Patents

Literature

42results about How to "Bonding force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

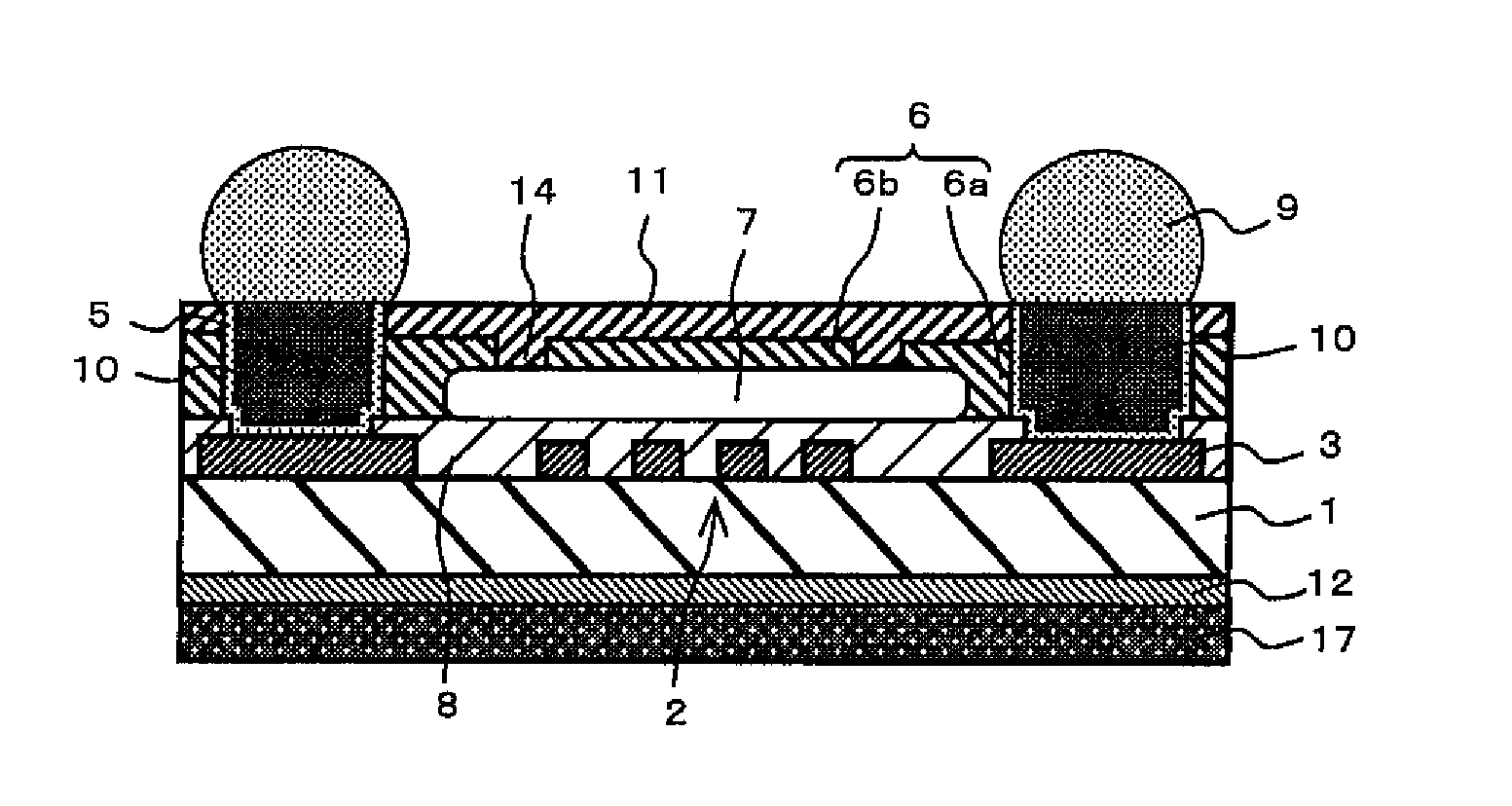

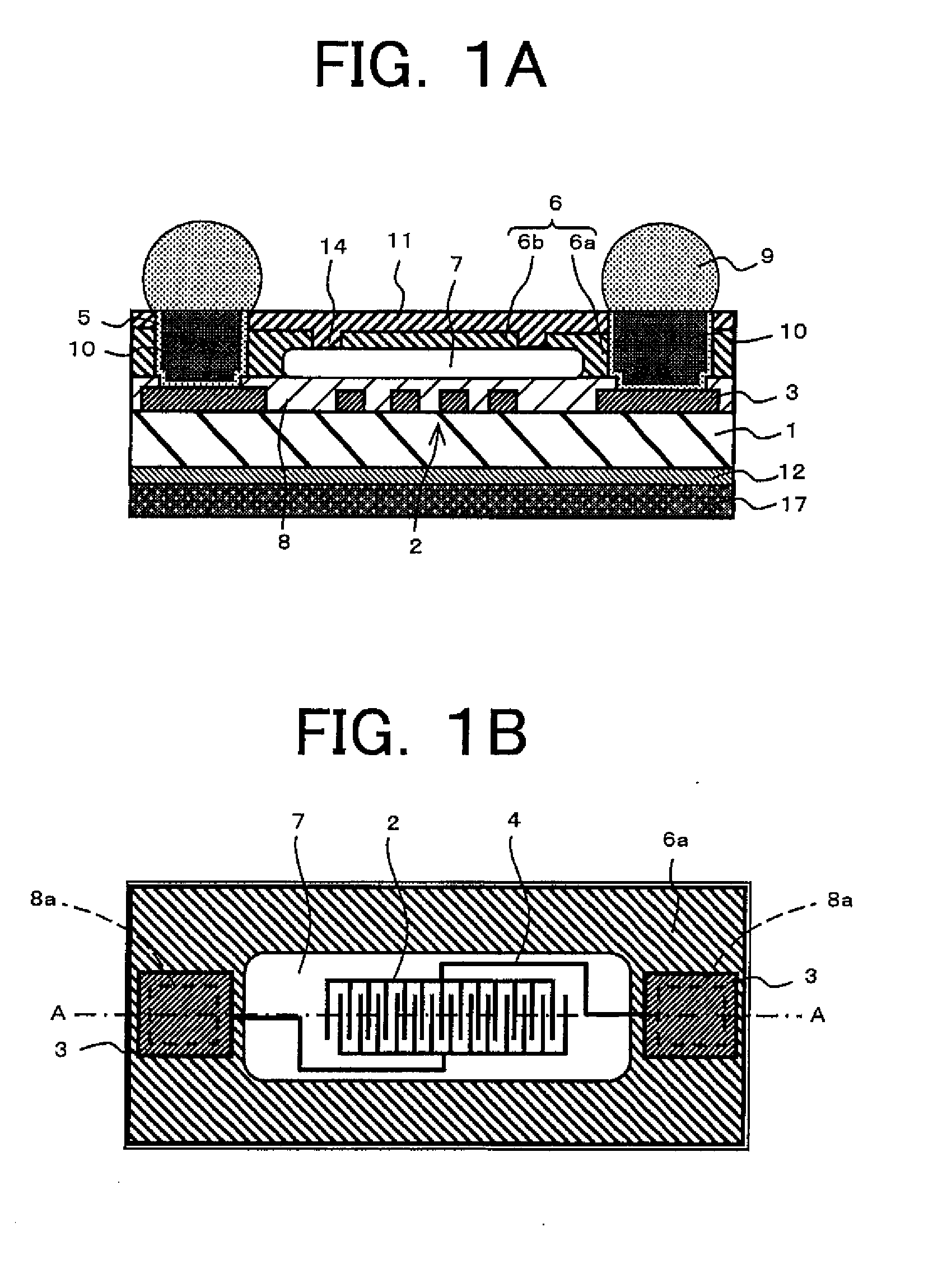

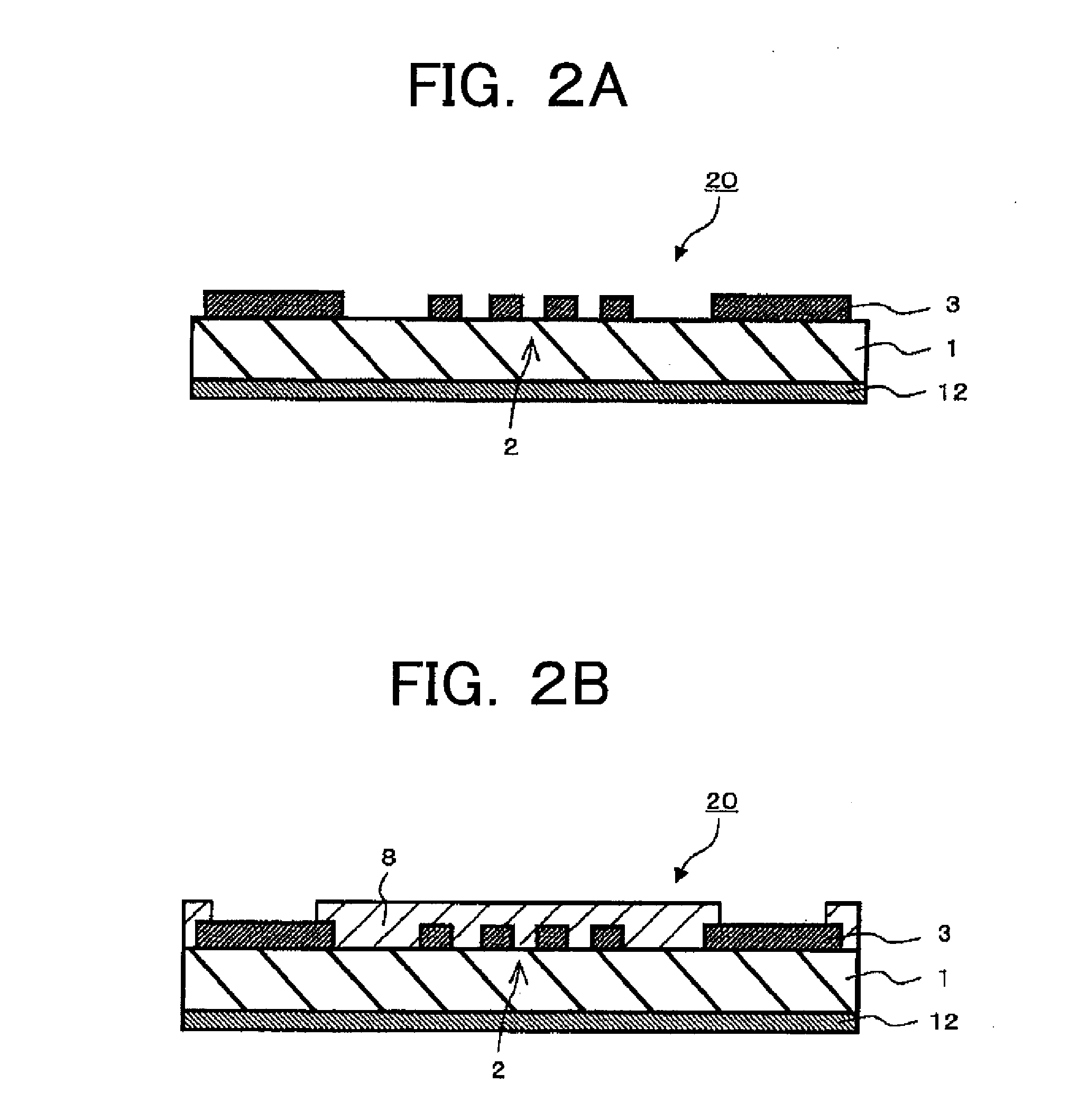

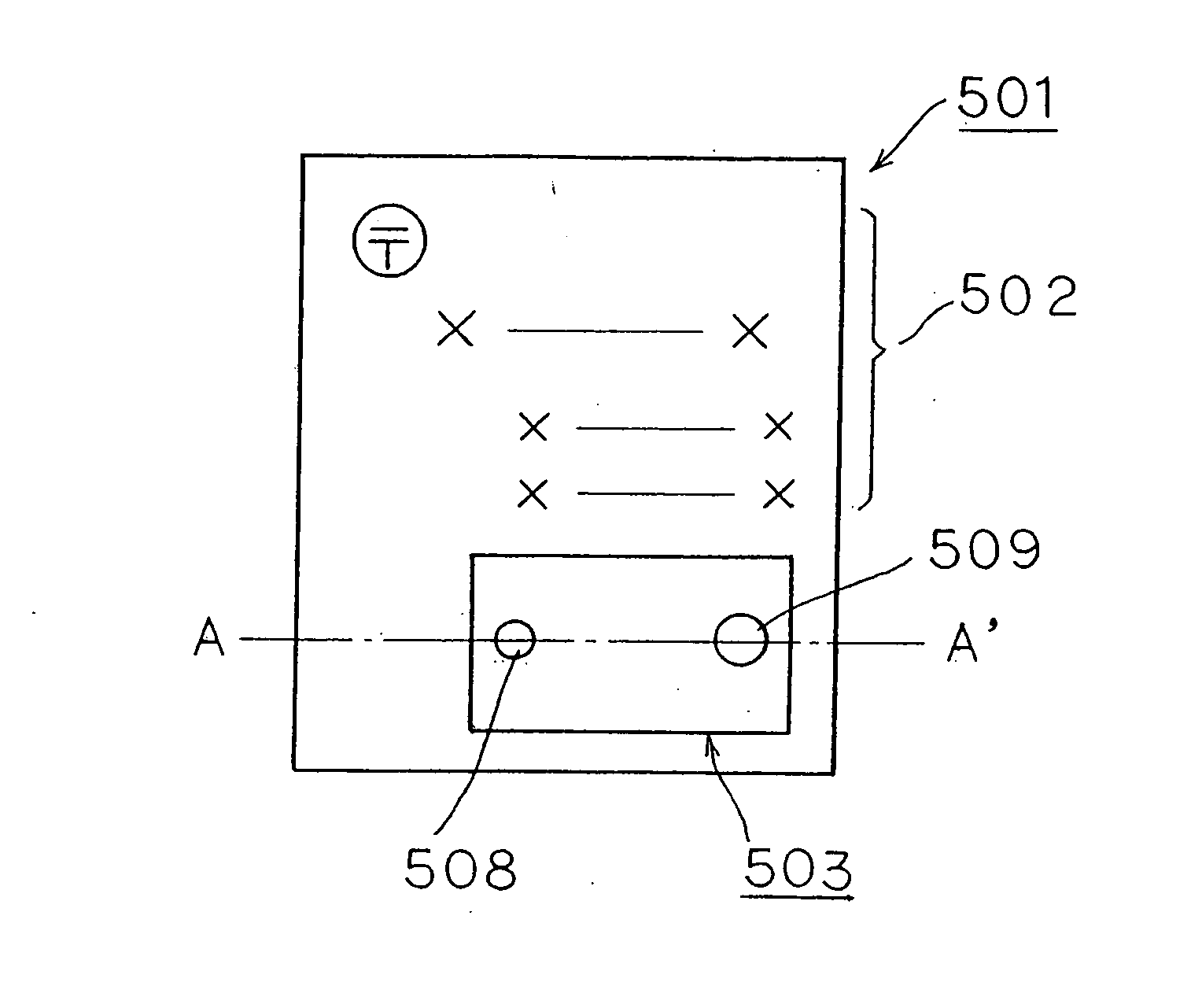

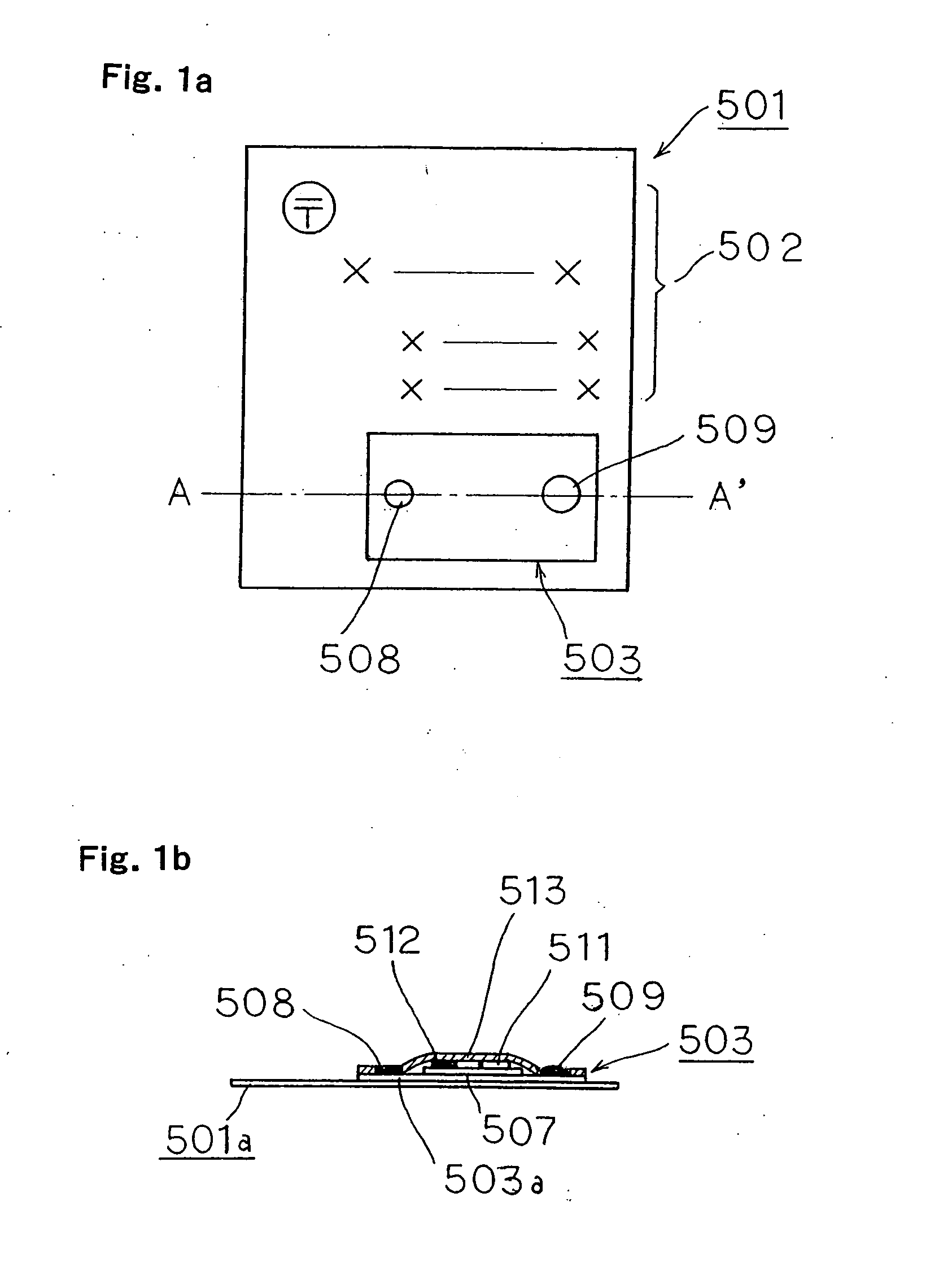

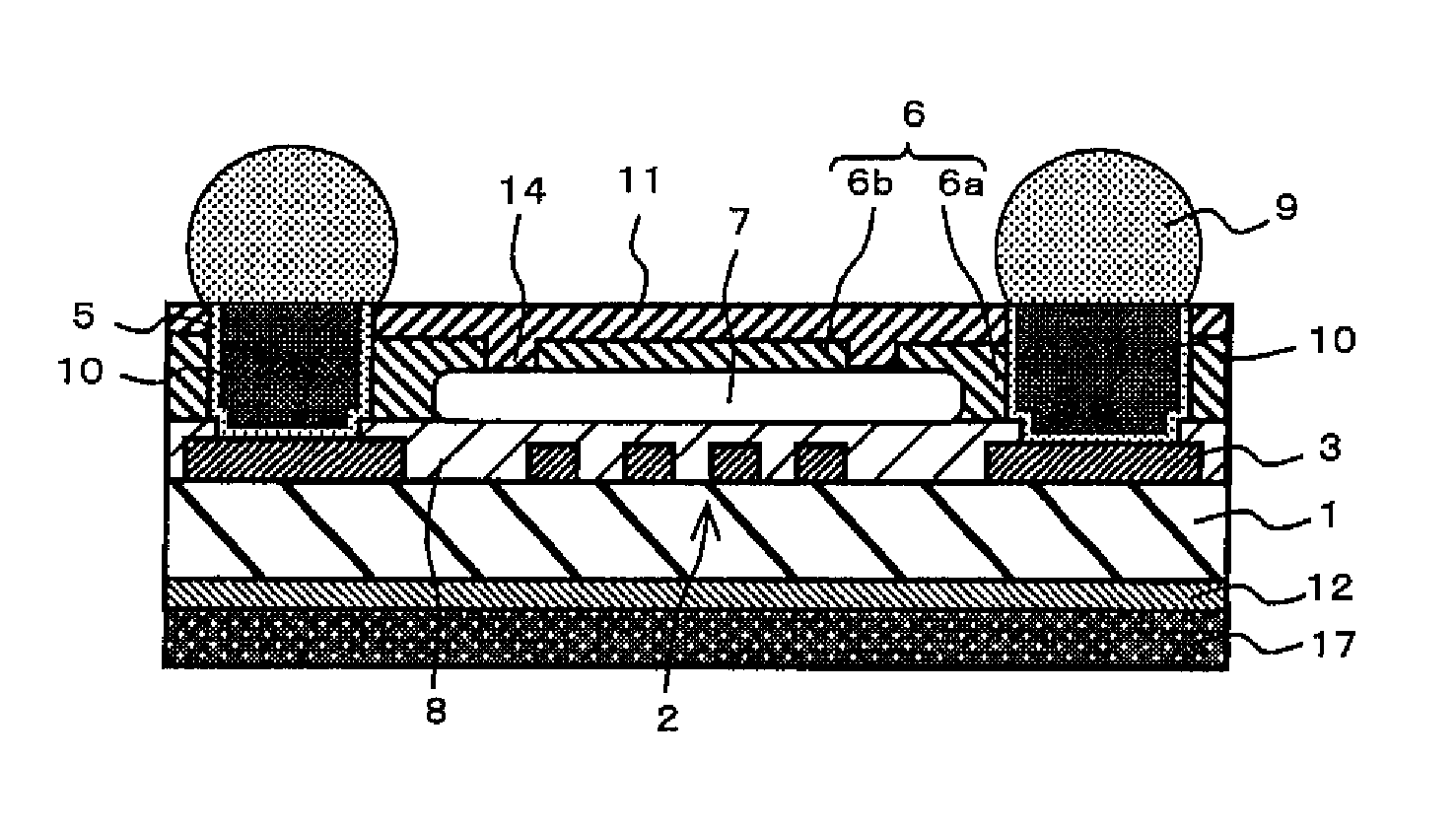

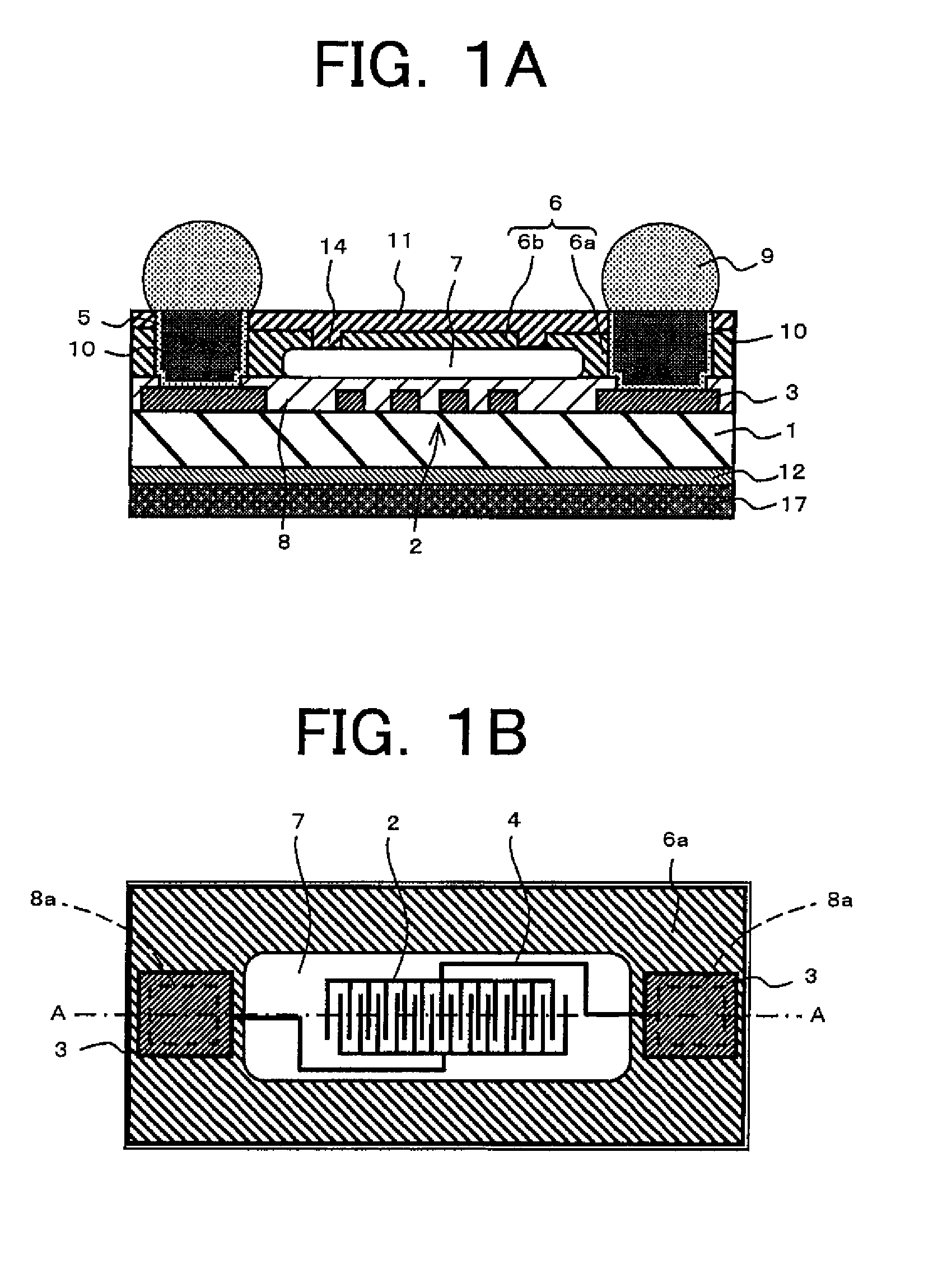

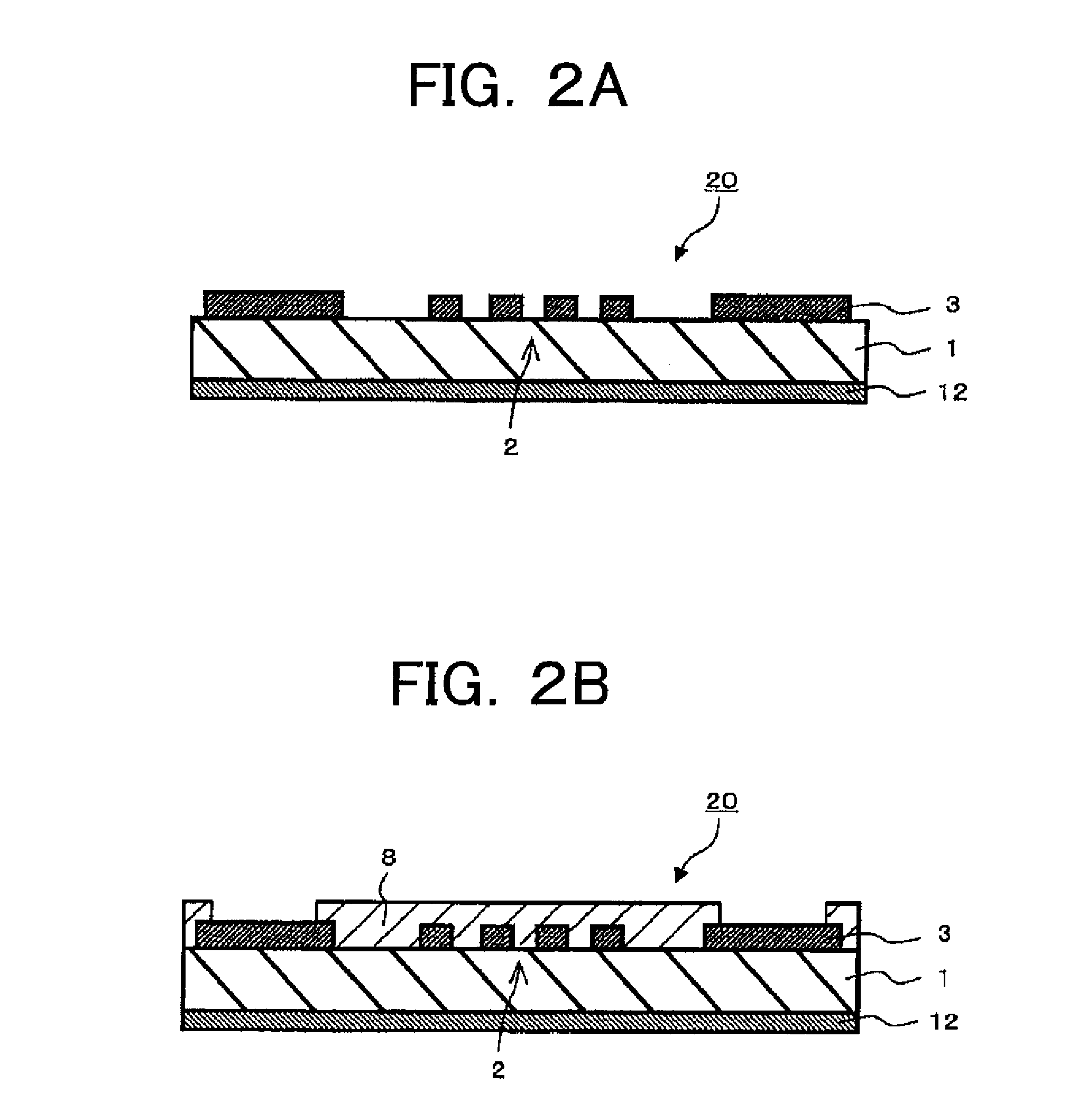

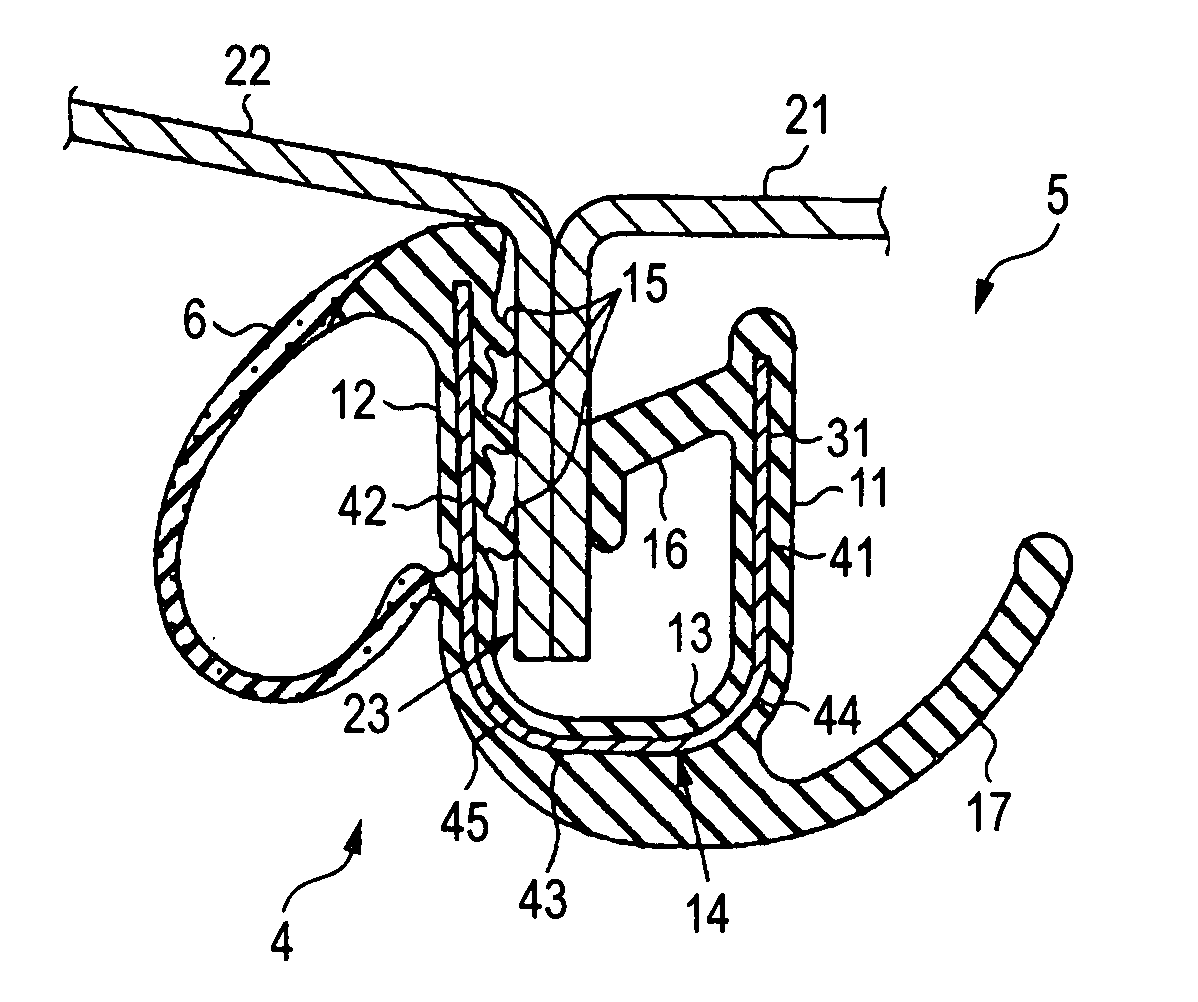

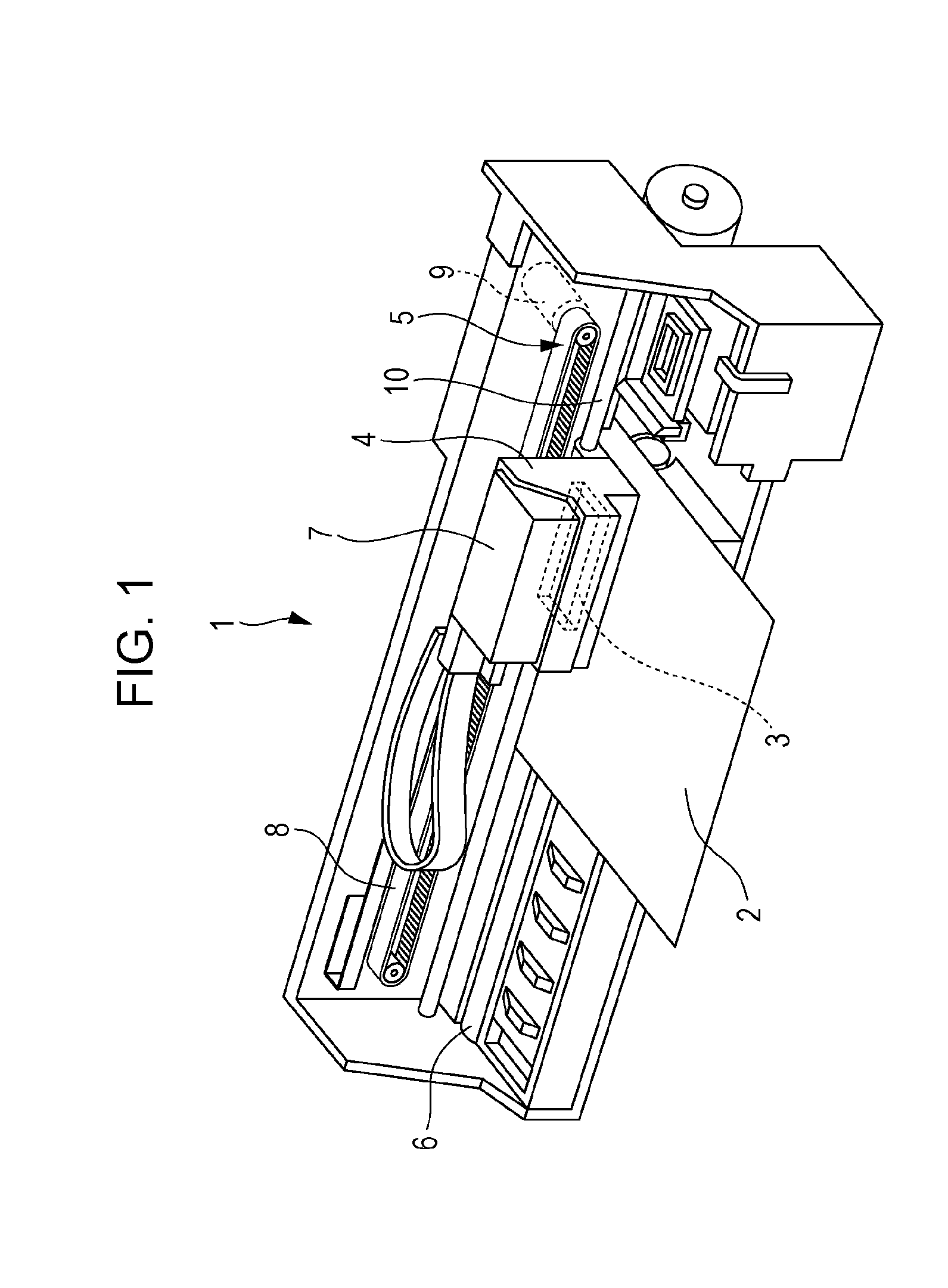

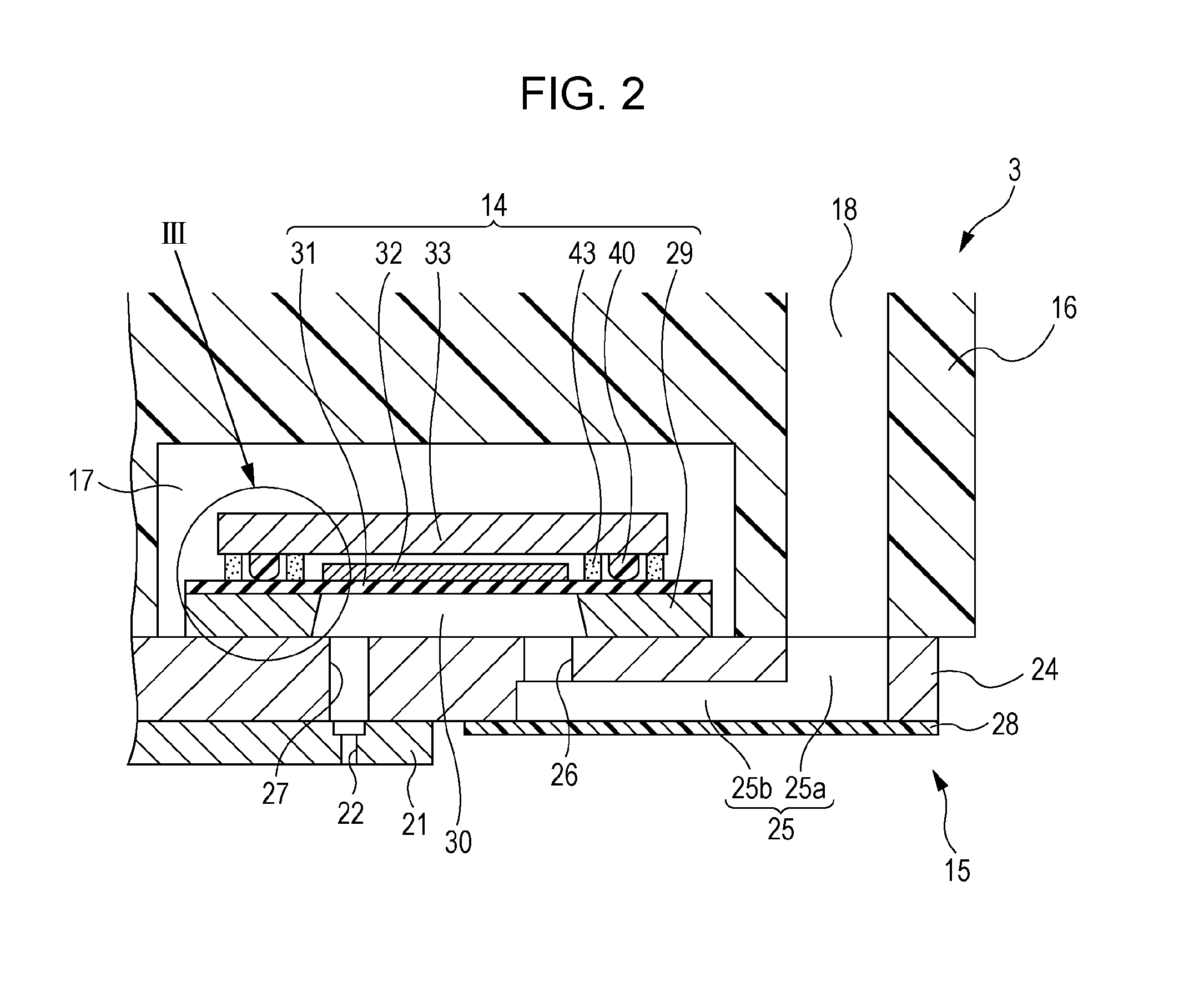

Acoustic Wave Device and Method for Production of Same

ActiveUS20110018389A1Stably keep tight sealImprove reliabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectrical conductorAcoustic wave

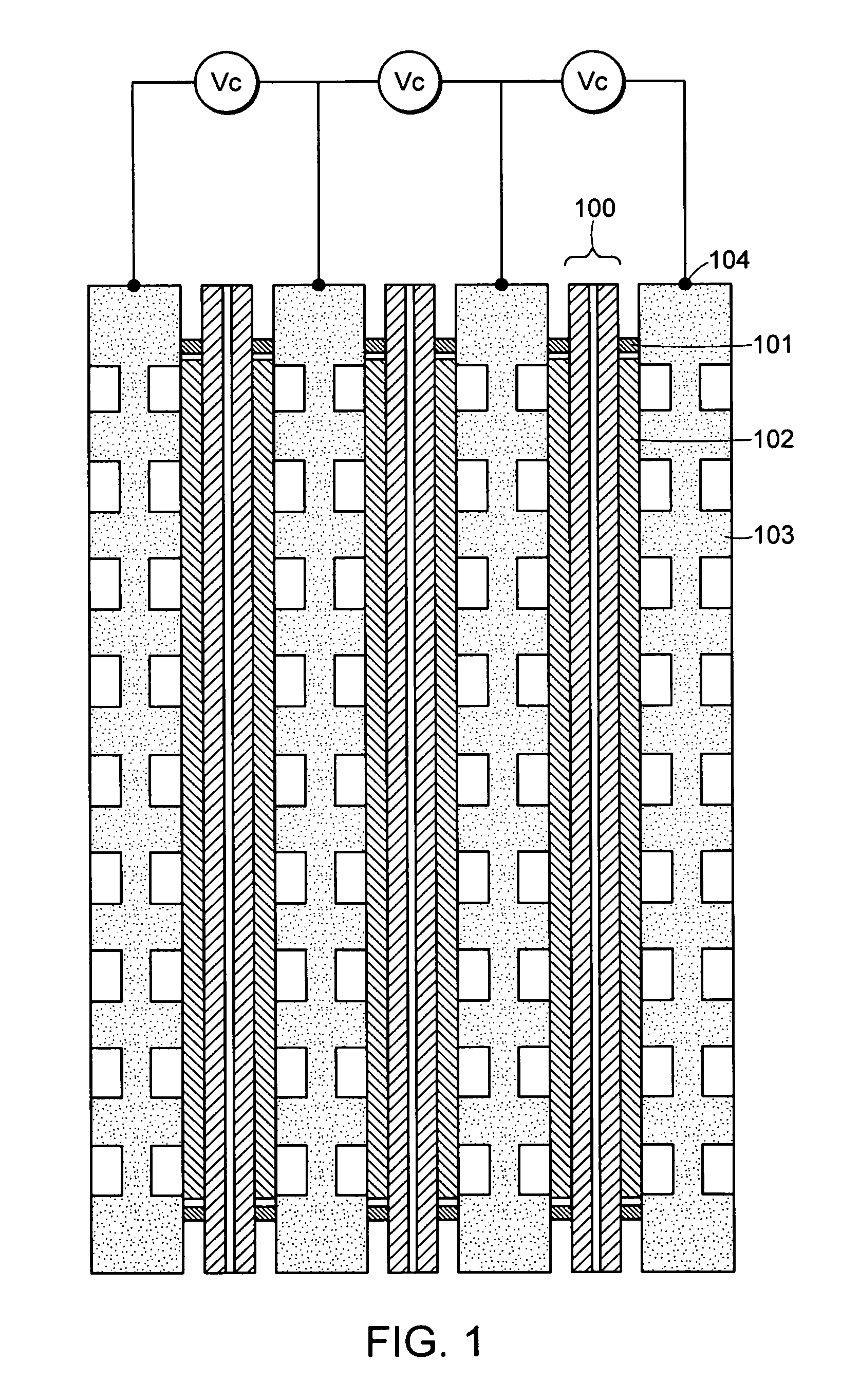

A small and highly reliable acoustic wave device and a method for production of the same will be provided. The acoustic wave device has a piezoelectric substrate 1; a SAW element 2 on one main surface of the piezoelectric substrate 1; an outside connection-use conductor 3 formed on the one main surface of the piezoelectric substrate 1 and electrically connected to the SAW element 2; a columnar electrode 10 on the outside connection-use conductor 3; and a protective cover 6 defining inner walls of a vibration space 7 for vibration of the SAW element 2 and planarly surrounding a side surface of the columnar electrode 10.

