Production method of high-density laminated printed circuit board of high-frequency material

A technology for printed circuit boards and high-frequency materials, applied in the direction of multi-layer circuit manufacturing, etc., can solve the problems of high cost, removal of high-frequency materials, and high safety hazards of sulfuric acid, so as to enhance the bonding force between layers and improve reliability. , the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

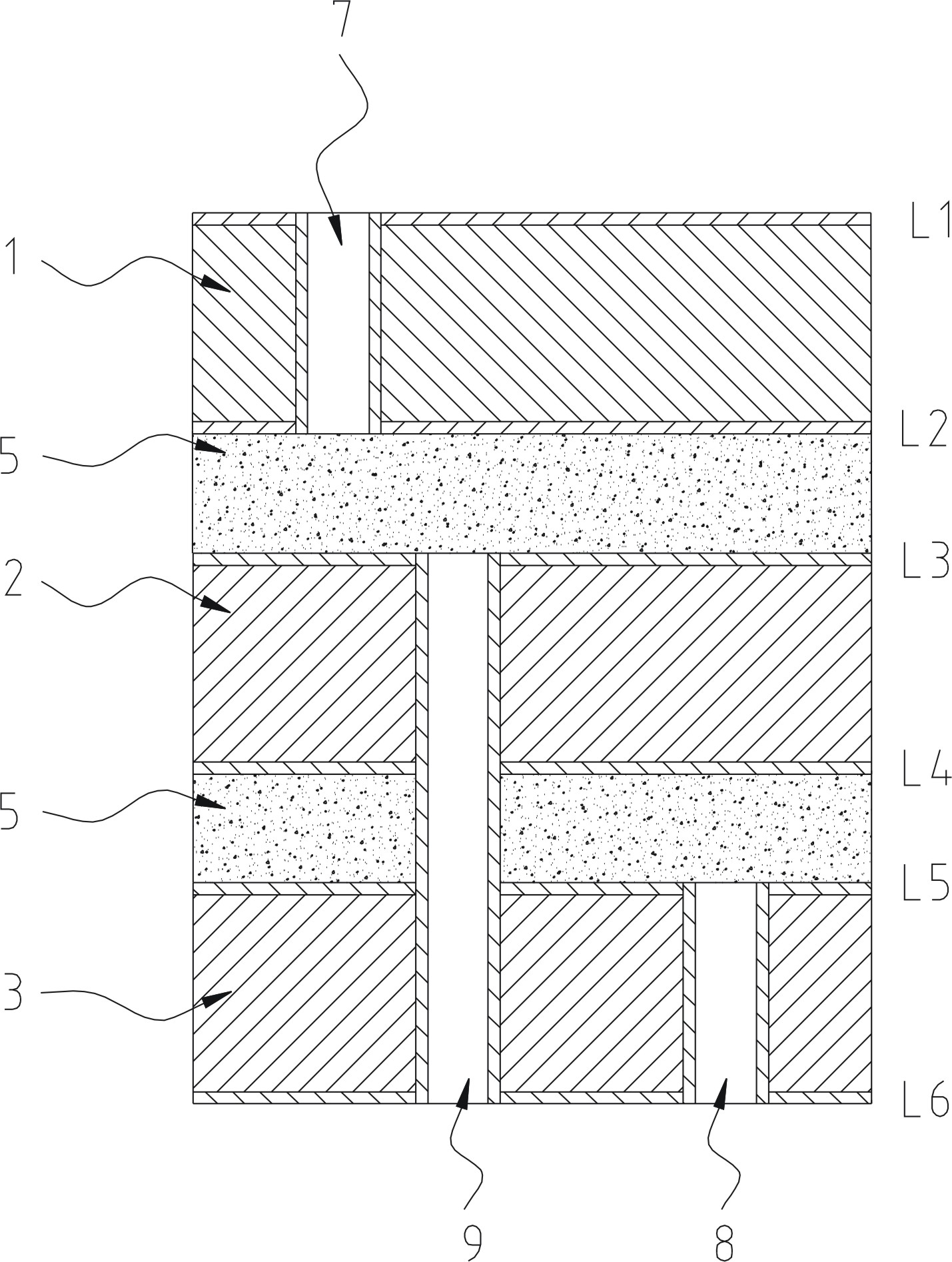

[0019] figure 1 Shown is a schematic structural diagram of a high-density laminated board with 6 layers of high-frequency materials. This board is composed of three high-frequency board sub-boards 1, 2, and 3 and several high-frequency prepregs 5, 6. Among them, There are three types of blind holes in the board design, one is blind holes 7 on layers L1-L2, one is blind holes 9 on layers L3-L6, and the other is blind holes 8 on layers L5-L6. Its processing flow is as follows.

