A method of repairing parts with laser directional solidification technology

A technology of directional solidification and parts, used in laser welding equipment, coatings, metal material coating processes, etc., can solve the problem of unable to repair columnar crystal or single crystal structure, and achieve integrity and orientation consistency, good applied effects

Inactive Publication Date: 2005-05-18

NORTHWESTERN POLYTECHNICAL UNIV

View PDF1 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to overcome the shortcomings in the existing technology that the repaired area cannot be realized to have a columnar crystal or single crystal structure consistent with the original part structure, the present invention proposes a method for repairing parts using laser directional solidification technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Login to View More

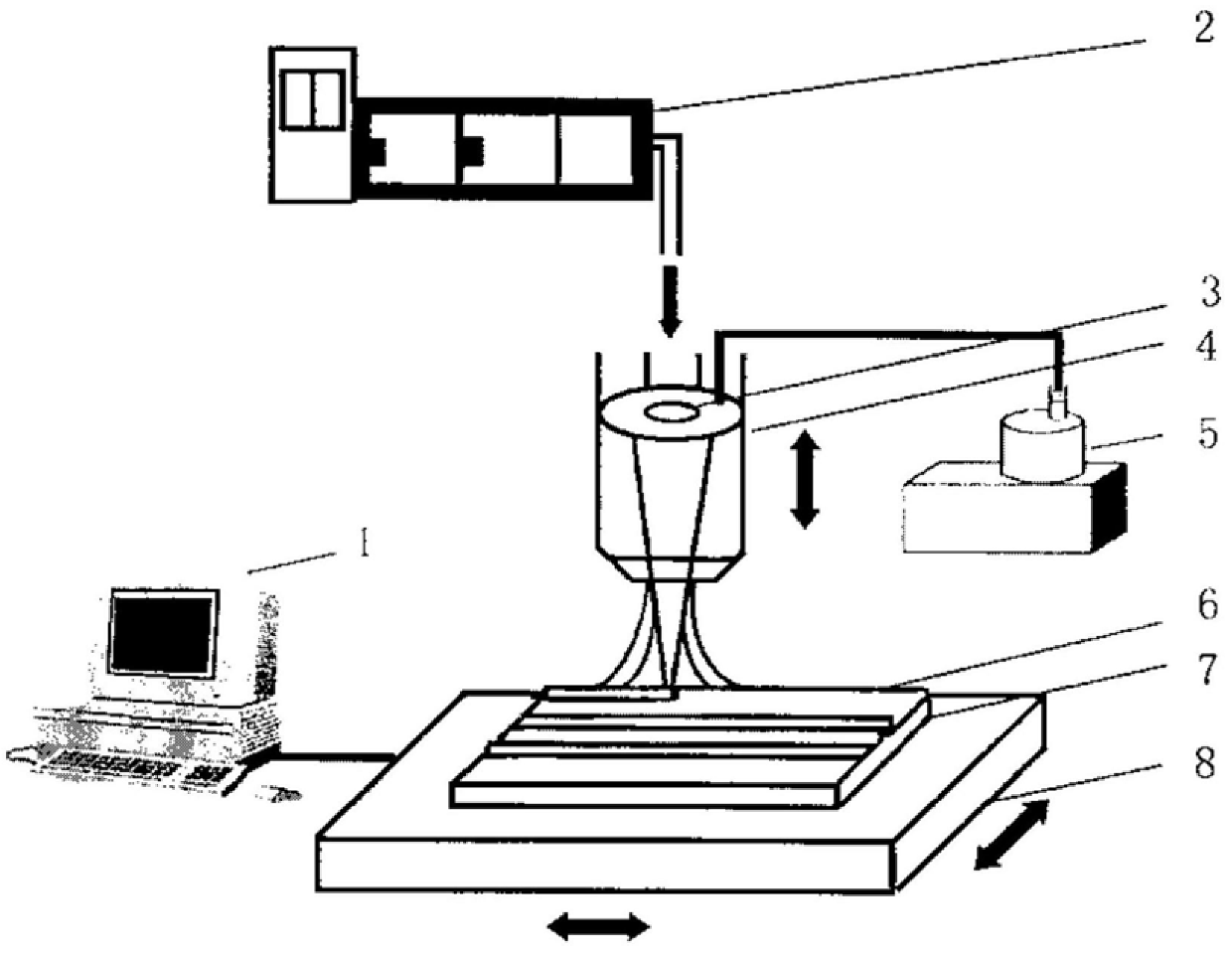

Abstract

The invention is a method for repairing parts by laser directional solidification technology. In order to overcome the deficiency in the prior art that the columnar crystal or single crystal structure in the repaired area is consistent with the original part structure, the present invention slices and processes the three-dimensional information of the part to be repaired into a series of two-dimensional plane data information, The CNC machine tool scans according to the scanning trajectory determined by the two-dimensional plane data. The laser beam forms a laser molten pool in the repair area of the part. Covering and stacking layer by layer, so as to realize the repair of parts by using epitaxial laser metal forming method. By adopting the technical solution of the present invention, a directionally solidified columnar crystal or single crystal repair layer can be obtained in the repair area, which is epitaxially grown from the original part tissue, which ensures the integrity and orientation consistency of the repair layer and the matrix grains, and has good applicability .

Description

A method of repairing parts with laser directional solidification technology (1) Technical field: The invention is a method for directional solidification and repair of single crystal components in the industrial field. (two) background technology: The repair of parts is an important topic in the industrial field. Appropriate parts repair technology can save production costs and generate considerable economic benefits. At present, the commonly used method of repairing metal parts is TIG welding (tungsten argon arc welding of inert gas), but this method is often prone to welding hot cracks under normal conditions. In recent years, with the development of laser technology, people have gradually applied laser cladding technology to the repair of parts. This is mainly due to the fact that the laser cladding coating can obtain a fine and dense internal structure, no defects and a surface structure with excellent performance without changing the base material of the part. Ther...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K26/00C23C6/00

Inventor 黄卫东冯莉萍

Owner NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com