Owner:KYOCERA CORP

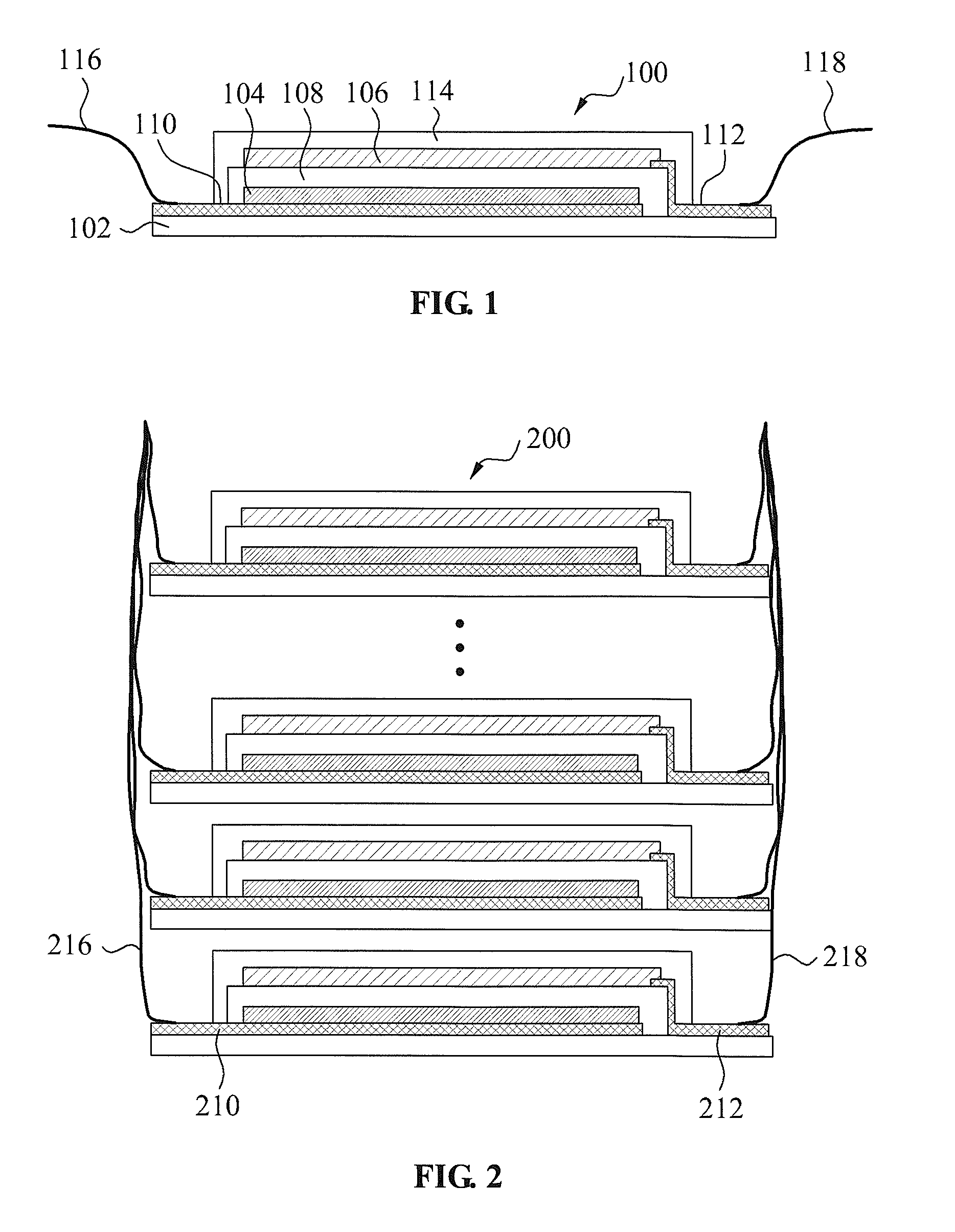

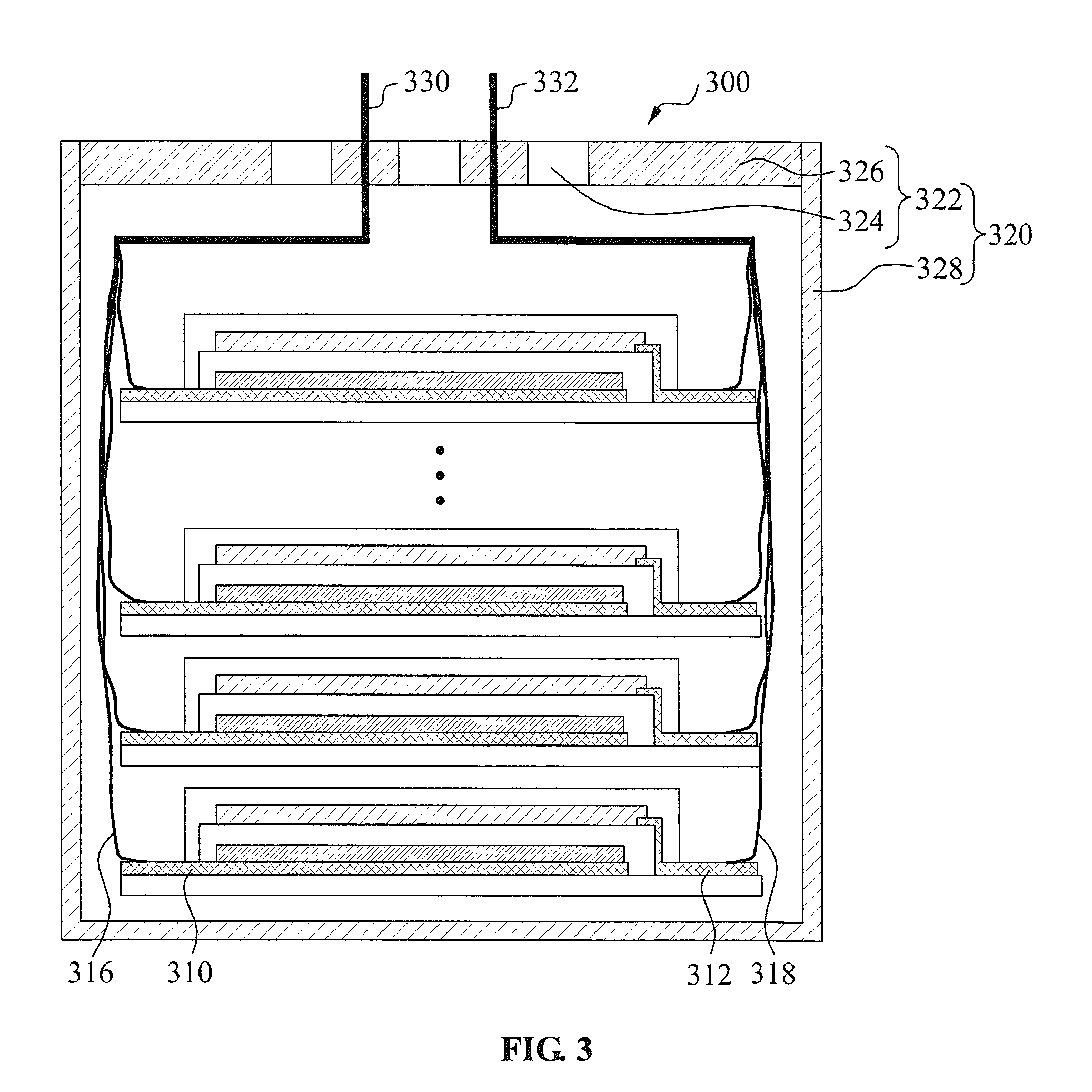

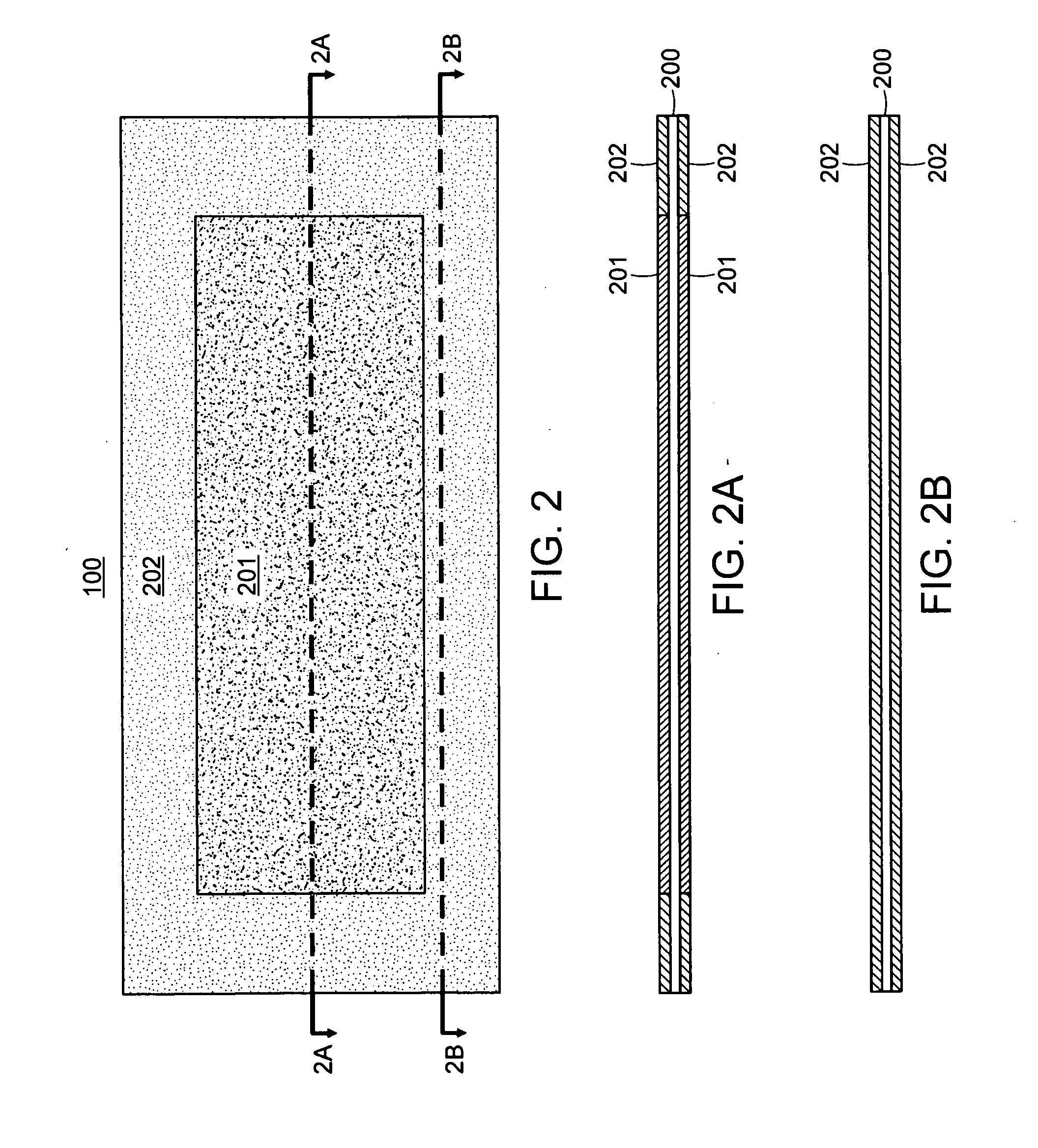

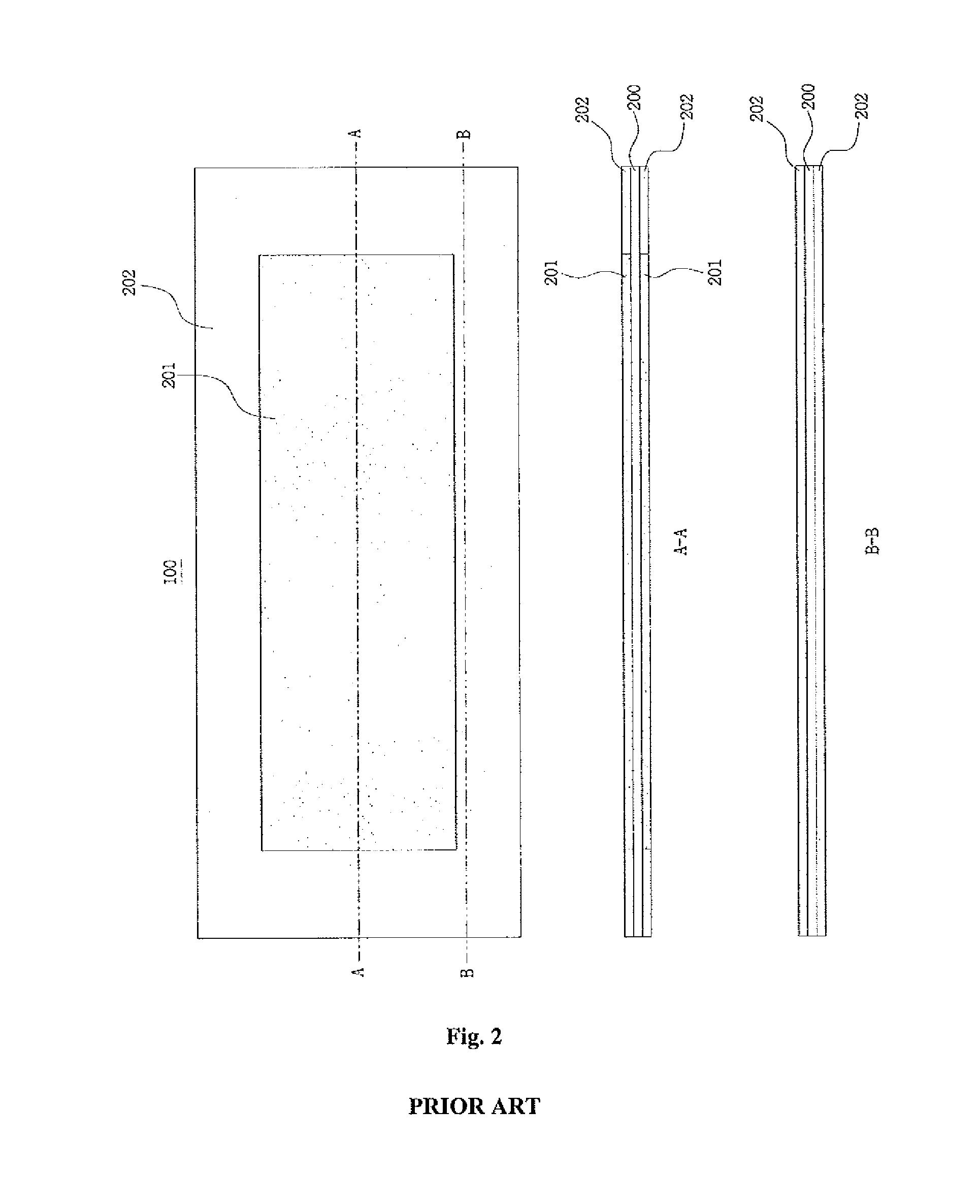

Thin film battery and method of connecting electrode terminal of thin film battery

InactiveUS20100330411A1Bonding forceReduce heat damagePrimary cell to battery groupingFinal product manufactureEngineeringAnode

Provided is a thin film battery, including: a base substrate; a cathode current collector pattern and an anode current collector pattern being formed on the base substrate and being electrically separate from each other; a cathode terminal and an anode terminal being directly bonded with the cathode current collector pattern and the anode current collector pattern; a cathode and an anode being disposed on the cathode current collector pattern and the anode current collector pattern; and an electrolyte layer being disposed between the cathode and the anode.

Owner:GSNANOTECH

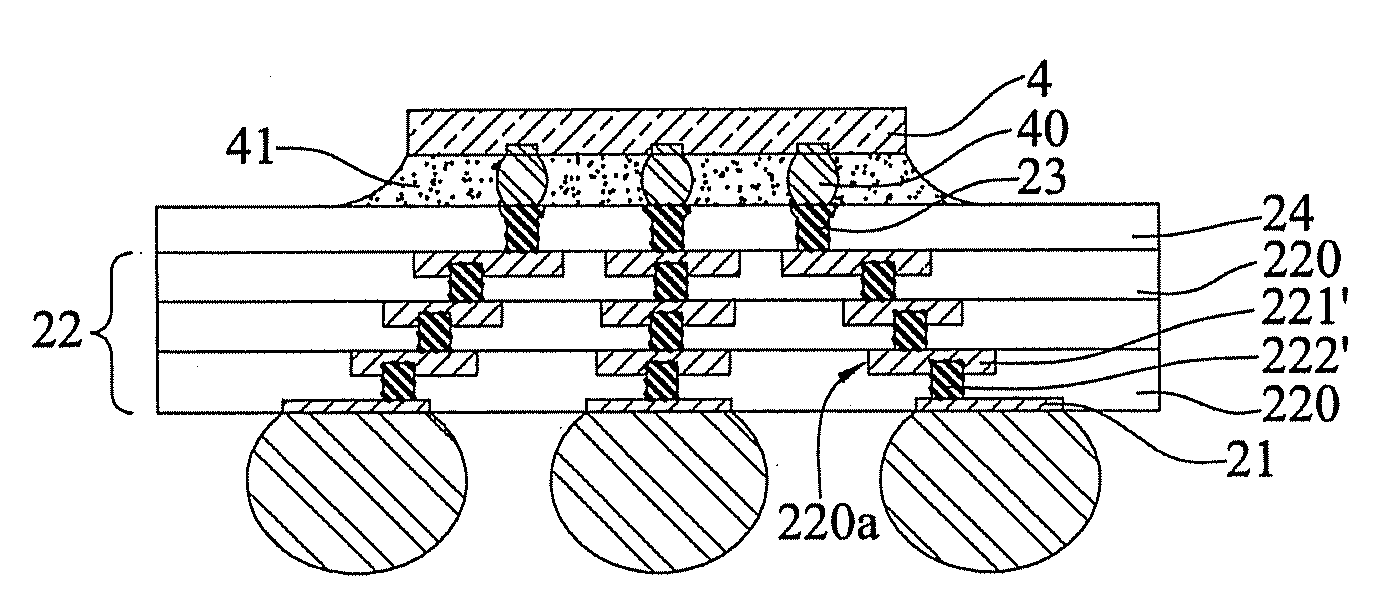

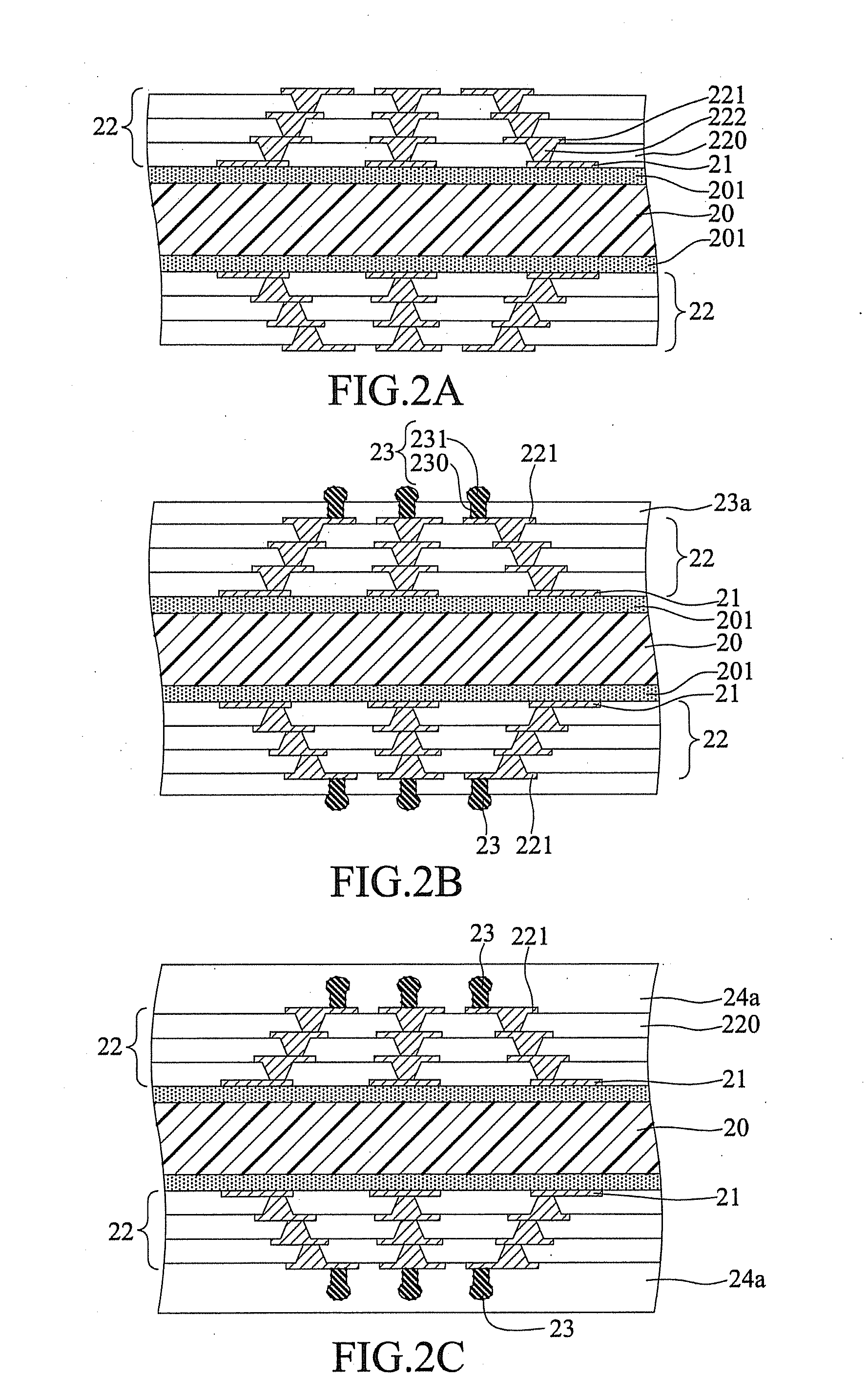

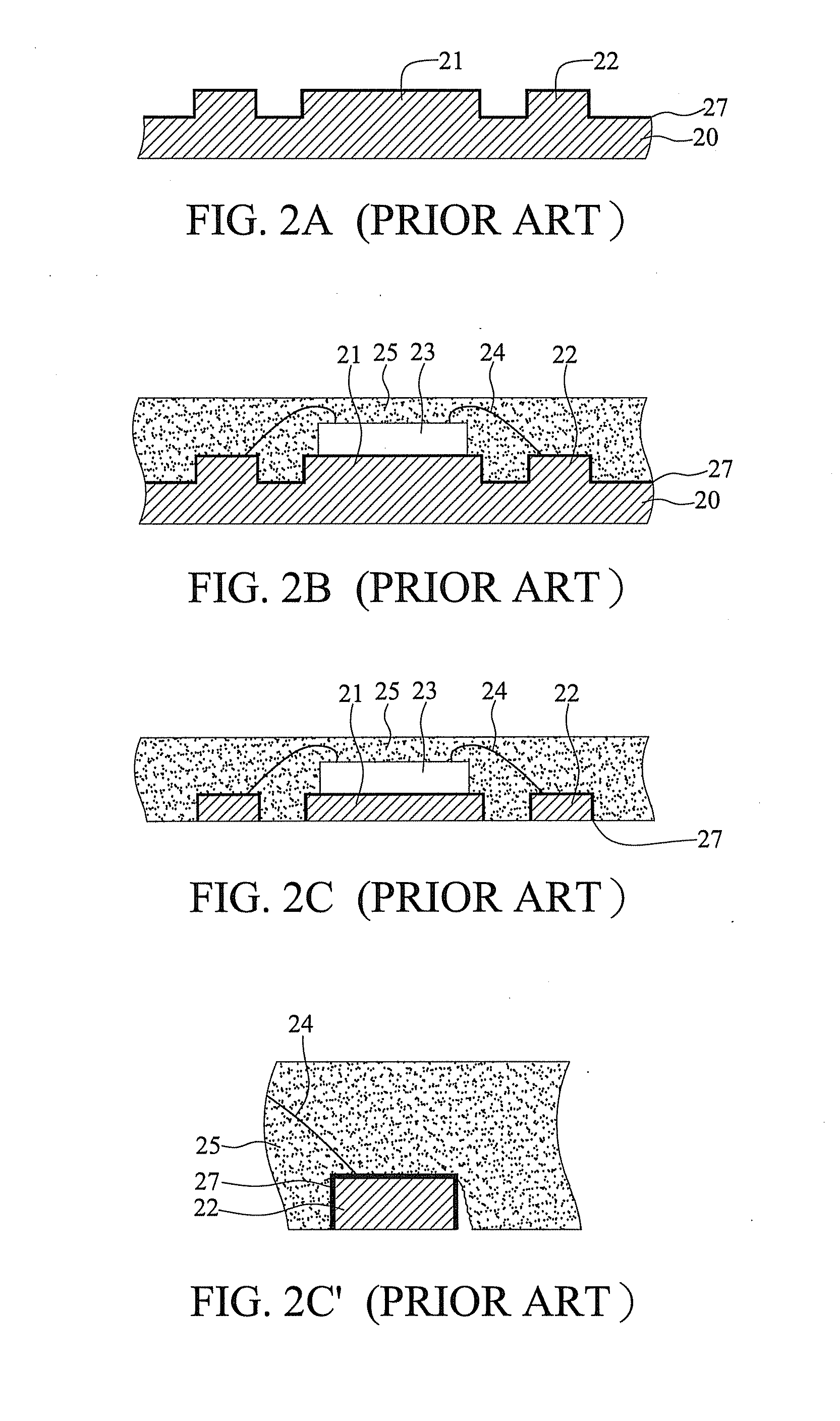

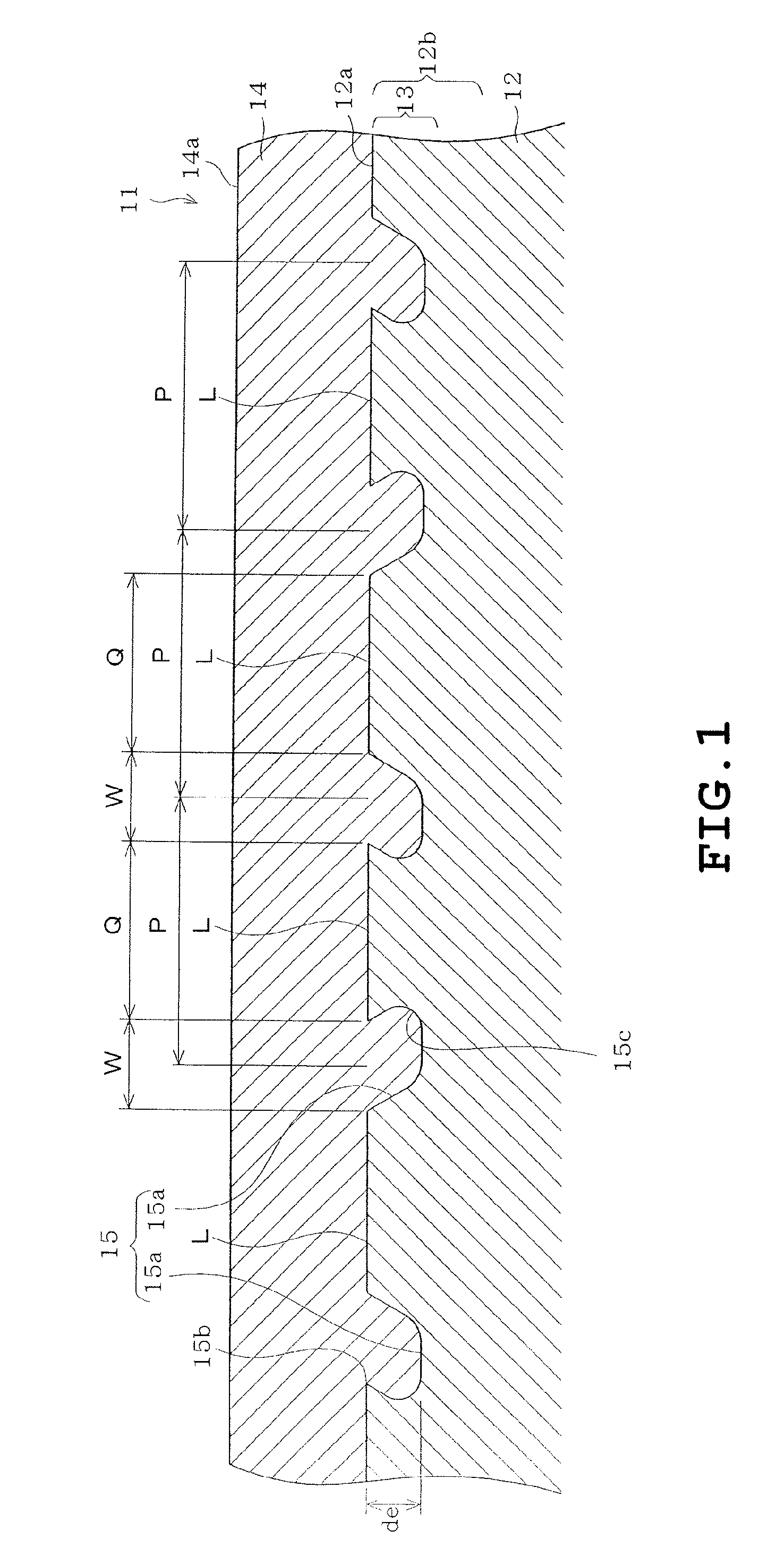

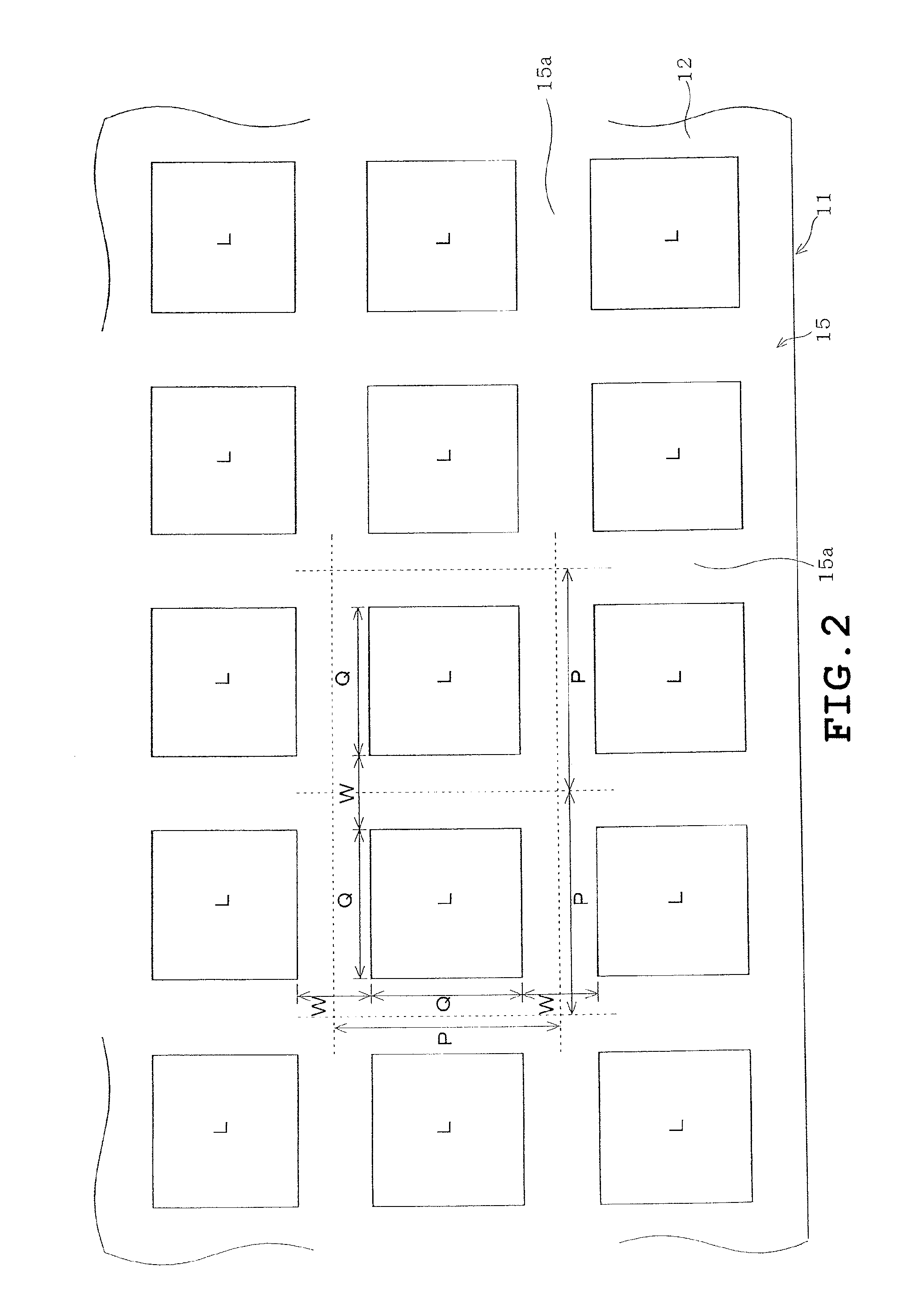

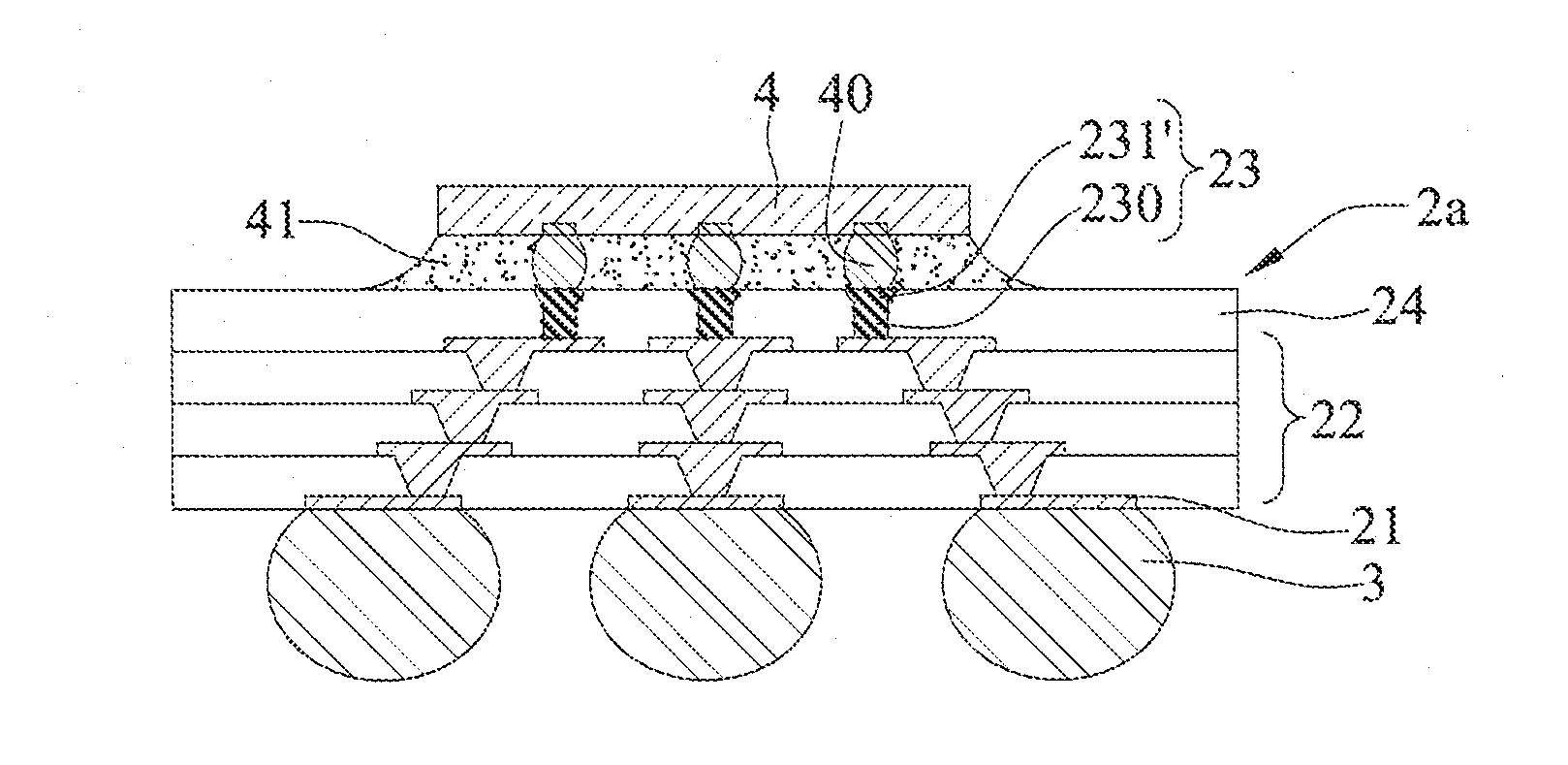

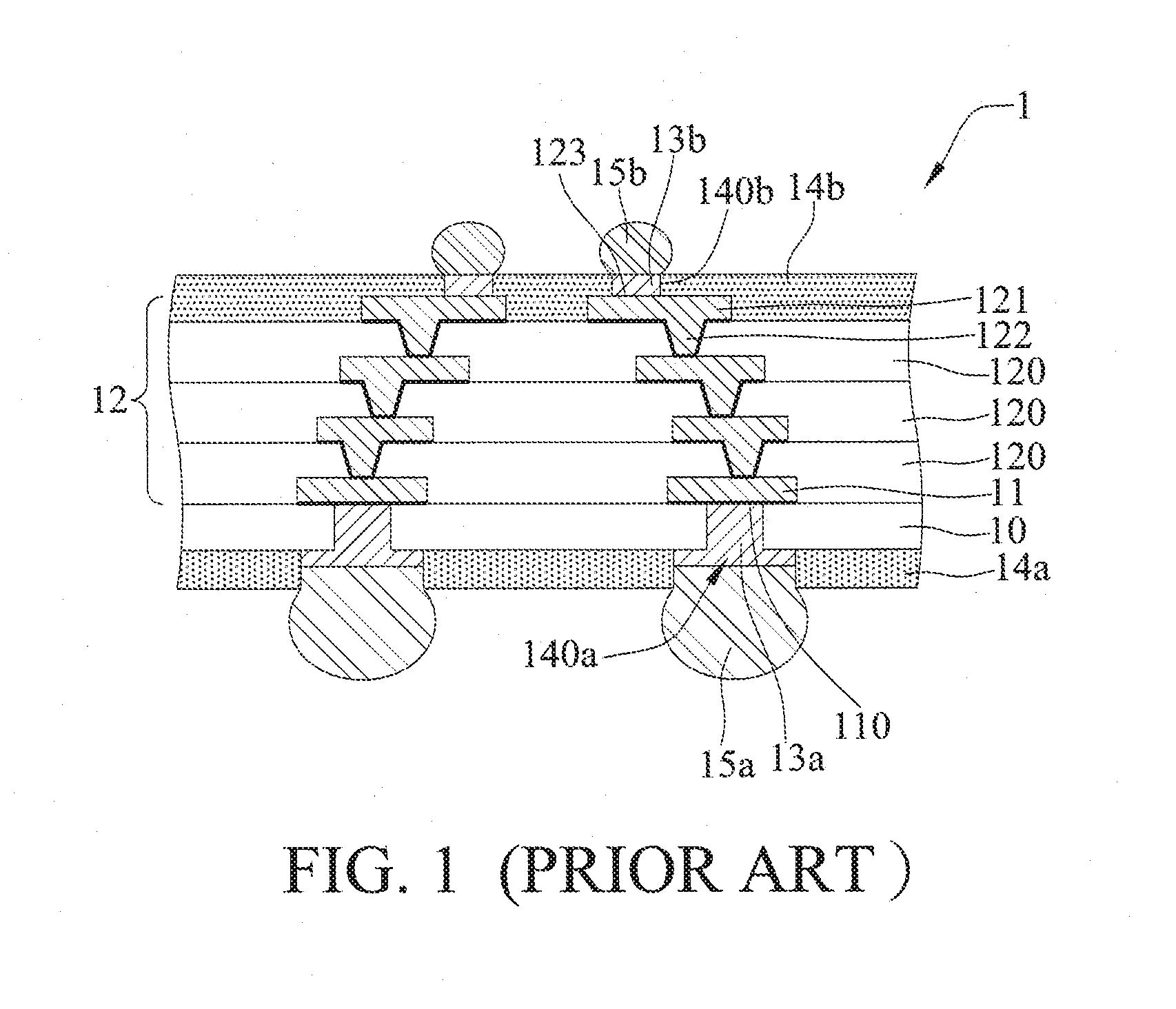

Coreless packaging substrate and method of fabricating the same

ActiveUS20130008706A1Easy to manufactureAvoid problemsSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipDielectric layer

