Alluminide coatings containing silicon and yttrium for superalloys and method of forming such coatings

a technology of superalloys and alluminide coatings, which is applied in the direction of superimposed coating process, liquid/solution decomposition chemical coating, soldering apparatus, etc., can solve the problems of high production cost of platinum aluminide, inability to adhere well to the superalloy commonly used to form jet engine components, and increase the cost of jet engine components and the cost of refurbishing used jet engine components. , to achieve the effect of less production cost and competitive performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

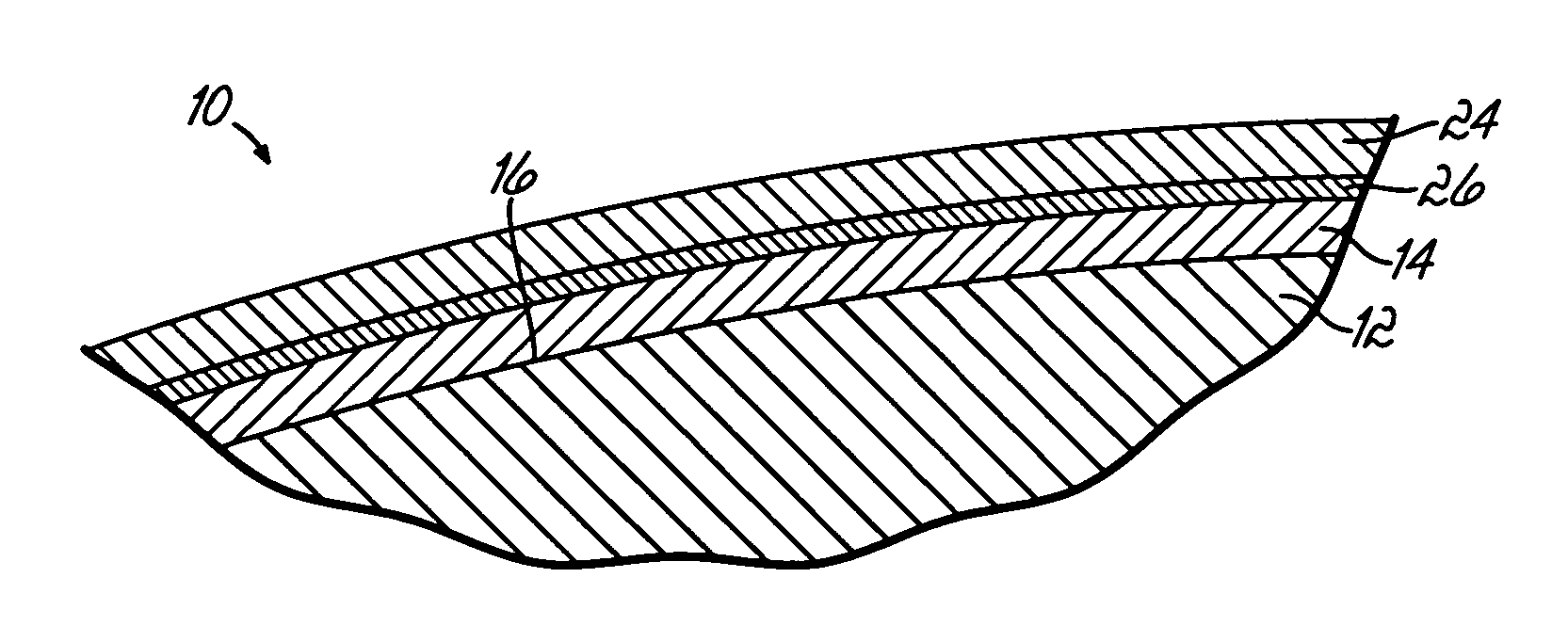

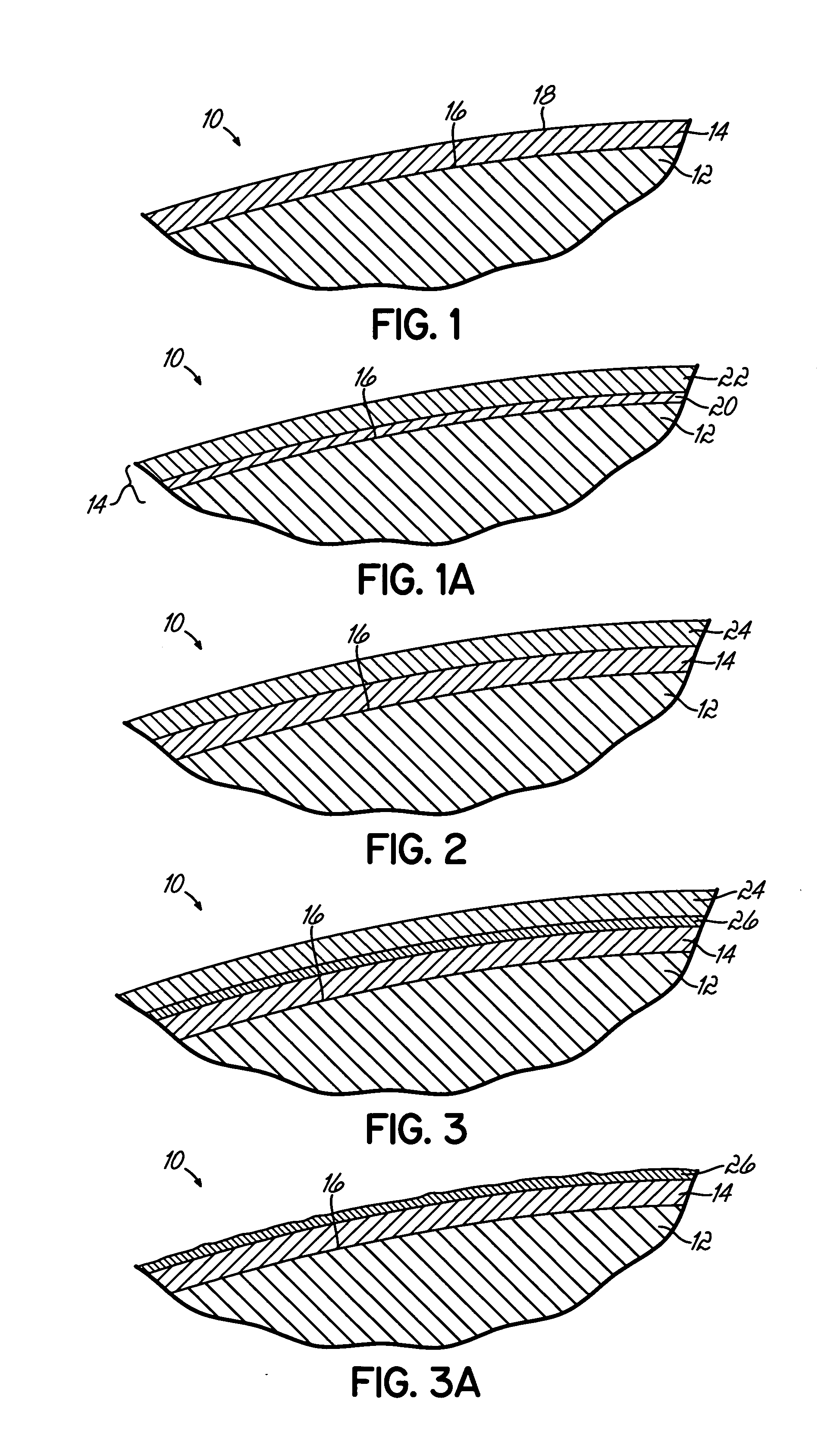

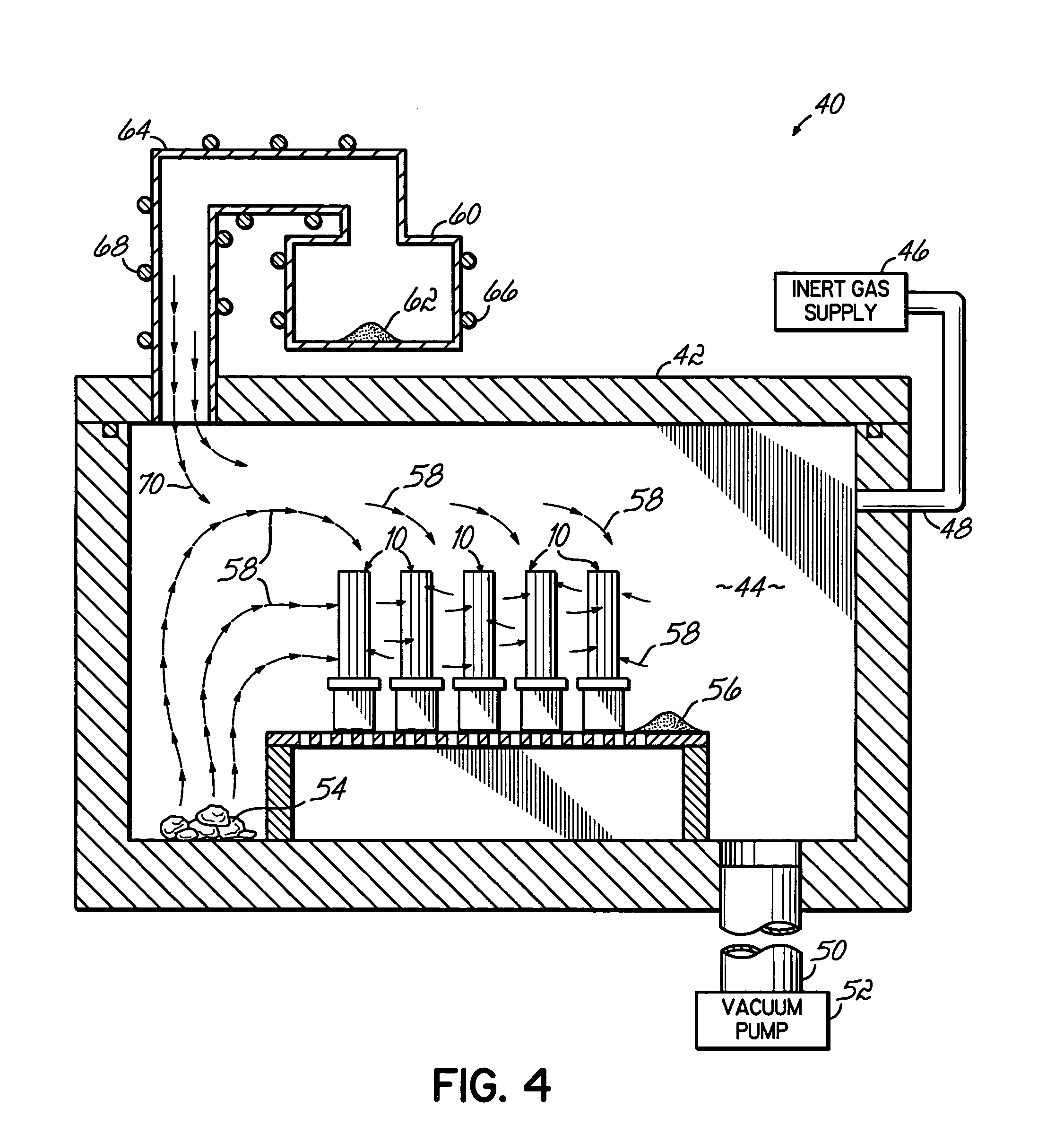

[0020] With reference to FIG. 1, a detailed view of a portion of a much larger jet engine component, generally indicated by reference numeral 10, is shown. The jet engine component 10 includes a metallic substrate 12 and an aluminide layer 14 coating an original surface 16 of the substrate 12. The metallic substrate 12 is made of any nickel-, cobalt-, or iron-based high temperature superalloy from which such jet engine components 10 are commonly made. For example, the substrate 12 may be the nickel-based superalloy Inconel 795 Mod5 A. The present invention is not intended to be limited to any particular jet engine component 10, which may be a turbine blade, a vane, a nozzle guide, or any other part requiring protection from high temperature oxidation and corrosion while operating in a jet engine. The substrate 12 may be masked to define areas across which the aluminide layer 14 is absent.

[0021] In this specific embodiment of the present invention, aluminide layer 14 operates as an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com