Process for producing pre-tin-plated connectors for pv cells and metal foil having a groove structure running in one direction

A metal foil and pre-tinning technology, applied in the field of metal foil, can solve the problems of insufficient pre-tinning and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

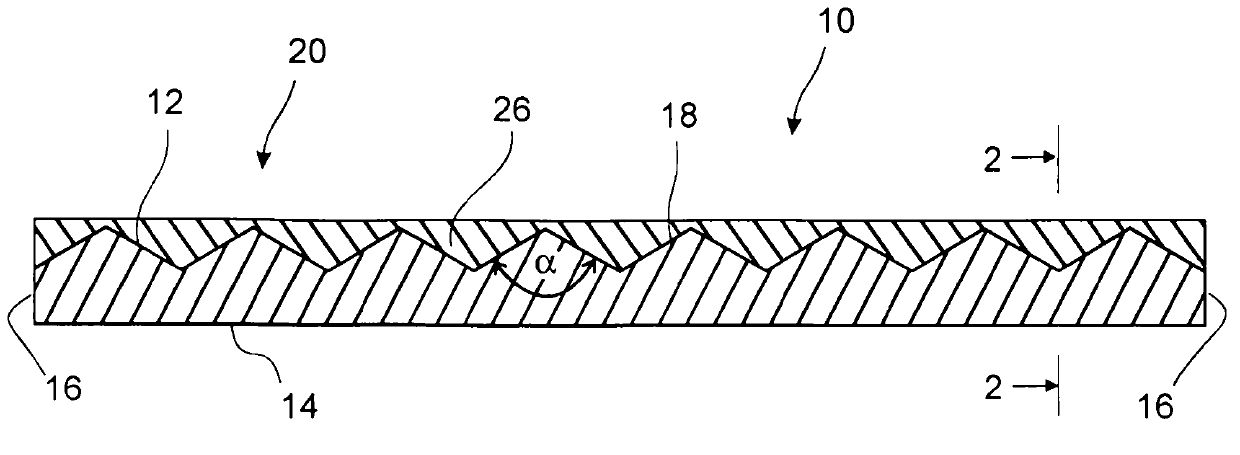

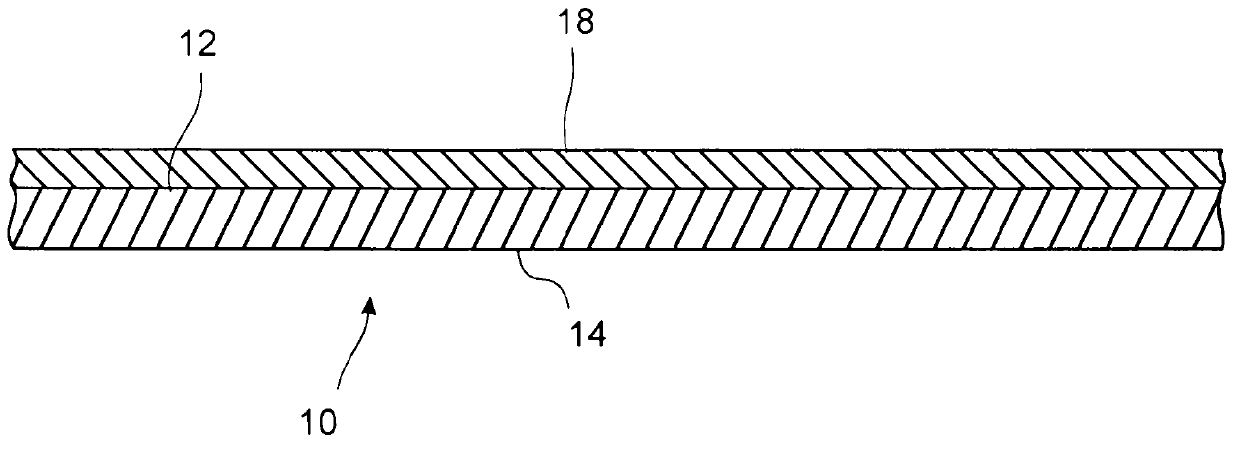

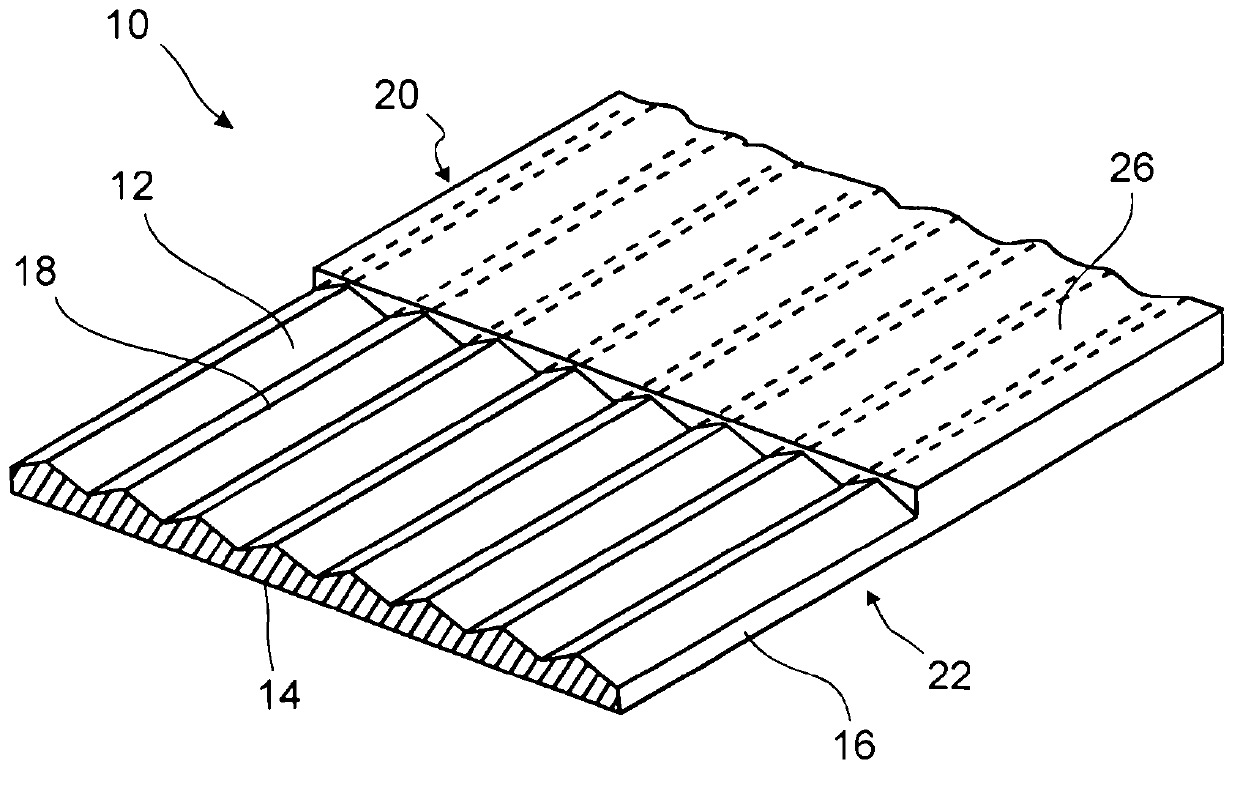

[0058] By means of the method according to the invention should be produced pre-tinned connectors for PV cells 29 ( Figure 4 and 5 ), the connector is a strip 10 with a flat cross-section, and has a first wide side 12 above and a second wide side 14 below and two narrow sides 16, which connect the wide sides 12 respectively , 14 opposite edges. The cross-section of the strip 10 has a width of 1 mm and a height of 0.1 mm ( figure 1 ). The strip 10 has a copper core and has a thin silver layer on its upper and lower broad sides for improved conductivity and reflectivity. The silver layer is not shown in the figure.

[0059] The lower broadside 14 is smooth, while the upper broadside 12 has a corrugated structure 18 with a triangular profile ( figure 1 ), the triangular profile has an angle α of 120° at the peak and valley. The distance between the peaks of the groove structure 18 is 150 μm, and the depth of the groove structure is correspondingly about 40 μm. The length ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com