A coreless packaging substrate is provided which includes: a circuit buildup structure having at least a dielectric layer, at least a wiring layer and a plurality of conductive elements, a plurality of electrical pads embedded in the lowermost one of the at least a dielectric layer, a plurality of metal bumps formed on the uppermost one of the at least a wiring layer, and a dielectric passivation layer formed on the surface of the uppermost one of the circuit buildup structure and the metal bumps, with the metal bumps exposed from the dielectric passivation layer. The metal bumps each have a metal column portion and a wing portion integrally connected to the metal column portion, such that the bonding force between the metal bumps and a semiconductor chip is enhanced by the entire top surface of the wing portions of the metal bumps being completely exposed.

Owner:UNIMICRON TECH CORP

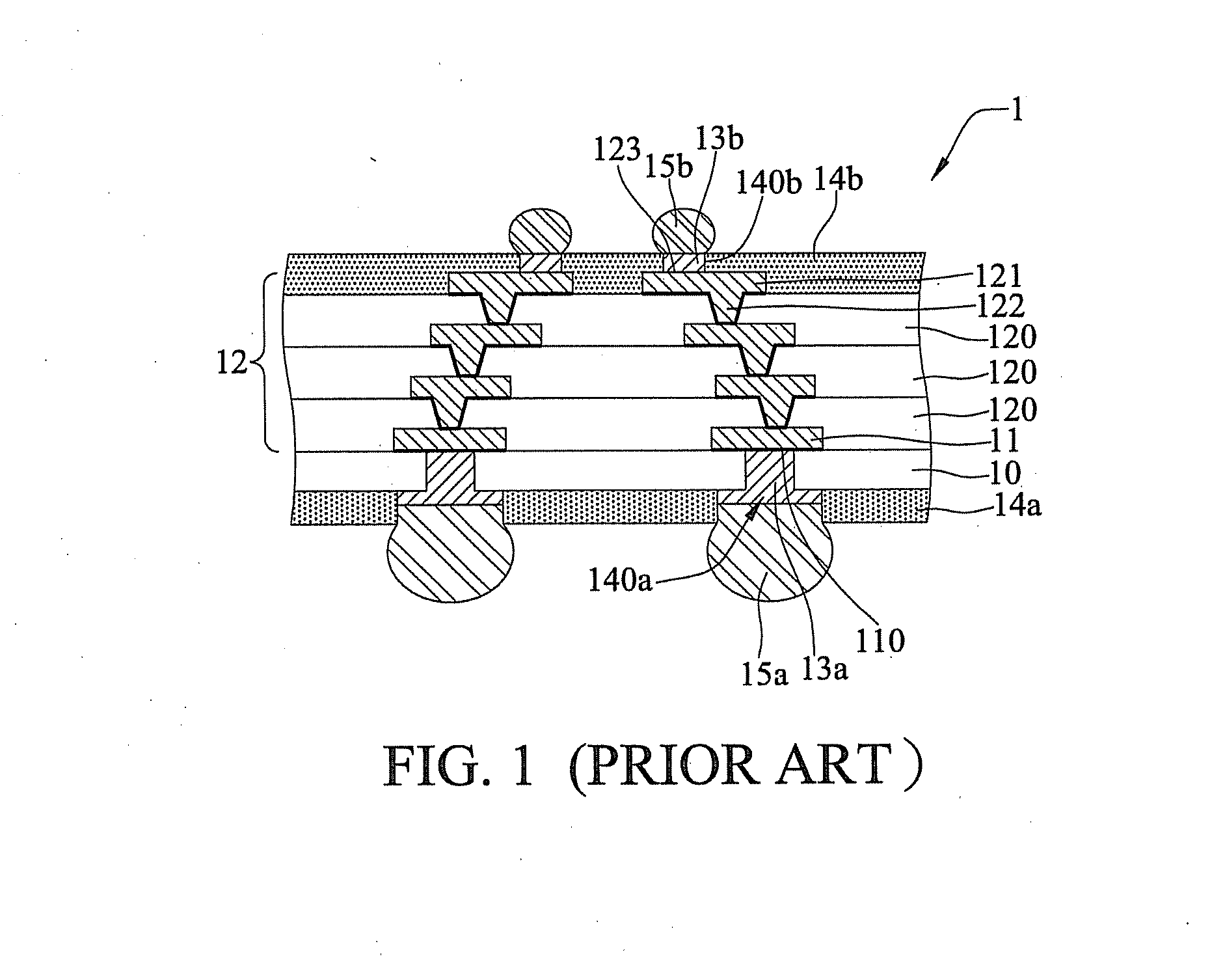

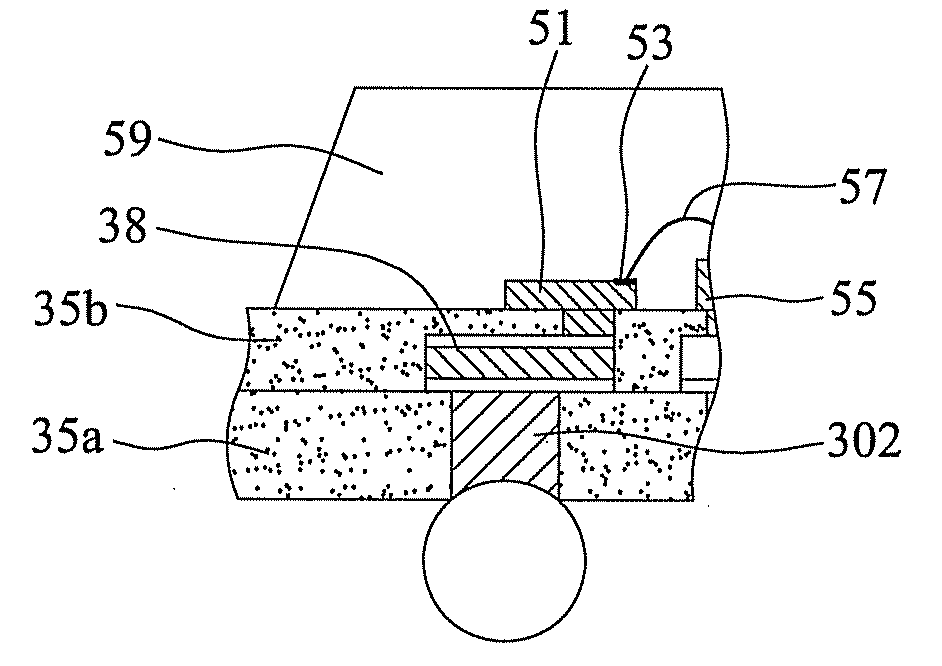

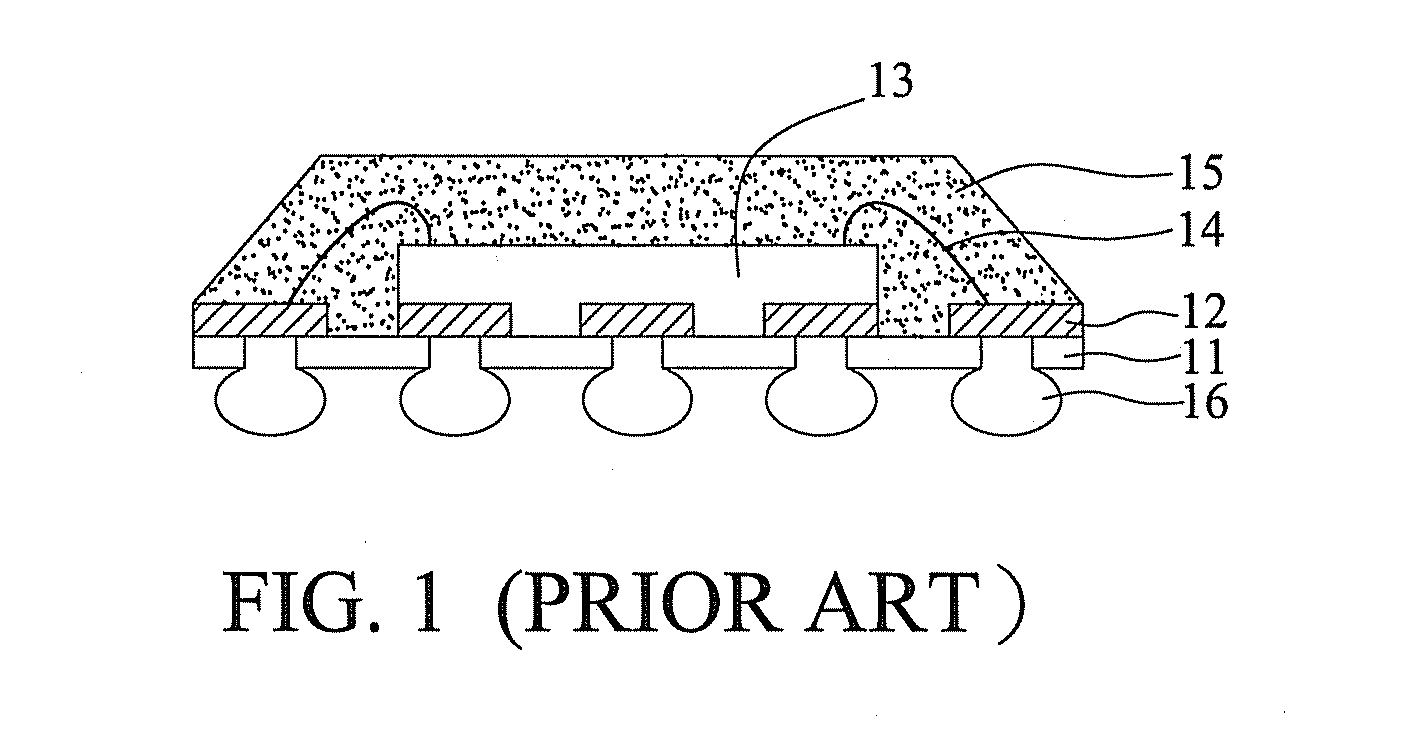

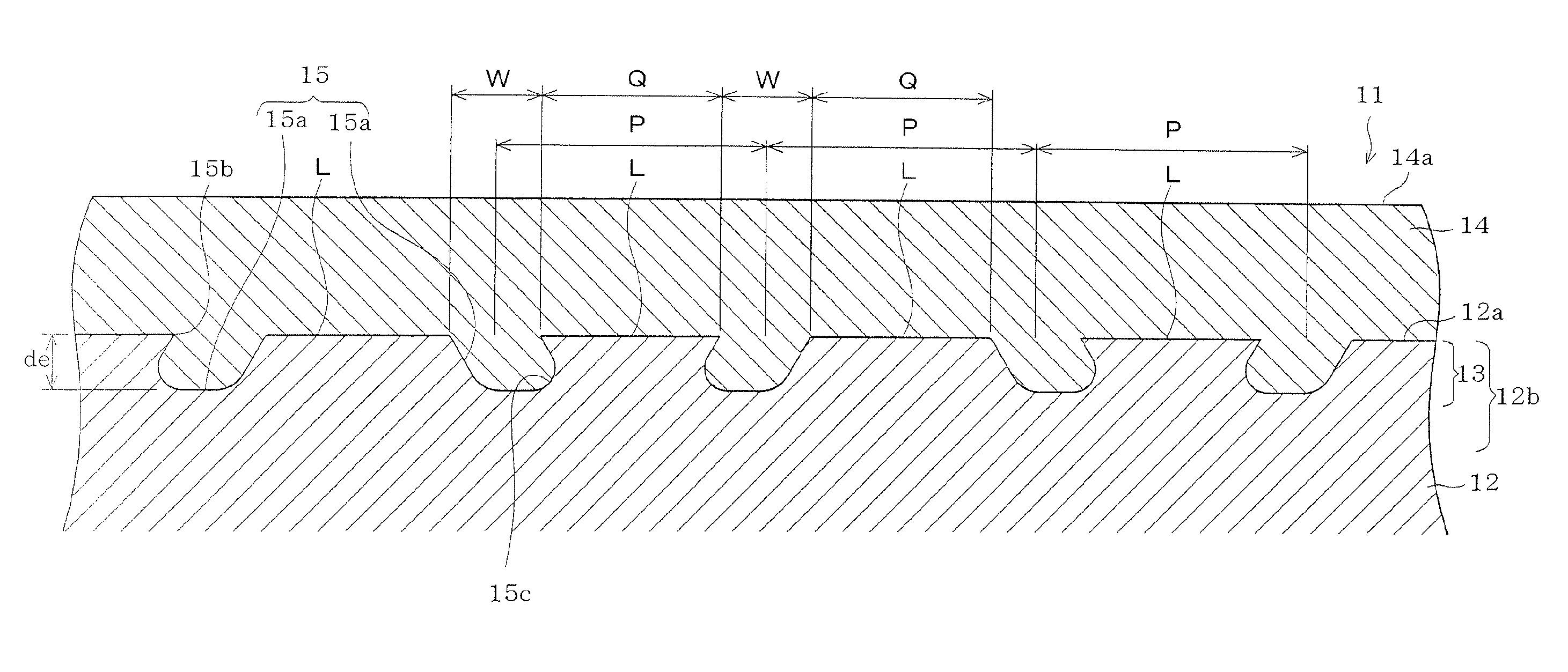

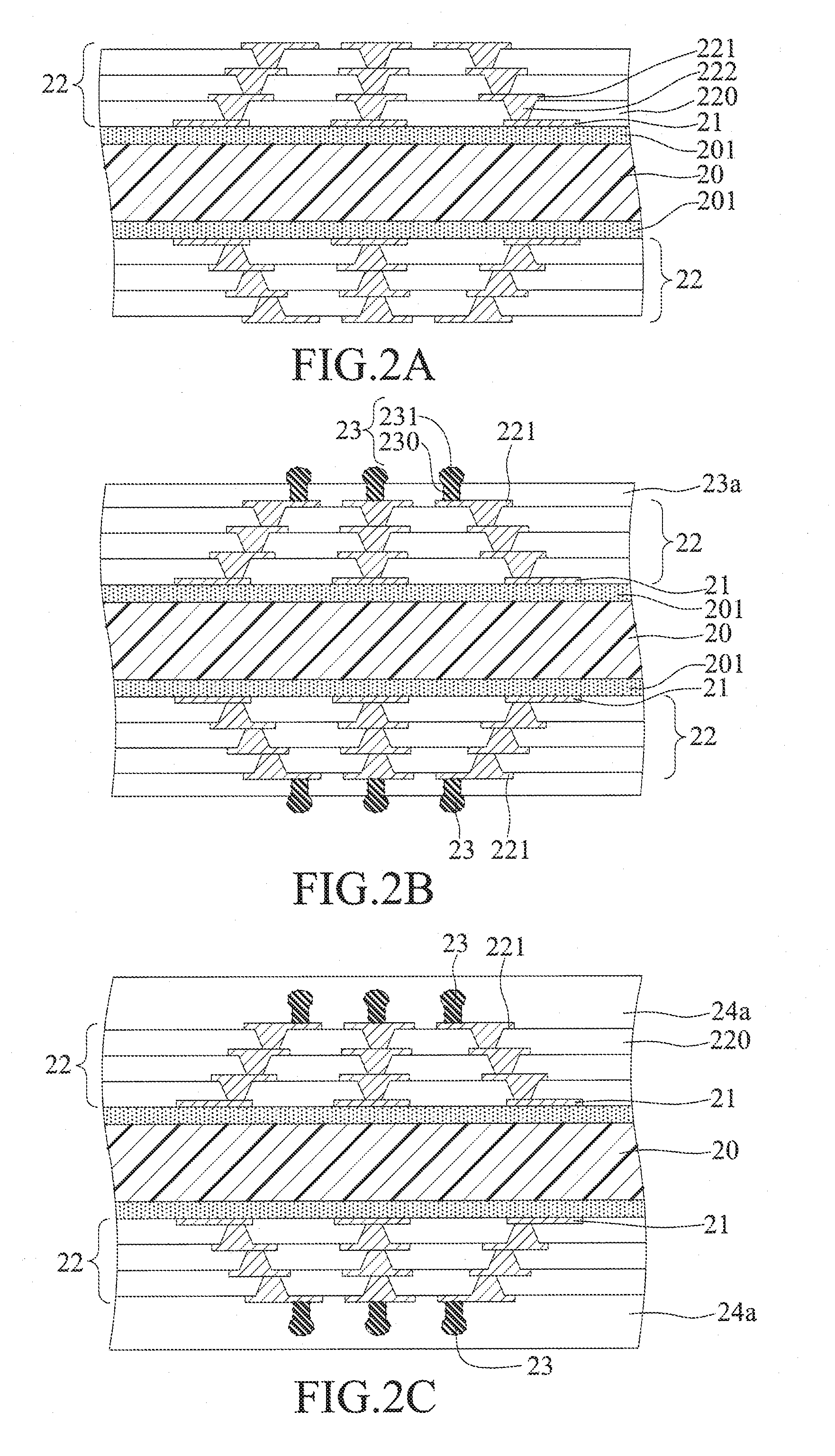

Semiconductor package without chip carrier and fabrication method thereof

ActiveUS20120007234A1Reduce manufacturing costAvoid layeringSemiconductor/solid-state device detailsSolid-state devicesResistLead bonding

A semiconductor package without a chip carrier formed thereon and a fabrication method thereof. A metallic carrier is half-etched to form a plurality of grooves and metal studs corresponding to the grooves. The grooves are filled with a first encapsulant and a plurality of bonding pads are formed on the metal studs. The first encapsulant is bonded with the metal studs directly. Each of the bonding pads and one of the metal studs corresponding to the bonding pad form a T-shaped structure. Therefore, bonding force between the metal studs and the first encapsulant is enhanced such that delamination is avoided. Die mounting, wire-bonding and molding processes are performed subsequently. Since the half-etched grooves are filled with the first encapsulant, the drawback of having pliable metallic carrier that makes transportation difficult to carry out as encountered in prior techniques is overcome, and the manufacturing cost is educed by not requiring the use of costly metals as an etching resist layer.

Owner:SILICONWARE PRECISION IND CO LTD

Optic film and backlight module using same

InactiveUS20100046249A1Improve performanceImprove rigidityAircraft componentsMechanical apparatusComputer moduleOptical thin film

Owner:GAMMA OPTICAL +1

Sliding member and method of manufacturing same

InactiveUS20130023451A1Bonding forceImprove the bonding force between layersShaftsBearing componentsMetalComposite material

A slide member provided with a base, an impregnated layer, and a resin layer. The base made of metal or ceramic. The impregnated layer is defined on a surface portion of a sliding side of the base by forming a recess on the base. The resin layer impregnates the impregnated layer so as to cover a sliding side surface of the base.

