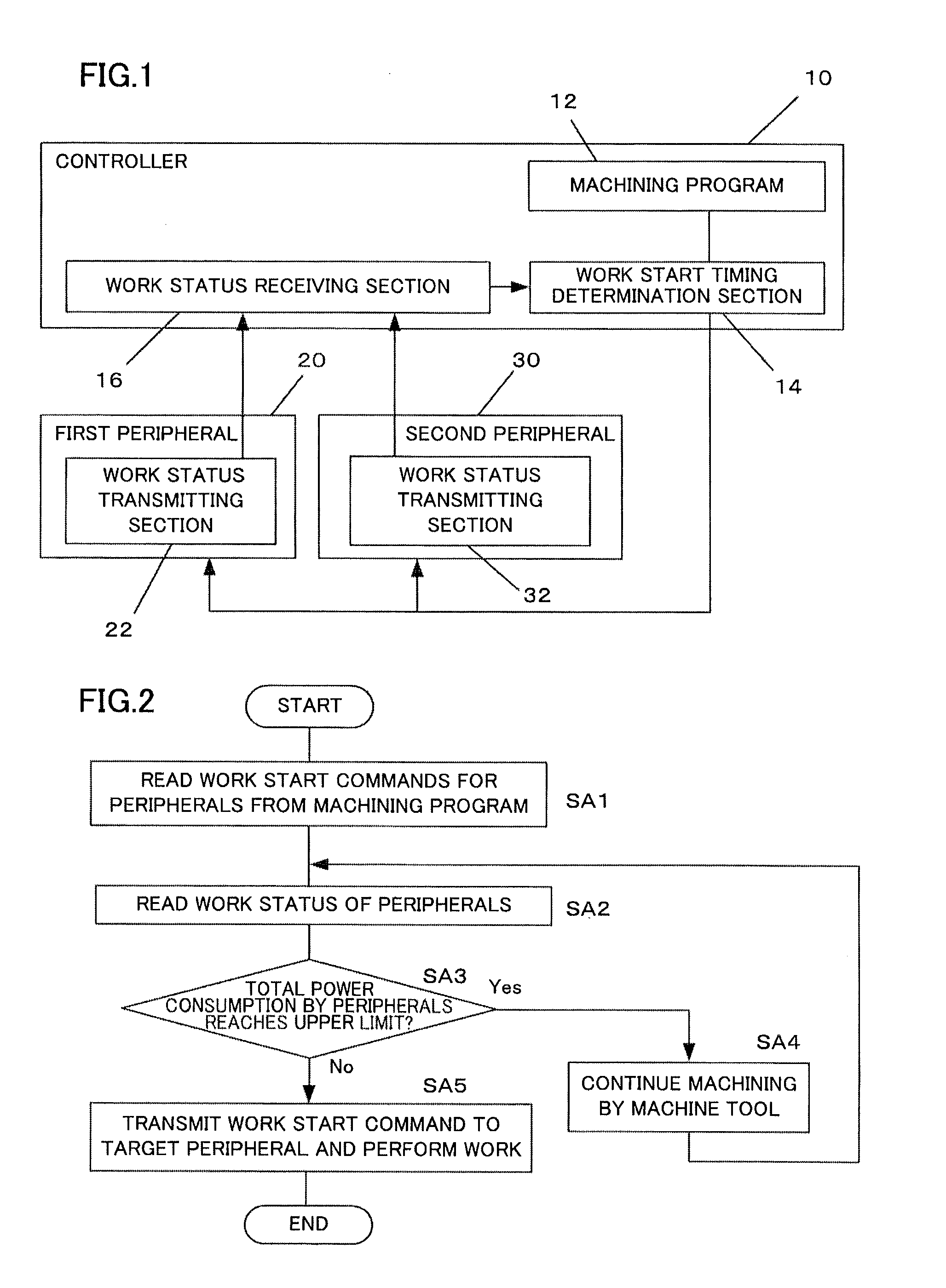

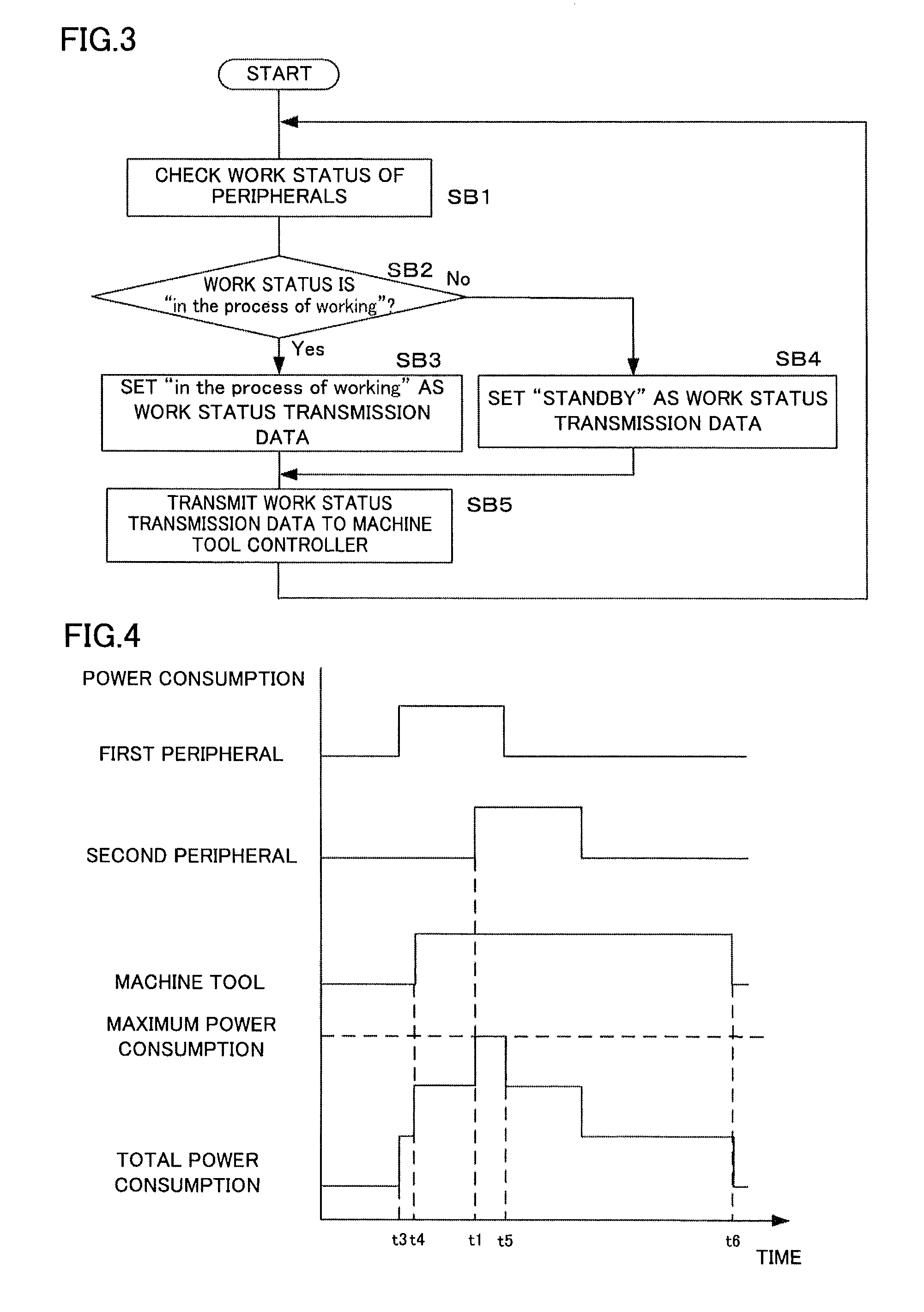

Machine controller

ActiveUS20150012119A1Solve the large consumptionWithout lowering productivityComputer controlEnergy industryMachine controlStart time

A machine controller intercommunicates with, and issues machining program commands to, a plurality of peripherals. The controller receives work status information on the peripherals, calculates the total power consumption by the plurality of peripherals based on the received information, and decides the work start timing for the peripherals such that the total does not reach a preset upper limit.

