Completely-biodegradable film bag material and preparation method of film bag

A biodegradable film and film bag technology, which is applied in the field of completely biodegradable film bag materials and film bag preparation, can solve problems such as white pollution, and achieve the effects of simple production process, reduced production cost, and good molding stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the fully biodegradable film bag of the present invention comprises the following steps:

[0026] Step I, filler modification: add fillers with a moisture content of ≤0.2% to the mixer and stir, and set the temperature of the high-speed mixer to 110-140°C; add surface modification additives in batches during stirring, and add The proportion is 0.5-2.5% of the filler, the stirring speed is 400-800r / min, the material is mixed for 15-30 minutes, and the modified filler is obtained; the filler includes: inorganic filler talcum powder, calcium carbonate, barium sulfate, mica powder , organic filler lignin, cellulose;

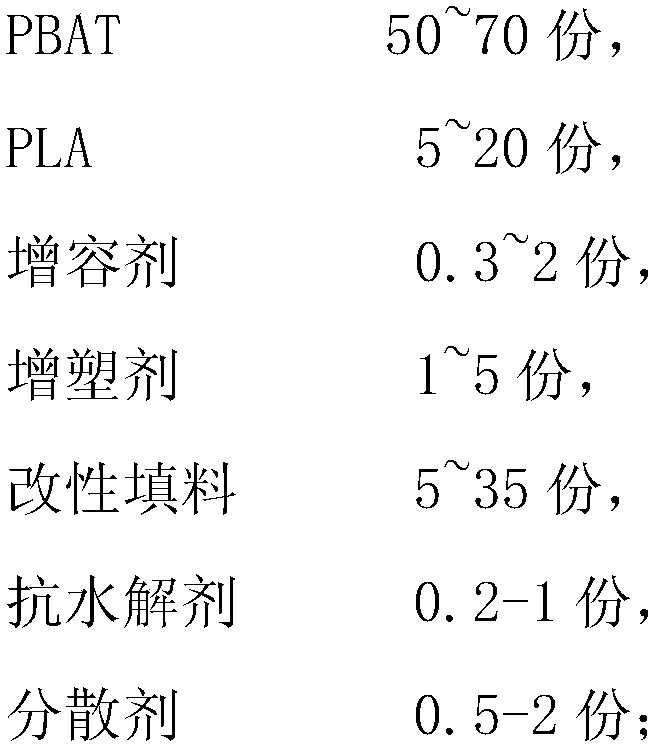

[0027] Step II: 50-70 parts of film bag material PBAT, 5-20 parts of PLA, 0.3-2 parts of compatibilizer, 1-5 parts of plasticizer, 5-35 parts of modified filler, 0.2-1 part of anti-hydrolysis agent , add 0.5-2 parts of dispersant to a high-speed mixer and stir at room temperature for 5-10 minutes, mix well and then discharge; among t...

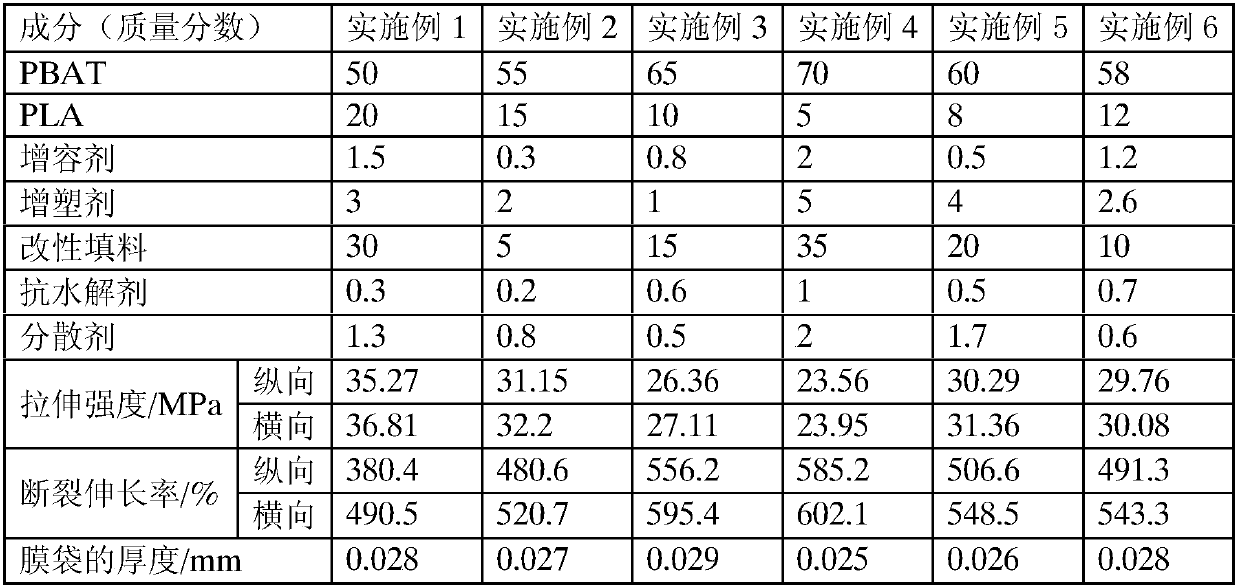

Embodiment 1

[0032] Add barium sulfate with a moisture content of ≤0.2% and a particle size of 1250-3000 mesh into a high-speed mixer at a temperature of 110-140°C and stir at a speed of 400-800r / min for 10 minutes, then add titanate coupling agents successively and a silane coupling agent as two surface modification additives, the addition ratio of the surface modification additive is 0.5-2.5% of the filler, and the material is stirred for 5 minutes to obtain modified barium sulfate for later use.

[0033] 50 parts of PBAT, 20 parts of PLA, 1.5 parts of compatibilizer PCL, 3 parts of plasticizer epoxy soybean oil, 30 parts of modified barium sulfate, 0.3 parts of carbodiimide or epoxy anti-hydrolysis agent, dispersant Add 1.3 parts of stearamide into a high-speed mixer and stir at room temperature for 5-10 minutes, mix well and discharge. Among them, the melt flow rate of PBAT and PLA is 3-5g / 10min (190°C / 2.16kg).

[0034] Add the uniformly mixed material into a twin-screw extruder, melt...

Embodiment 2

[0037] Add talcum powder with a moisture content of ≤0.2% and a particle size of 1250-3000 mesh into a high-speed mixer at a temperature of 110-140°C and stir at a speed of 400-800r / min for 10 minutes, then add aluminate coupling agent and Two kinds of borate-based surface modification additives, the addition ratio of the surface modification additives is 0.5-2.5% of the filler, and the material is stirred for 20 minutes to obtain modified talcum powder for later use.

[0038] 55 parts of PBAT, 15 parts of PLA, 0.3 parts of bisoxazoline chain extender as compatibilizer, 2 parts of plasticizer polyethylene glycol, 5 parts of modified talc, carbodiimide or epoxy anti-hydrolysis Add 0.2 parts of dispersant and 0.8 parts of vinyl bis stearamide into a high-speed mixer at room temperature and stir for 5-10 minutes, mix well and discharge. Among them, the melt flow rate of PBAT and PLA is 3-5g / 10min (190°C / 2.16kg).

[0039] Add the uniformly mixed material into a twin-screw extrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com