Owner:DAIDO METAL CO LTD

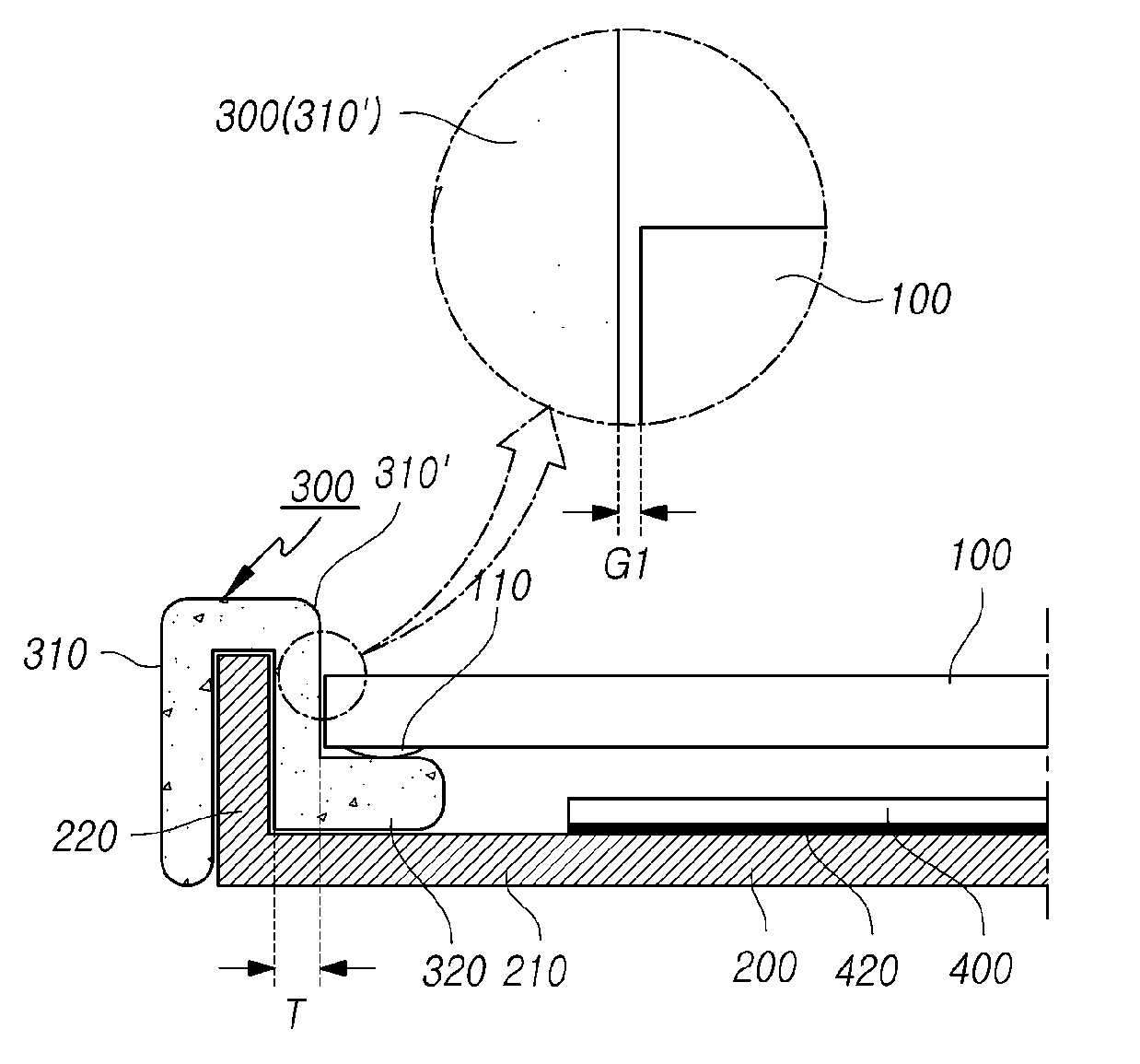

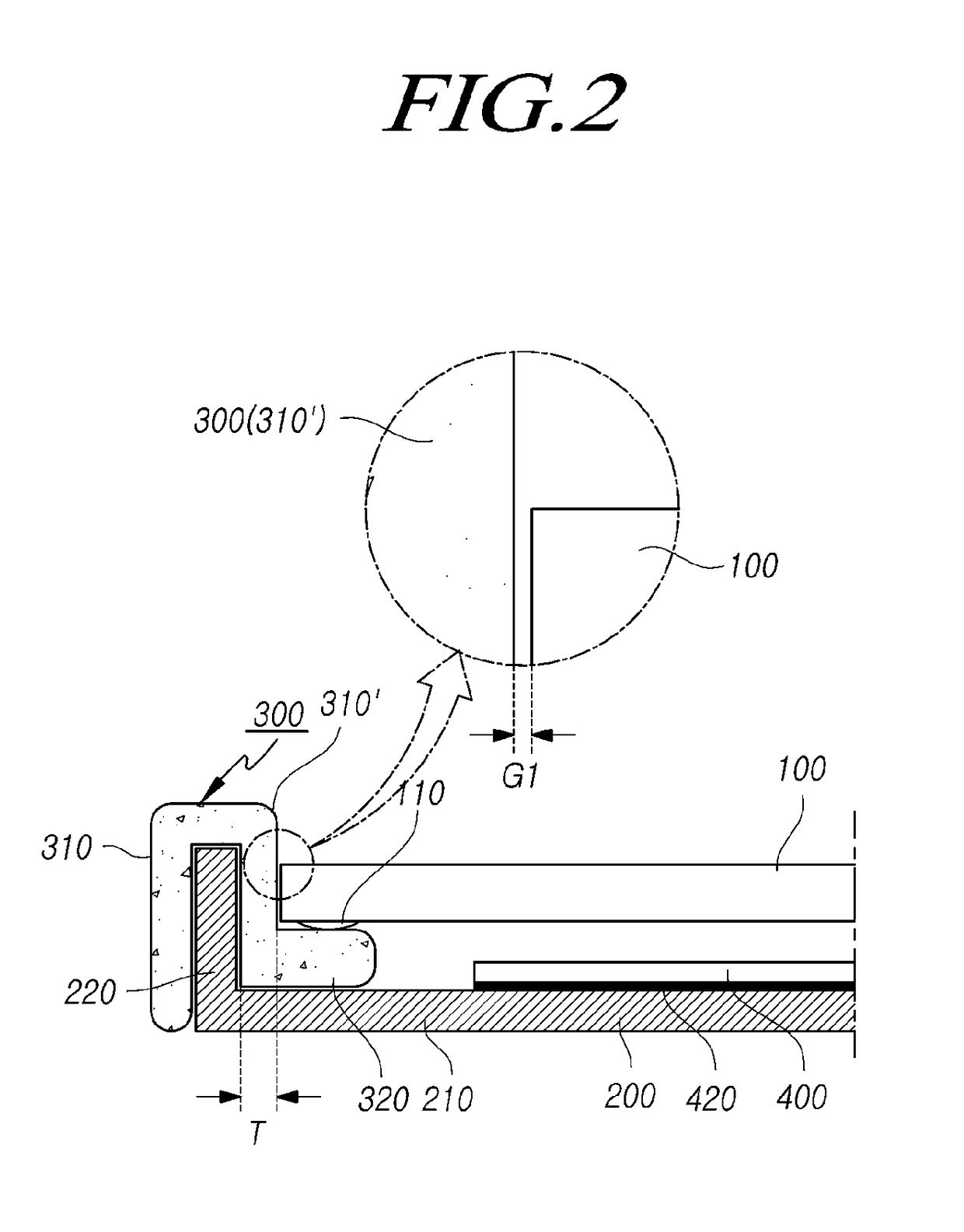

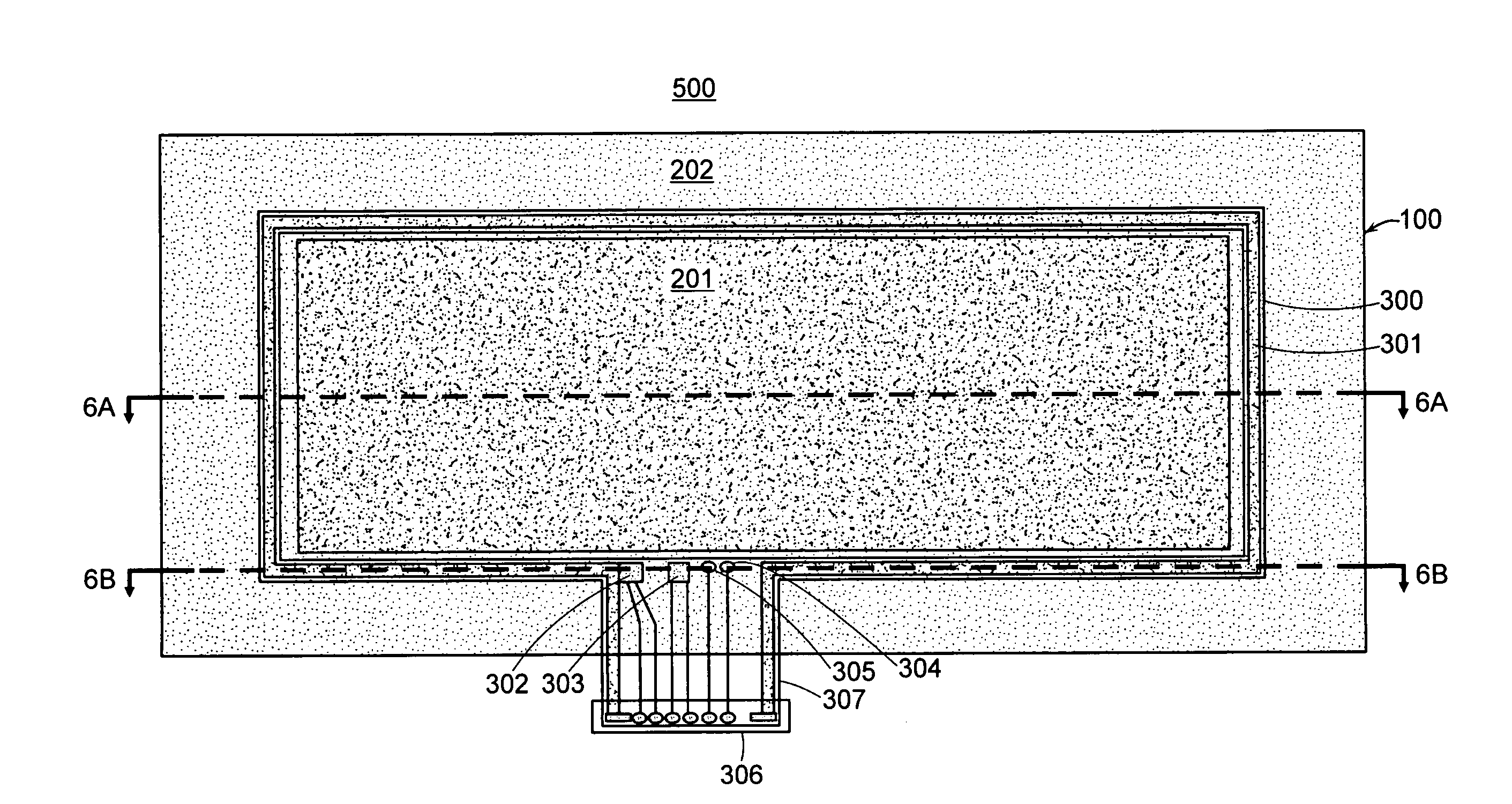

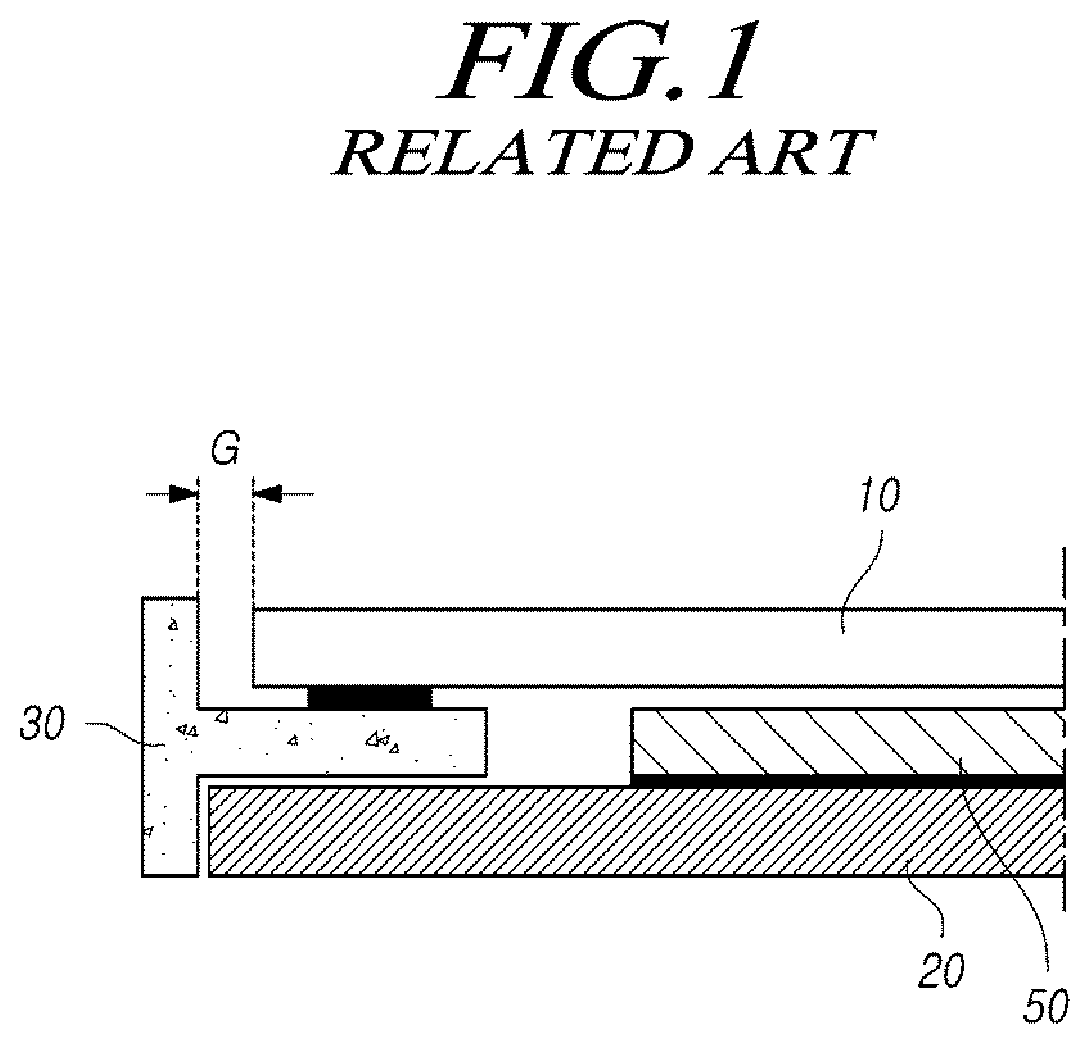

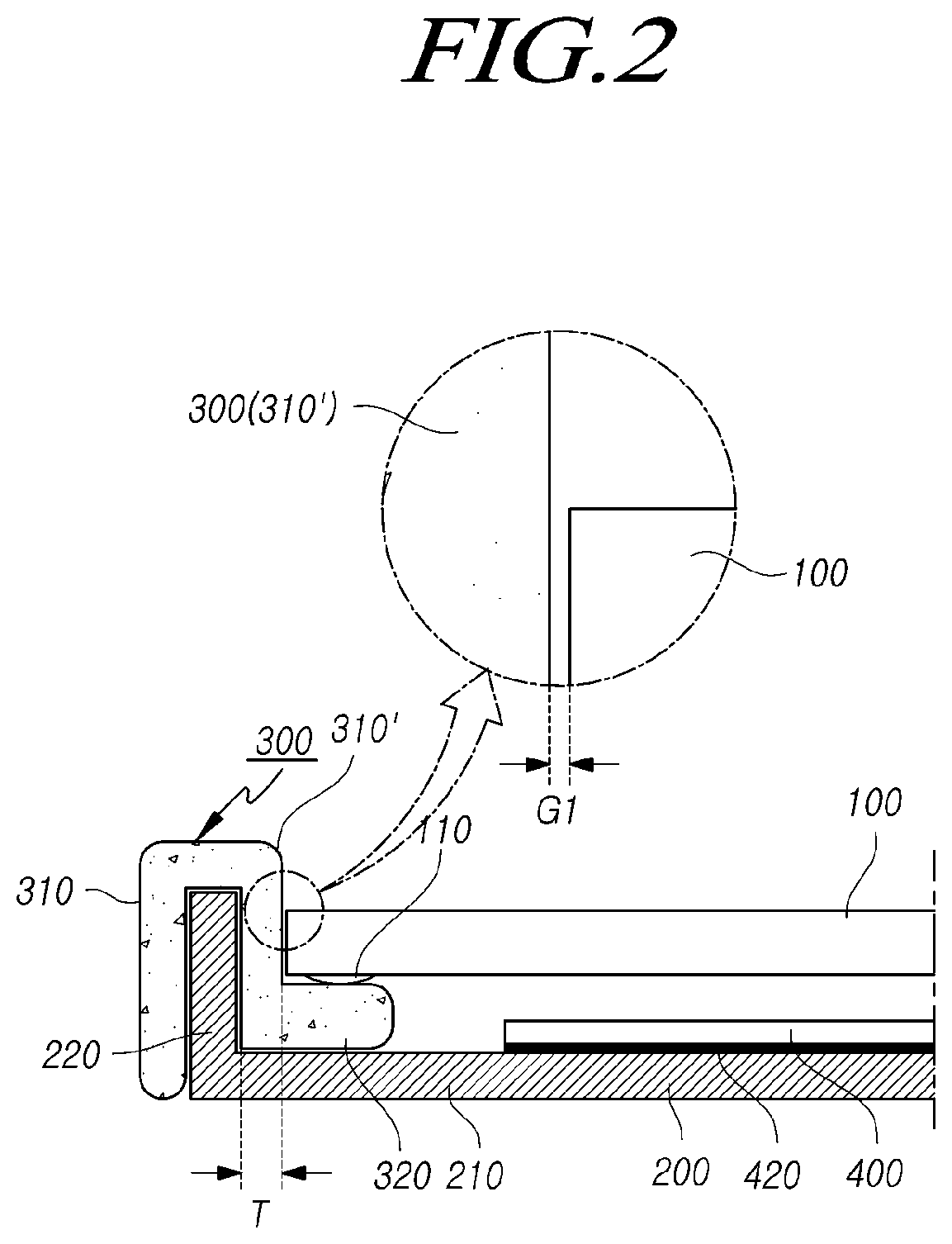

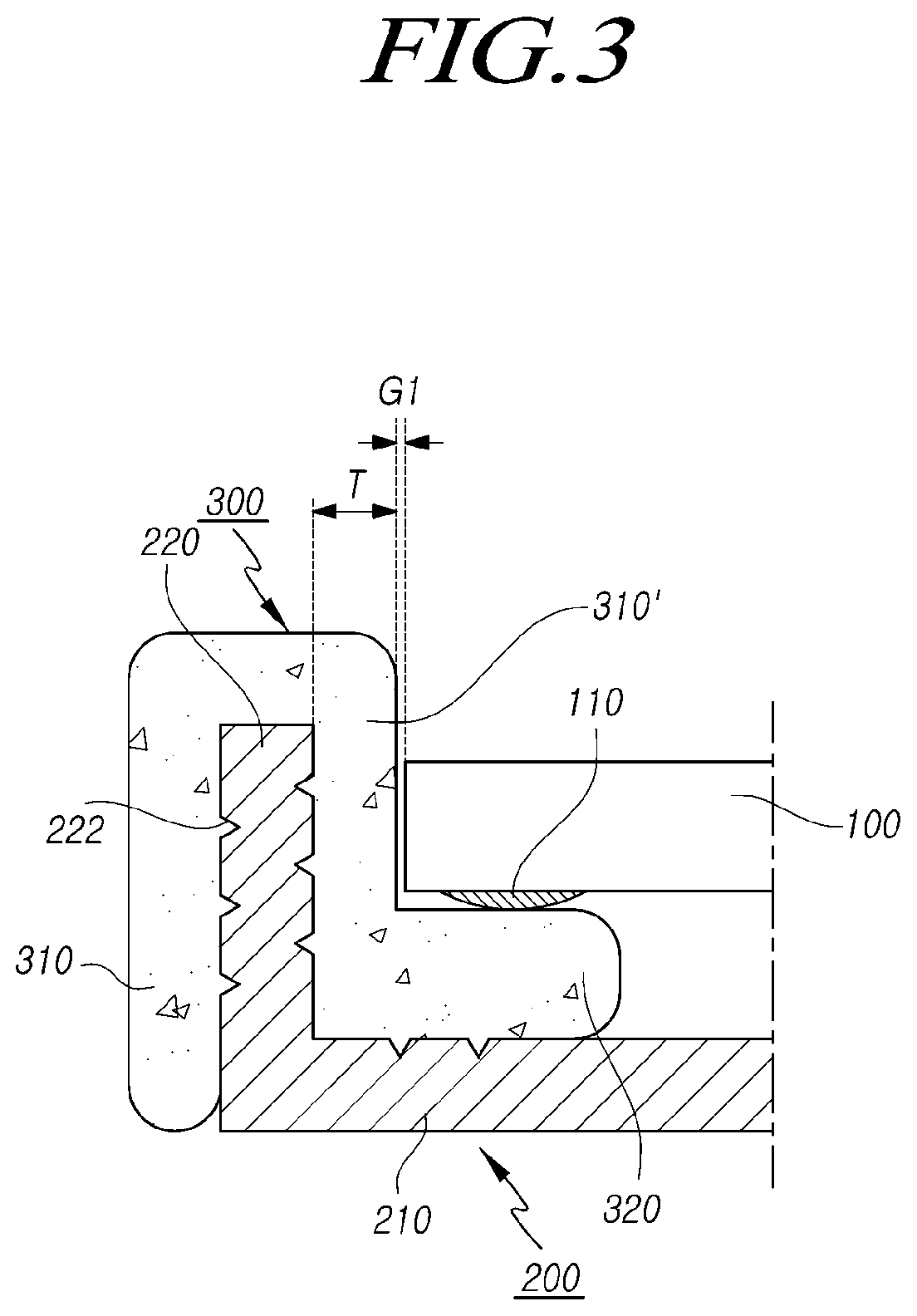

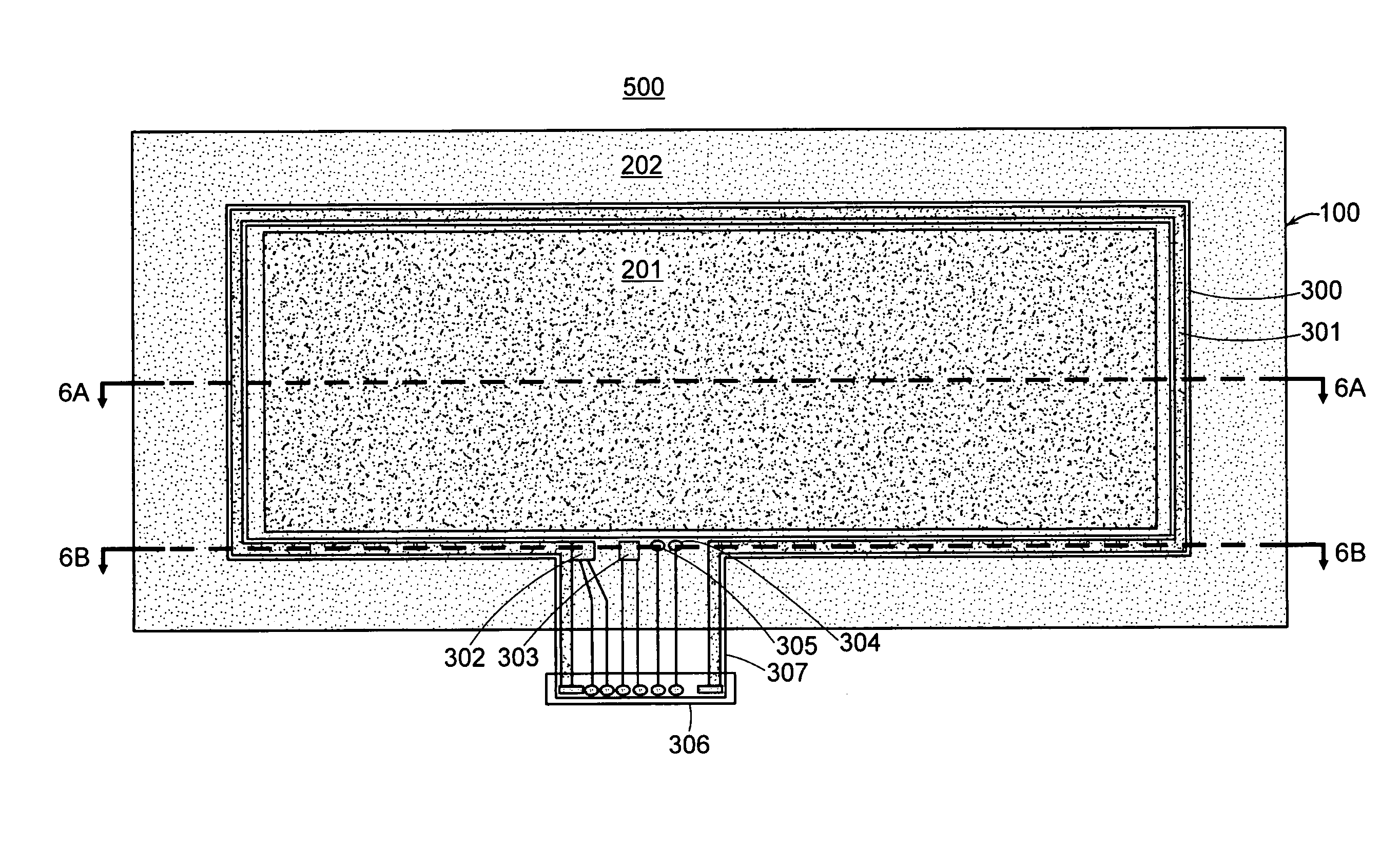

Display device

ActiveUS20170344053A1Prevent penetrationBonding forceDigital data processing detailsCasings/cabinets/drawers detailsForeign matterDisplay device

Disclosed aspects relate to a display device. By forming a back cover, which is the support structure constituting the display device, in a bent structure and forming a molding part made of an elastic material to enclose the vertical extension portion, a border gap, which is a clearance between the side surfaces of the display panel and the side surface support structure, can be minimized to maintain an excellent external appearance of the display device, and to prevent infiltration of foreign matter and damage of the display panel, which may be caused by the gap between the display panel and the support structure. By disposing a metal inner plate on the inner surface of the horizontal portion of the back cover, the rigidity of the back cover can be increased, the thickness of the back cover can be decreased, and heat generated from the display panel and the like can be smoothly dissipated.

Owner:LG DISPLAY CO LTD

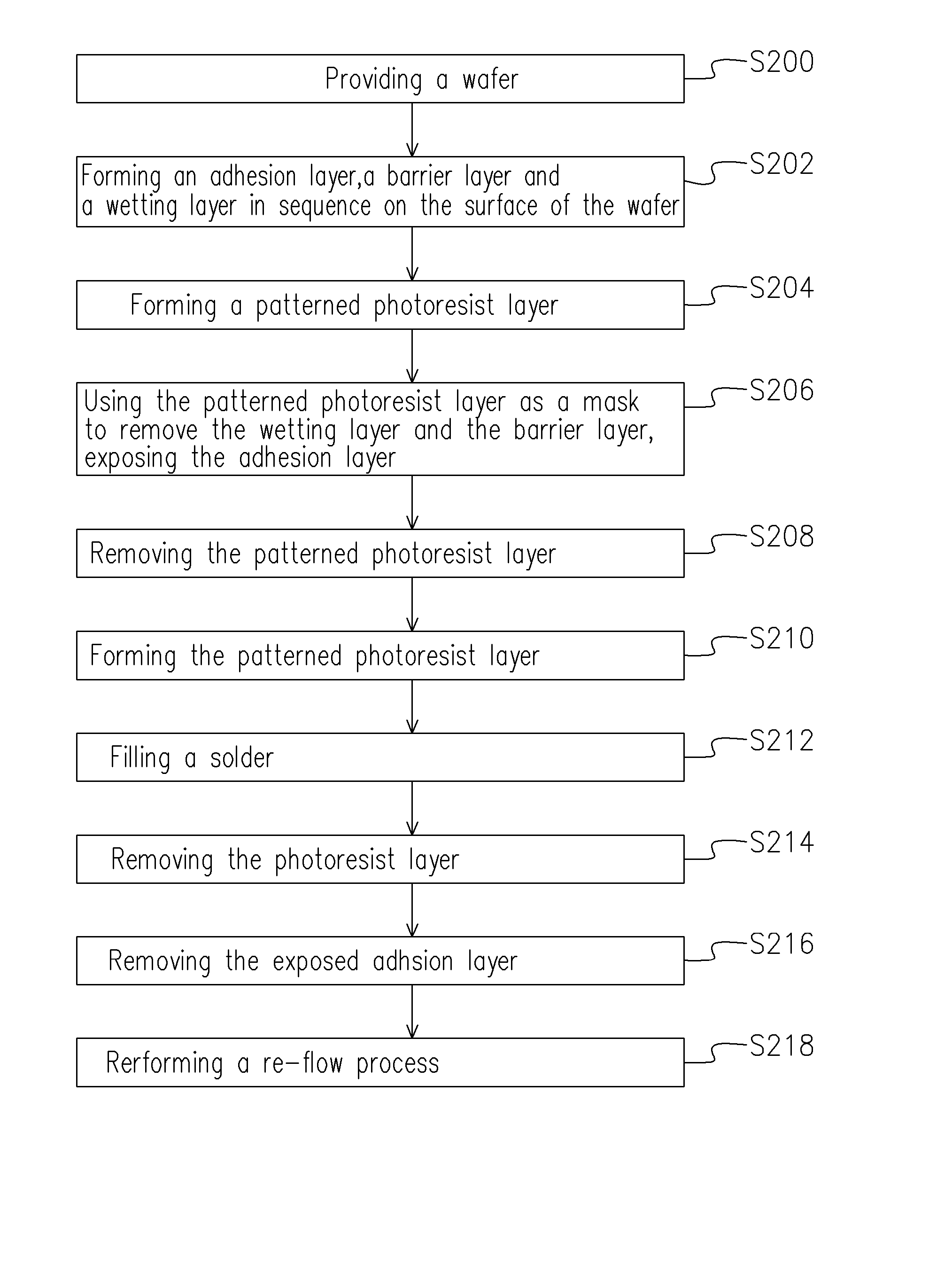

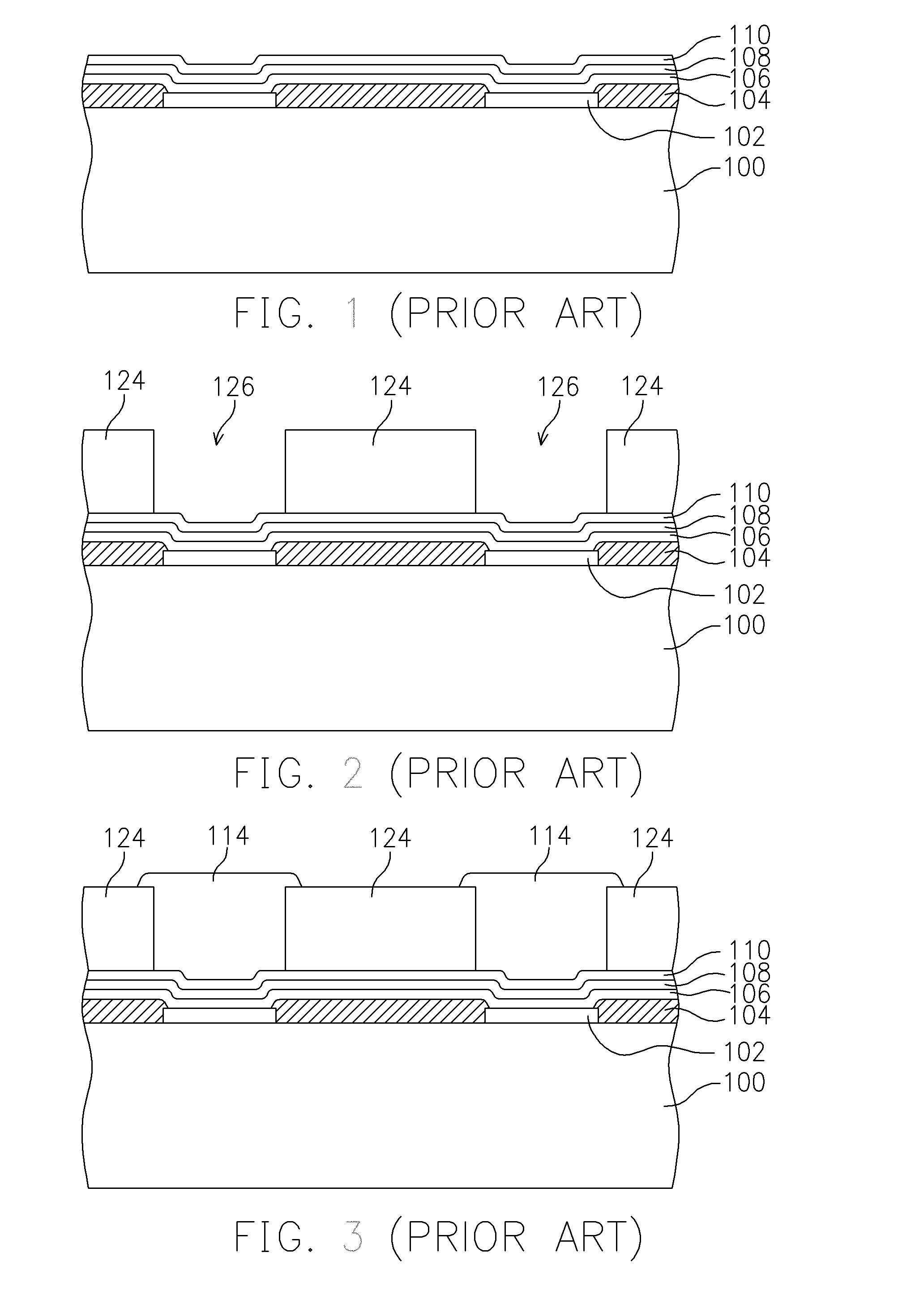

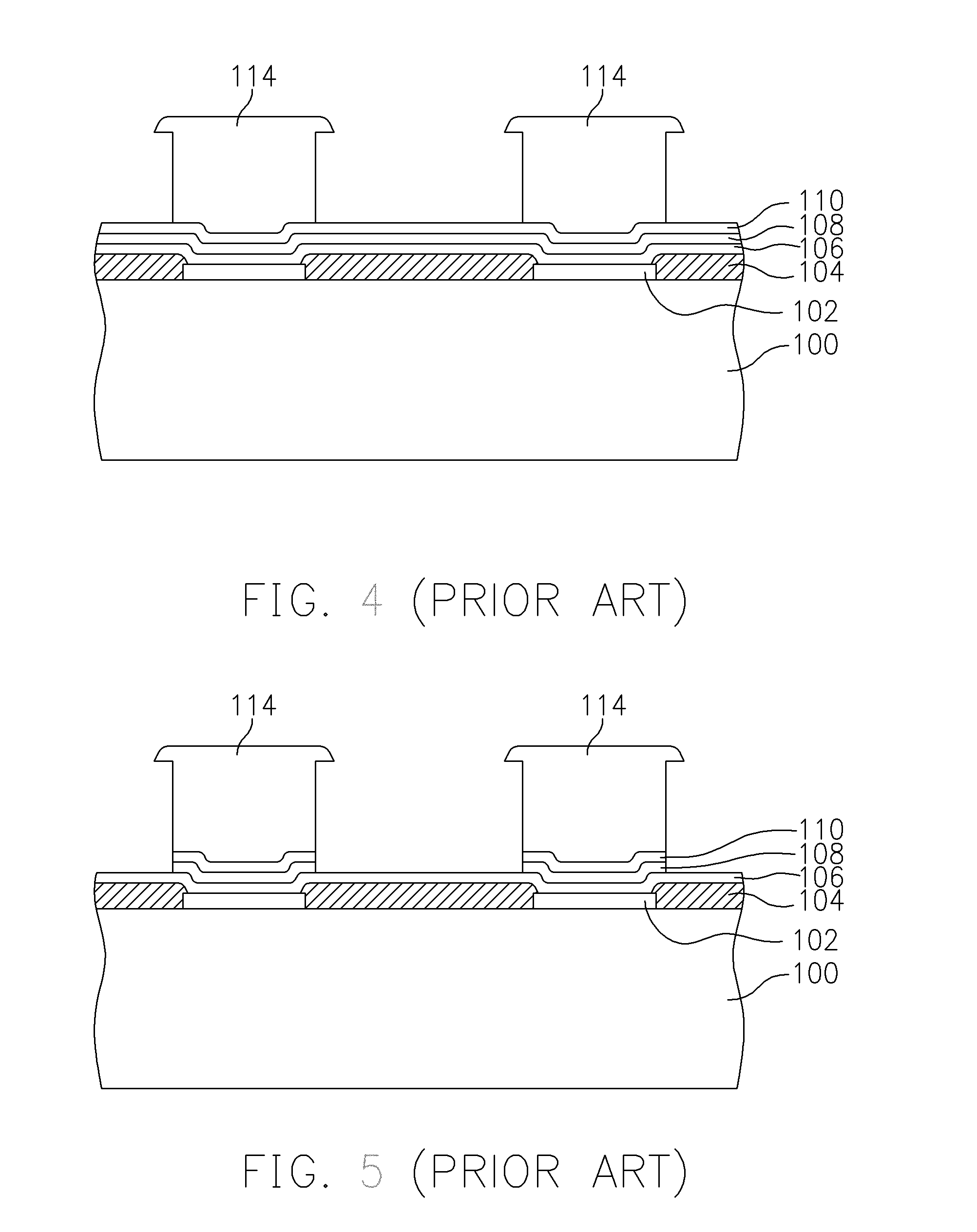

Bump fabrication method

InactiveUS20030129821A1Improve reliabilityMaintain volumeSolid-state devicesSemiconductor/solid-state device manufacturingPresent methodMetallurgy

Abstract of Disclosure A method of fabricating bumps is disclosed. In the present method, prior to forming solder layer pattern, the wetting layer and the barrier layer are removed, and after a solder layer pattern is formed, only the exposed adhesion layer is removed. The method can avoide etching the solder layer pattern in the course of etching the solder layer and the barrier layer, and therefore the volume of the required solder layer pattern can be maintained. Thus, the height of the bump after the re-flow process is maintained at an appropriate range and the required bonding force between the bump and the under ball metallurgy layer pattern can be maintained so as to improve the reliability.

Owner:ADVANCED SEMICON ENG INC

Iron-based soft magnetic powder for dust core, method for manufacturing the same, and dust core

InactiveUS20100212455A1High magnetic flux densityMechanical strengthMetal-working apparatusPretreated surfacesReflectance spectroscopyVolumetric Mass Density

An iron-based soft magnetic powder for dust core having a high magnetic flux density, maintaining high electric insulation even after annealing, and more excellent in the mechanical strength in which a coating film having a phosphate conversion coating film is formed on the surface thereof and the peak height for the absorption of hydroxyl groups formed at 3700 cm−1 to 2500 cm−1 is 0.04 or more being indicated by absorbance when the coating film is analyzed by infrared diffuse reflectance spectroscopy.

Owner:KOBE STEEL LTD

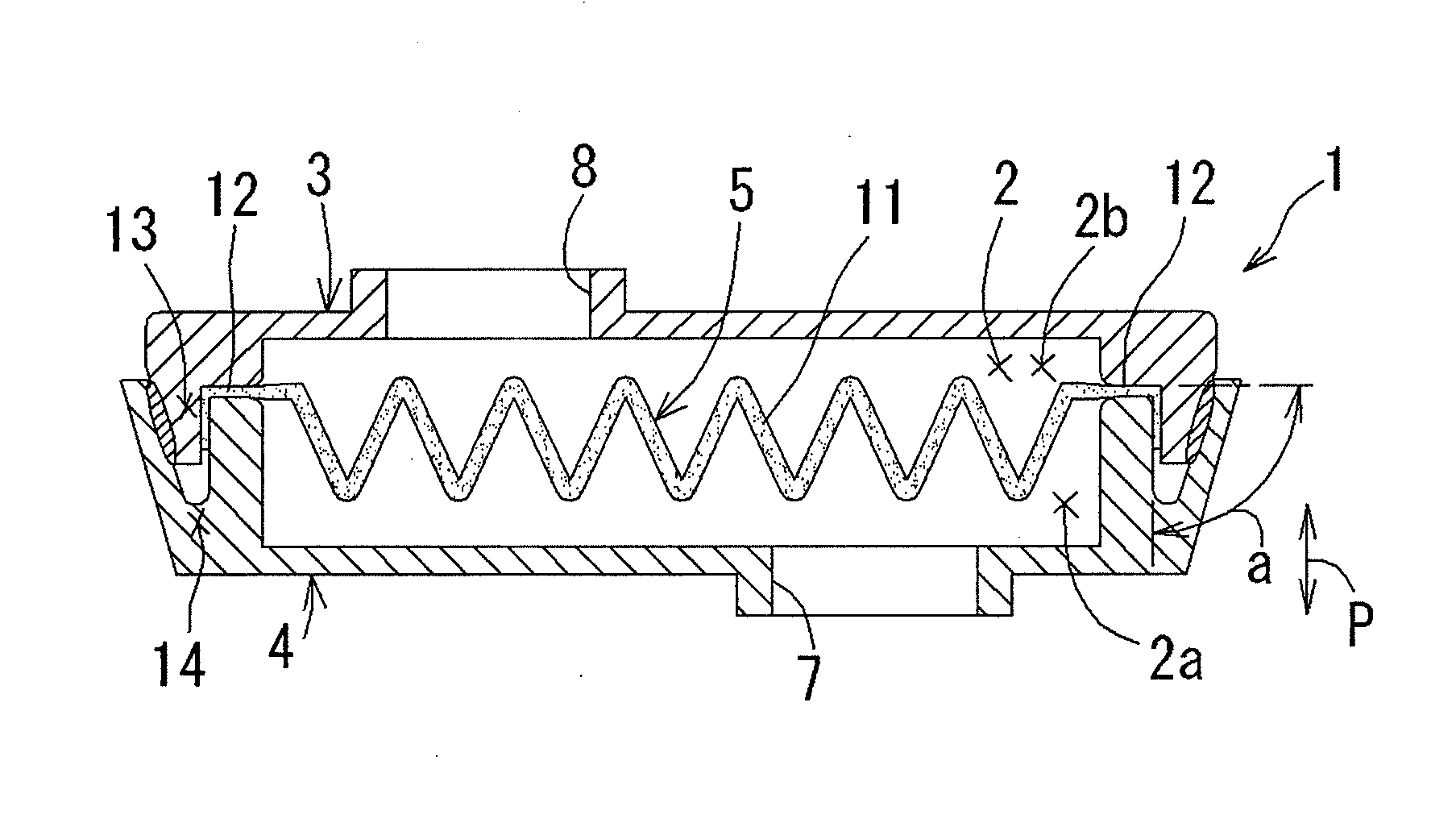

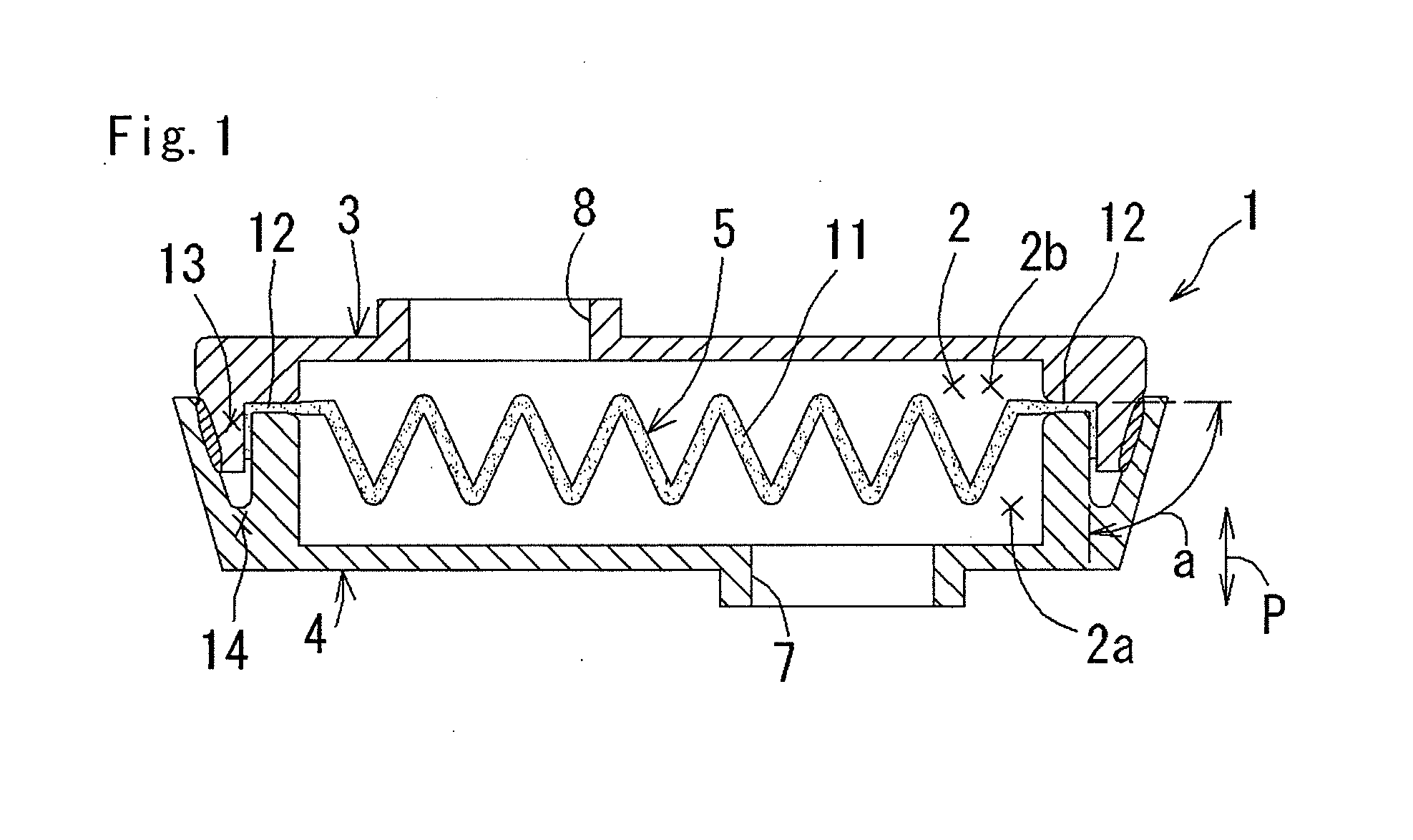

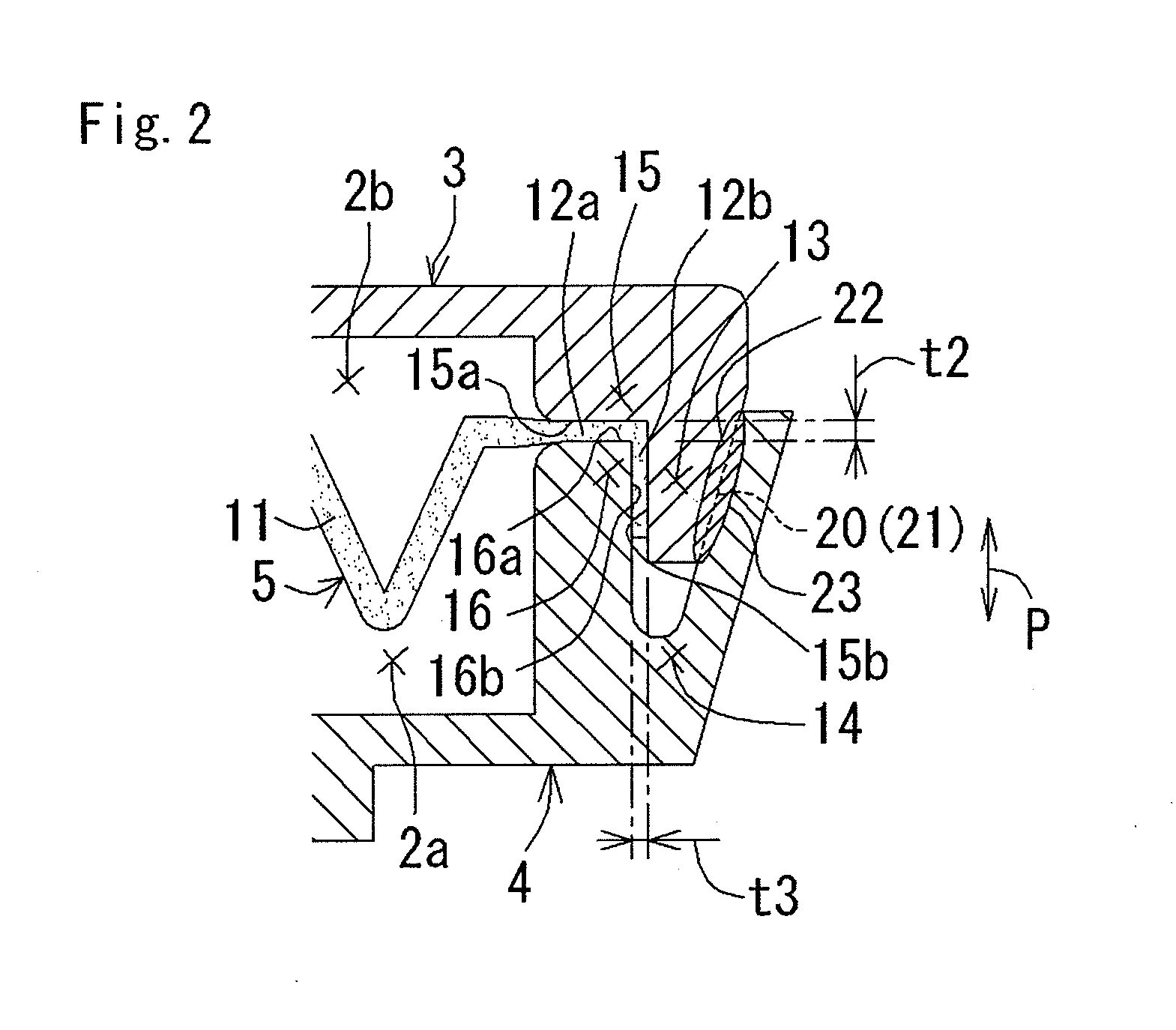

Filter and manufacturing method therefor

InactiveUS20080169235A1Inexpensive and simply structuredImprove mechanical bondingGear lubrication/coolingCartridge filtersFilter mediaEngineering

The filter 1 includes a first case member (an upper case member), a second case member (a lower case member) that are mutually joined to form a filter chamber therebetween, and a filter medium with an end portion held between the first and second case members. The first and second case members include holding portions, respectively, for holding the end portion of the filter medium in a bent position and welded portions, respectively, which are spaced apart from the holding portions and are welded together by a laser beam. The holding portions include vertical press surfaces, respectively, for pressing an inner end portion of the filter medium in the joining direction between the case members. The holding portions also include lateral press surfaces and, respectively, for pressing an outer end portion of the filter medium in a direction intersecting the joining direction.

