Liquid spurting method, its spurting device and electronic instrument thereof

A liquid-like, jet-head technology, which is applied to devices for coating liquids on surfaces, jetting devices, jetting devices, etc., and can solve problems such as uneven brightness of panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Next, the present invention will be described in detail.

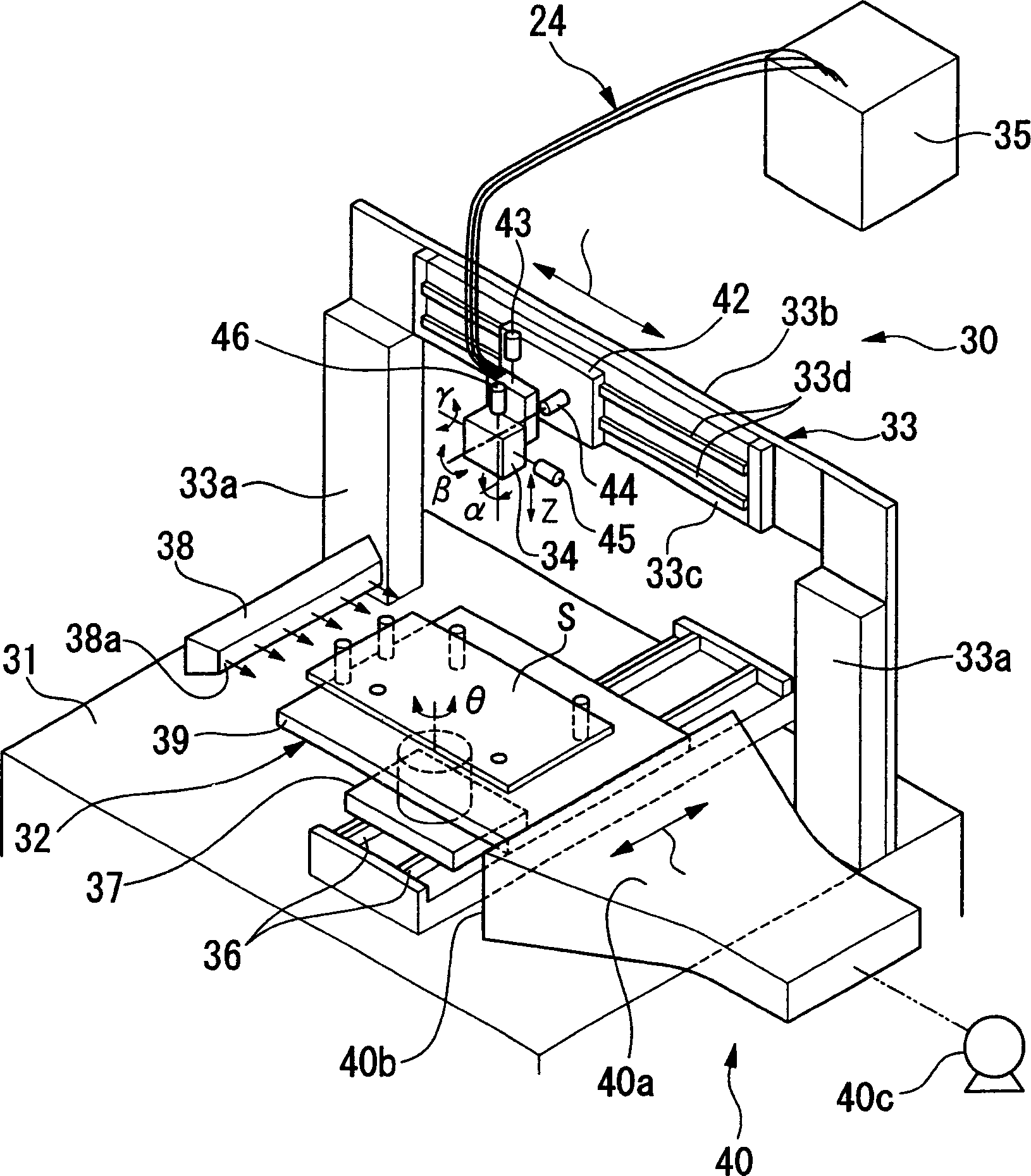

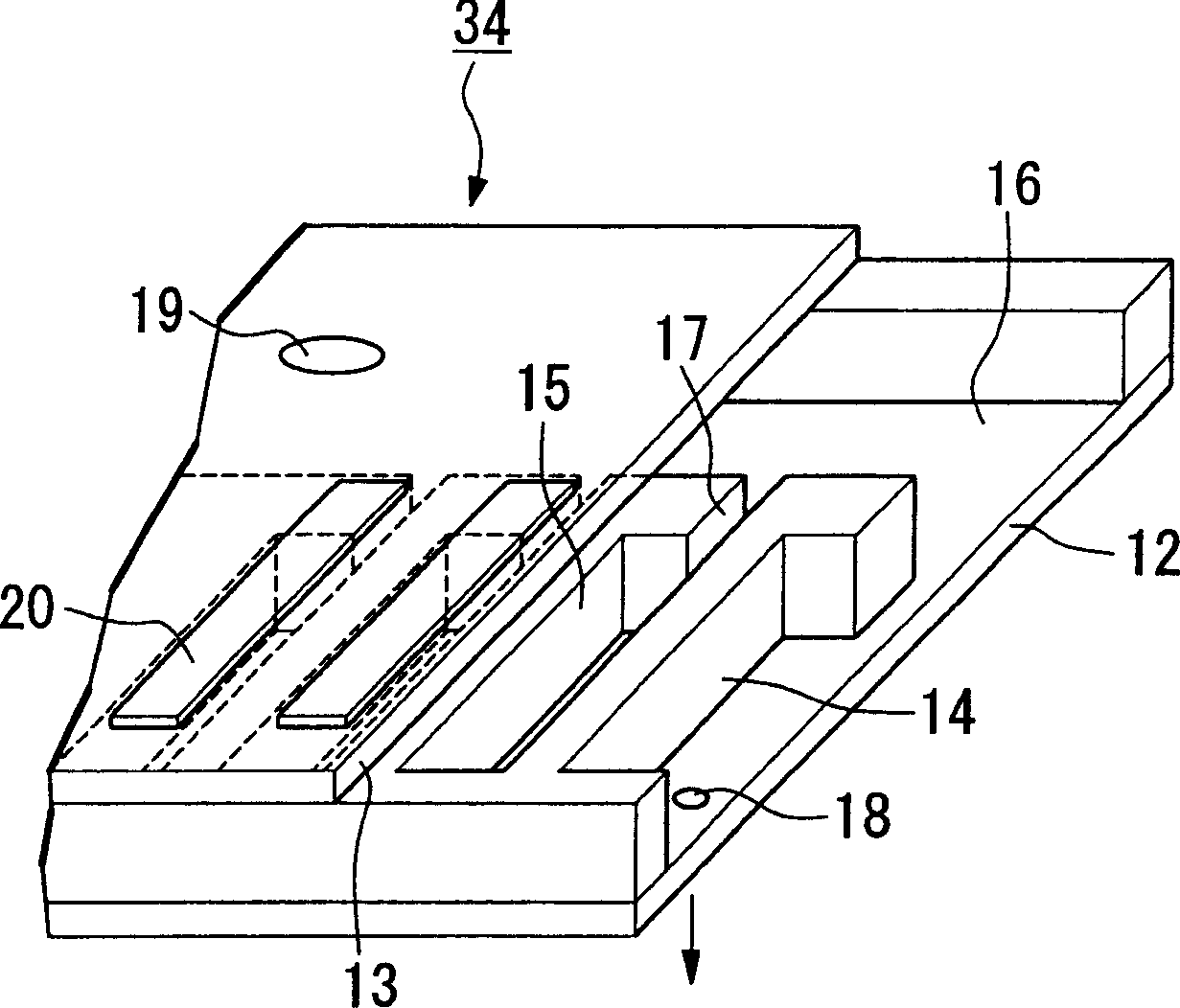

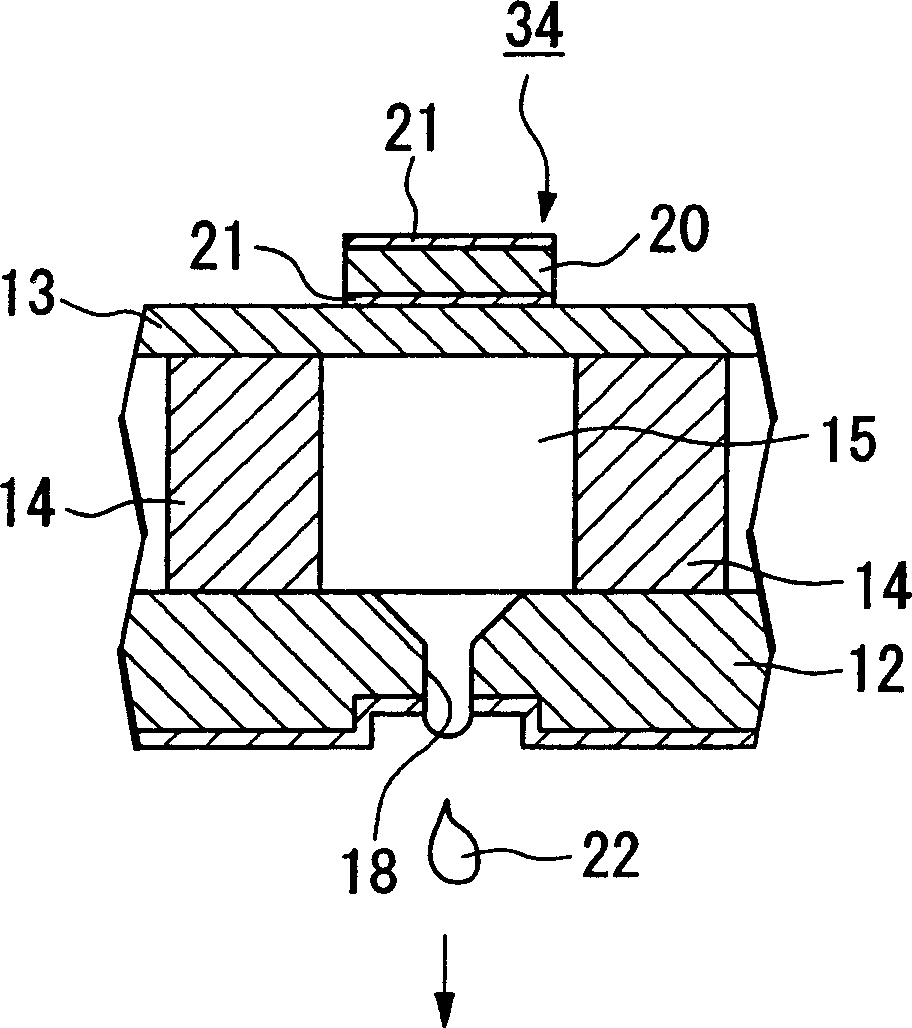

[0055] figure 1 It is an embodiment showing the liquid ejection device (hereinafter referred to as the ejection device) of the present invention, figure 1 In , symbol 30 denotes a discharge device. The ejection device has a base 31, a substrate moving part 32, a head moving part 33, an ejection head 34, a liquid container 35, an ion generating part 38, an exhaust part 40, etc., and the liquid is ejected to the substrate S by the ejection head 34. Body, the liquid body coated into a film. In addition, in the liquid ejection device 34 of the present embodiment, a substrate provided with an easily chargeable component is used as the substrate S, or an easily chargeable material is used as the liquid material.

[0056] The base 31 is provided with the substrate moving part 32 and the head moving part 33 thereon.

[0057] The substrate moving member 32 functions as a substrate holding portion of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com