Owner:FANUC LTD

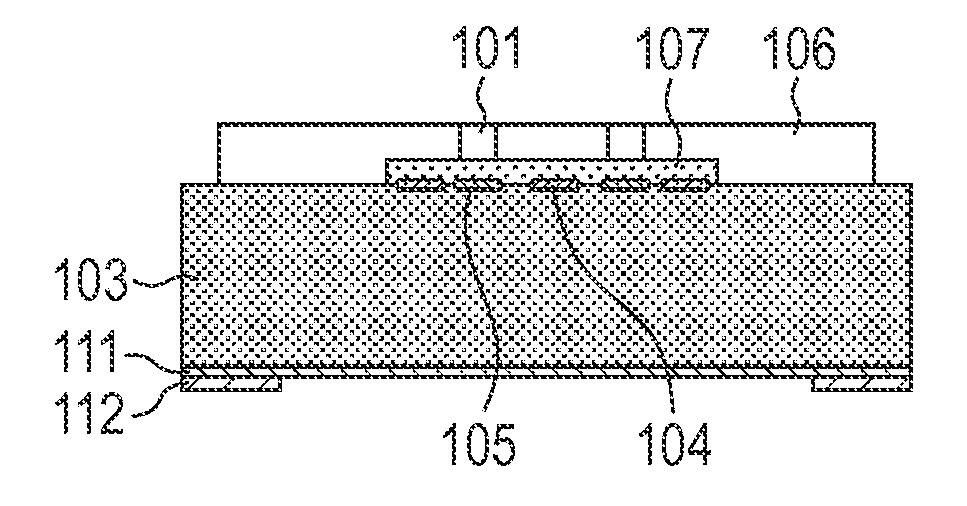

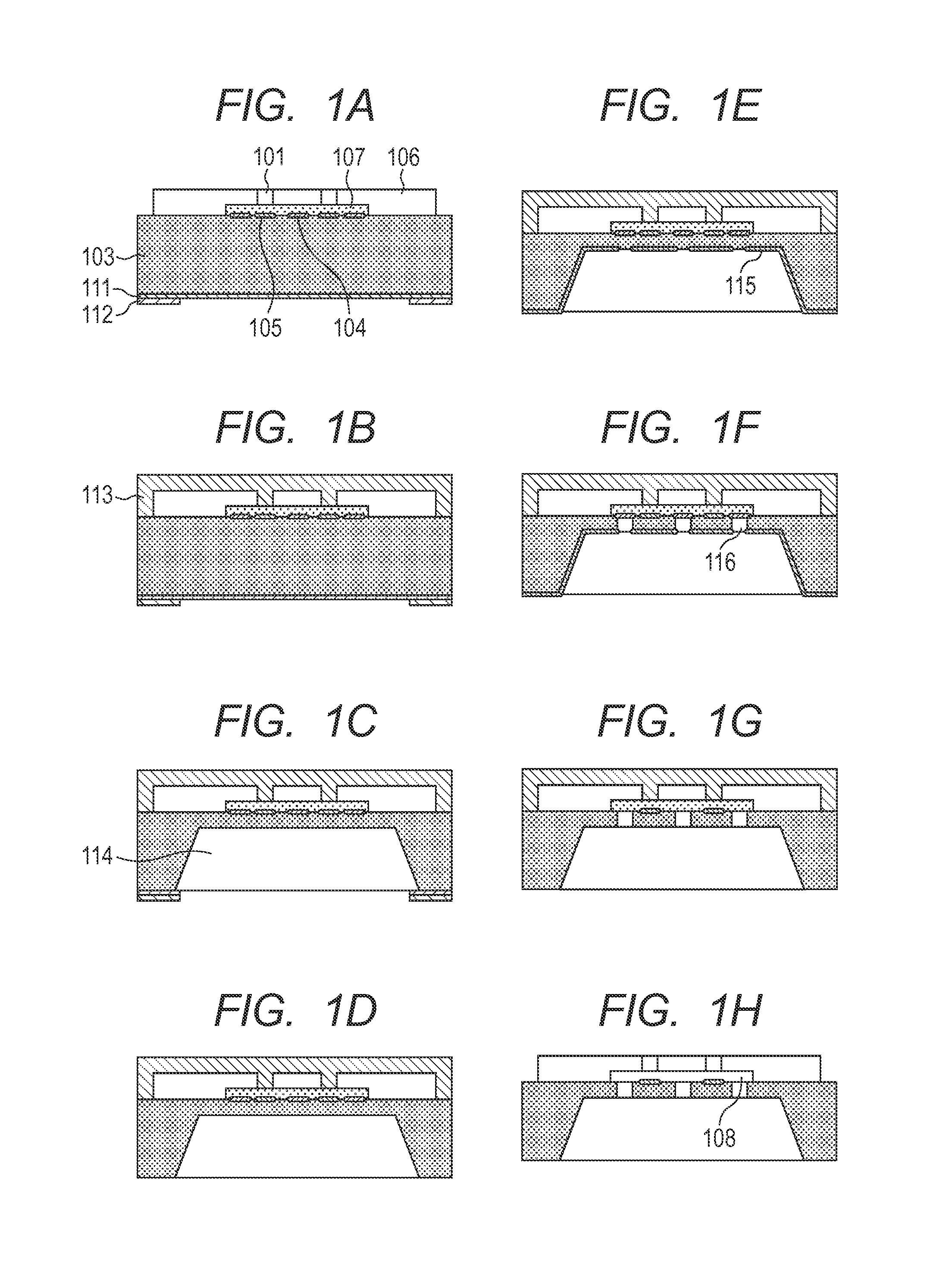

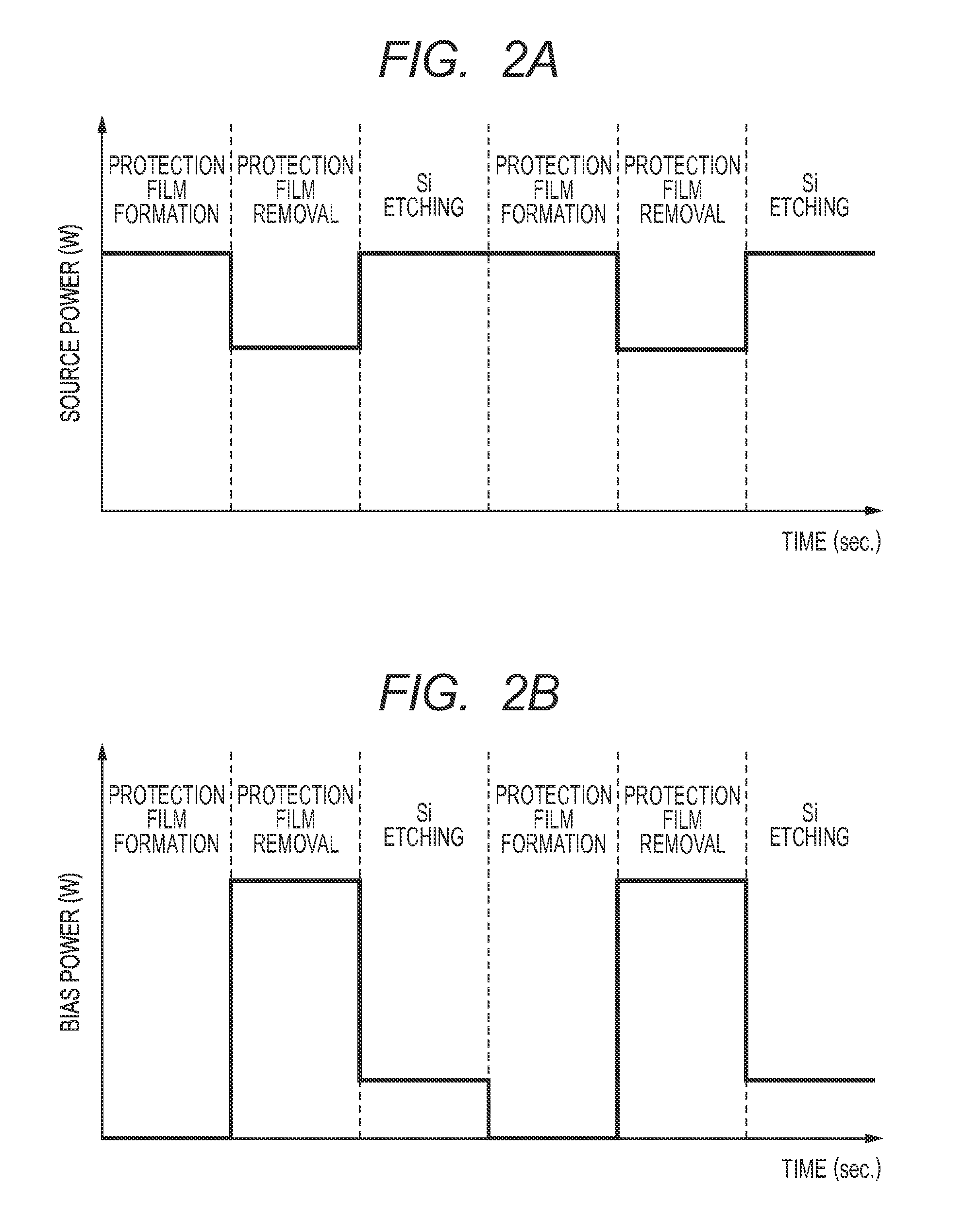

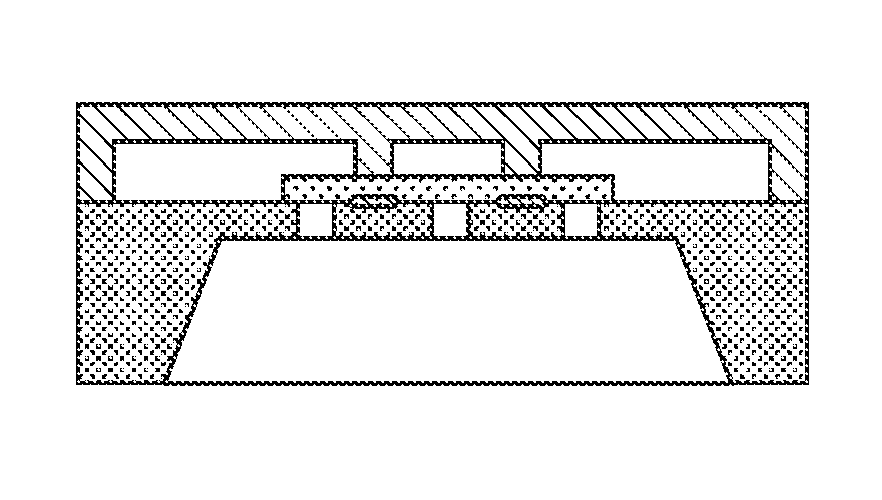

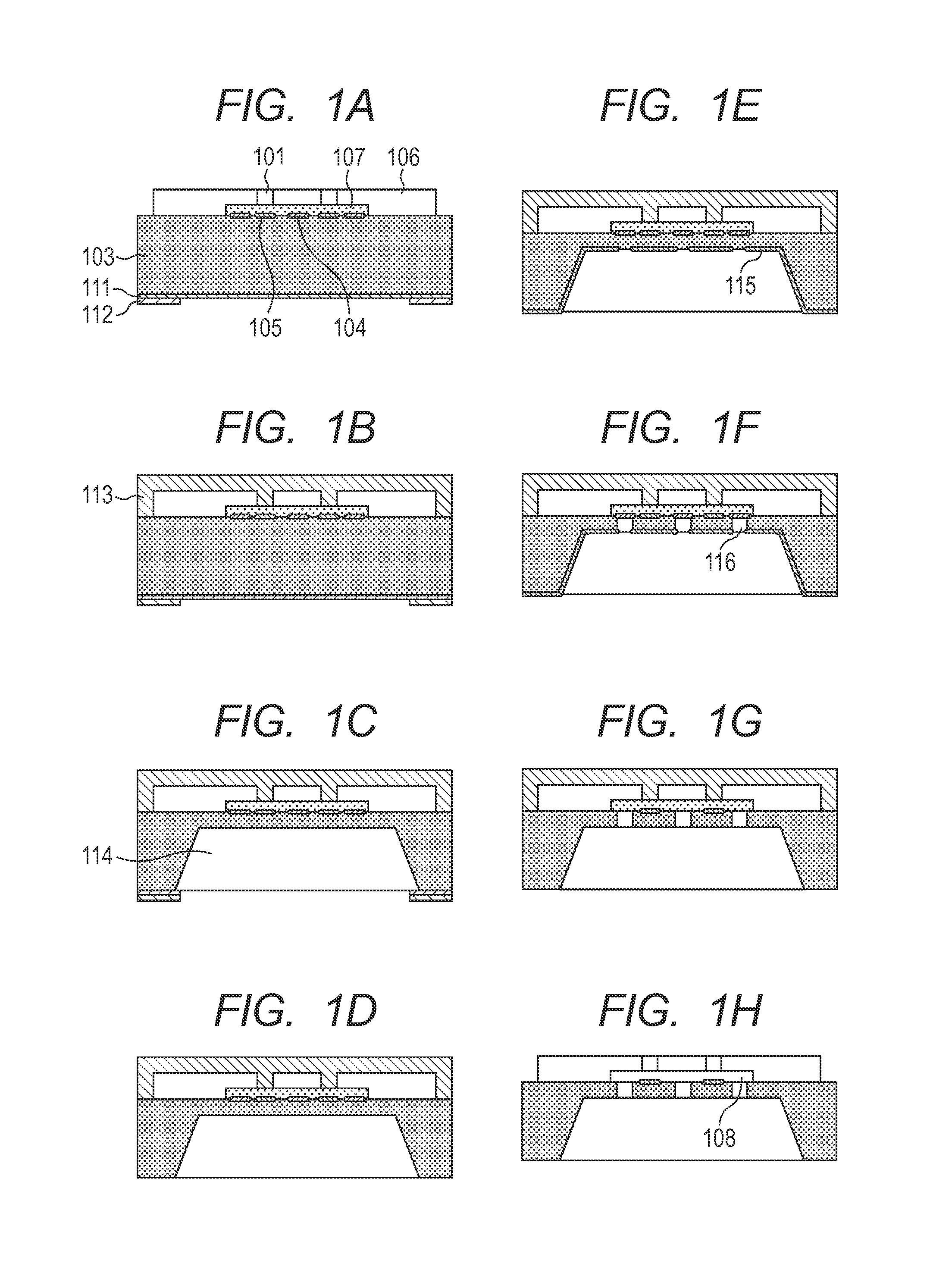

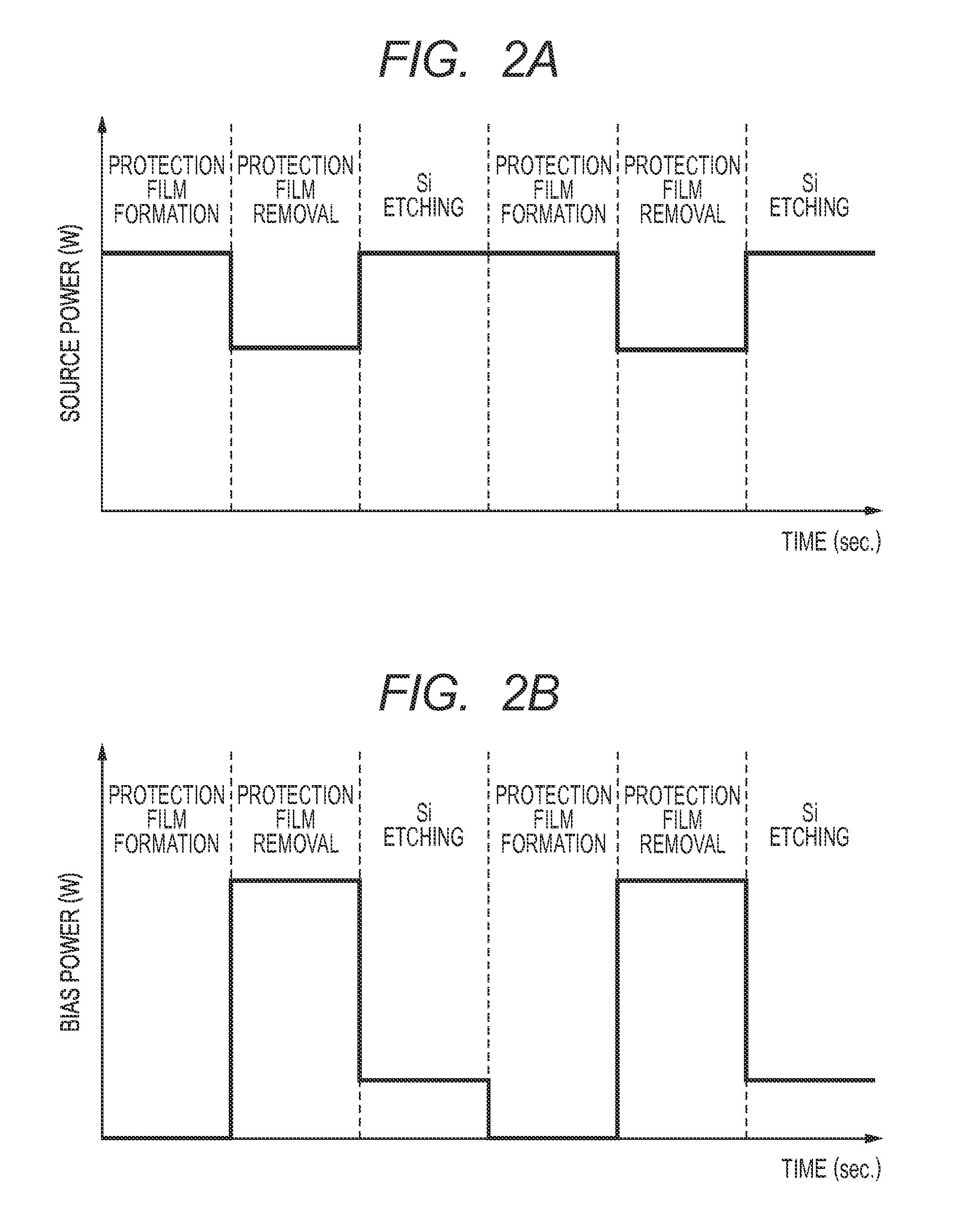

Processes for producing substrate for liquid ejection head

ActiveUS20140363907A1Without lowering productivityIncrease in sizeElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringSilicon

A process for producing a substrate for a liquid ejection head, including a step of forming a liquid supply port passing through a silicon substrate by dry etching, the step being a step of sequentially repeating the steps of (1) forming an etching protection film on the silicon substrate, (2) removing a bottom portion of the etching protection film, and (3) etching the silicon substrate, wherein a sheath formed in the step (2) is thicker than a sheath formed in the step (3).

Owner:CANON KK

Mutant polyhydroxyalkanoate synthetase, gene and transformant thereof, and method for producing polyhydroxyalkanoate