Owner:TOYOTA BOSHOKU KK

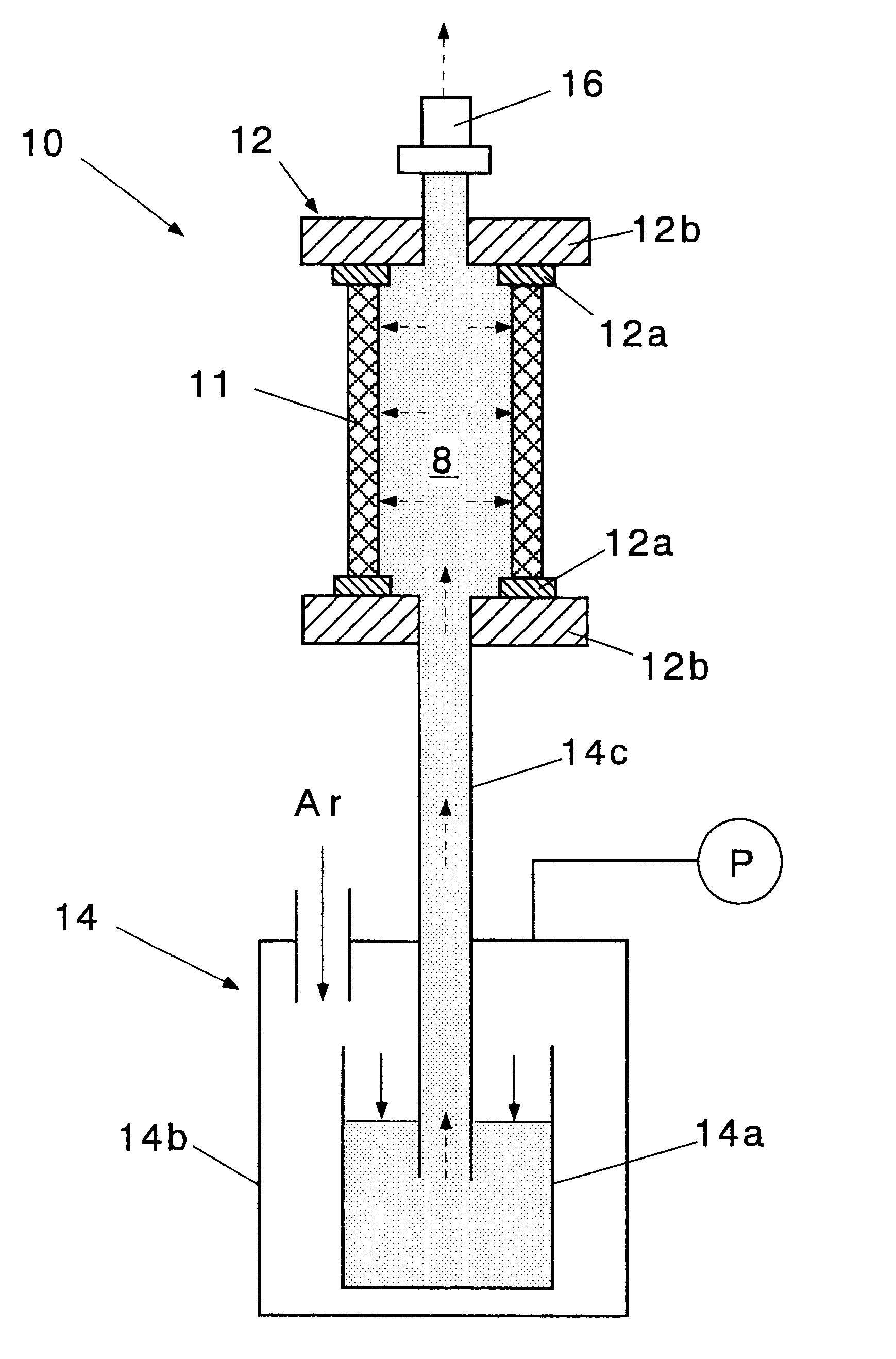

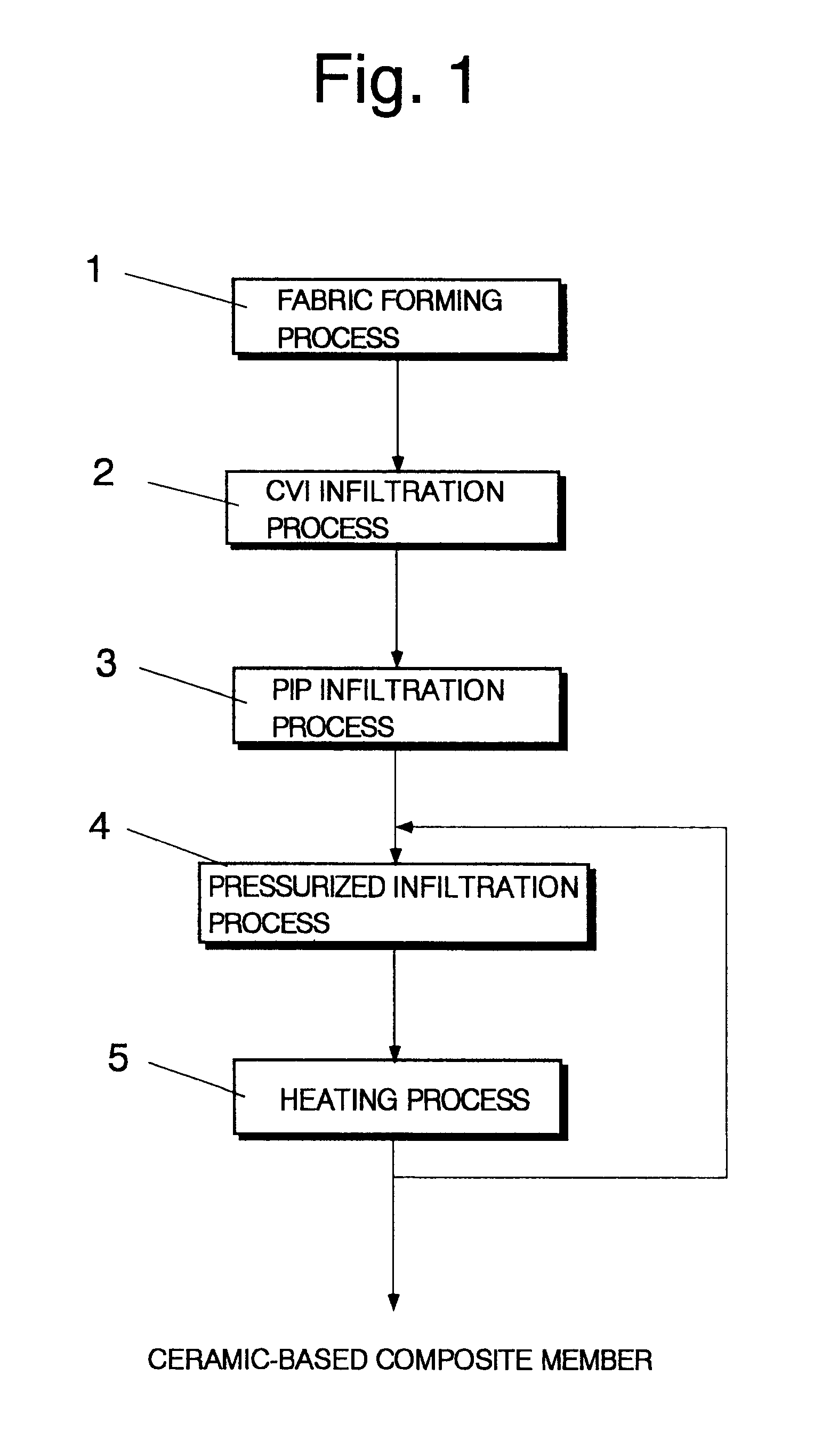

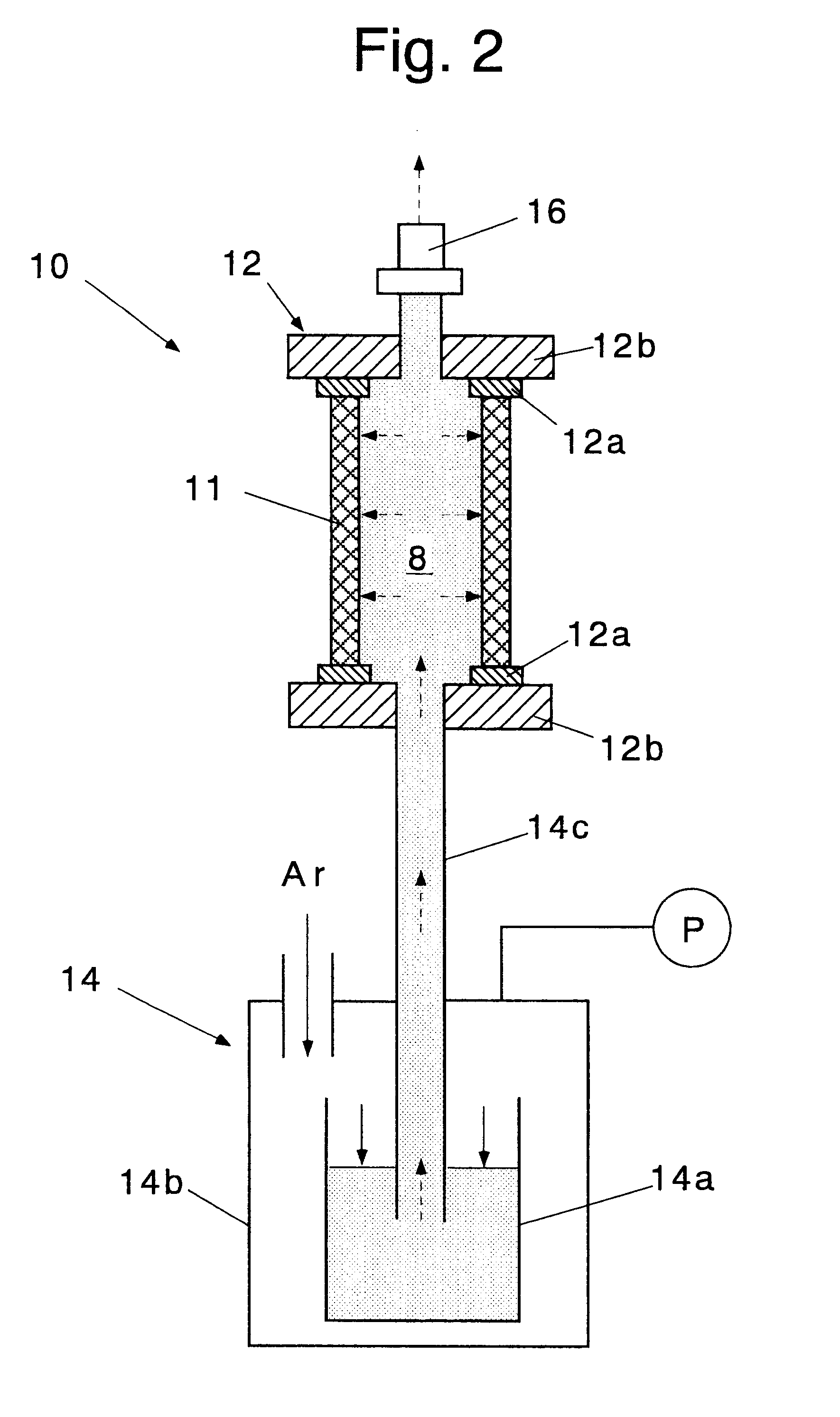

Method and apparatus for manufacturing ceramic-based composite member

InactiveUS6723381B1Improve air tightnessBonding forceFeeding arrangmentsSurface layering apparatusPolymer scienceCeramic matrix composite

An organic silicon polymer is infiltrated and charged into gaps in a matrix phase of a formed fiber fabric, and its airtightness is increased by (a) CVI infiltration process 2 for forming the SIC matrix phase on the surface of the fiber fabric formed, (b) pressurized infiltrations process 4 for pressurizing the organic silicon polymer in the direction operating pressure is applied to the fiber fabric during use and infiltrating the organic silicon polymer into gaps in the aforementioned matrix phase, and (c) heating process 5 for heating the infiltrated fiber fabric at a high temperature. Thus, airtightness can be increased quickly, and fired work can be applied practically even to thrust chambers etc.

Owner:IHI CORP

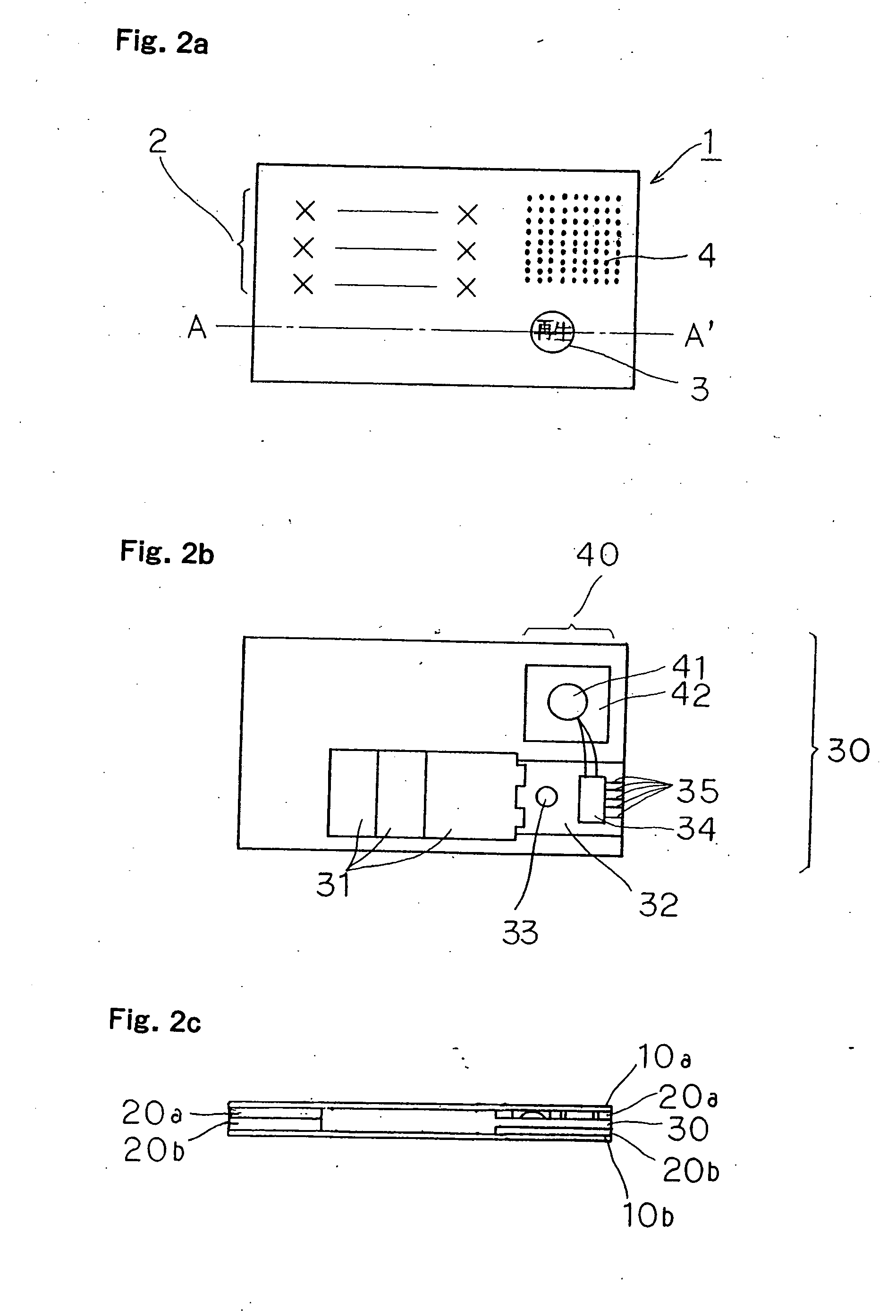

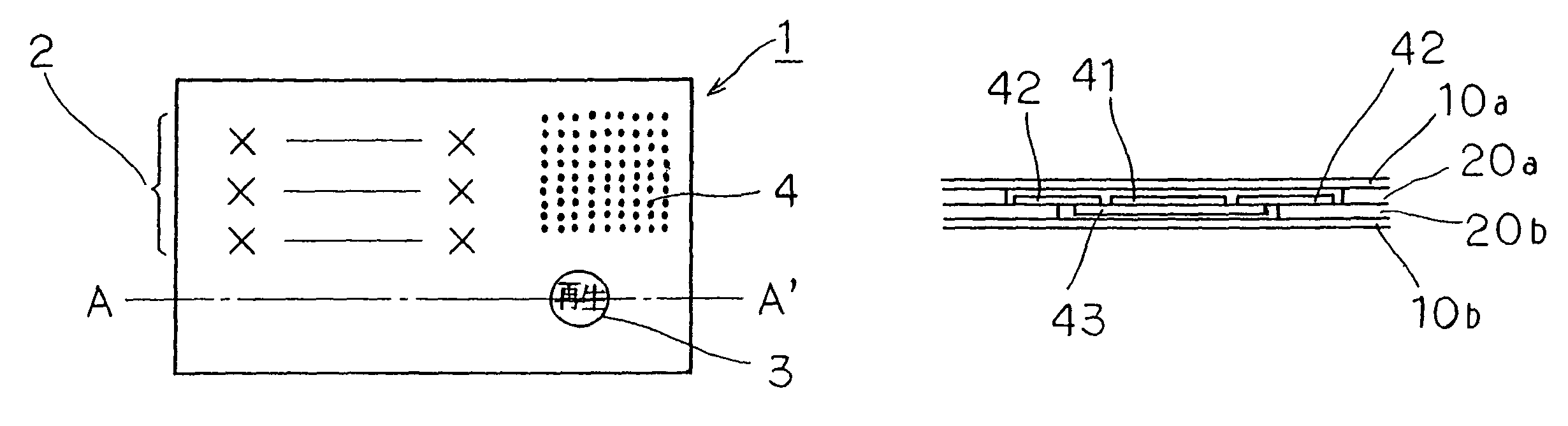

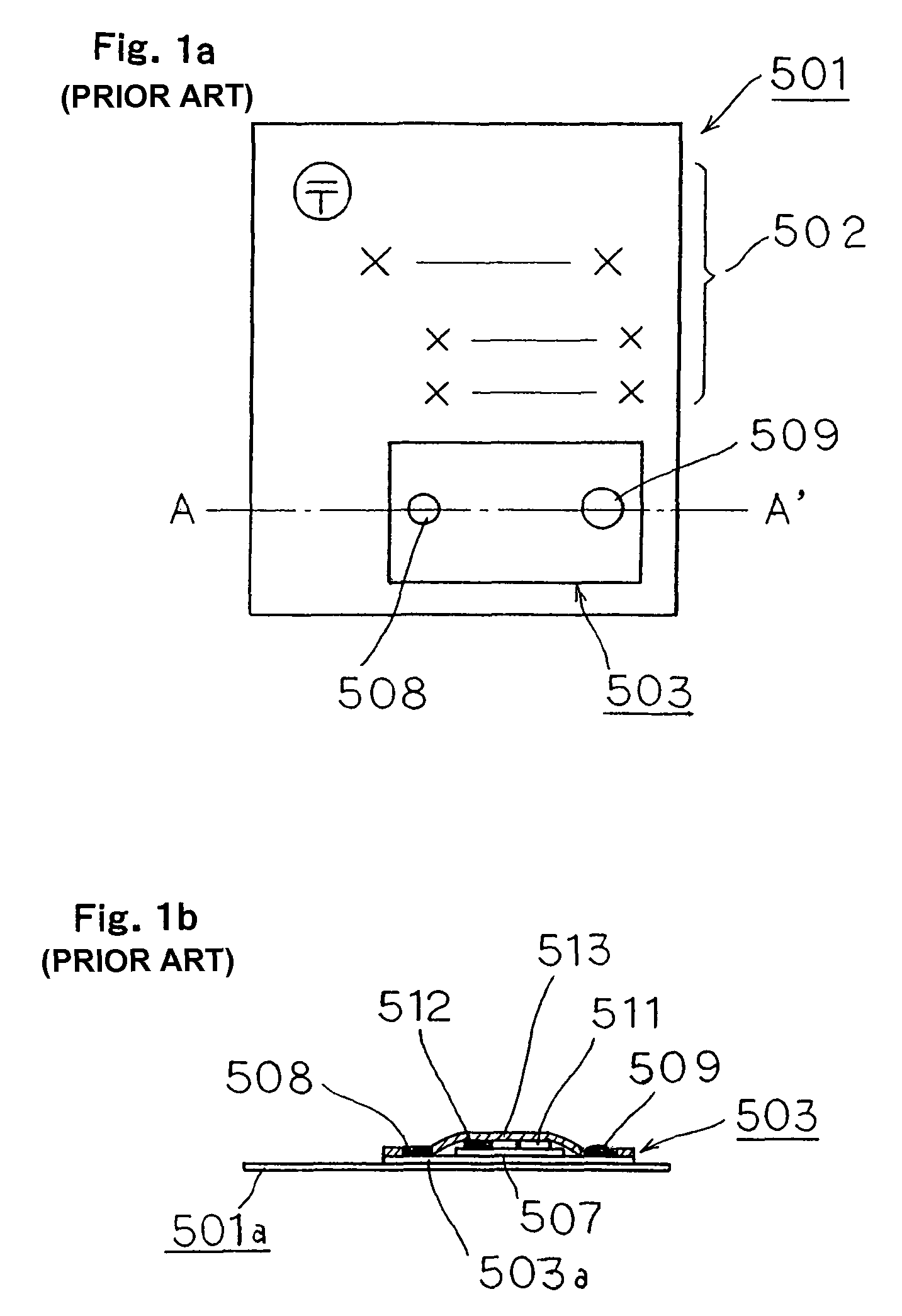

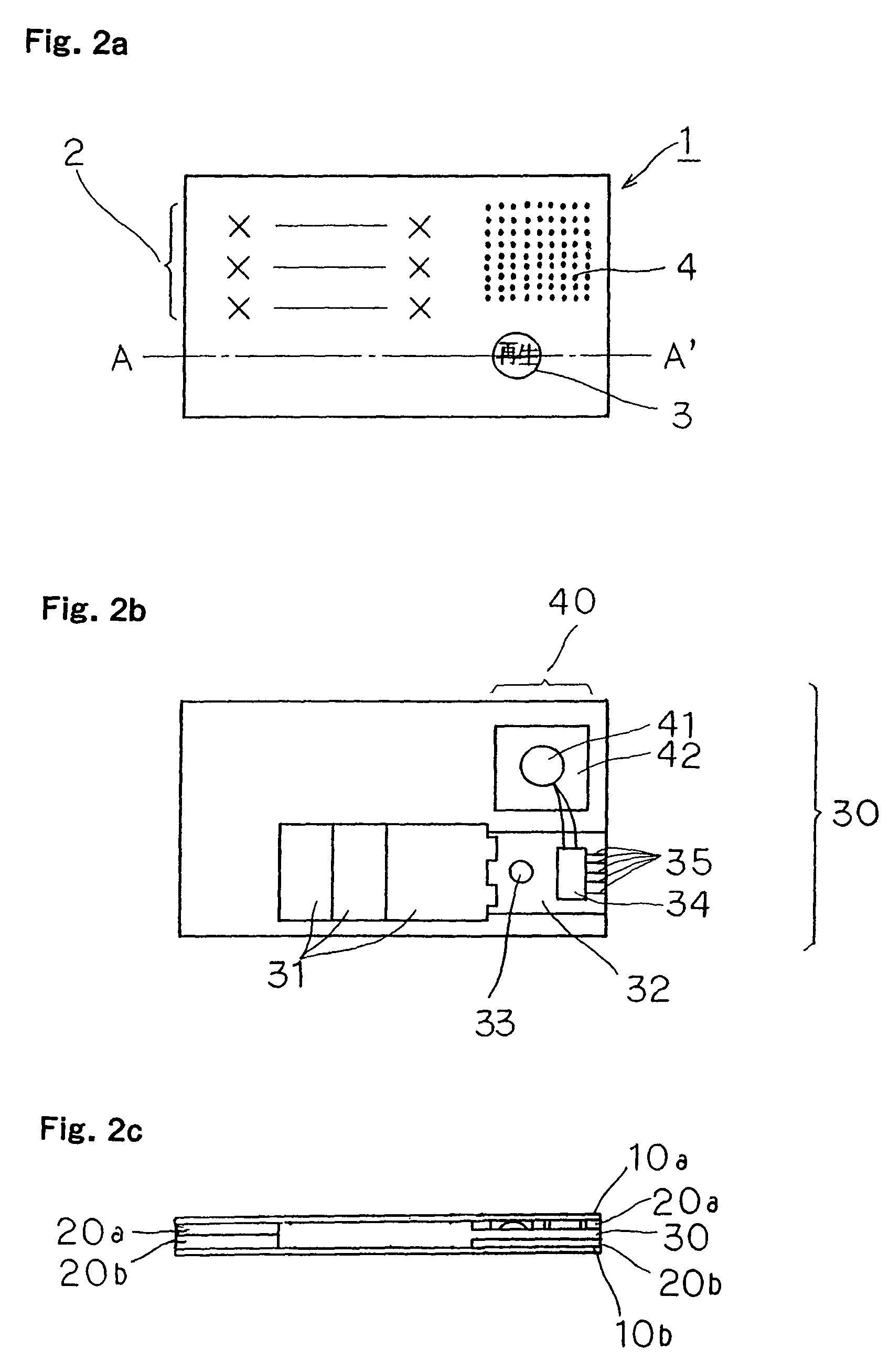

Speech-message delivery sheet, its manufacturing method, and power supply circuit

InactiveUS20070018446A1Attract attentionEasy to operateOther printing matterPiezoelectric/electrostrictive transducersMessage deliveryPower circuits

Owner:TOPPAN MOORE CO LTD

Curable Resin Composition, Surface Protection Method, Temporary Fixation Method, and Separation Method

InactiveUS20080289750A1Shorten operation timeLabor savingLiquid surface applicatorsLamination ancillary operationsOrganic solventMeth-

To provide an environmentally-friendly curable resin composition for surface protection, having a high adhesive strength and being capable of forming a protective film which will readily be removed in the film form without adhesive residue in water on a member to be processed, a photocurable adhesive using it, a method for temporarily fixing a member, and a method for removing a protective film.A curable resin composition for surface protection, comprising (A) a polyfunctional (meth)acrylate, (B) a monofunctional (meth)acrylate, and (C) a resin having a cyclopentadiene skeleton. Further, a curable resin composition for surface protection, comprising (A) a polyfunctional (meth)acrylate, (B) a monofunctional (meth)acrylate, (C) a resin having a cyclopentadiene skeleton, and (D) a photopolymerization initiator. Still further, a curable resin composition for surface protection, comprising (A) a polyfunctional (meth)acrylate, (B) a monofunctional (meth)acrylate, (C) a resin having a cyclopentadiene skeleton, (D) a photopolymerization initiator, and (E) a polar organic solvent.

Owner:DENKA CO LTD

Audio message transfer sheet and manufacturing method thereof, and power supply circuit

InactiveUS7840017B2Bonding forceImprove the bonding force between layersNear-field transmissionOther printing matterEngineeringElectrical and Electronics engineering

Owner:TOPPAN MOORE CO LTD

Acoustic wave device and method for production of same

ActiveUS8384272B2Stably keep tight sealImprove vibrationPiezoelectric/electrostriction/magnetostriction machinesImpedence networksElectrical conductorAcoustic wave

A small and highly reliable acoustic wave device and a method for production of the same will be provided. The acoustic wave device has a piezoelectric substrate 1; a SAW element 2 on one main surface of the piezoelectric substrate 1; an outside connection-use conductor 3 formed on the one main surface of the piezoelectric substrate 1 and electrically connected to the SAW element 2; a columnar electrode 10 on the outside connection-use conductor 3; and a protective cover 6 defining inner walls of a vibration space 7 for vibration of the SAW element 2 and planarly surrounding a side surface of the columnar electrode 10.

Owner:KYOCERA CORP

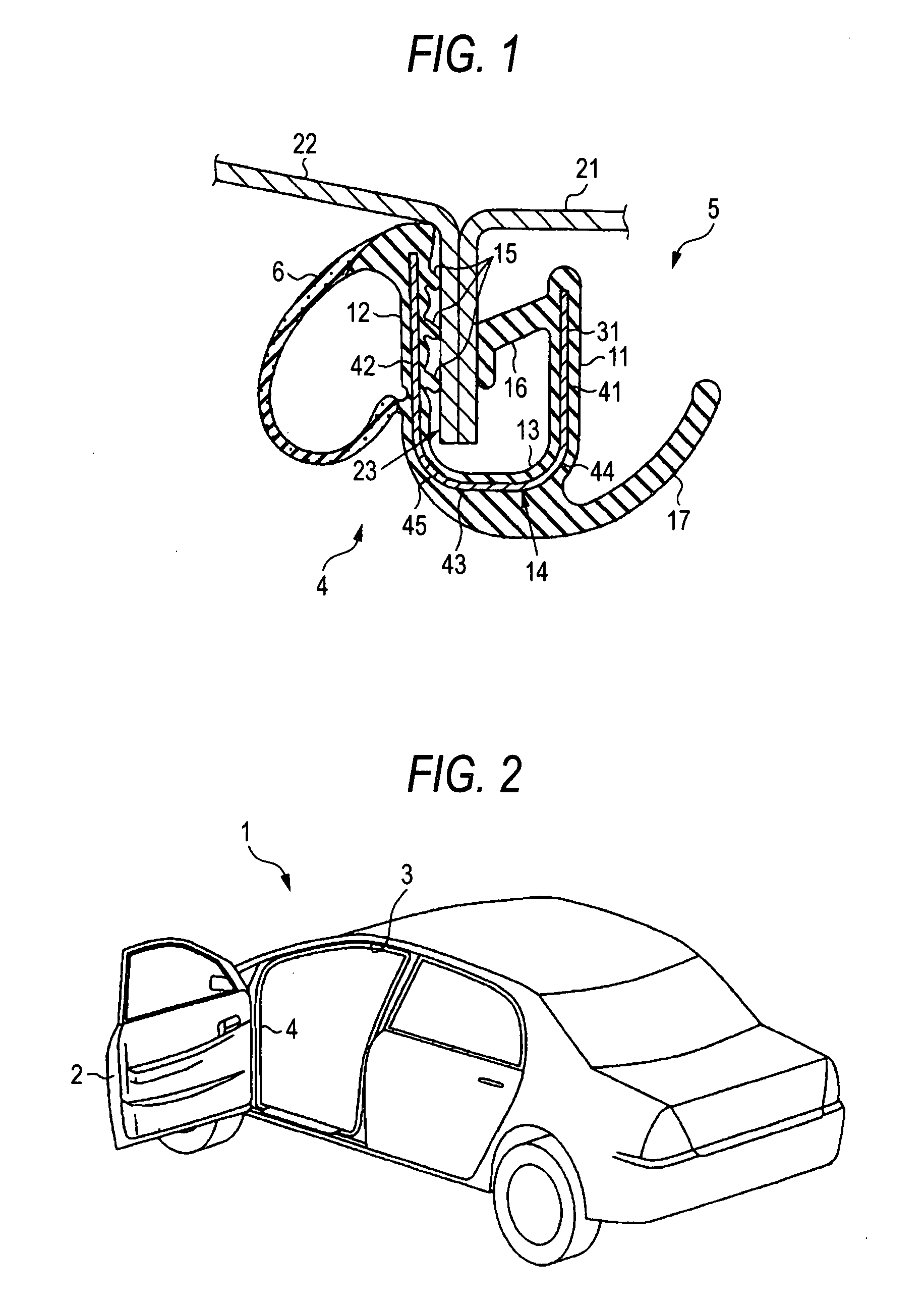

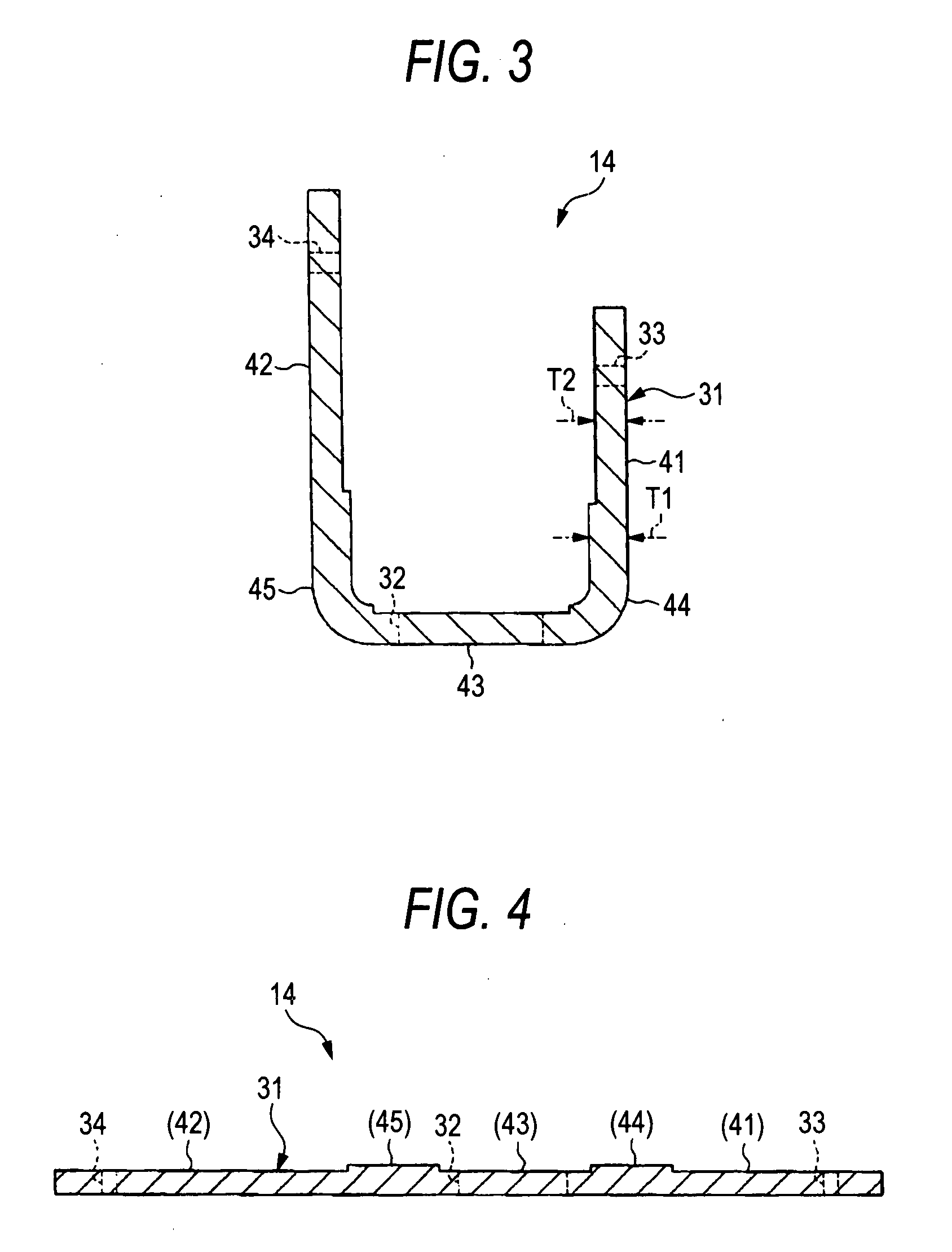

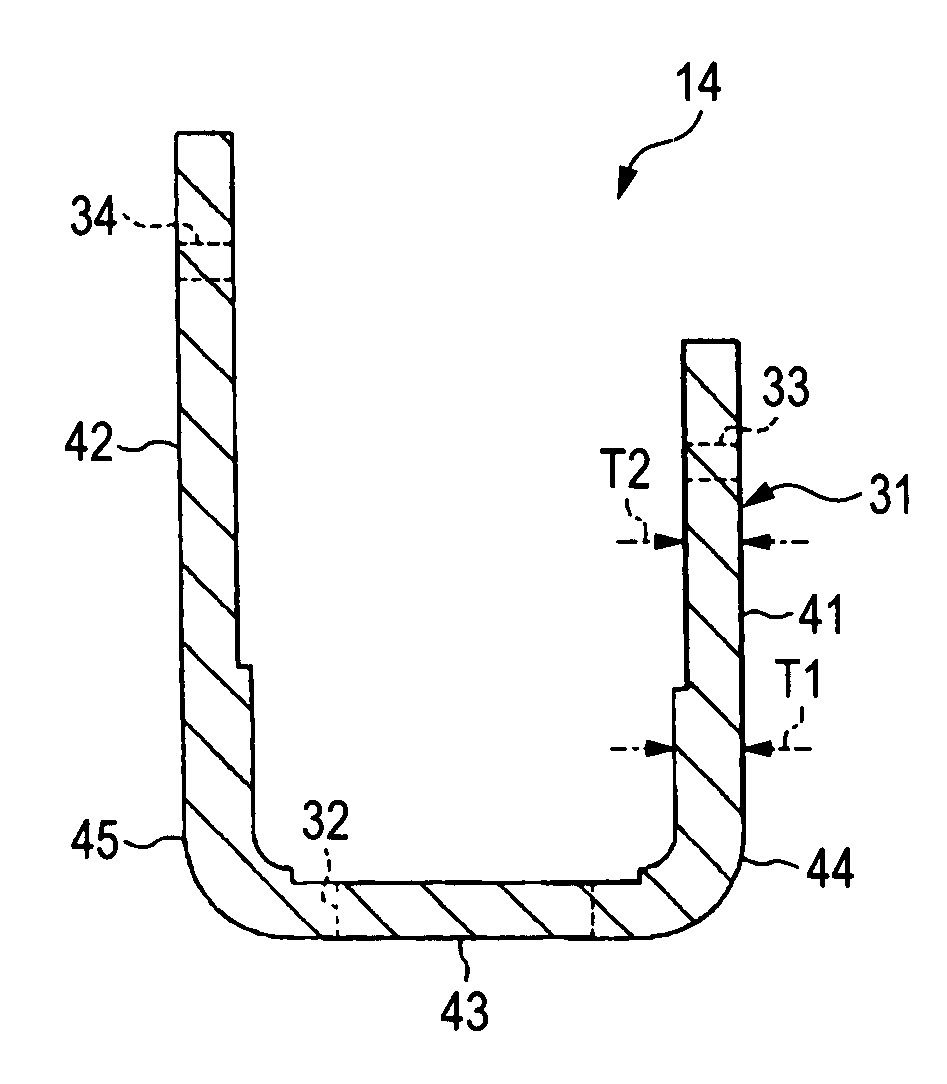

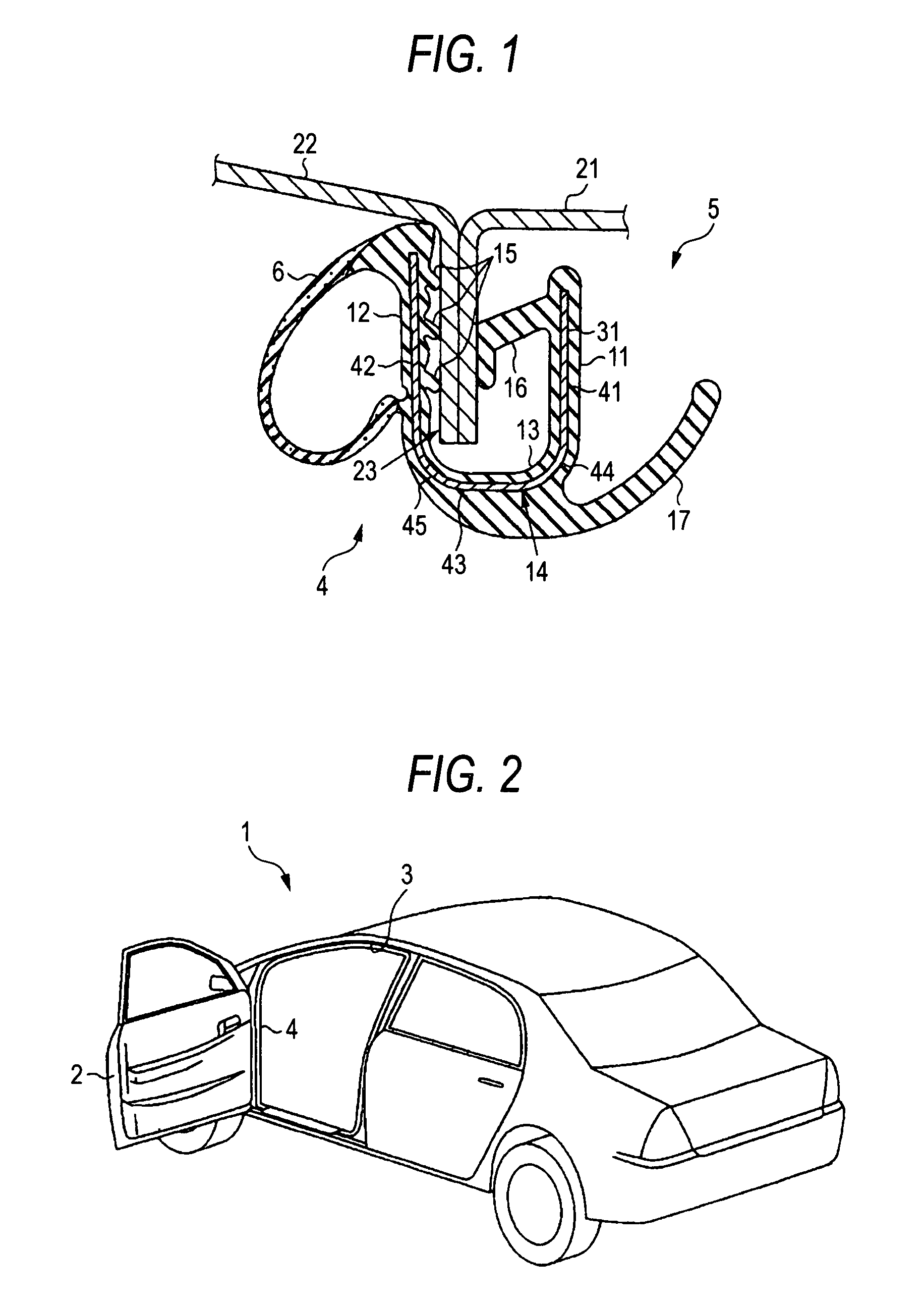

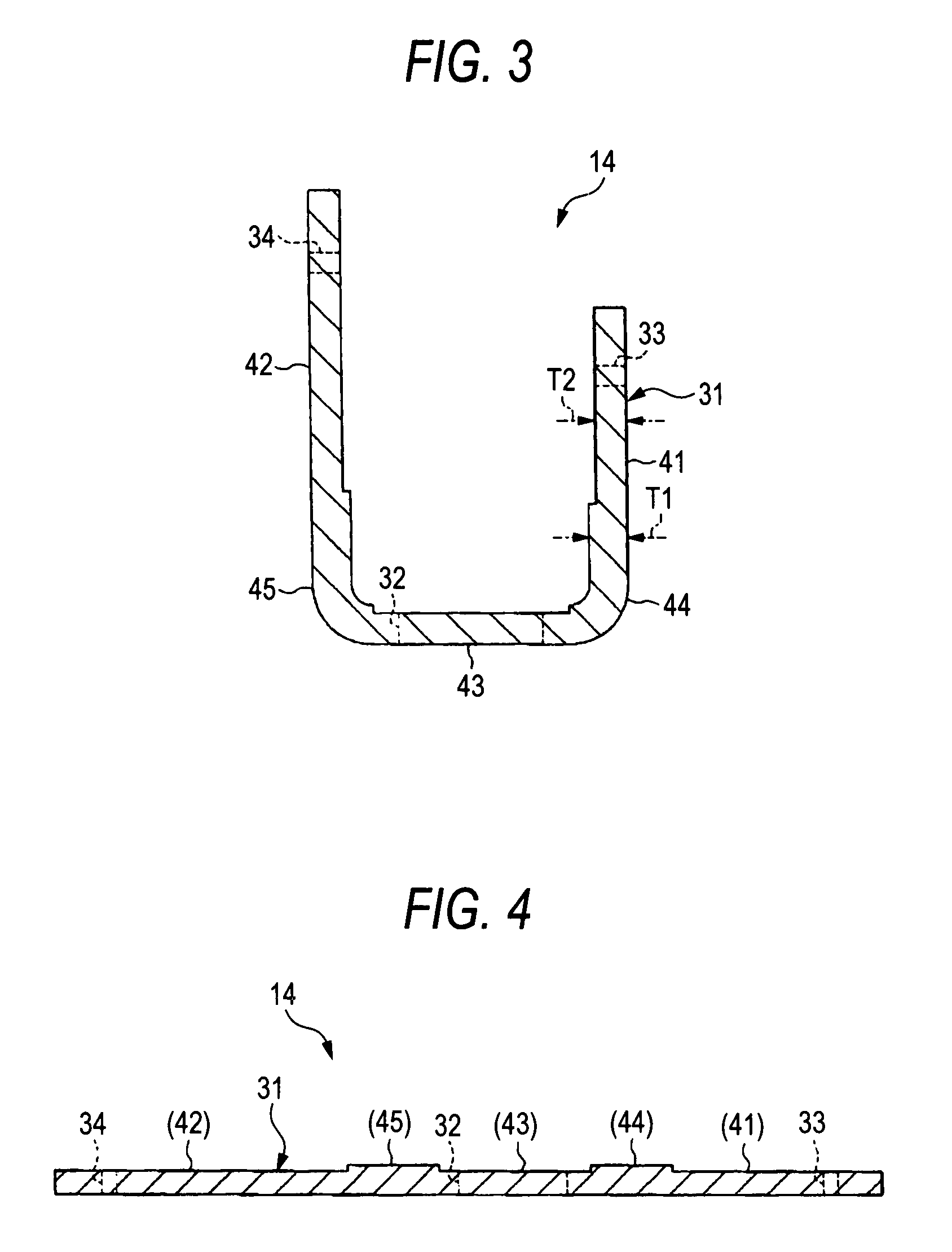

Weather strip

ActiveUS20080026196A1Suppress reduction of strength and bonding forceReduce weightLayered productsSealing arrangementsEngineeringUltimate tensile strength

A weather strip has a trim portion and a seal portion. The trim portion has a vehicle interior side wall, a vehicle exterior side wall, and a connecting portion. A metal insert is embedded in the trim portion. The insert has piece portions and a center bond portion which connects the piece portions to one another. The thickness of each of parts of the insert, which are other than both curved parts, is set to be thinner than the thickness of each of both the curved parts. Thus, the thickness of the insert, except for the curved parts, is small. Consequently, the entire insert, thus, the entire weather strip can be lightened. On the other hand, both the curved parts are relatively thick. Accordingly, the weather strip can assure predetermined strength and stiffness and can easily maintain an initial shape.

