Preparation method of high-polymer self-adhesive waterproof roll

A technology of self-adhesive waterproof membrane and polymer waterproofing, applied in the direction of non-polymer adhesive additives, adhesives, adhesive types, etc., can solve problems such as ignoring the waterproof requirements of vertical walls, and achieve good resistance and strong durability Chemical corrosion, strong wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

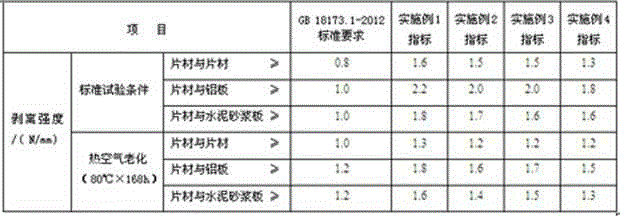

Examples

Embodiment 1

[0042] 1. Preparation method of SIS hot-melt pressure-sensitive self-adhesive

[0043] First, add 15 parts of naphthenic white oil, 20 parts of polyisobutylene, 1 part of antioxidant, 1 part of light stabilizer and 45 parts of petroleum resin into a reaction kettle with a stirring device and mix when the temperature rises to 100-140 ° C. After fully melted, slowly add 20 parts of SIS thermoplastic rubber and 3 parts of modifier, then stir and raise the temperature to 180-190°C under the protection of nitrogen, then keep stirring for more than 30 minutes until no visible particles are found, then add 0.5 parts of coupling agent to cool down Stir well and set aside.

[0044] 2. Composite molding preparation method of coil

[0045] Add the pre-prepared SIS hot-melt pressure-sensitive self-adhesive adhesive to the hot-melt pressure-sensitive adhesive coating machine, and apply the 0.4mm hot-melt pressure-sensitive self-adhesive adhesive to the thickness of 0.8mm through the hot-mel...

Embodiment 2

[0049] 1. Preparation method of SIS hot-melt pressure-sensitive self-adhesive

[0050] First, add 20 parts of naphthenic white oil, 15 parts of polyisobutylene, 2 parts of antioxidant, 1 part of light stabilizer and 40 parts of petroleum resin into the reaction kettle with stirring device and mix when the temperature rises to 100-140 °C, the material After fully melted, slowly add 25 parts of SIS thermoplastic rubber and 1 part of modifier, then stir and raise the temperature to 180-190°C under the protection of nitrogen, then keep stirring for more than 30 minutes until no visible particles are found, then add 0.5 parts of coupling agent to cool down Stir well and set aside.

[0051] 2. Composite molding preparation method of coil

[0052] Add the pre-prepared SIS hot-melt pressure-sensitive self-adhesive to the hot-melt pressure-sensitive adhesive coating machine, and apply the hot-melt pressure-sensitive self-adhesive of 0.35mm to 0.8mm through the hot-melt pressure-sensit...

Embodiment 3

[0054] 1. Preparation method of SIS hot-melt pressure-sensitive self-adhesive

[0055] First, add 10 parts of naphthenic white oil, 10 parts of polyisobutylene, 0.5 parts of antioxidant, 0.5 parts of light stabilizer and 30 parts of petroleum resin into a reaction kettle with a stirring device and mix them when the temperature rises to 100-140 °C. Slowly add 20

[0056] Part SIS thermoplastic rubber and 0 part modifier, then stir and heat up to 180-190°C under the protection of nitrogen gas, and then keep warm

[0057] After stirring for more than 30 minutes until no particles are visible to the naked eye, then add 0 parts of coupling agent, cool down and stir evenly for later use.

[0058] 2. Composite molding preparation method of coil

[0059] Add the pre-prepared SIS hot-melt pressure-sensitive self-adhesive adhesive to the hot-melt pressure-sensitive adhesive coating machine, and apply the 0.38mm hot-melt pressure-sensitive self-adhesive adhesive to the thickness of 0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com