Composite plate

a technology of sole plate and composite material, which is applied in the direction of uppers, bootlegs, apparel, etc., can solve the problems of reducing flexibility, reducing comfort of shoes, and uncomfortable conventional metal sole plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

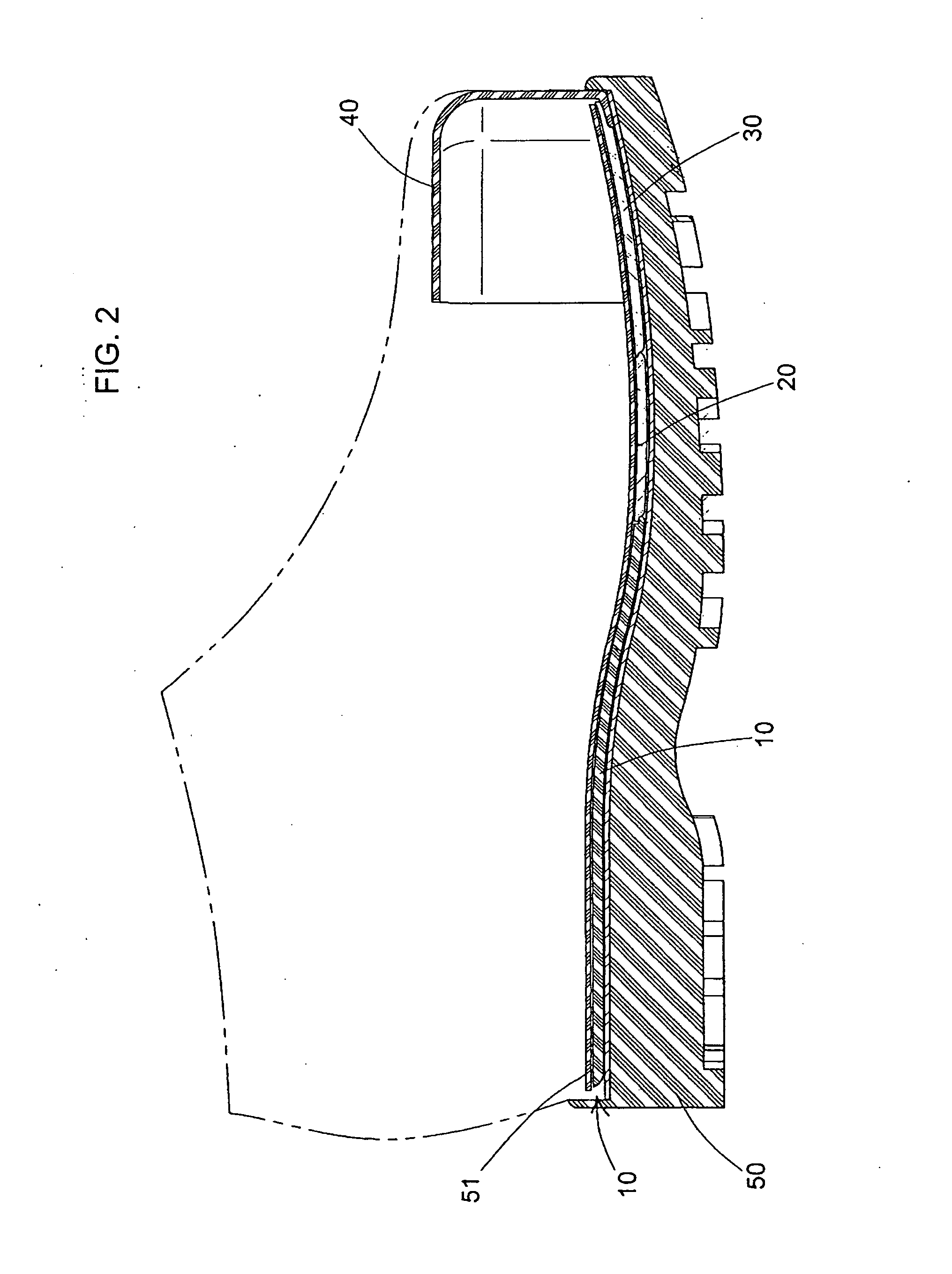

[0020] Referring to FIGS. 9 and 10, which illustrate a configuration of the conventional shoes, a shoe sole 60 is topped with a conventional metal inner sole plate 70, which is bonded together therewith. The metal inner sole plate 70 itself is sandwiched between two layers 61 of material, in order to obtain a better combination. A protective shoe head 71, which is made of metal material, is positioned on the shoe sole 60 at a location corresponding to the wearer's toes.