Owner:TOYODA GOSEI CO LTD

Weather strip

ActiveUS7687133B2Suppress reduction of strength and bonding forceReduce weightLayered productsSealing arrangementsEngineeringUltimate tensile strength

A weather strip has a trim portion and a seal portion. The trim portion has a vehicle interior side wall, a vehicle exterior side wall, and a connecting portion. A metal insert is embedded in the trim portion. The insert has piece portions and a center bond portion which connects the piece portions to one another. The thickness of each of parts of the insert, which are other than both curved parts, is set to be thinner than the thickness of each of both the curved parts. Thus, the thickness of the insert, except for the curved parts, is small. Consequently, the entire insert, thus, the entire weather strip can be lightened. On the other hand, both the curved parts are relatively thick. Accordingly, the weather strip can assure predetermined strength and stiffness and can easily maintain an initial shape.

Owner:TOYODA GOSEI CO LTD

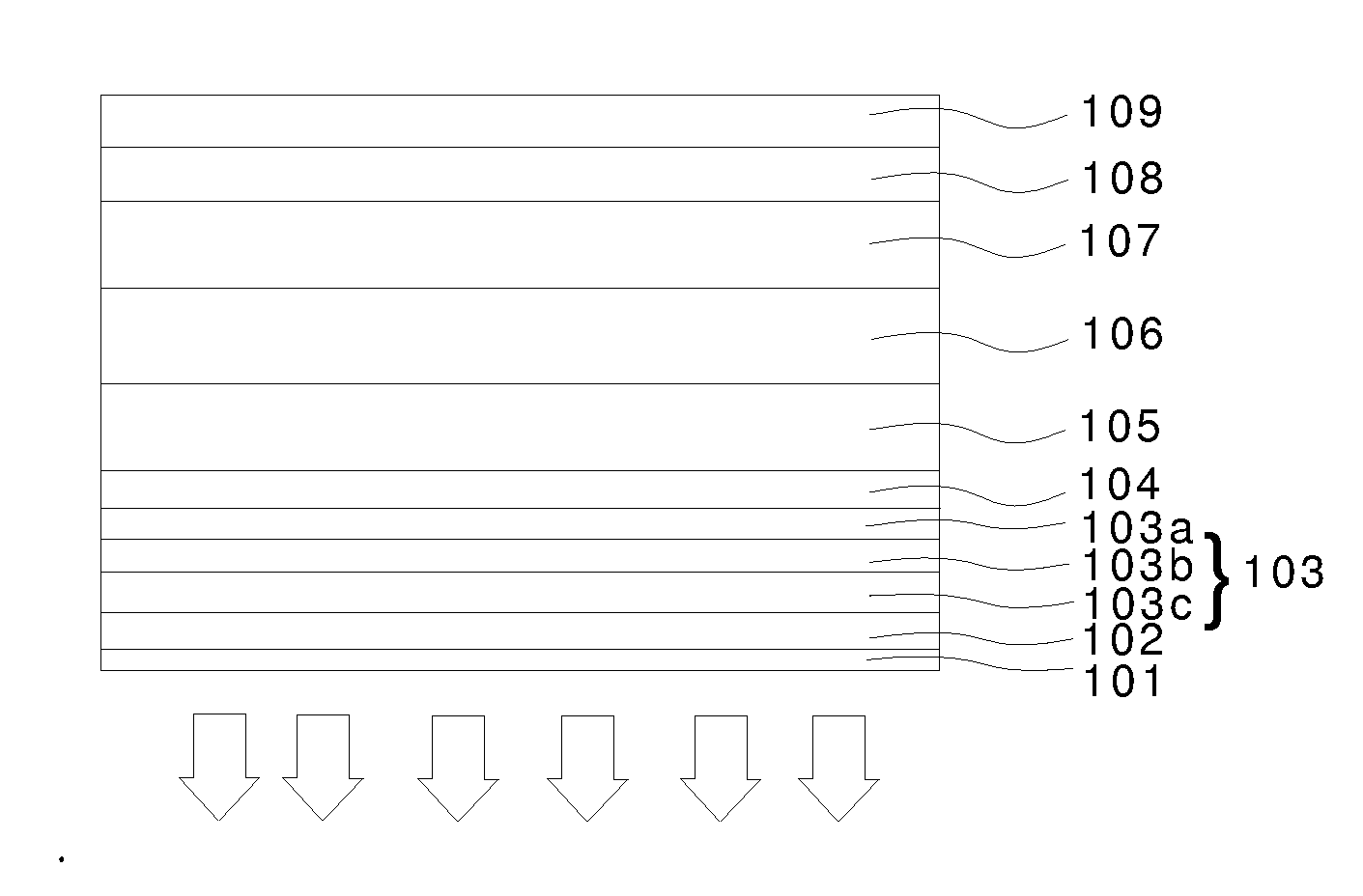

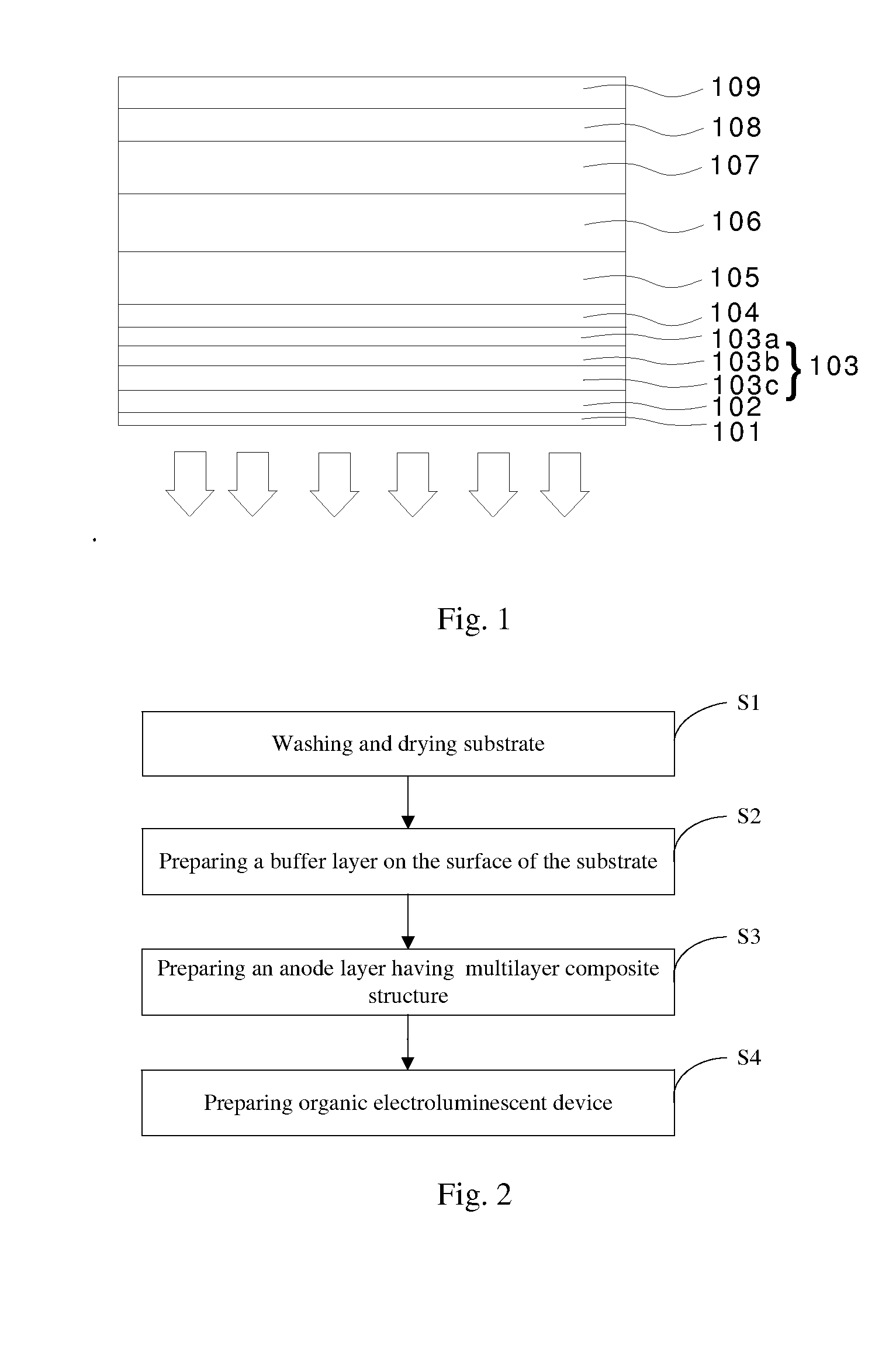

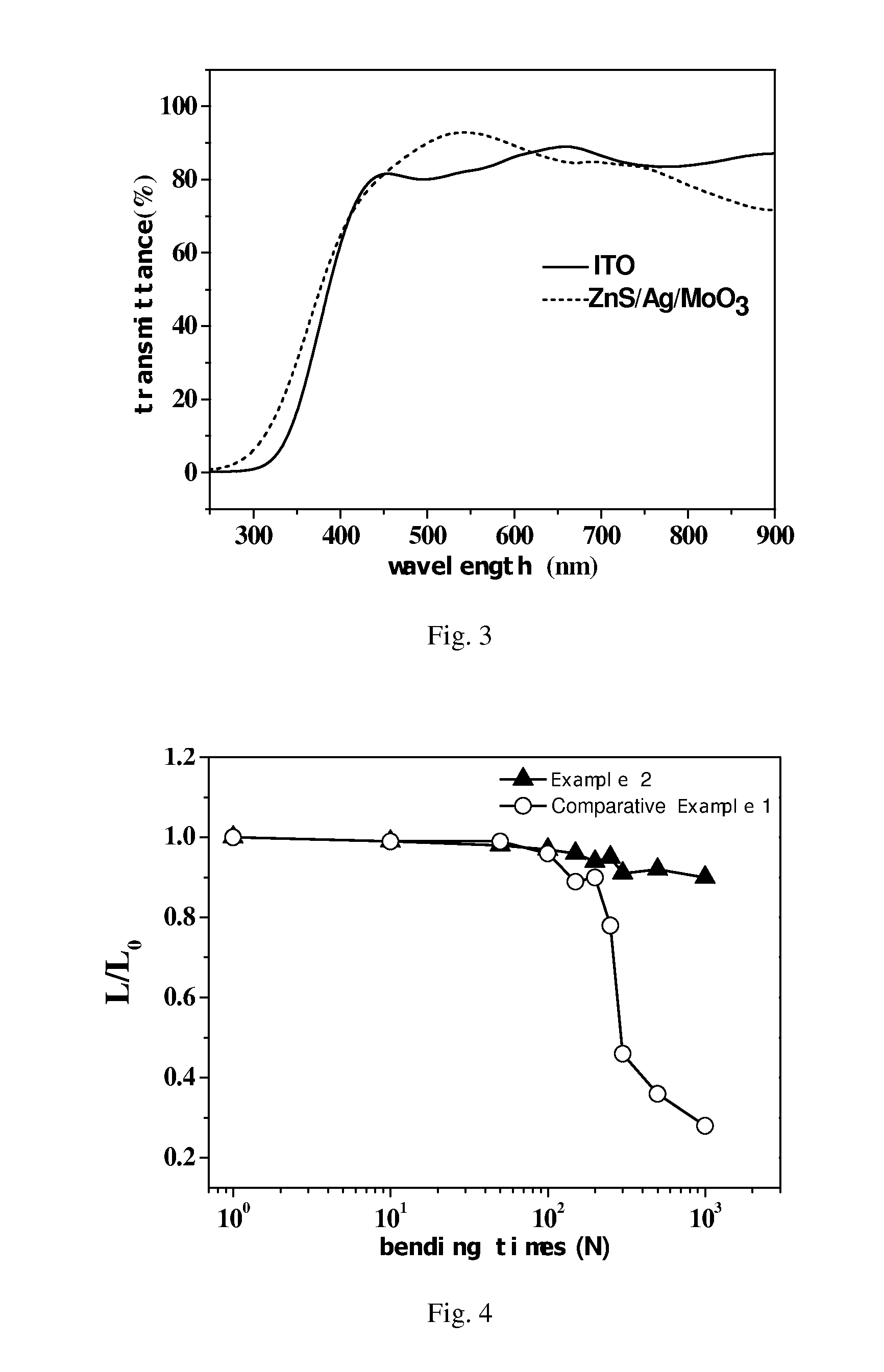

Flexible organic electroluminescent device and manufacturing method thereof

InactiveUS20130306956A1Less destructiveGood light transmissionSolid-state devicesSemiconductor/solid-state device manufacturingHole injection layerOrganic electroluminescence

A flexible organic electroluminescent device and a manufacturing method thereof are provided. The device comprises a substrate (101), an anode layer (103), a hole-injecting layer (104), a hole-transporting layer (105), a light-emitting layer (106), an electron-transporting layer (107), an electron-injecting layer (108), and a cathode layer (109), which are stacked in order. The device further comprises a buffer layer (102) between the substrate (101) and the anode layer (103). The anode layer (103) is a multilayer composite structure, which comprises ZnS / Ag / MoO3. The bonding force between the anode layer (103) and the substrate (101) is enhanced by inserting buffer layer (102). The device has a good bending endurance performance, a stable luminous property and a high light emitting efficiency.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

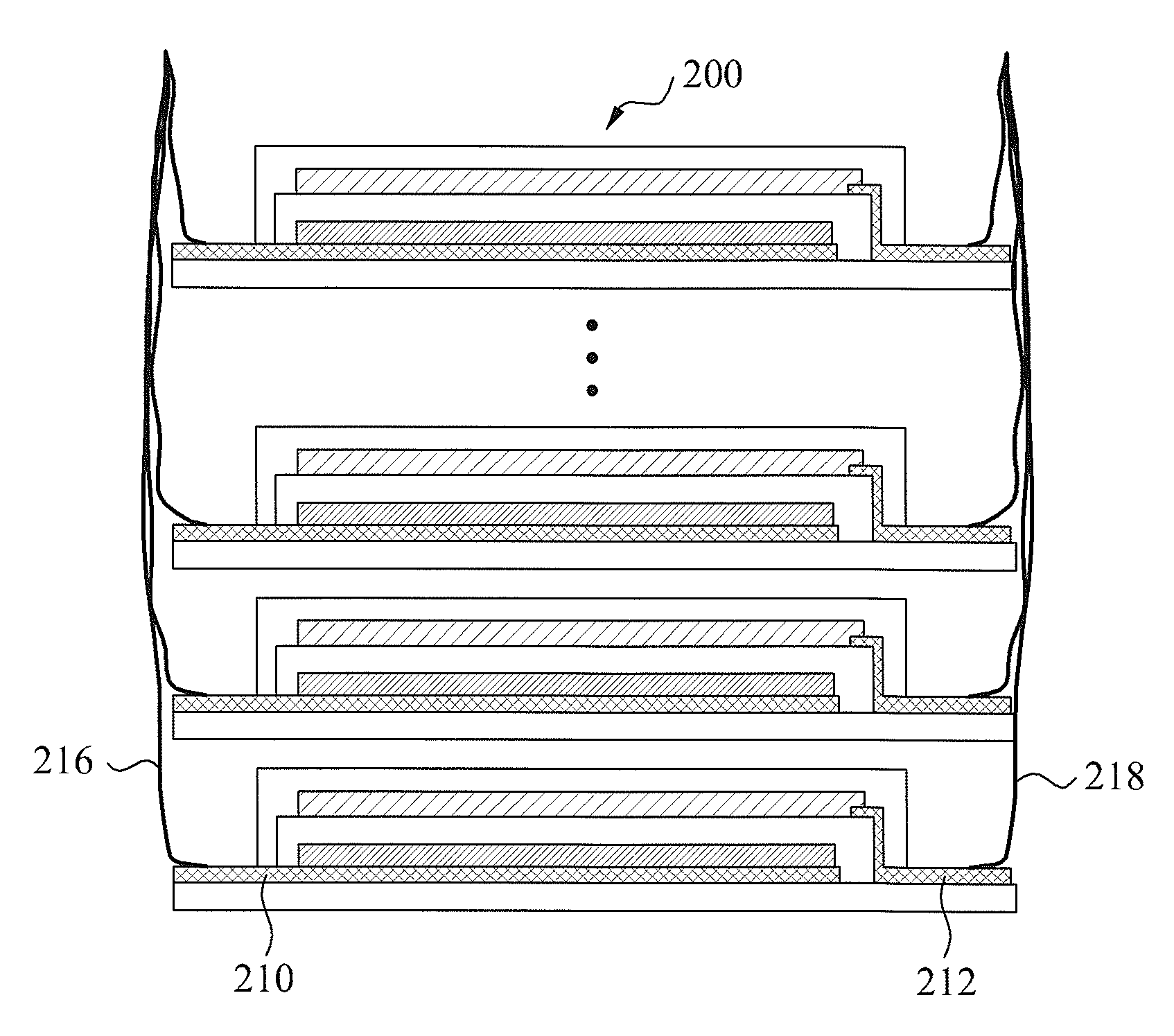

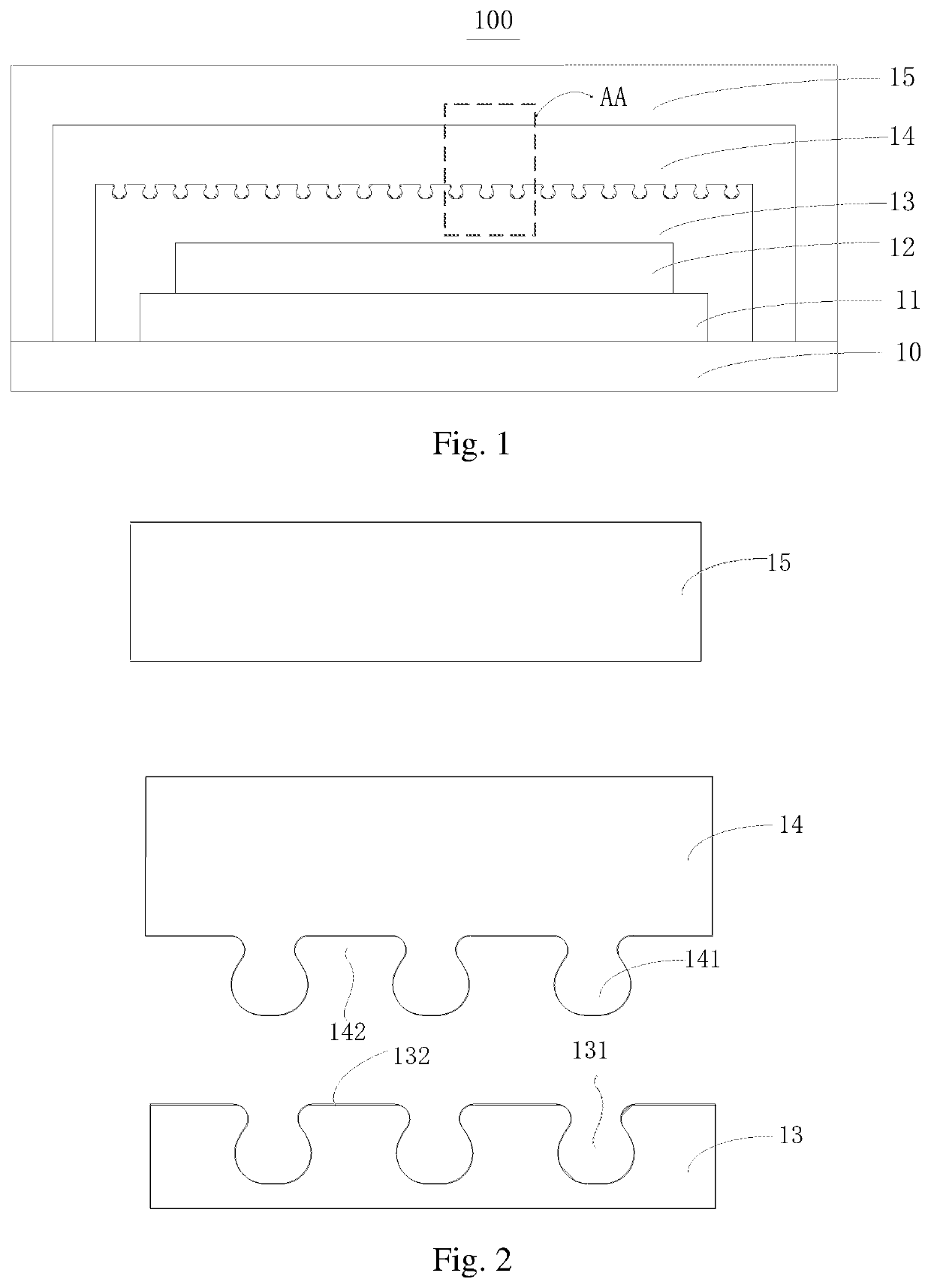

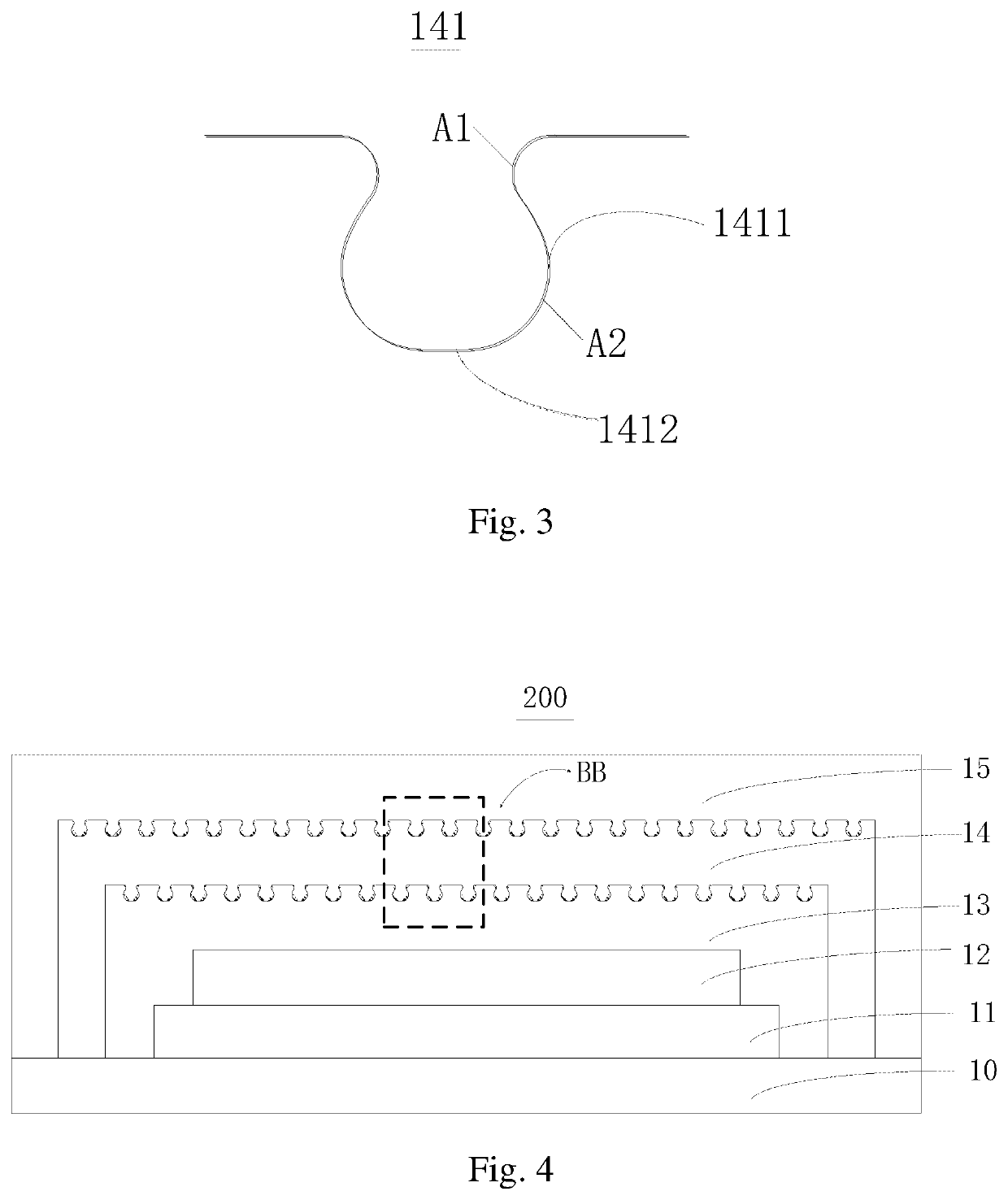

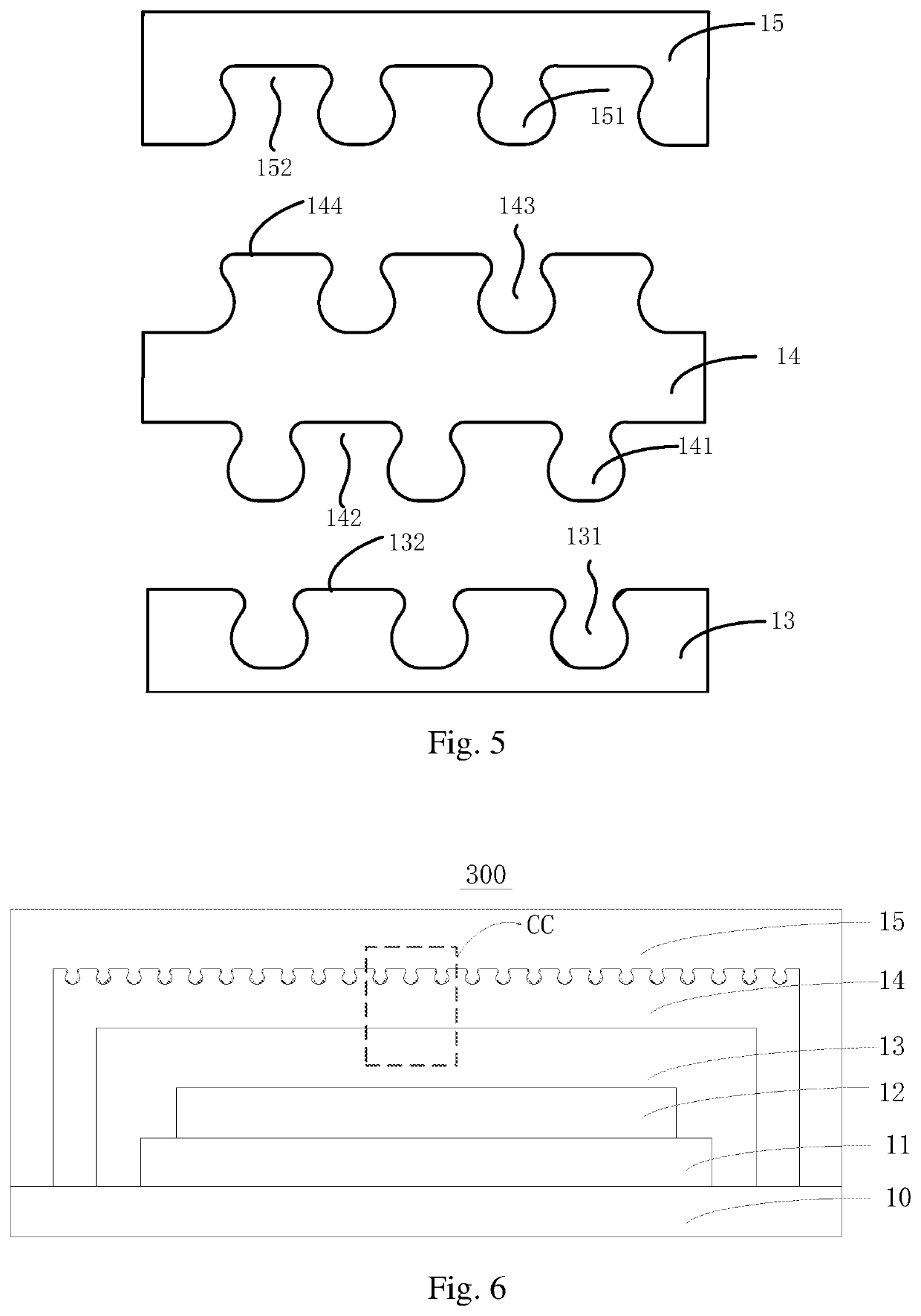

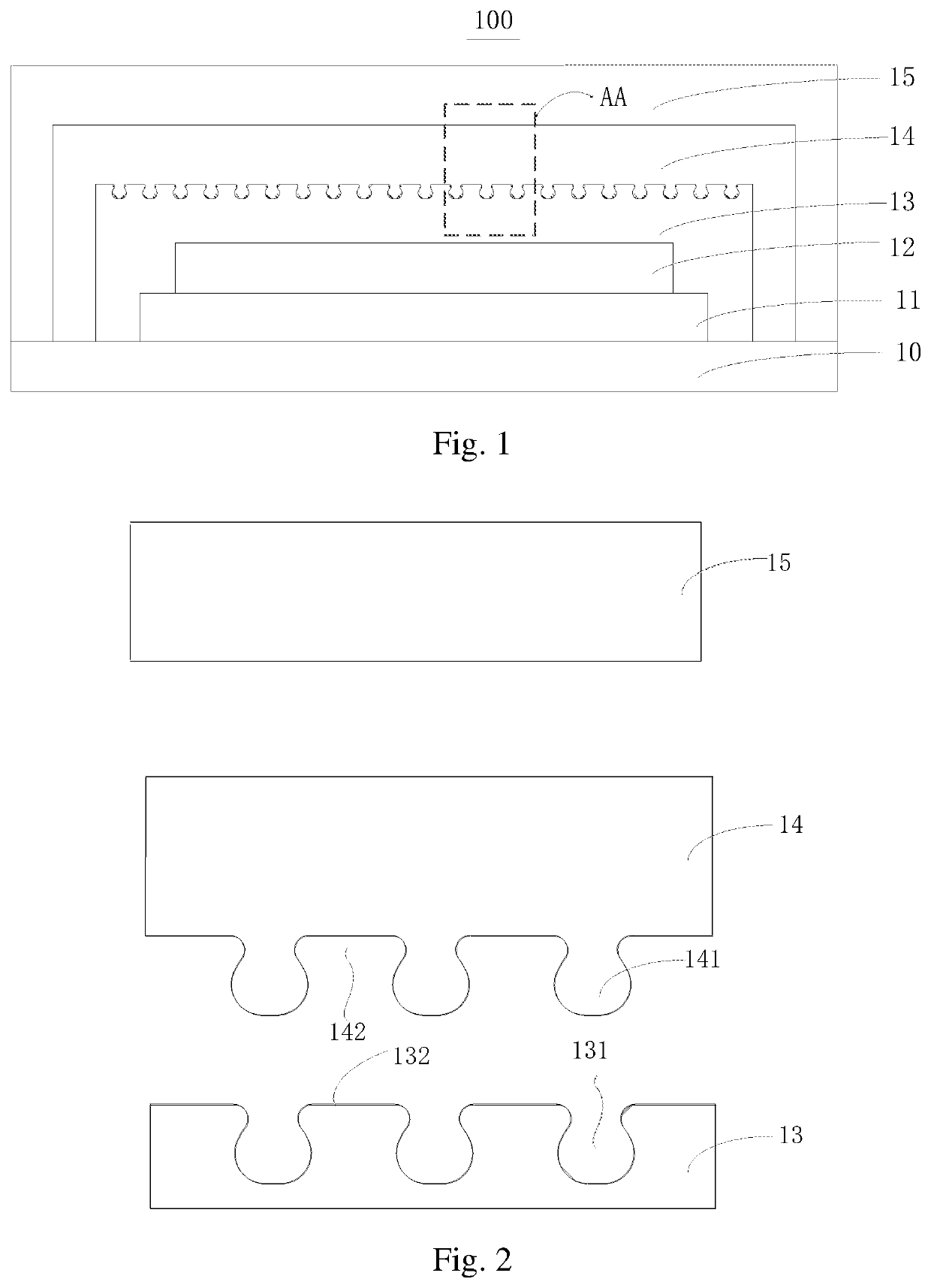

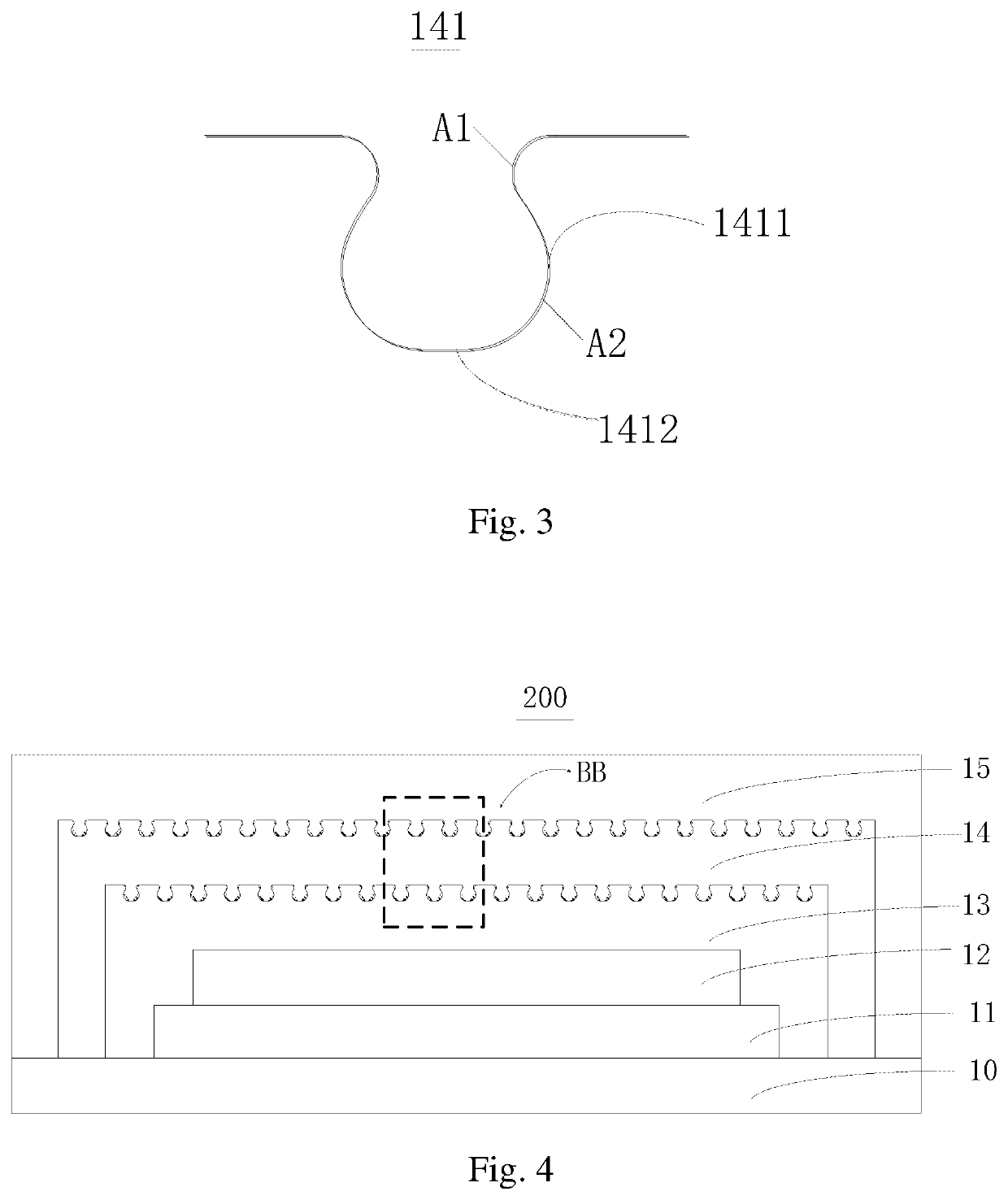

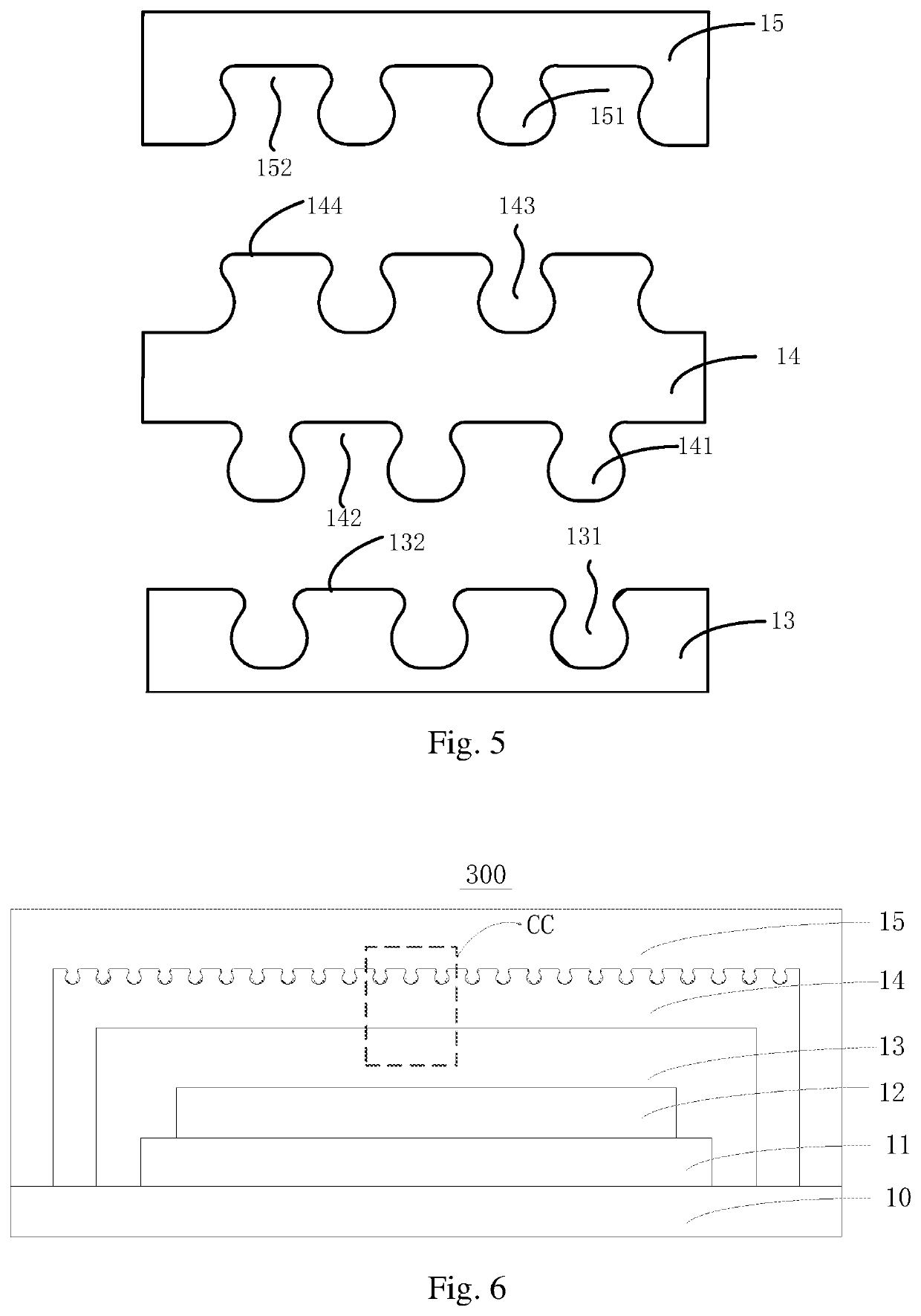

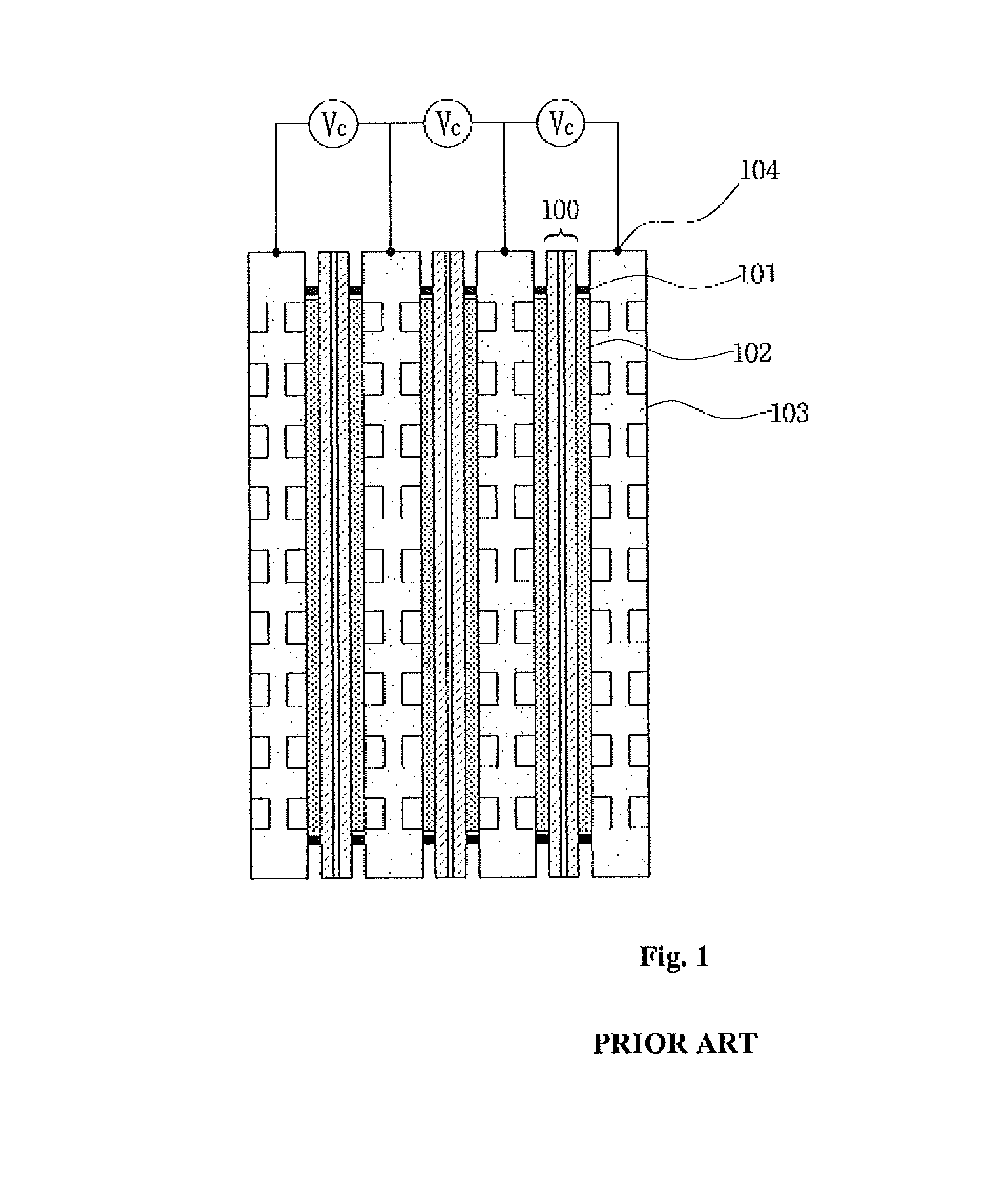

Display panel having thin film layers with recesses and protrusions

ActiveUS11114641B2Improve the bonding force between layersImproving dynamic bending resistance capabilitySolid-state devicesSemiconductor/solid-state device manufacturingThin membraneEngineering

Owner:BAZHOU YUNGU ELECTRONICS TECH CO LTD

Intelligent MEA for fuel cell

ActiveUS20080318101A1Inhibit transferBonding forceFuel cell heat exchangeFuel cells groupingIon-exchange membranesFlexible electronics

The present invention provides an intelligent MEA for fuel cell including means for easily measuring the voltage of unit cells and means for preventing heat transfer from an outside low-temperature heat source to a catalyst layer of the MEA during operation of the fuel cell stack at low temperature.For this, the present invention provides n intelligent membrane electrode assembly (MEA) for fuel cell, including: an MEA in which a catalyst layer is coated on both sides of an ion exchange membrane, and an ion exchange membrane support film is attached on both sides of an edge portion of the ion exchange membrane; a flexible printed circuit board (PCB) mounted on one surface of the ion exchange membrane support film along the outer line of the catalyst layer of the MEA; a PCB terminal formed on one end of the flexible PCB; and a connector connected to the PCB terminal to communicate with an external controller, wherein the flexible PCB includes an electrical heating element, an electrical heating element temperature sensor for measuring the temperature of the electrical heating element, an MEA temperature sensor for measuring the temperature of the MEA, an electrical contact for measuring the resistance of unit cells, and an electrical contact for measuring the voltage of the unit cells, formed in a predetermined arrangement to communicate with the PCB terminal.