Provided is a mutant polyhydroxyalkanoate synthetase having an amino acid sequence which has 85% or more sequence identity with the amino acid sequence of SEQ ID NO: 1 and which contains a mutation of substitution of at least one of the amino acids at the 27th to 33rd, 39th, 56th, 106th, 129th, 144th, 165th, 170th and 172nd to 187th positions from the N-terminus of the amino acid sequence of SEQ ID NO: 1 with another amino acid.

Owner:KANEKA CORP

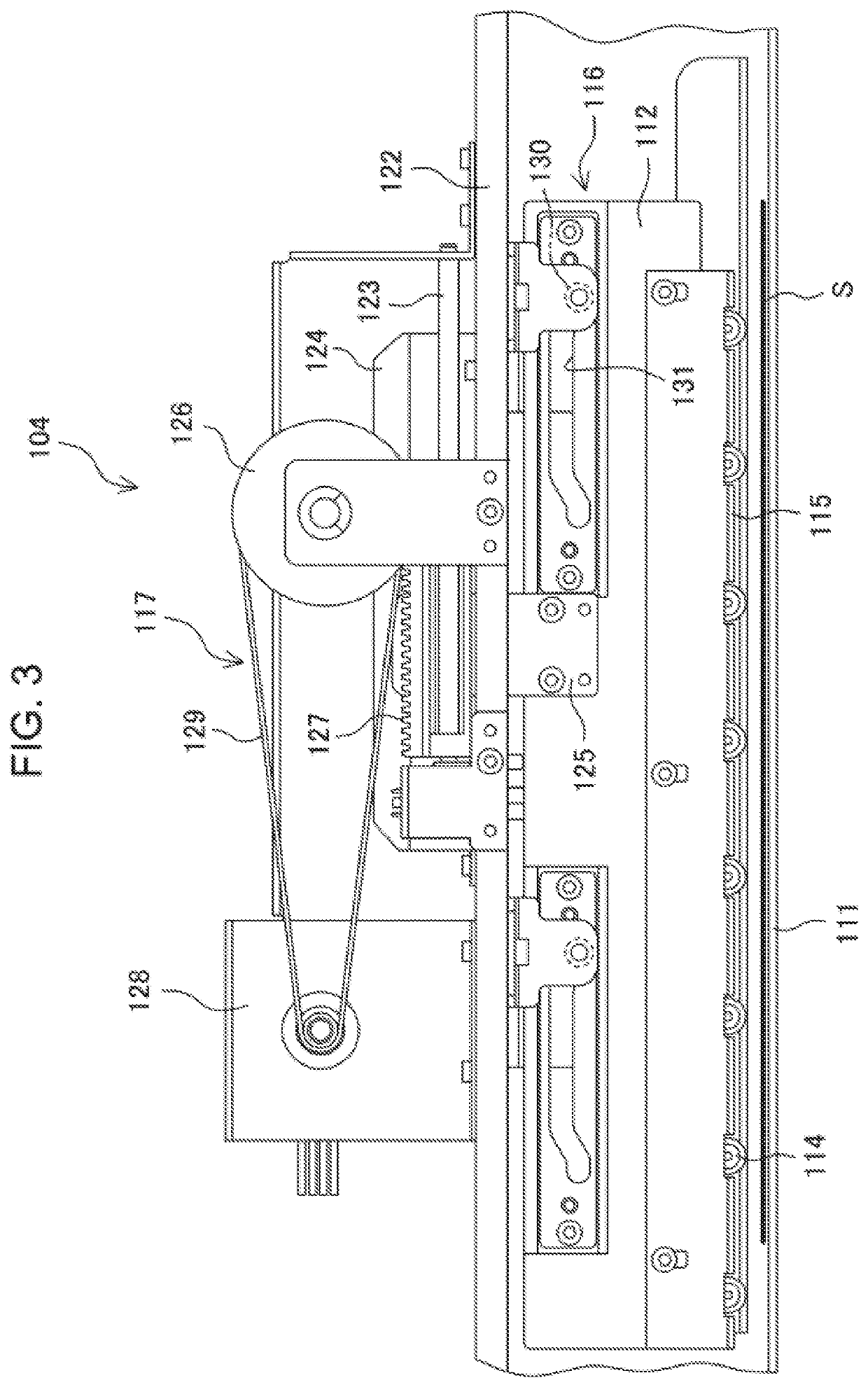

Sheet folding processing apparatus and image forming system including the same

ActiveUS11167950B2Ensure correct executionWithout lowering productivityFolding thin materialsElectrographic process apparatusImage formationEngineering

A sheet folding processing apparatus performs folding processing on continuously conveyed sheets without lowering productivity. A sheet folding processing apparatus includes a conveyance roller pair, a folding roller pair forming a plurality of fold lines by bending a sheet conveyed from the conveyance roller pair in Z-shape, an additional folding roller and a lower folding guide arranged downstream of the folding roller pair to face each other and pressing the fold line of the sheet in corporation with each other, and a controller controlling operation of the above. The controller controls the folding roller pair to convey the sheet with the fold line downstream in a conveyance direction until the fold line passes through the additional folding position by a predetermined conveyance amount, to return the sheet upstream by reversely rotating the folding roller pair, and to position the fold line to the additional folding position for additional folding processing.

Owner:COPYER

Image forming apparatus operable in a duplex print mode

InactiveUS7027762B2Without lowering productivityElectrographic process apparatusImage transferImage formation

Owner:RICOH KK

Processes for producing substrate for liquid ejection head

ActiveUS9102153B2Without lowering productivityIncrease in sizeElectric discharge tubesPrintingEngineeringSilicon

A process for producing a substrate for a liquid ejection head, including a step of forming a liquid supply port passing through a silicon substrate by dry etching, the step being a step of sequentially repeating the steps of (1) forming an etching protection film on the silicon substrate, (2) removing a bottom portion of the etching protection film, and (3) etching the silicon substrate, wherein a sheath formed in the step (2) is thicker than a sheath formed in the step (3).