[0021] Thus, the wearer's foot sole is protected by the inner sole plate 70. The metal inner sole plate 70 prevents sharp tips of an object from penetrating therethrough to injure the wearer's foot sole when the wearer's foot accidentally steps on the sharp tips of the object. The rigid protective shoe head 71 protects the vulnerable toes from being injured even when a heavy object falls thereon.

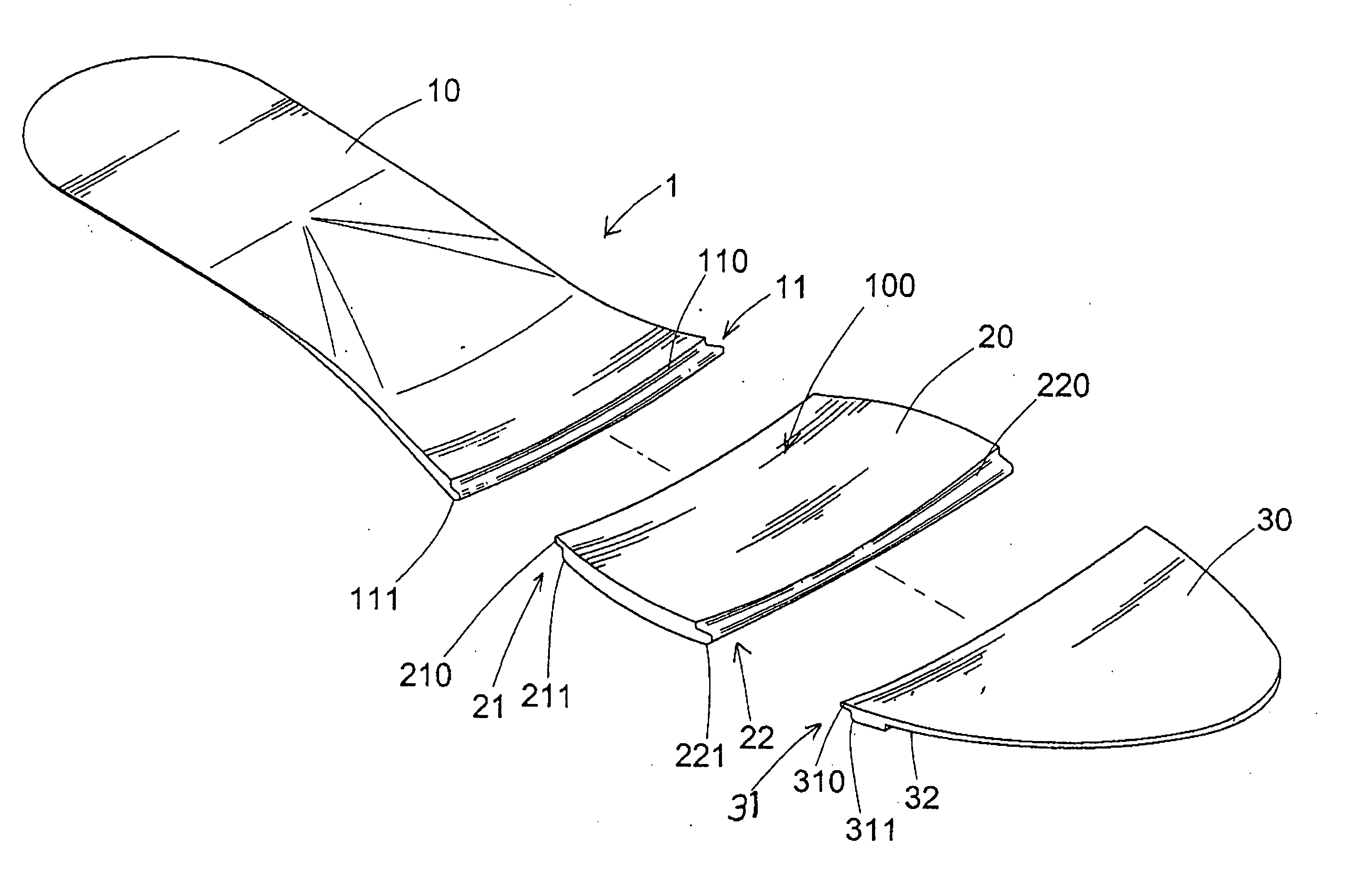

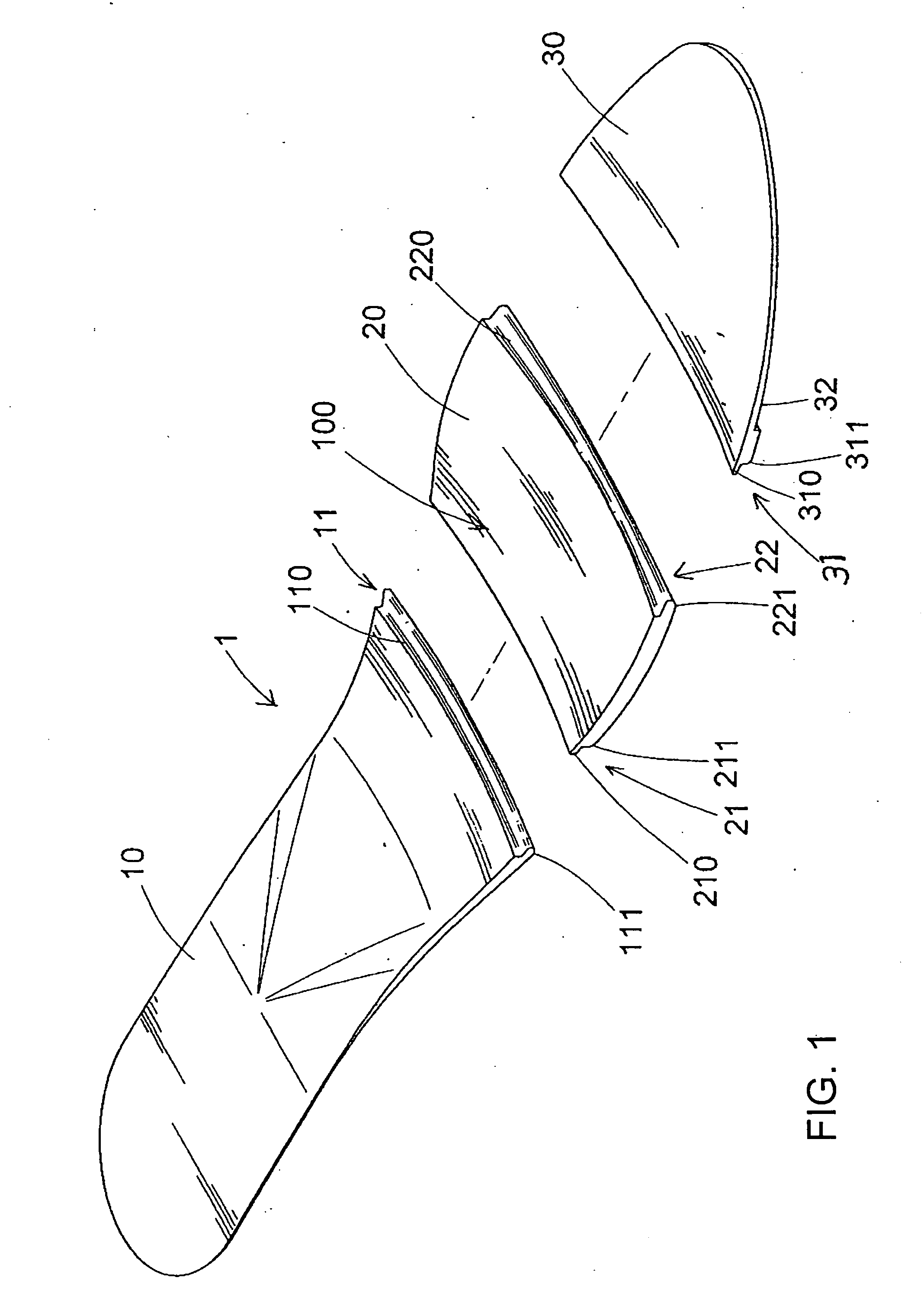

[0022] Referring to FIGS. 1-7, the present invention relates to an improvement of an inner sole configuration for protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com