Owner:HYUNDAI MOTOR CO LTD

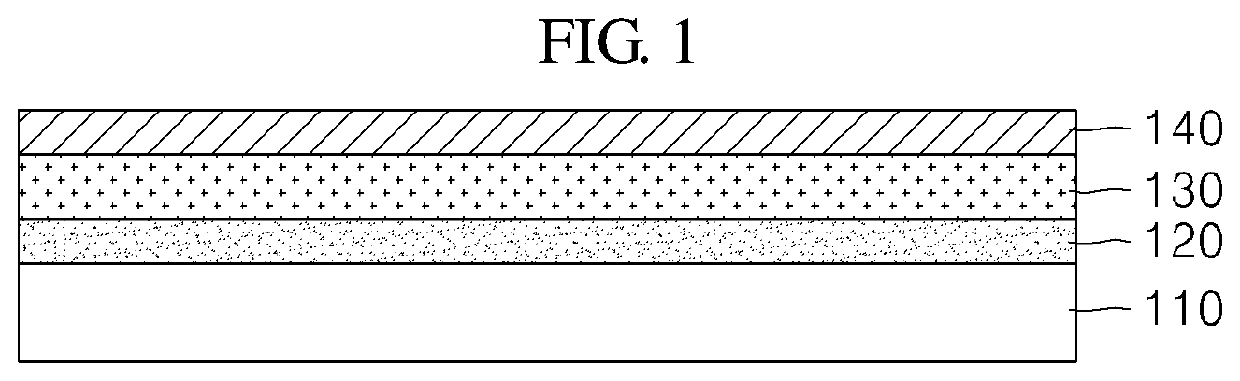

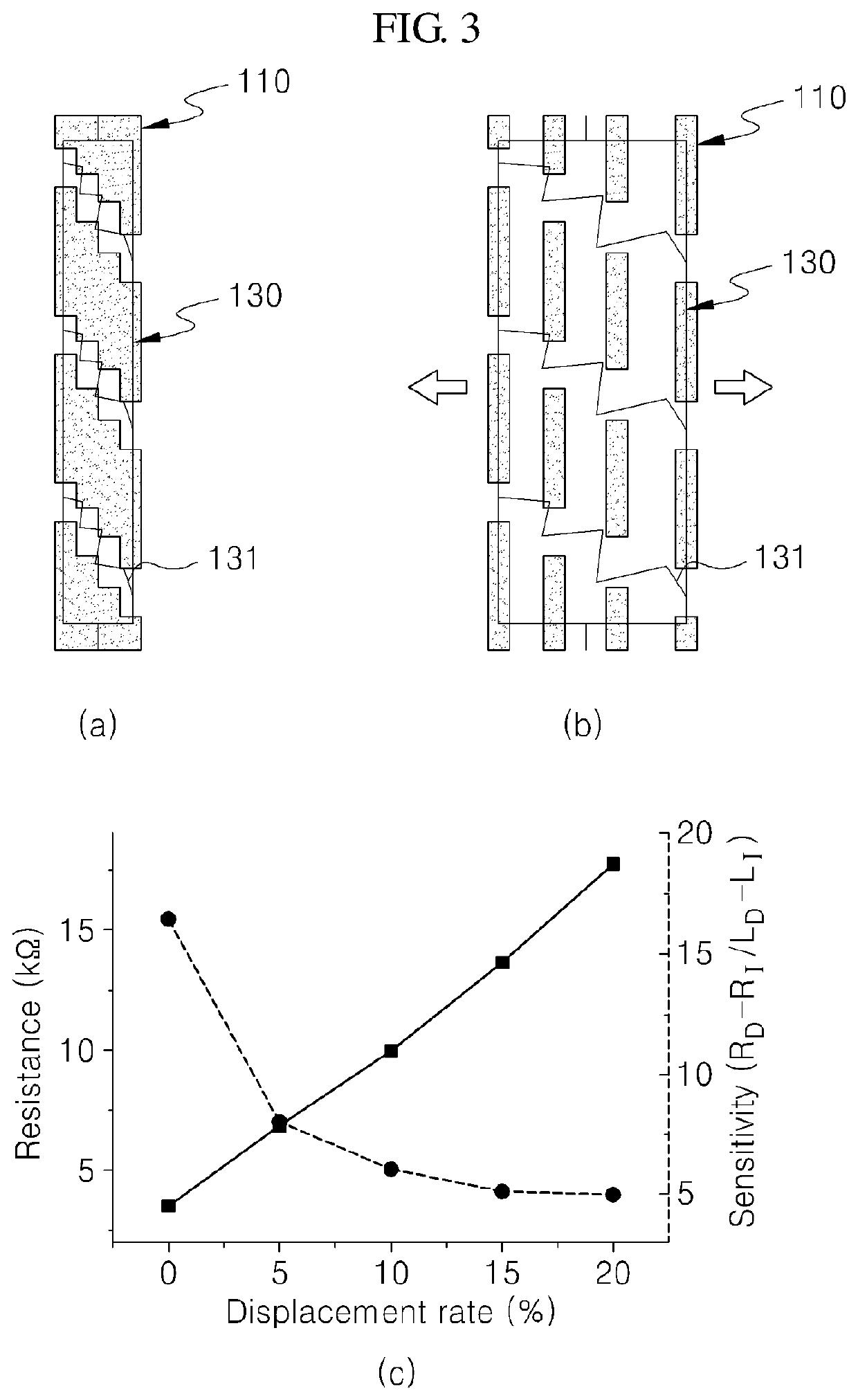

Wearable sensor and method for manufacturing same

ActiveUS10890549B2Prevent peelingBonding forceBioelectric signal measurementTextile testingFiberCarbon nanotube

The present invention provides a wearable sensor including a fiber; a self-assembled monolayer formed on at least one surface of the fiber and including a functional group; a carbon nanotube layer formed on the self-assembled monolayer by adsorbing a plurality of carbon nanotubes on the self-assembled monolayer; and an electrode electrically connected to the carbon nanotube layer.

Owner:MCELL CO LTD

Display device

ActiveUS10691163B2Prevent penetrationBonding forceDigital data processing detailsSolid-state devicesForeign matterDisplay device

Disclosed aspects relate to a display device. By forming a back cover, which is the support structure constituting the display device, in a bent structure and forming a molding part made of an elastic material to enclose the vertical extension portion, a border gap, which is a clearance between the side surfaces of the display panel and the side surface support structure, can be minimized to maintain an excellent external appearance of the display device, and to prevent infiltration of foreign matter and damage of the display panel, which may be caused by the gap between the display panel and the support structure. By disposing a metal inner plate on the inner surface of the horizontal portion of the back cover, the rigidity of the back cover can be increased, the thickness of the back cover can be decreased, and heat generated from the display panel and the like can be smoothly dissipated.

Owner:LG DISPLAY CO LTD

Display panel

ActiveUS20200313117A1Improve the bonding force between layersImproving dynamic bending resistance capabilitySolid-state devicesSemiconductor/solid-state device manufacturingThin membraneEngineering

The present disclosure discloses a display panel. The display panel may include multiple thin film layers. The multiple thin film layers may include a first layer and a second layer adjacent to the first layer. The first layer may define a recess at a face toward the second layer. The second layer may include a protrusion at a face toward the first layer. The protrusion may be engaged in the recess. A diameter of a tip of the protrusion may be larger than a diameter of a root of the protrusion. A shape of a space in the recess may match with a contour of the protrusion.

Owner:BAZHOU YUNGU ELECTRONICS TECH CO LTD

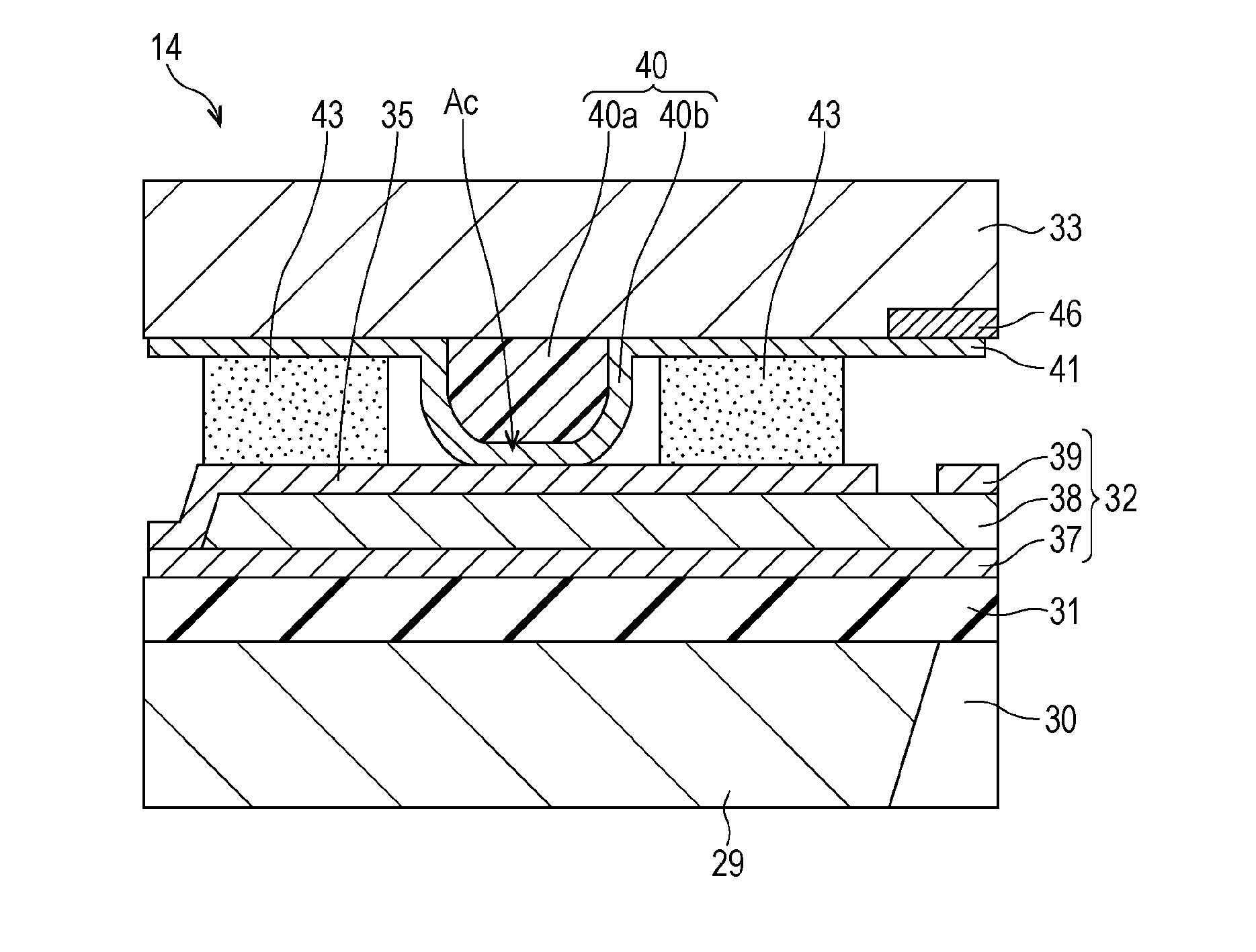

Bonded structure, piezoelectric device, liquid ejecting head, and method of manufacturing bonded structure

ActiveUS20170050437A1Easy to manufactureSuppress disconnectionPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusAdhesiveEngineering

Provided is a bonded structure including a first substrate in which a resin portion made of an elastic member protrudes on one surface and a first electrode layer is formed to cover at least a part of the resin portion, and a second substrate in which a second electrode layer electrically connected to the first electrode layer is formed on a surface facing the first substrate, the first substrate and the second substrate being bonded to each other in a state in which a photosensitive adhesive is interposed therebetween. In a surface of one of the first substrate and the second substrate on the photosensitive adhesive side, a first region reflecting light and a second region less likely to reflect light than the first region are provided in positions different from each other on a region overlapping the photosensitive adhesive in a substrate bonding direction.

Owner:SEIKO EPSON CORP

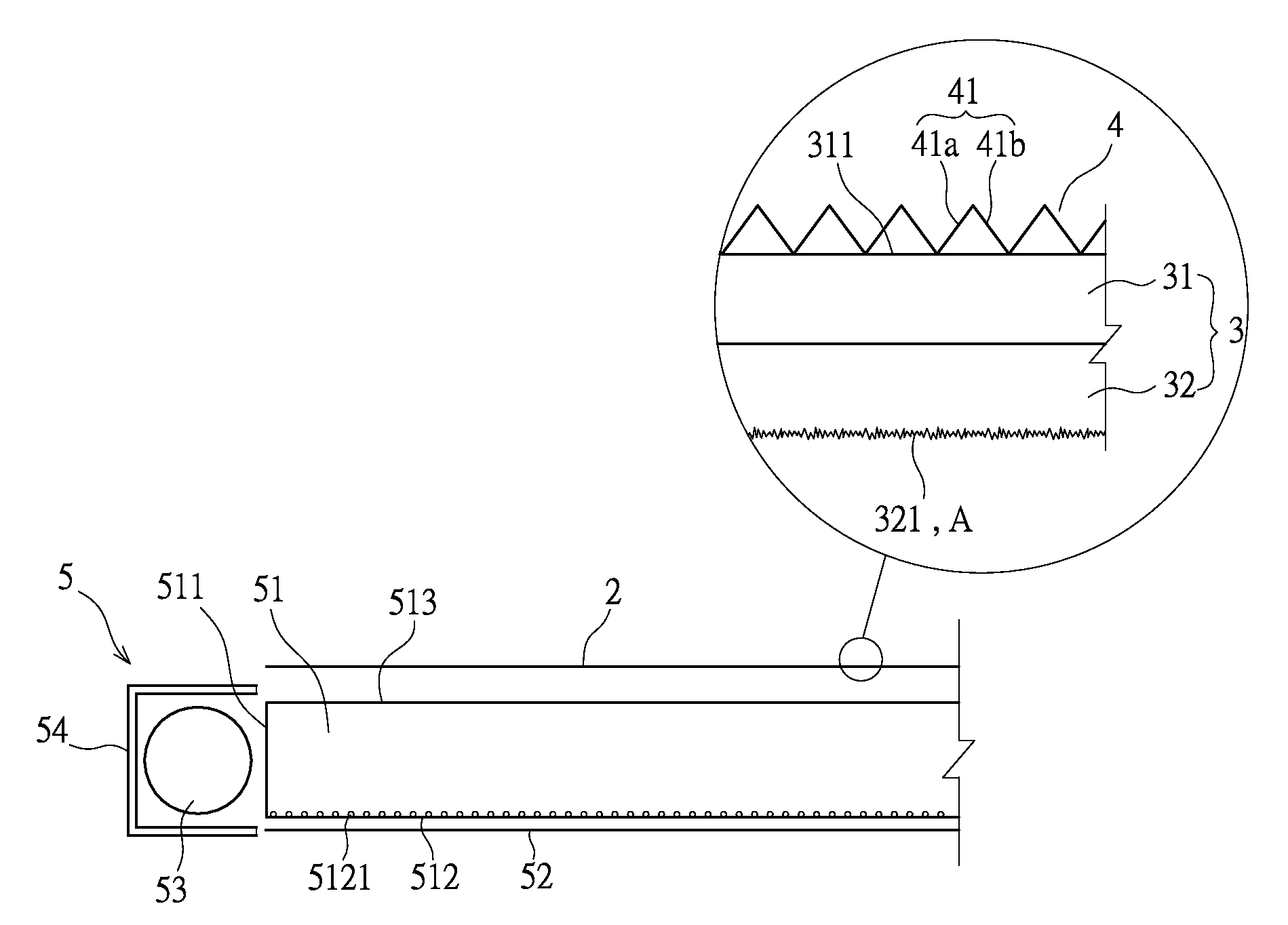

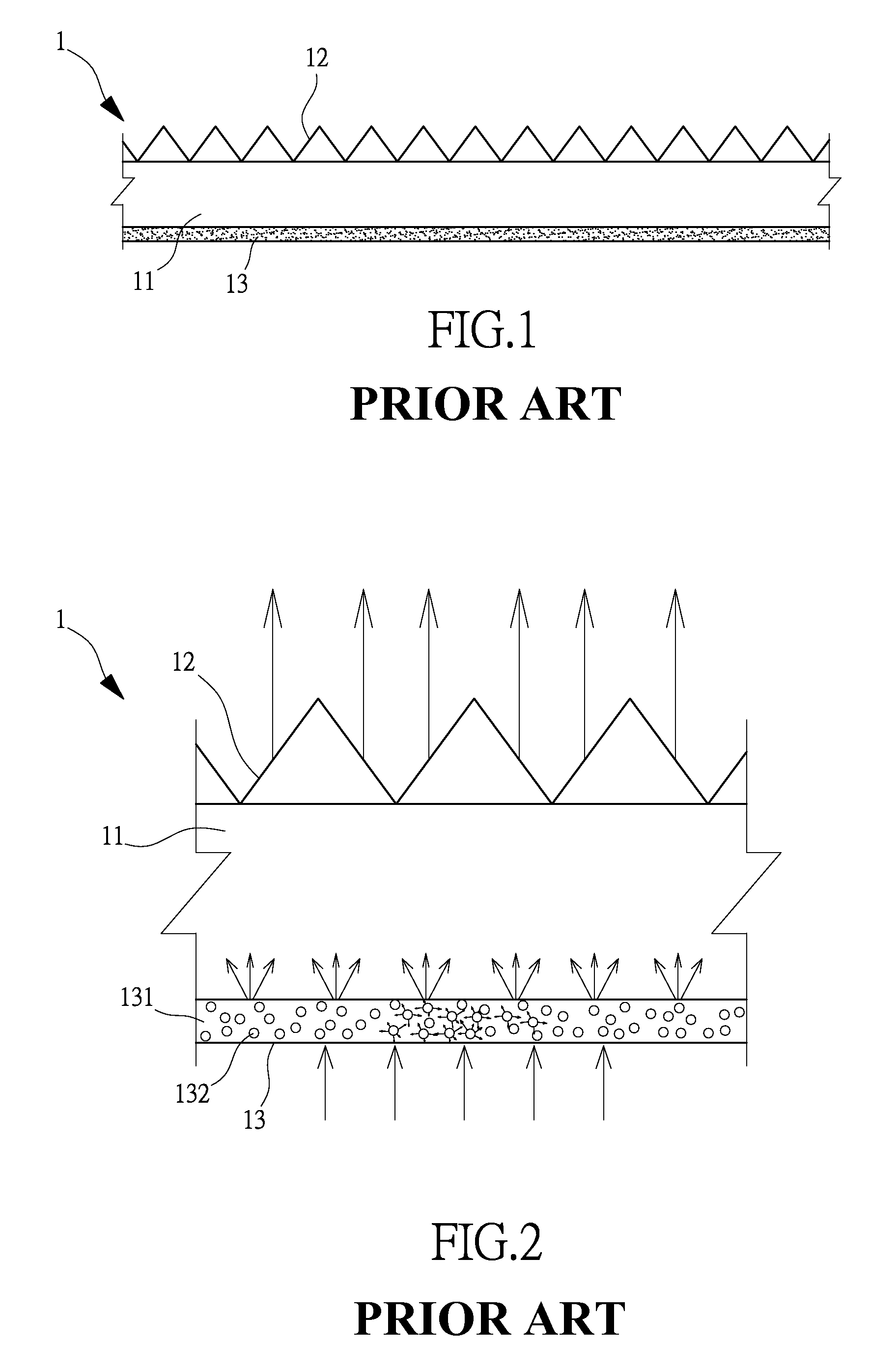

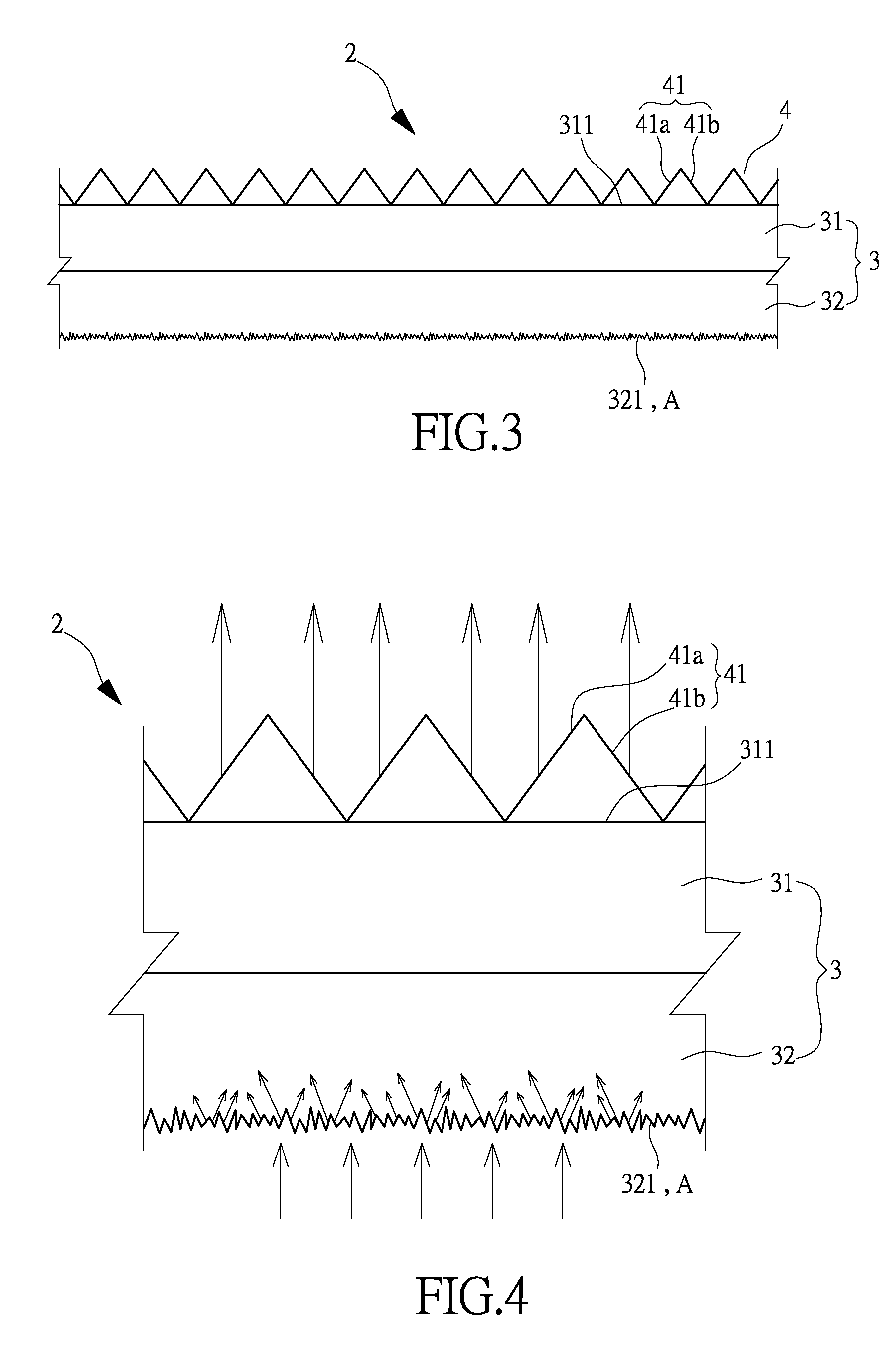

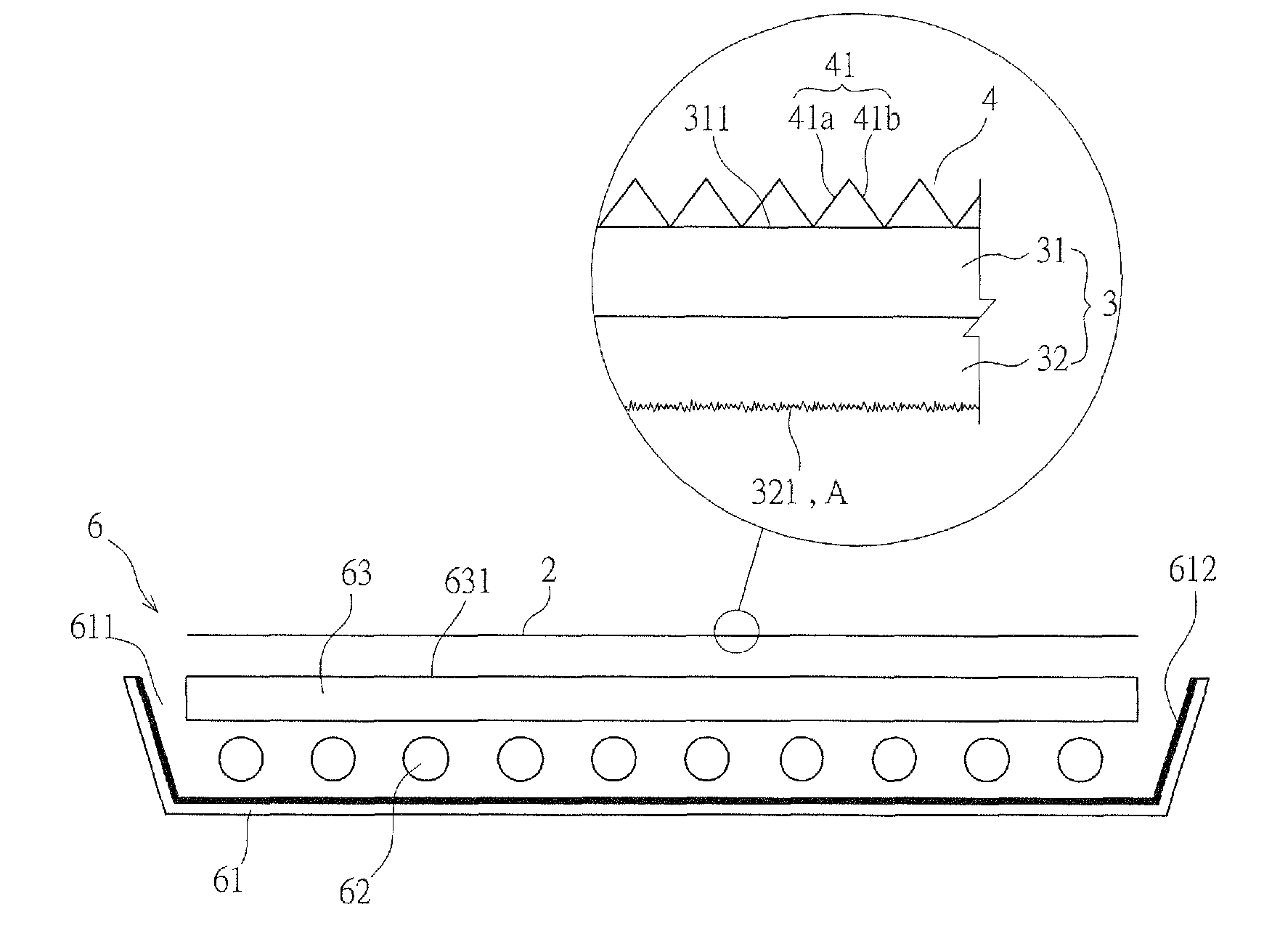

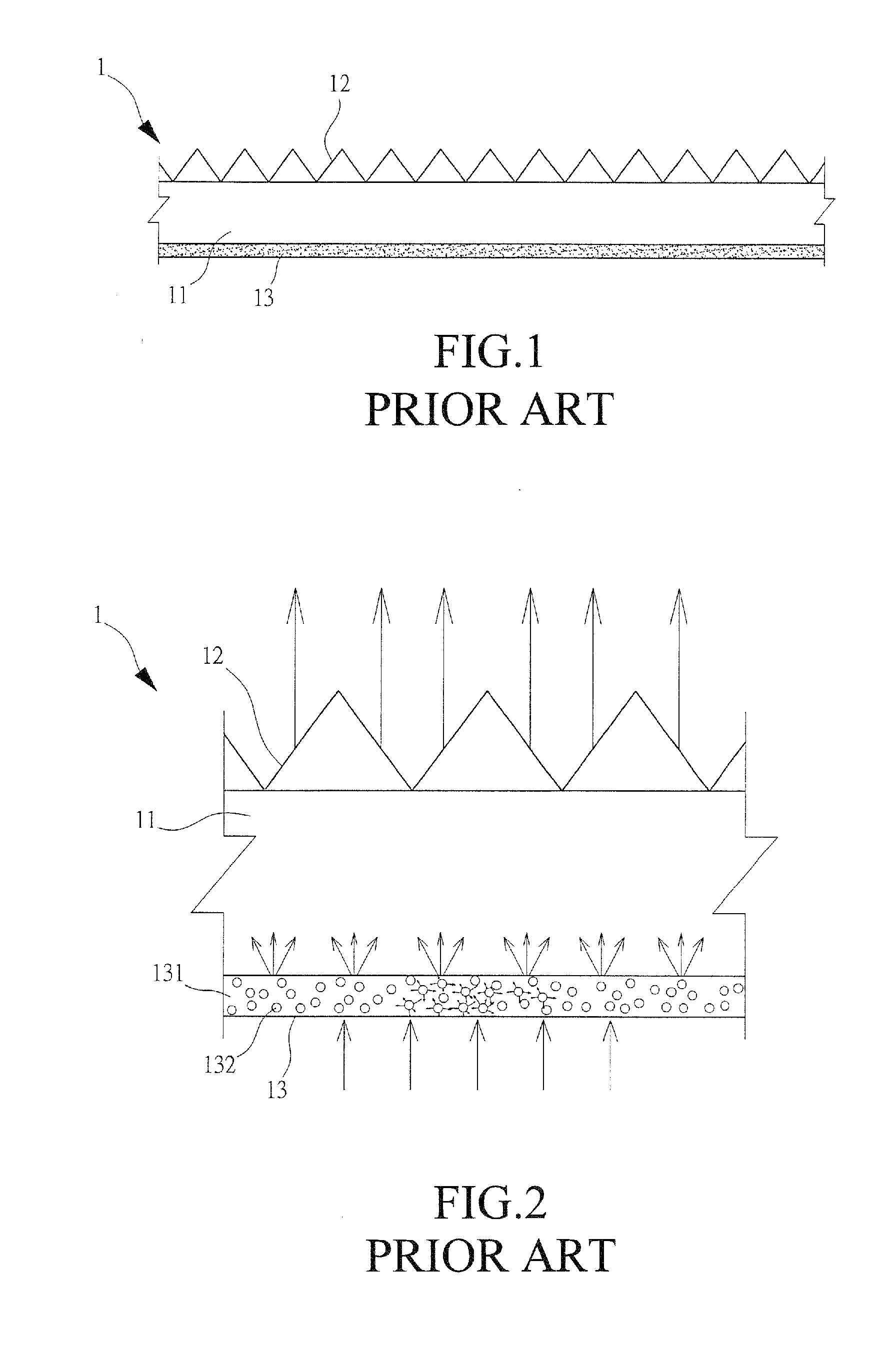

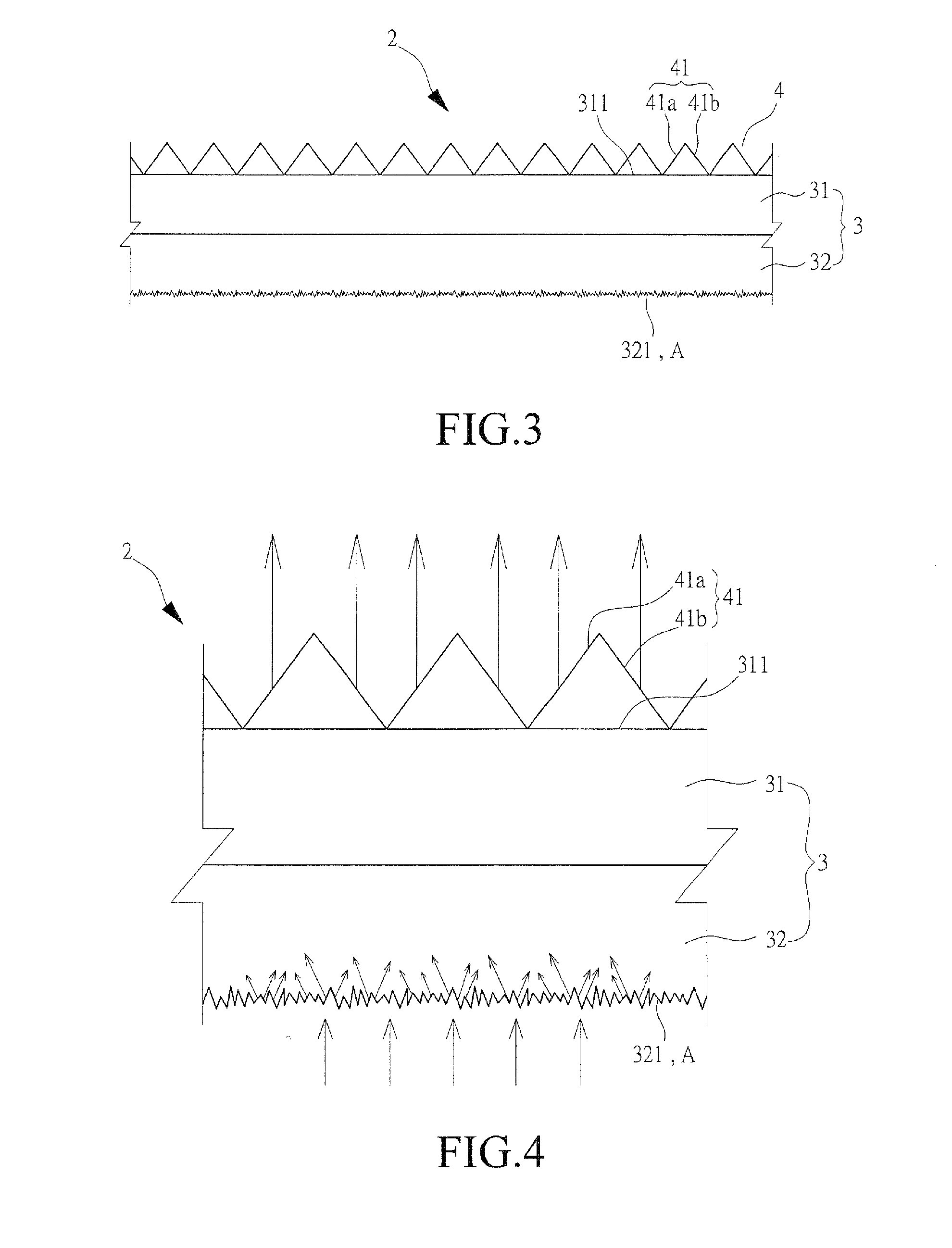

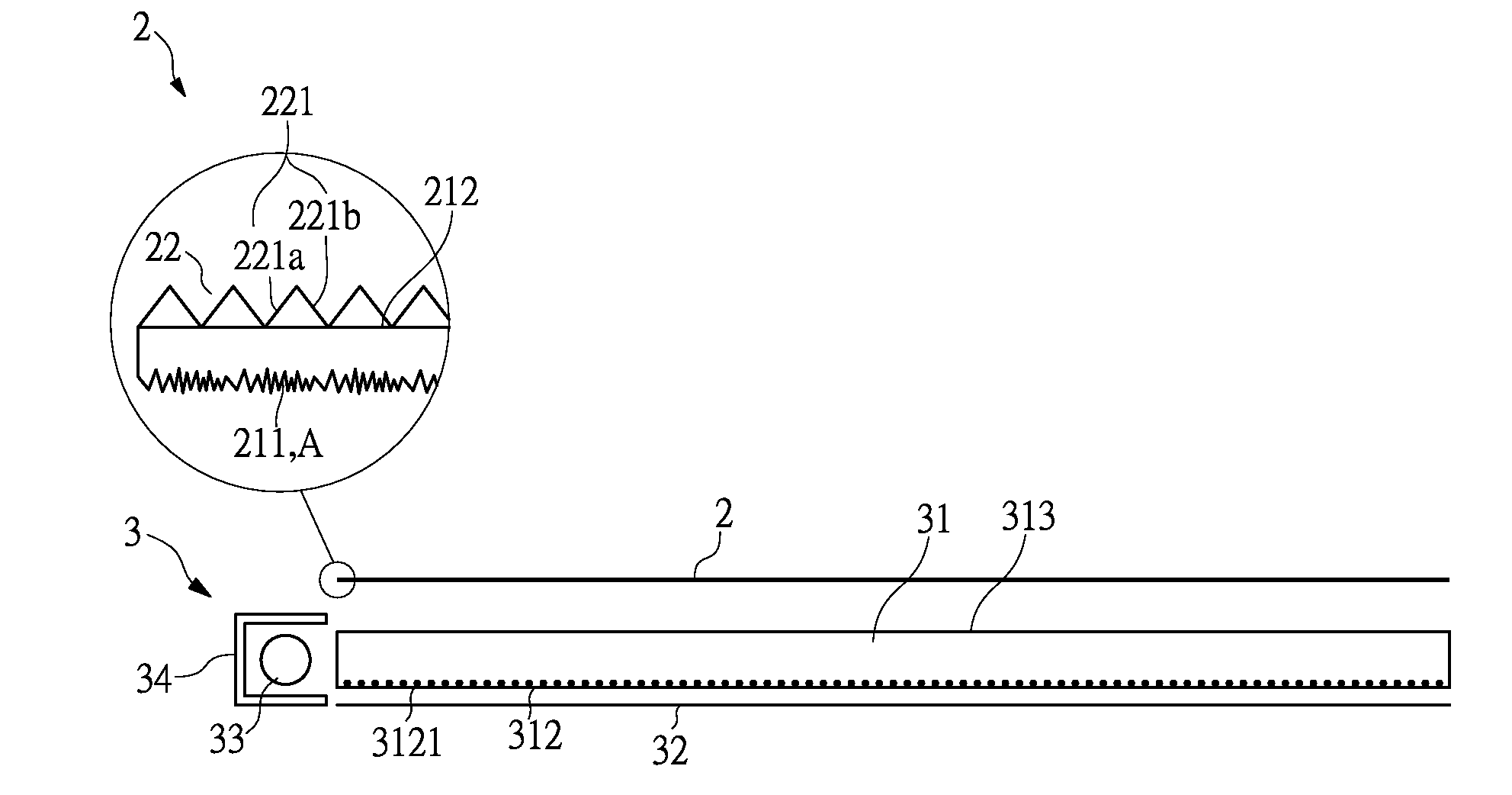

Optic film and backlight module using same

InactiveUS20100290249A1Poor adhesionDistribution can be difficultOptical light guidesNon-linear opticsEngineeringOptical film