Owner:CANON KK

Substrate processing method

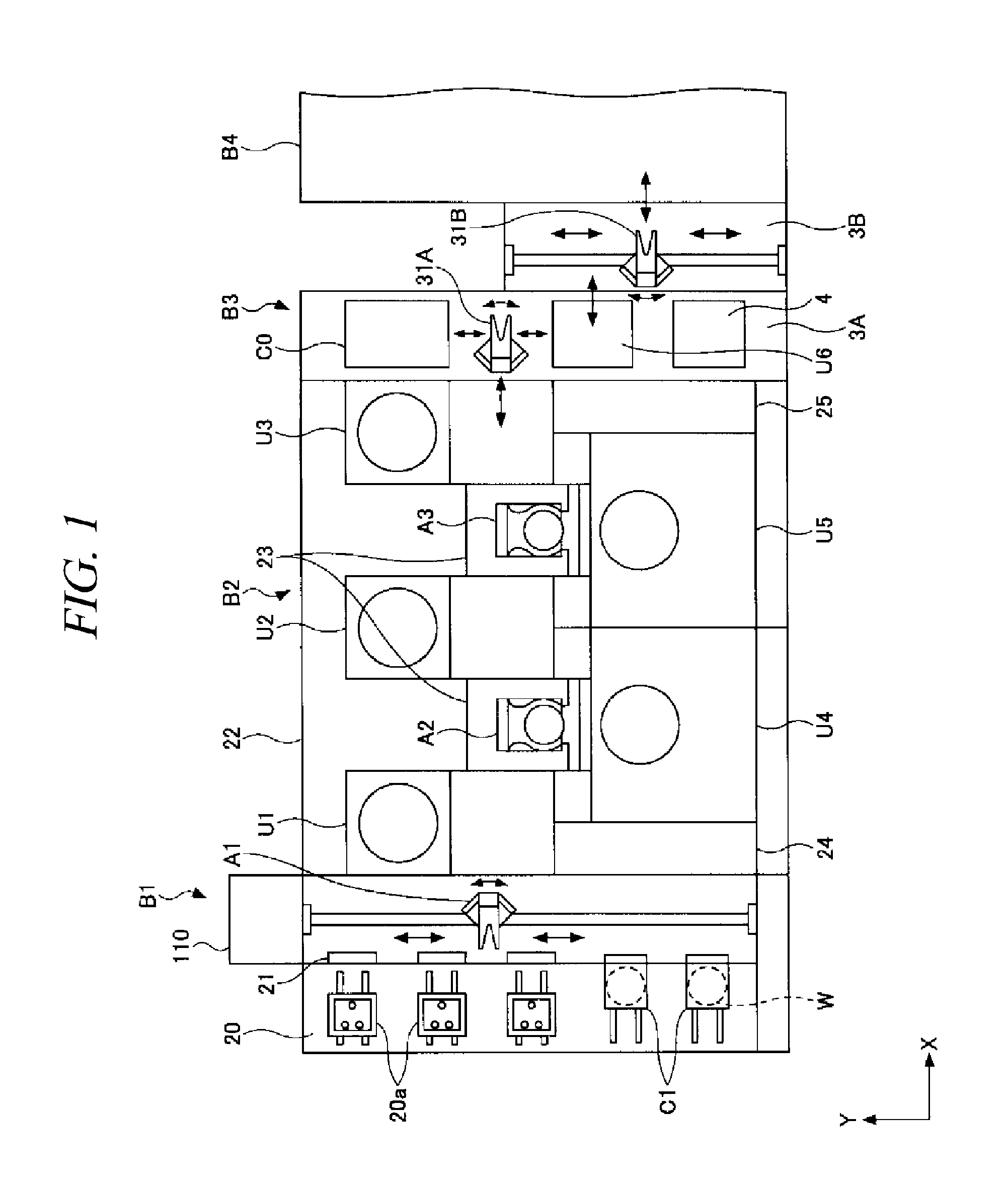

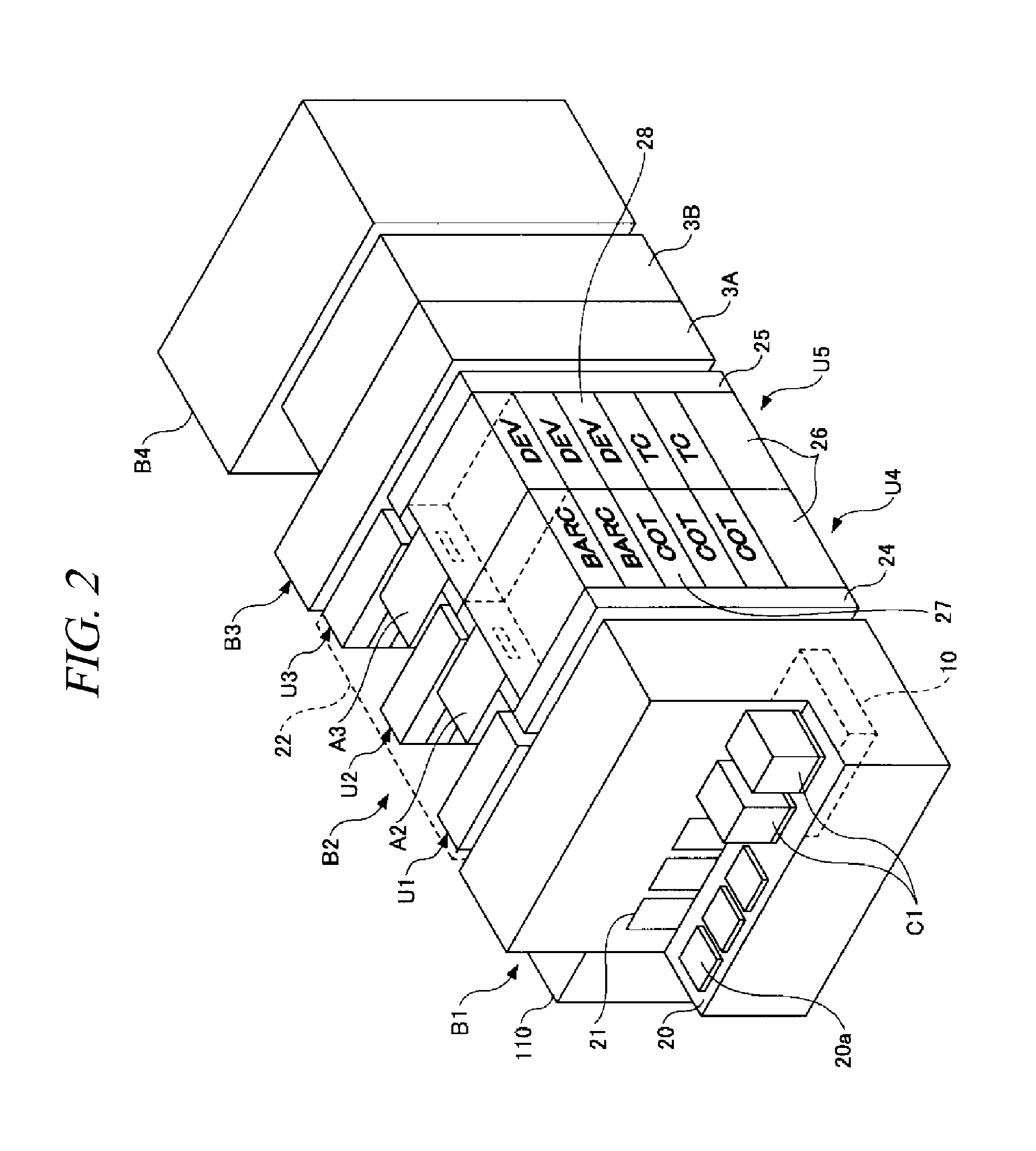

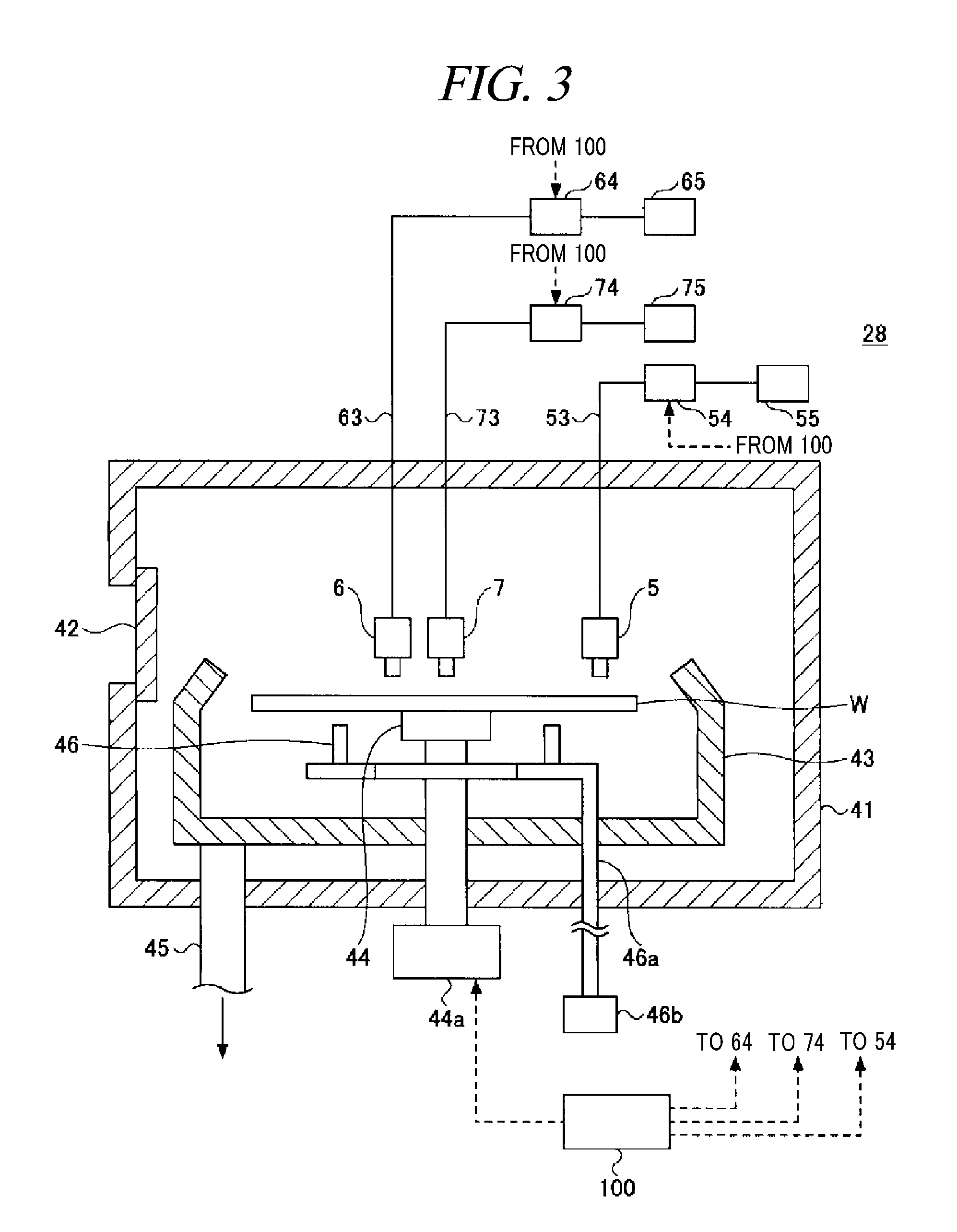

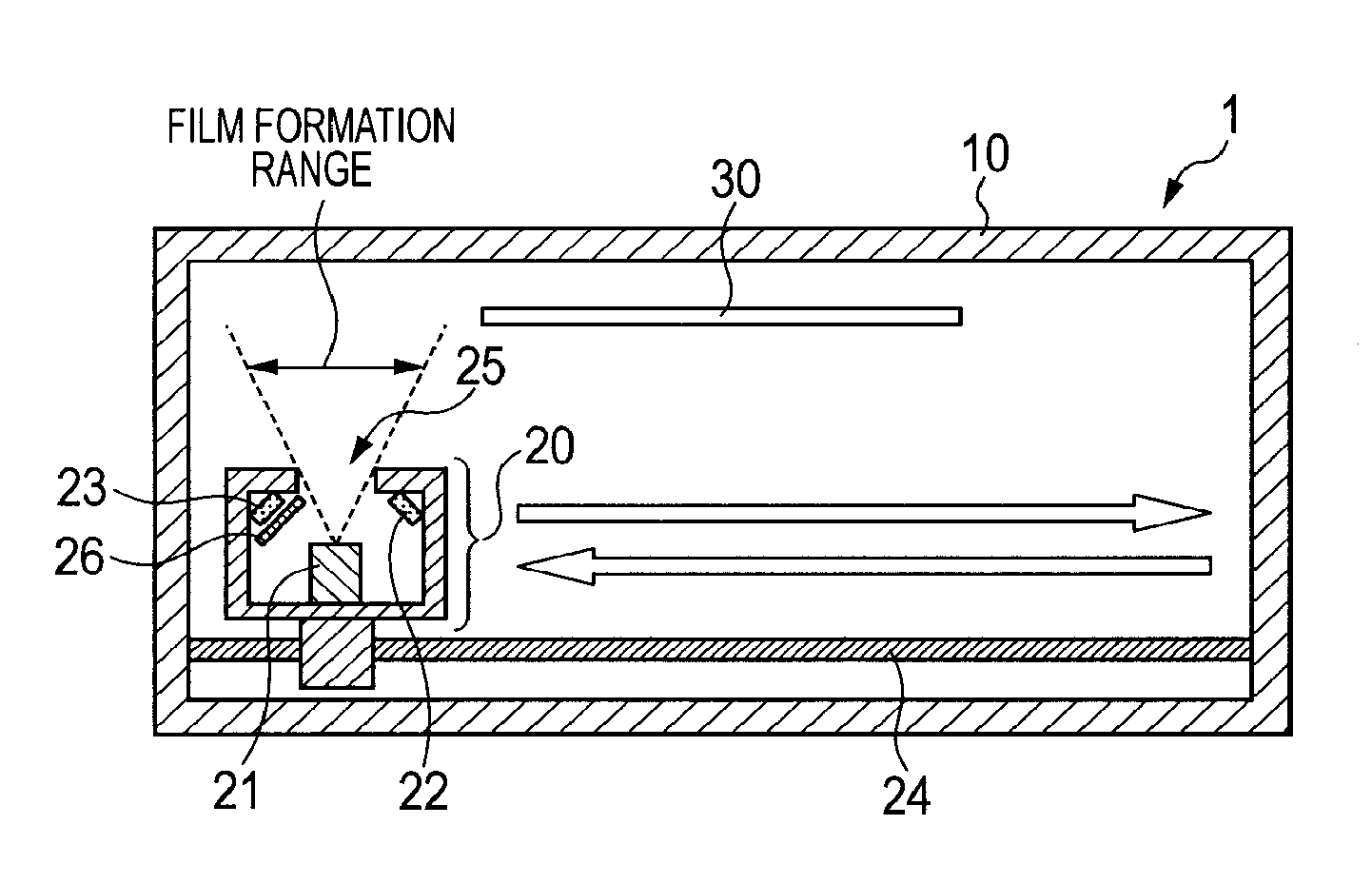

ActiveUS20110200949A1Reduce unevennessLowering productivitySemiconductor/solid-state device manufacturingElectrostatic cleaningResistElectrical and Electronics engineering

A substrate processing method includes a first process (step S12 to step S16) of forming a first resist pattern by exposing a substrate having thereon a first resist film to lights, developing the exposed substrate and cleaning the developed substrate; and a second process (step S17 to step S20) of forming a second resist pattern by forming a second resist film on the substrate having thereon the first resist pattern, exposing the substrate having thereon the second resist film to lights, and developing the exposed substrate. A first processing condition is determined based on first data showing a relationship between a first processing condition under which a cleaning process is performed on the substrate in the first process (step S16) and a line width of the second resist pattern, and the first process (step S16) is performed on the substrate under the determined first processing condition.