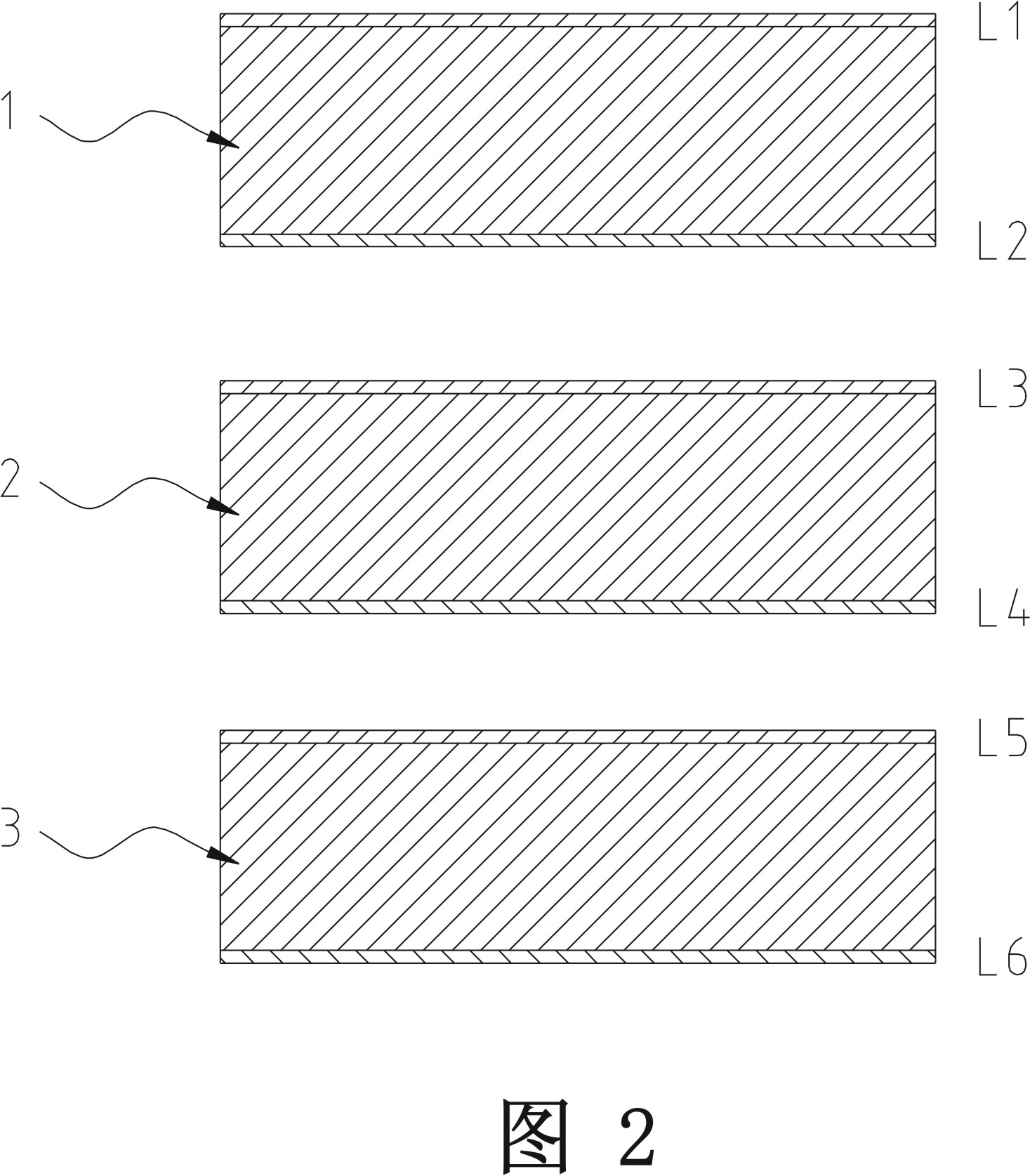

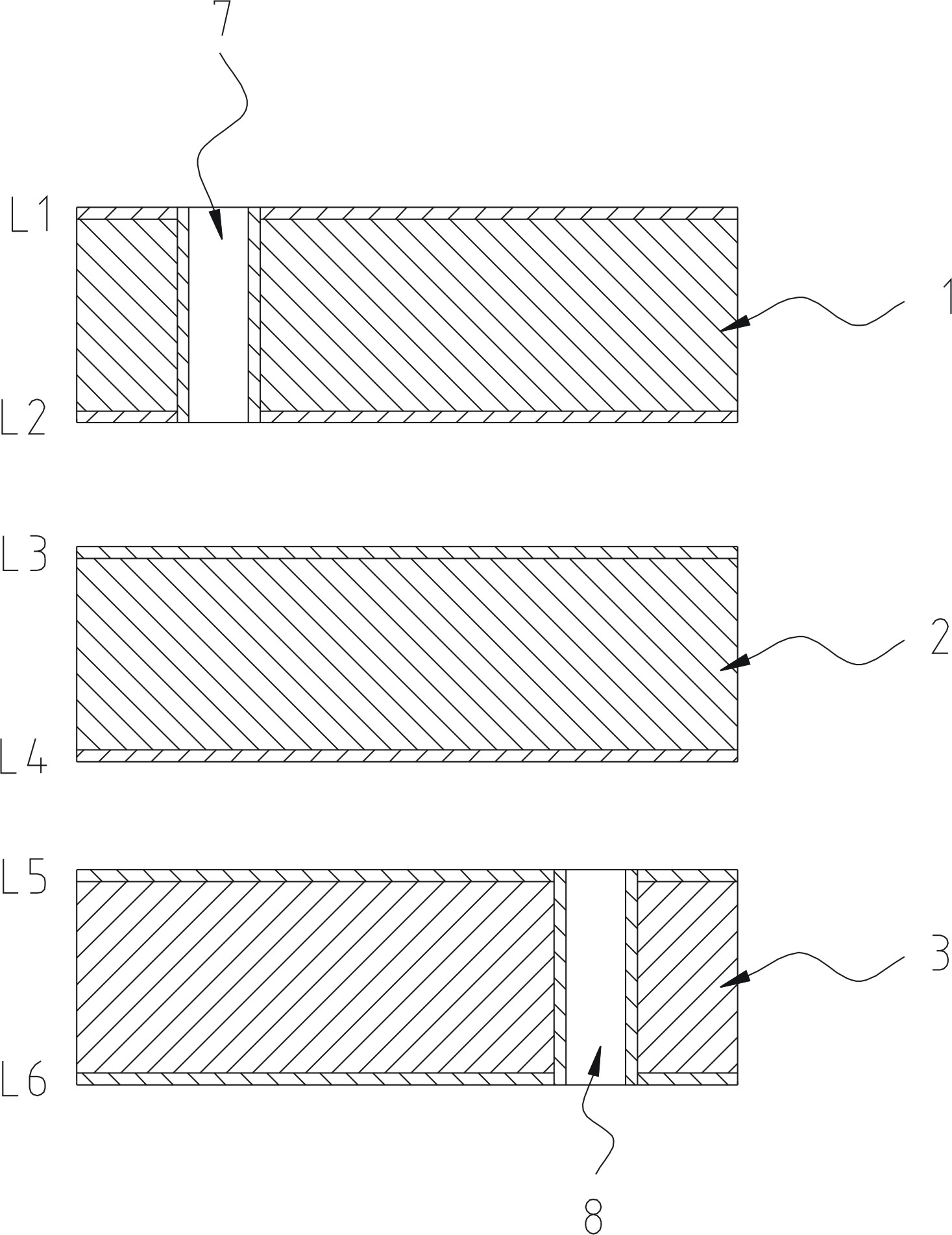

[0020] (1) Complete the production of sub-board 1, sub-board 2 and sub-board 3 respectively: see figure 2 , 3 The sub-board 1 completes the production of the blind hole 7 and the L2 layer circuit; the sub-board 2 completes the production of the L4 layer circuit; the sub-board 3 completes the production of the blind via 8 and the L5 layer circuit.

[0021] (2) Silk screen solder mask: see Figure 4 Firstly, the sub-board 3 is ground through the solder mask pretreatment line to clean the board surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com