Owner:GAMMA OPTICAL +1

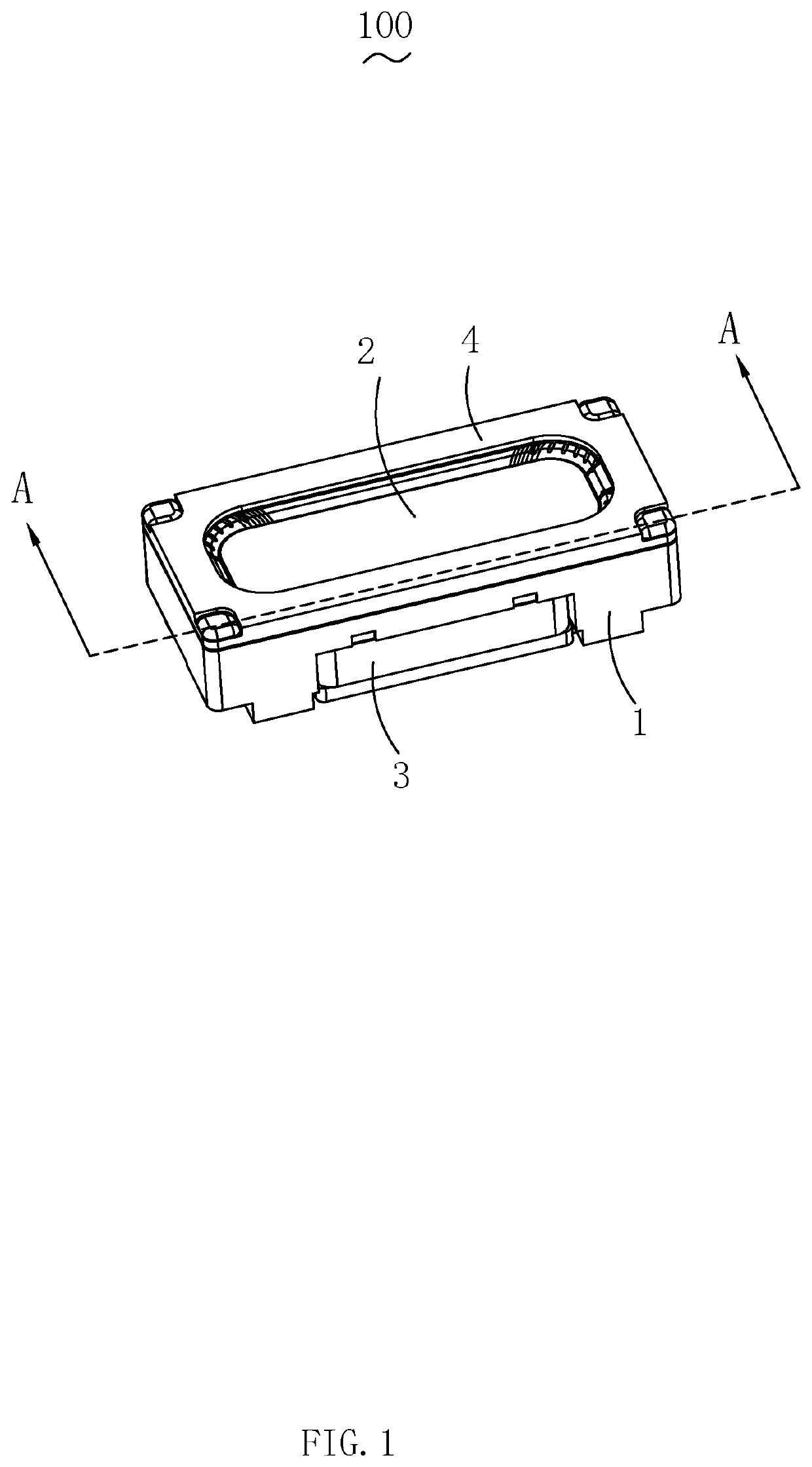

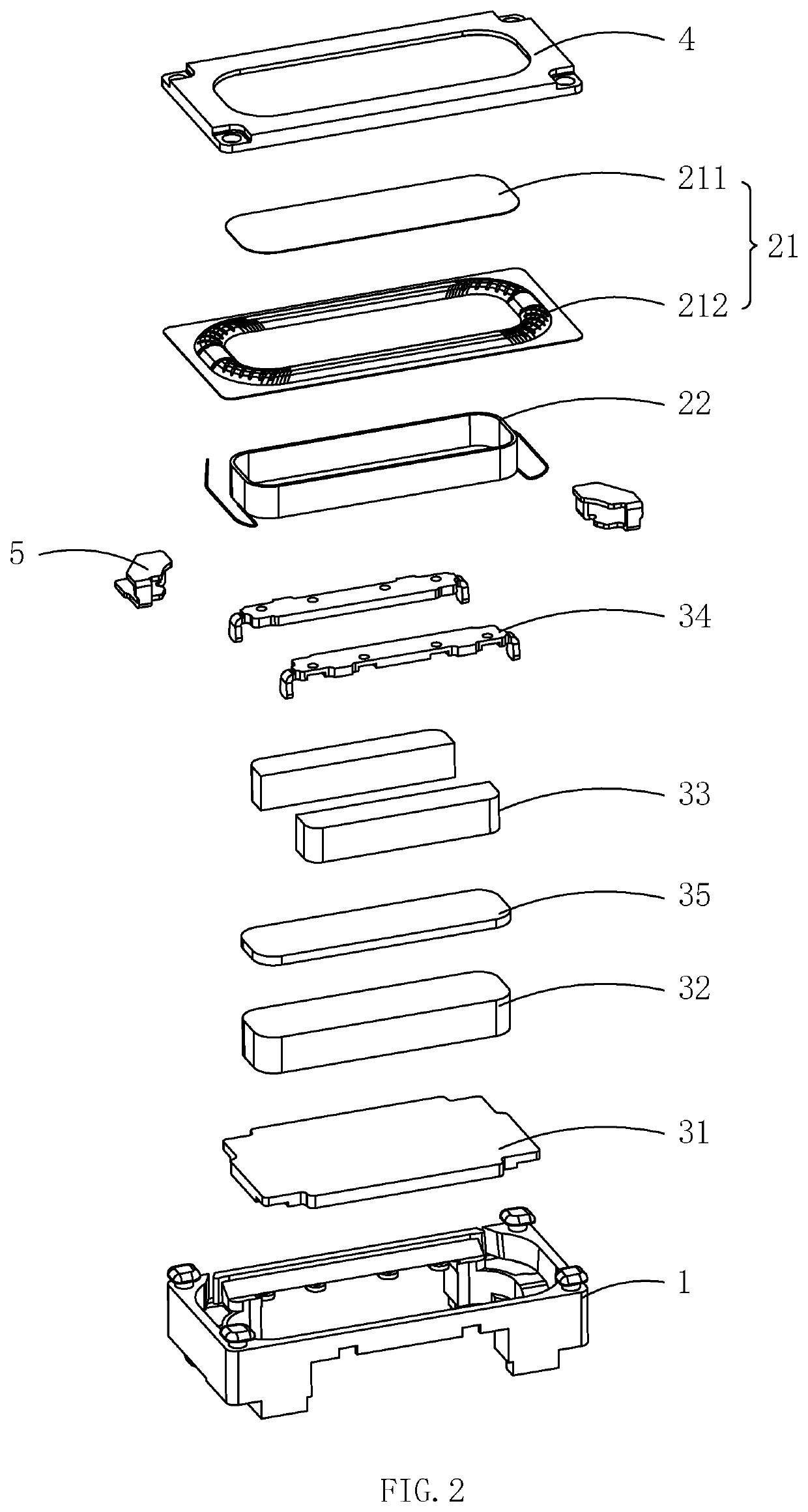

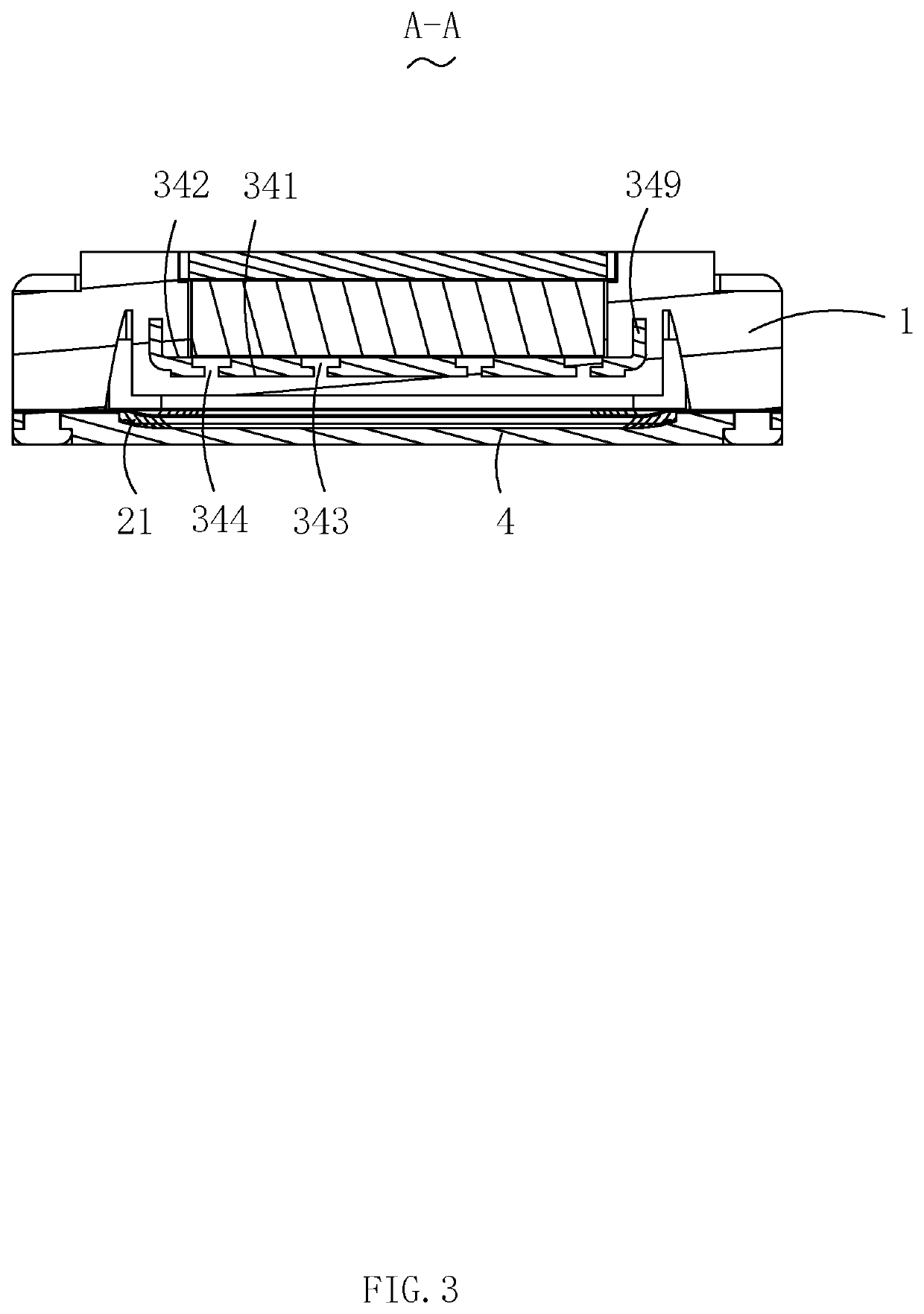

Speaker

ActiveUS20200068314A1Bonding forceLarge widthSingle transducer incorporationLoudspeakersLoudspeakerEngineering

The present disclosure provides a speaker, which includes a frame having receiving space, a magnetic circuit system and a vibration system received in the receiving space. The vibration system includes a diaphragm and a voice coil, the magnetic circuit system includes a lower plate fixed to the frame, a primary magnet fixed on the lower plate, two secondary magnets disposed on both sides of the primary magnet, and an upper plate disposed on the secondary magnet, the upper plate includes a first surface facing towards the diaphragm, a second surface distal from the diaphragm, a fixing groove recessed from the second surface towards the first surface and a fixing hole. The fixing groove includes a bottom surface distal from the second surface. The fixing hole extends from the bottom surface to the first surface. The frame being injection-molded is filled in the fixing groove and the fixing hole.

Owner:AAC TECH PTE LTD

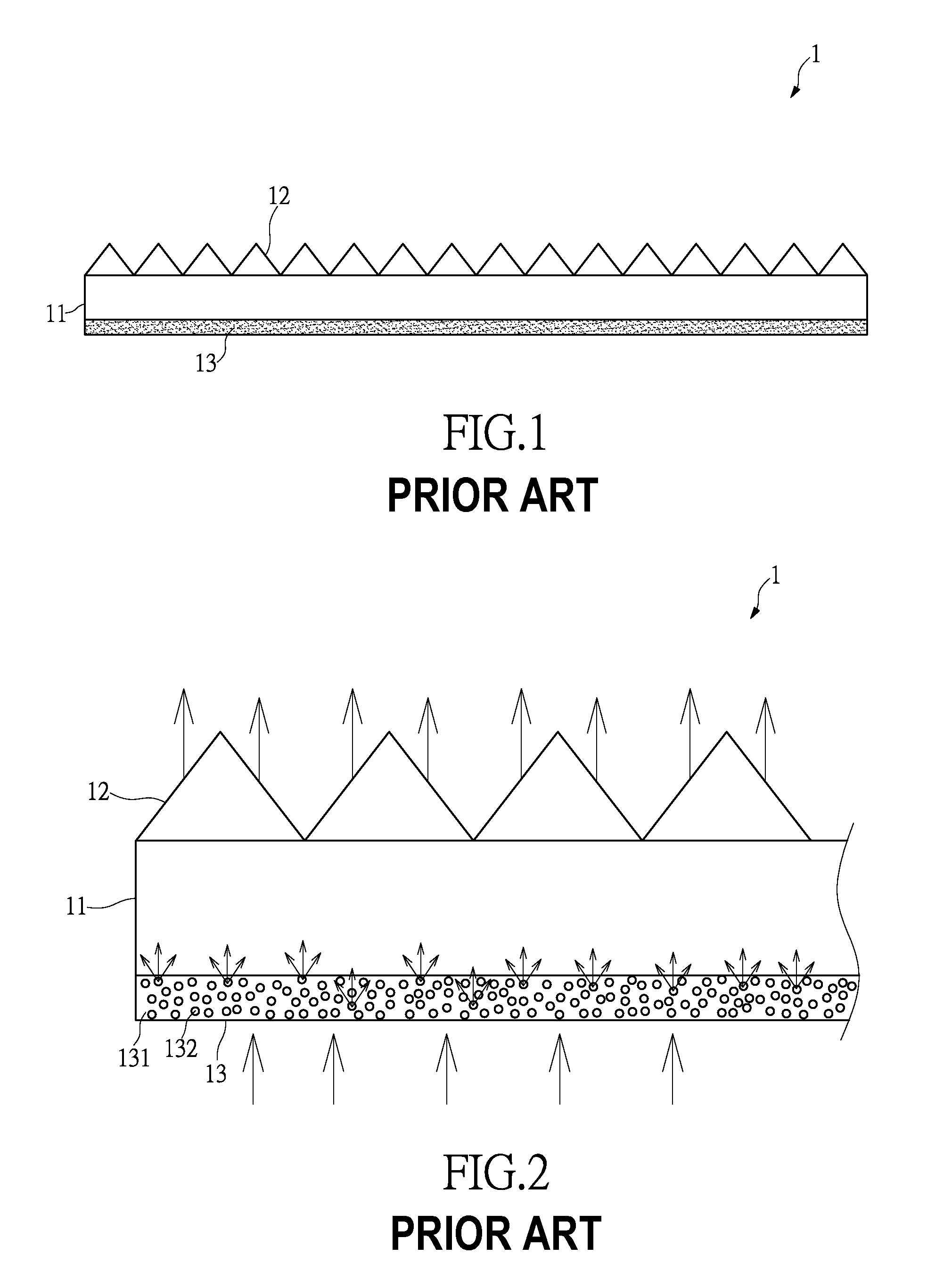

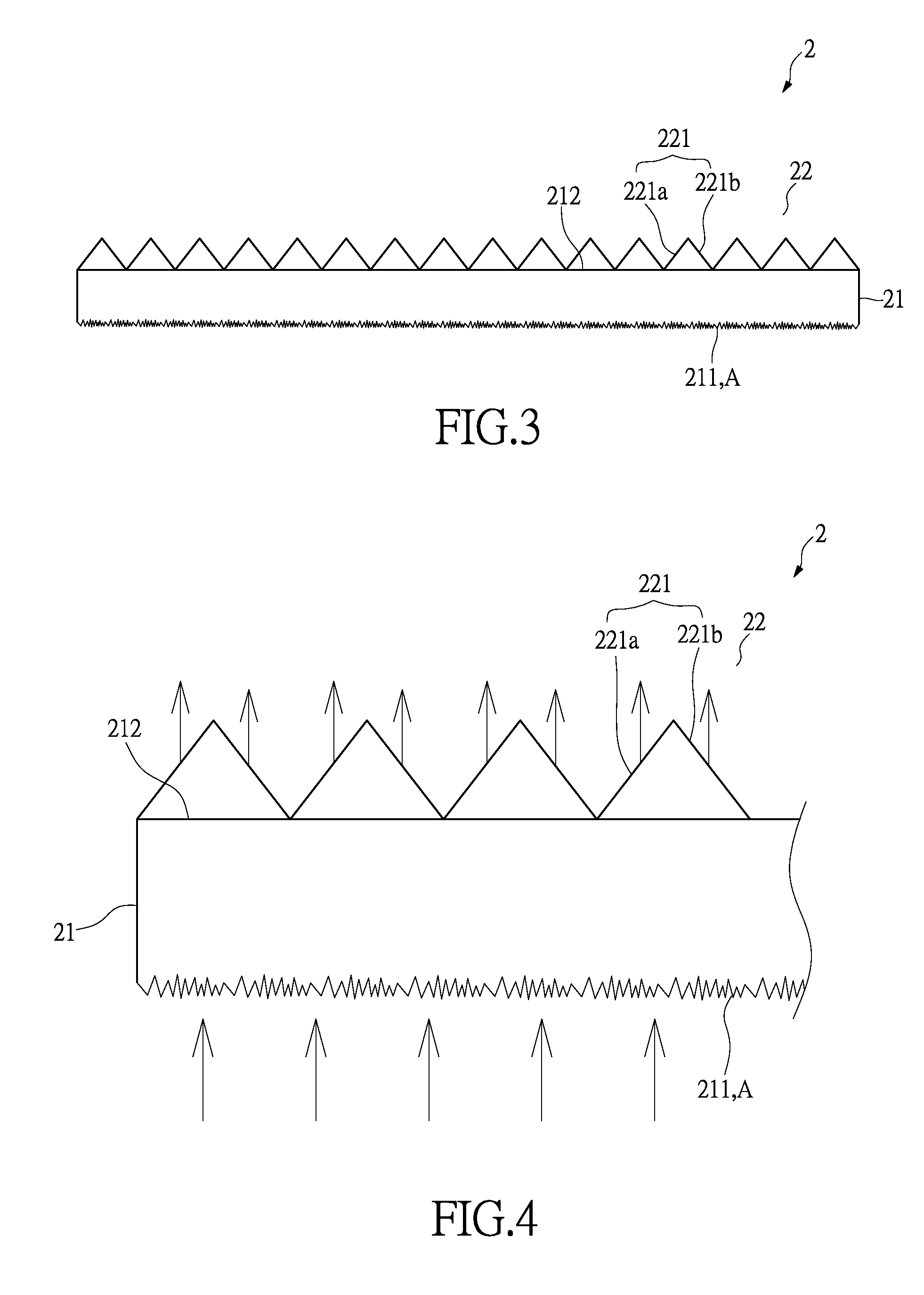

Optic film and backlight module using same

InactiveUS20100046248A1Increased material expenseBonding forceNon-electric lightingMechanical apparatusMicro structureSand blasting

An optic film includes a substrate and a condensation layer. The substrate has a light incidence surface and a light emission surface. The light incidence surface is treated to form a roughened frosted surface. The condensation layer is arranged on the light emission surface of the substrate and forms prism-like micro-structures. With the light incidence surface of the substrate being directly subjected to knurling or sand blasting to form the roughened frosted surface, when light enters the substrate through the light incidence surface, the light is diffused first by the frosted surface of the light incidence surface and is then subjected to condensation by the condensation layer, whereby when the optic film is applied to a backlight module, the optic film can effect both diffusion and condensation of light, so that the number of optic films used in the backlight module can be reduced.

Owner:MAI CHIEN CHIN +1

Coreless packaging substrate and method of fabricating the same

ActiveUS20160111301A1Easy to manufactureAvoid problemsSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

Owner:UNIMICRON TECH CORP

Membrane electrode assembly containing flexible printed circuit board formed on ion exchange membrane support film

ActiveUS8445152B2Inhibit transferBonding forceFuel cell heat exchangeFuel cells groupingIon-exchange membranesFlexible electronics

Disclosed is an MEA in which a catalyst layer is coated on both sides of an ion exchange membrane. An ion exchange membrane support film is attached on both sides of an edge portion of the ion exchange membrane, and a PCB is mounted on one surface of the ion exchange membrane support film along an outer line of the catalyst layer of the MEA. Furthermore, a PCB terminal is formed on one end of the PCB, and a connector is connected to the PCB terminal to communicate with an external controller. The PCB includes a heating element, a first temperature sensor measuring the temperature of the heating element, a second temperature sensor measuring the temperature of the MEA, a first contact measuring the resistance of unit cells, and a second contact measuring the voltage of the unit cells, formed in a predetermined arrangement to communicate with the PCB terminal.

Owner:HYUNDAI MOTOR CO LTD

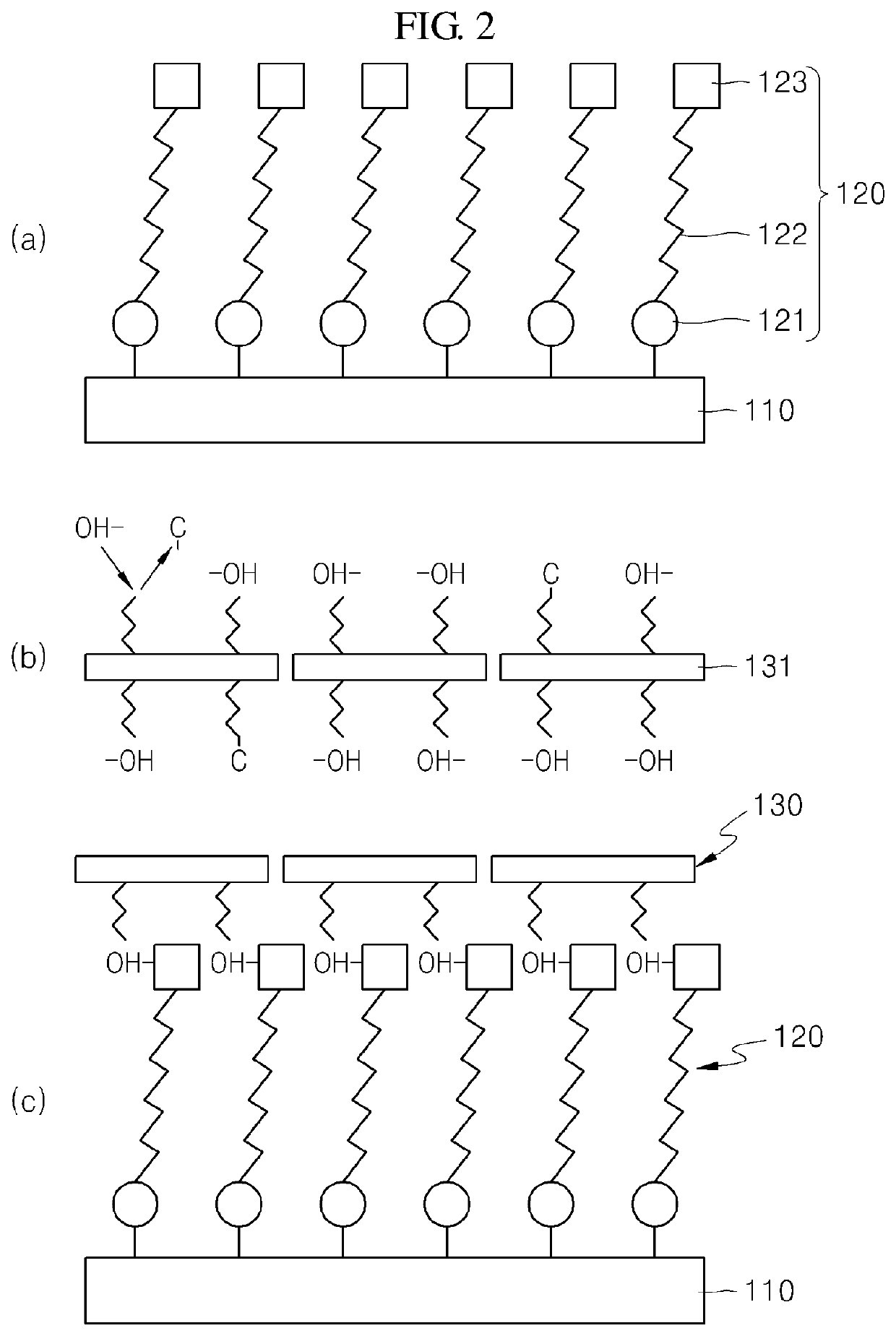

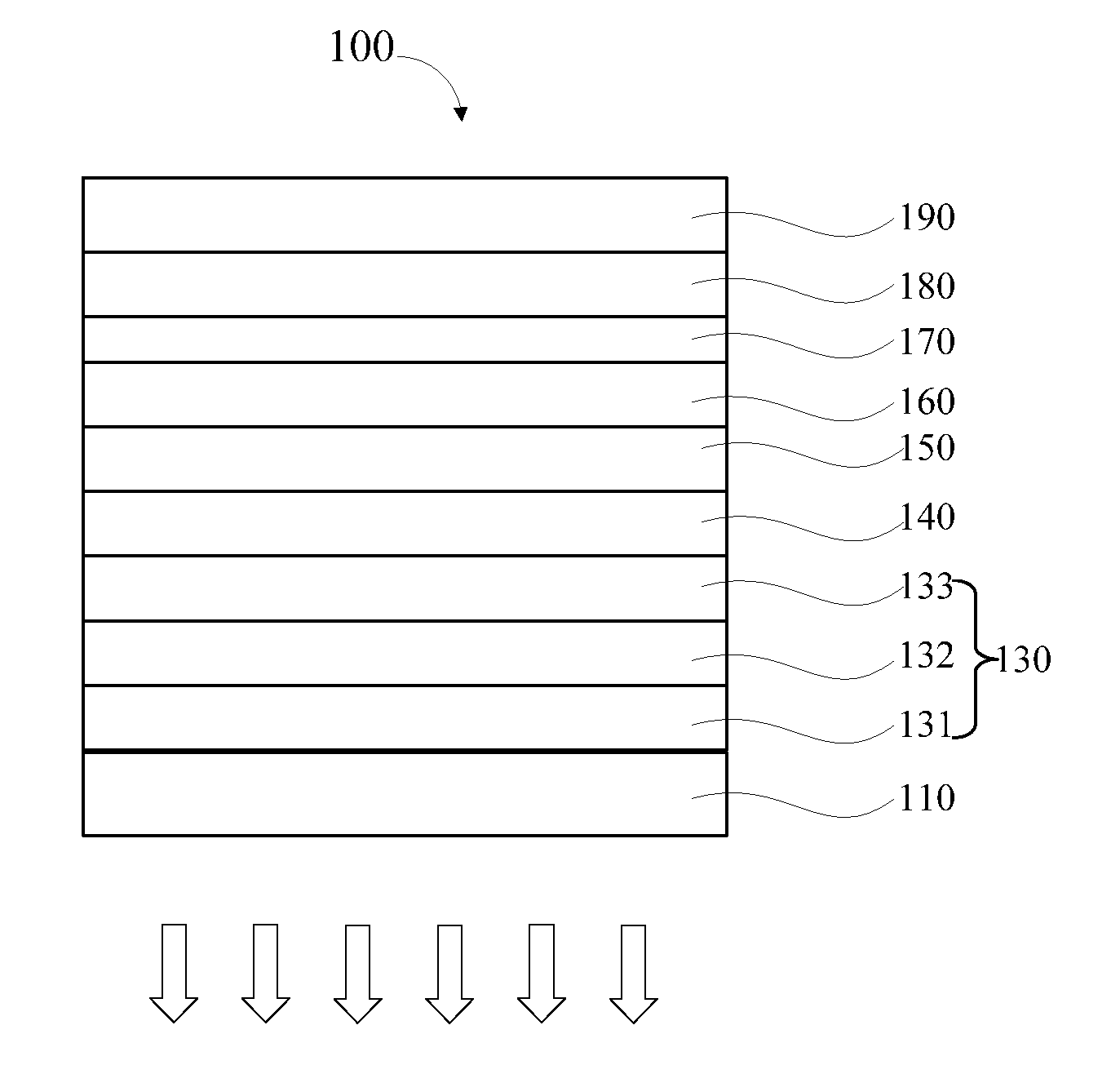

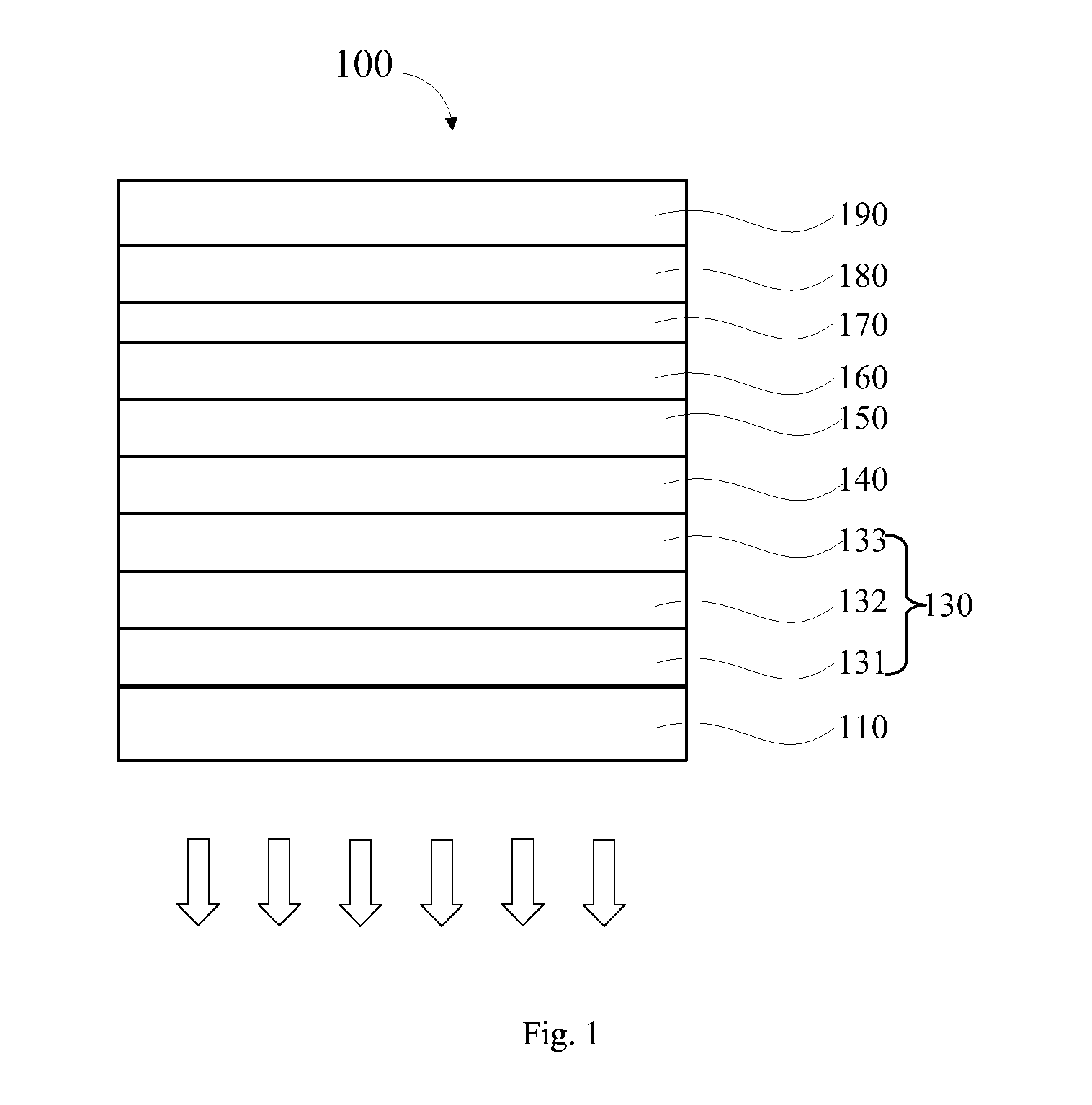

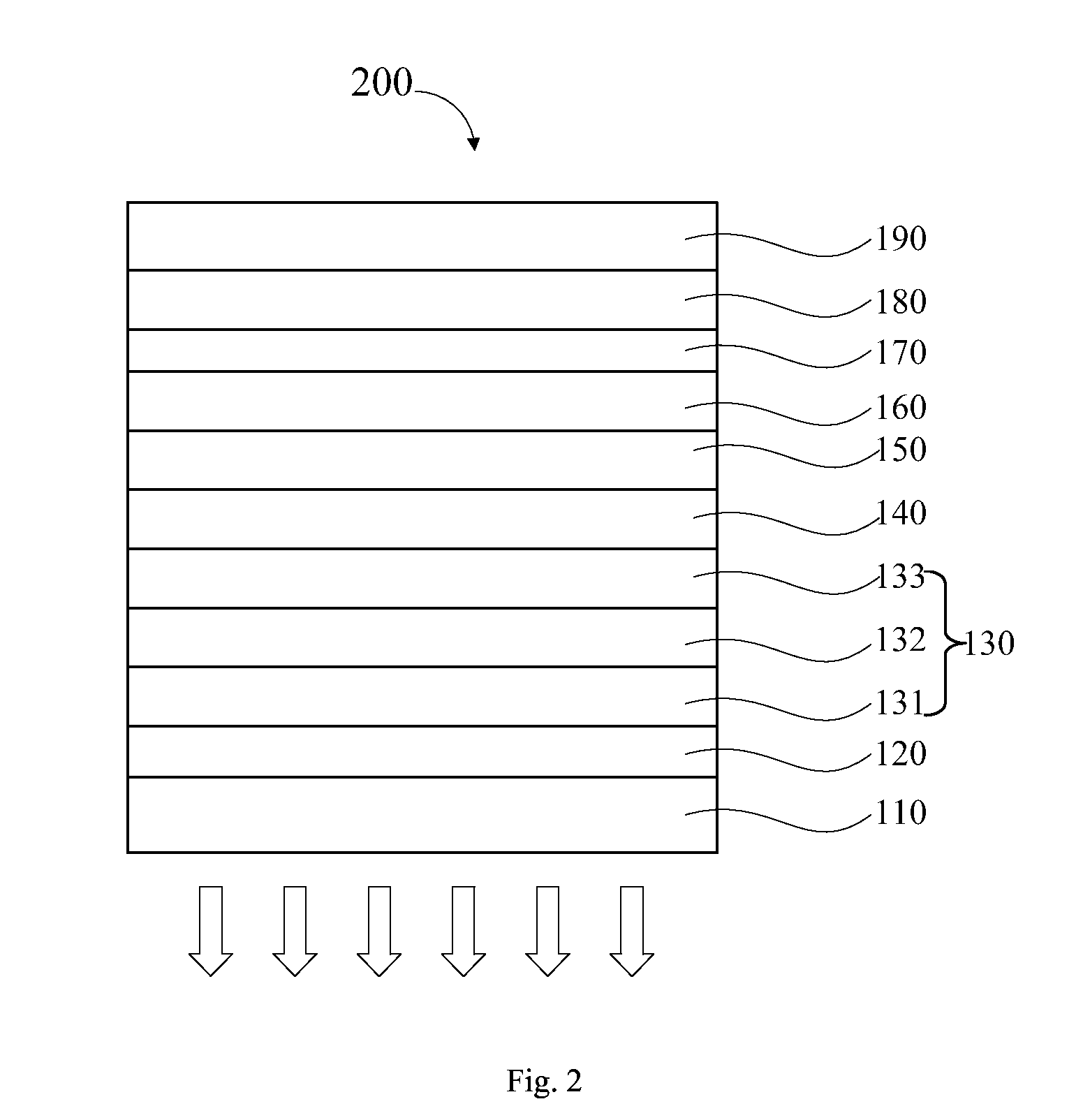

Organic electroluminescence device and method for manufacture thereof

InactiveUS20140332796A1High light transmittanceReduce surface resistanceOLED manufacture/treatment processesNanoinformaticsCompounds of zincRefractive index

An organic electroluminescence device (100, 200) comprises a substrate (110), an anode (130), a light emitting layer (160) and a cathode (190) stacked sequentially. The anode (130) comprises a light transmittance increased layer (131), a conductive layer (132) and a hole injection auxiliary layer (133) stacked on the substrate (110) sequentially. The materials of the light transmittance increased layer (131) are inorganic compounds of zinc with a light transmittance of 400 nm to 800 nm in the visible region and a refractive index greater than 2.3. The material of the conductive layer (132) is graphene. The utilization of light transmittance increased principle for multilayer anode structure can make the light transmittance of the anode in the visible region high and surface resistance low. The utilization of inorganic material with hole injection ability can reduce the hole injection barrier, make the luminous performance of the organic electroluminescence device (100, 200) stable and luminous efficiency high. A method for manufacturing the organic electroluminescence device (100, 200) is also provided. The anode is prepared by vacuum evaporation and pulling method, which is convenient to operate and is suitable for large scale production.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com