Owner:TOKYO ELECTRON LTD

Film formation apparatus and film formation method

ActiveUS20150176129A1Without lowering productivityControl with accuracy the thickness of a thin film formedVacuum evaporation coatingSputtering coatingQuartzMoving parts

Provided are a film formation apparatus and a film formation method which may control with accuracy the thickness of a thin film formed on the film formation object. A film formation apparatus includes a moving part (film formation source unit) for moving a film formation source between a predetermined film formation waiting position and a predetermined film forming position is provided, and the moving part holds a quartz oscillator for measurement and a quartz oscillator for calibration so that their relative positions with respect to the film formation source are maintained. And a calibration step for calibrating a monitored value of the quartz oscillator for measurement, using a monitored value of the quartz oscillator for calibration, is performed in a middle of the film forming step of forming the film on the film formation object.

Owner:CANON KK

Inkjet recording apparatus

InactiveUS20080297581A1No increase in costSimple constructionOther printing apparatusEngineeringRecording media

Owner:DAINIPPON SCREEN MTG CO LTD

Plunger water-soluble lubricant for die-casting

ActiveUS9206378B2Improve the lubrication effectReduce wearAdditivesBase-materialsParticulatesSilicon dioxide

Owner:AISIN SEIKI KK +1

Sheet folding processing apparatus and image forming system including the same

ActiveUS20200324994A1Increase productivityEliminate delaysFolding thin materialsElectrographic process apparatusImage formationCounter rotation

A sheet folding processing apparatus performs folding processing on continuously conveyed sheets without lowering productivity. A sheet folding processing apparatus includes a conveyance roller pair, a folding roller pair forming a plurality of fold lines by bending a sheet conveyed from the conveyance roller pair in Z-shape, an additional folding roller and a lower folding guide arranged downstream of the folding roller pair to face each other and pressing the fold line of the sheet in corporation with each other, and a controller controlling operation of the above. The controller controls the folding roller pair to convey the sheet with the fold line downstream in a conveyance direction until the fold line passes through the additional folding position by a predetermined conveyance amount, to return the sheet upstream by reversely rotating the folding roller pair, and to position the fold line to the additional folding position for additional folding processing.

Owner:COPYER

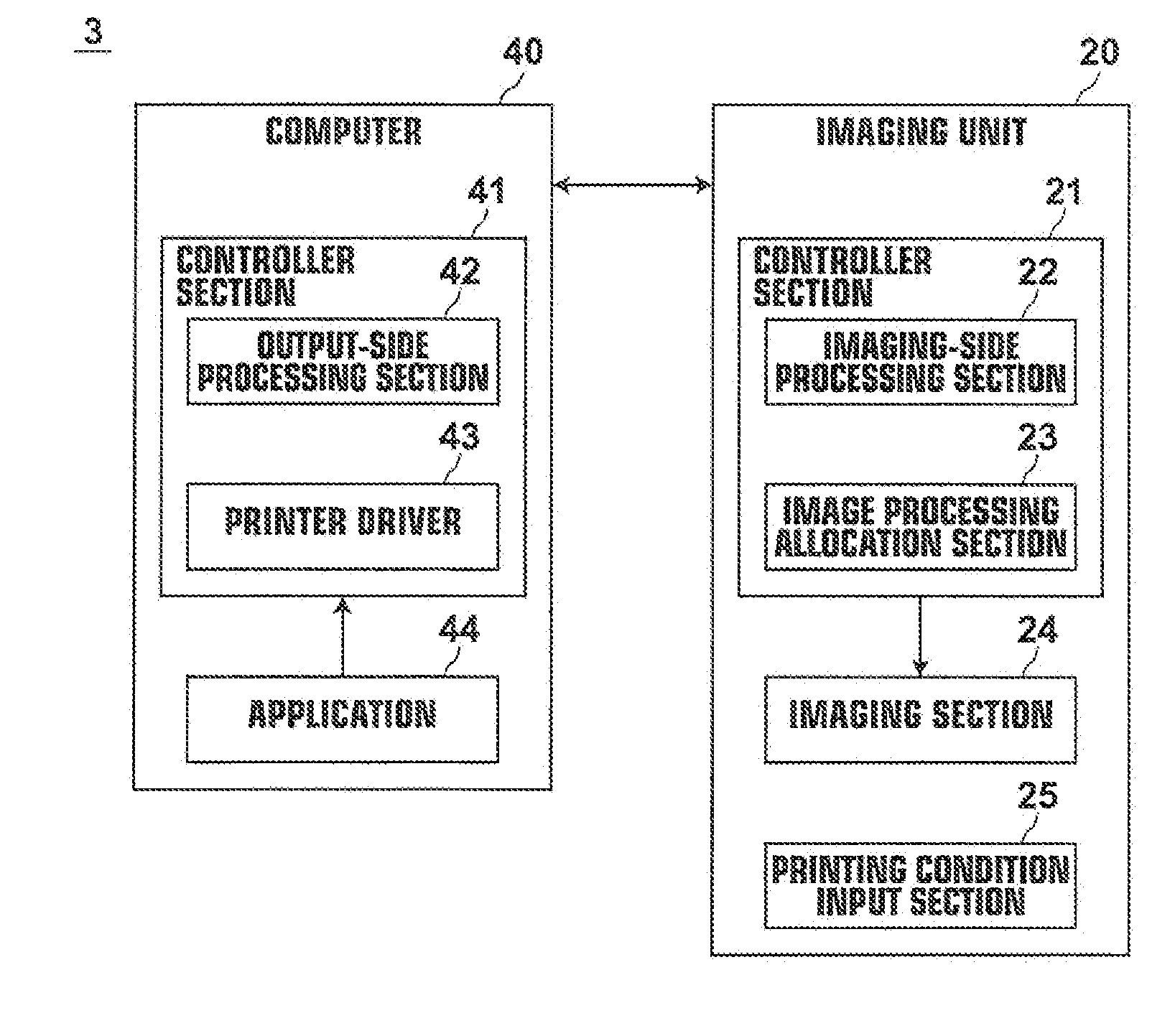

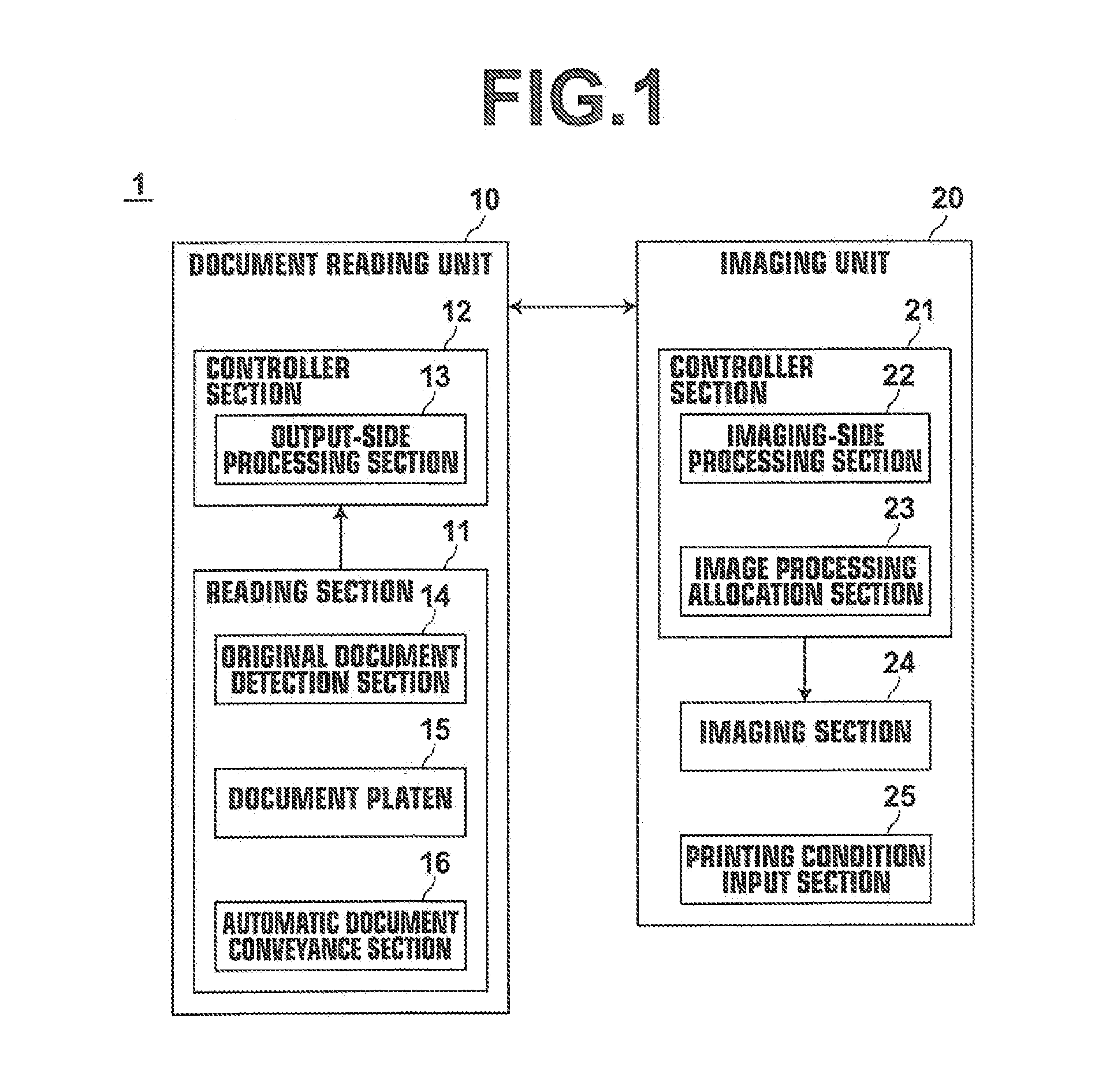

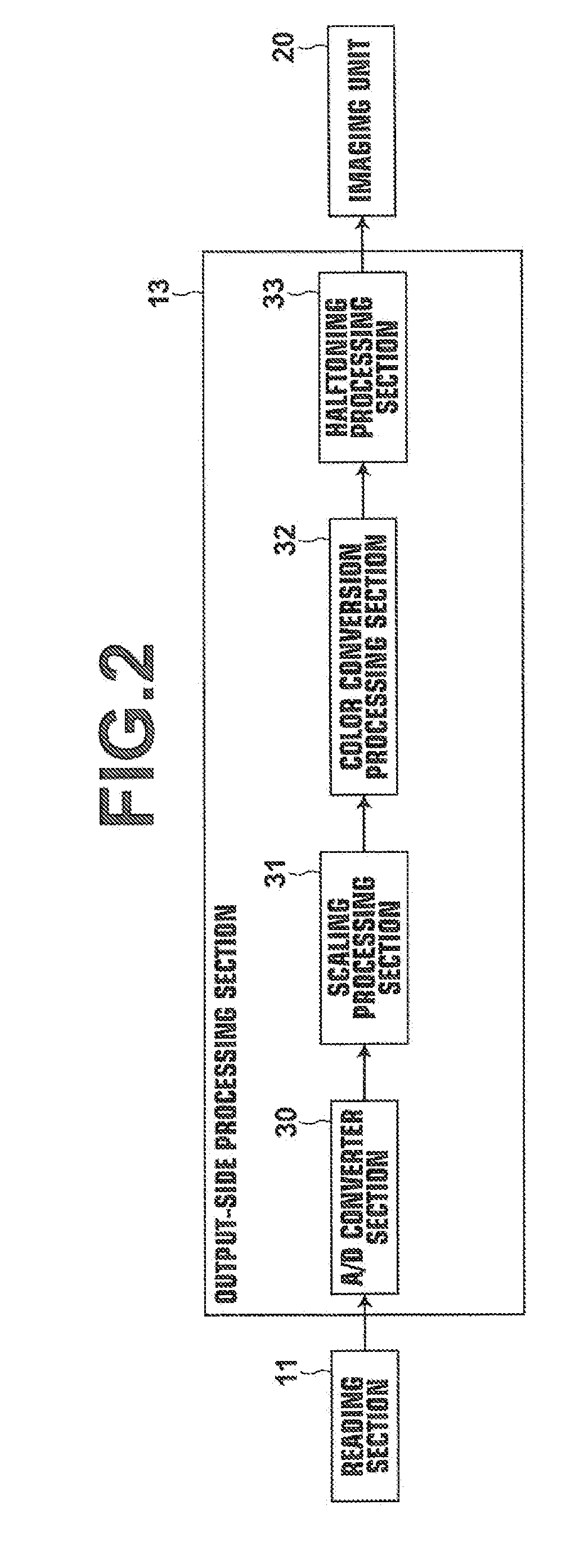

Imaging system

ActiveUS20140240798A1Improve reading speedEfficient outputPictoral communicationData transmissionComputer science

An image data output unit including an output-side processing section for performing a plurality of processing operations on image data, and an imaging unit including an imaging-side processing section for performing a given processing operation on image data outputted from the image data output unit and an imaging operation section for performing an imaging operation based on the image data outputted from the imaging-side processing section are provided. An amount of data to be transferred per unit time of processed image data that will result when the processing operations are performed on the image data at the output-side processing section is compared with a transferable amount of data transmission per unit time between the image data output unit and the imaging unit, and each of the processing operations is allocated to the output-side processing section or the imaging-side processing section based on the result of the comparison.

Owner:RISO KAGAKU CORP

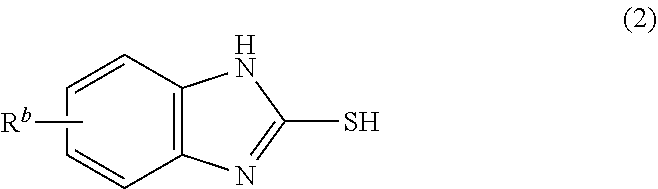

Slidable rubber material having an amino-modified interfacial modification layer, and method for producing said slidable rubber material

ActiveUS20220267572A1Increase elasticityImprove sealingInfusion syringesSynthetic resin layered productsRubber materialPolymer science

A slidable rubber material that has an amino-modified interfacial layer that does not affect the compression set. Although the slidable rubber material includes a rubber component such as a butyl rubber or halogenated butyl rubber etc. having the low-compression set, which contains a vulcanization agent such as a nitrogen / sulfur compound or a vulcanizing auxiliary agent, the rubber part is coated with a silicone rubber layer. The slidable rubber material exhibits a slidability and resists the detachment or elution of fine particles from the coating layer. A rubber component and a vulcanization agent; an interfacial modification layer that coats the rubber part and an amino-modified silicone compound is incorporated with surface molecules of the rubber part; and a layer that coats the interfacial modification and contains solid fine particles, an addition-type or condensation-type silicone rubber in which the particles are dispersed, and a curing catalyst for silicone rubber.

Owner:ASAHI RUBBER +1

Mutant polyhydroxyalkanoate synthase, gene thereof and transformant, and method for producing polyhydroxyalkanoate

ActiveUS11186831B2High and low HH ratioWithout lowering productivityBacteriaTransferasesAmino acid substitutionPHA synthase

Provided is a mutant PHA synthase which produces of a PHA copolymer with a high or low 3HH ratio while maintaining PHA productivity. The mutant PHA synthase is a mutant polyhydroxyalkanoate synthase having an amino acid sequence having 85% or more sequence identity with the amino acid sequence of SEQ ID NO: 1 and having at least one of the following mutations (a) to (c): (a) a substitution of serine at 389th position from N-terminus of the amino acid sequence of SEQ ID NO: 1 with an amino acid other than serine; (b) a substitution of leucine at 436th position from the N-terminus of the amino acid sequence of SEQ ID NO: 1 with an amino acid other than leucine; and (c) a deletion of 11 to 19 amino acid residues from the C-terminus of the amino acid sequence of SEQ ID NO: 1.

Owner:KANEKA CORP

Image forming apparatus, image inspection apparatus, and program

ActiveUS10523825B2Easy to detectWithout lowering productivityPictoral communicationImage InspectionImage formation

An image forming apparatus includes: an image former that forms an image on a recording medium; a slip sheet inserter that inserts a slip sheet; and a hardware processor capable of controlling image formation, slip sheet insertion and post-processing, wherein the hardware processor acquires a read image obtained by reading the recording medium on which the image is formed and determines whether an abnormality is present in the image on the recording medium based on the read image, and when detecting the abnormality in the image on the recording medium of a page to which bundle post-processing to bundle recording media as one bundle is applied, the hardware processor performs control to discharge the slip sheet after producing a bundle including the recording medium by the bundle post-processing without inserting the slip sheet.

Owner:KONICA MINOLTA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com