Sliding member and method of manufacturing same

a technology of sliding member and manufacturing method, which is applied in the direction of rotary machine parts, mechanical equipment, lubricant composition, etc., can solve the problems of difficult to change the sintering temperature, limited combinations of different types of base materials such as metal backings and porous sintered layer materials, etc., and achieves enhanced bonding force between base 12 and resin layer 14. , the effect of easy peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

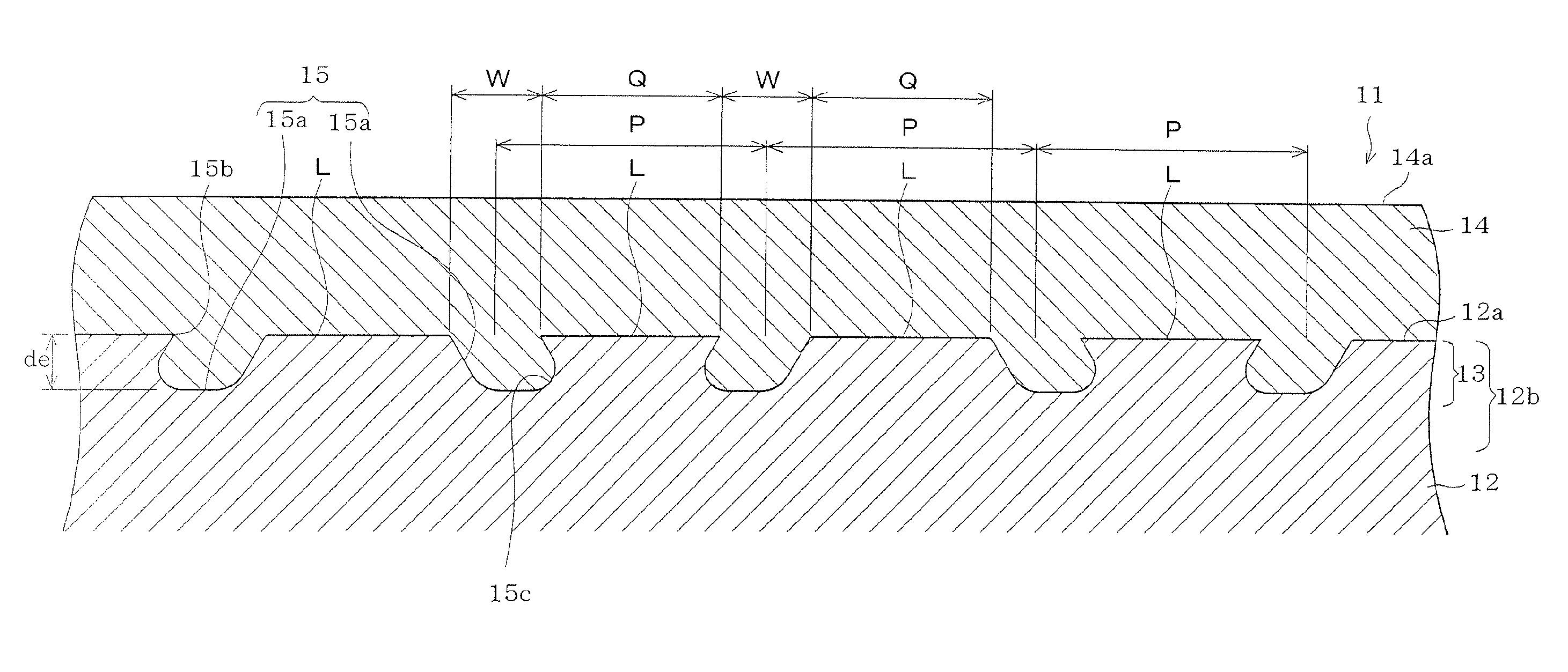

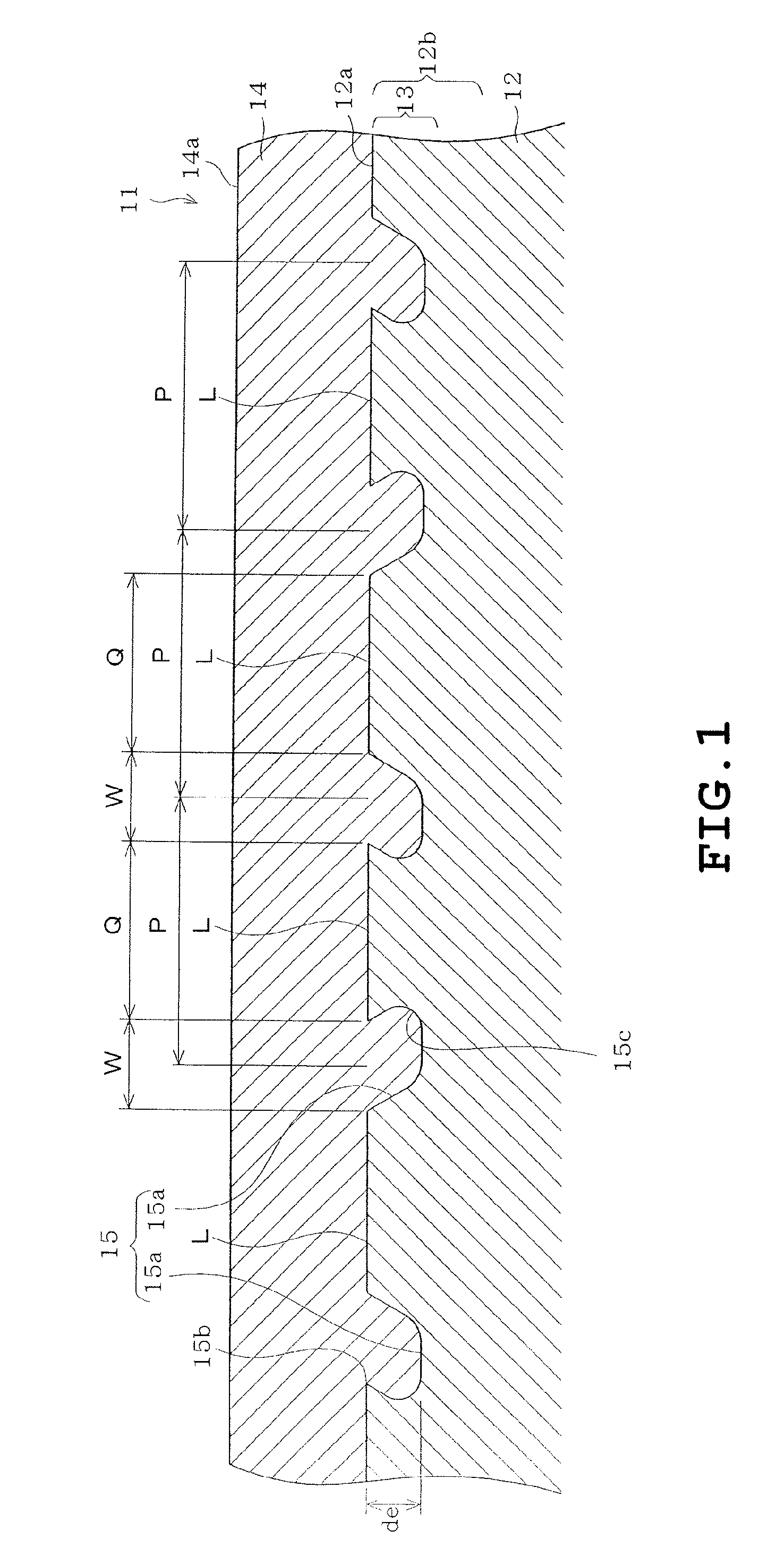

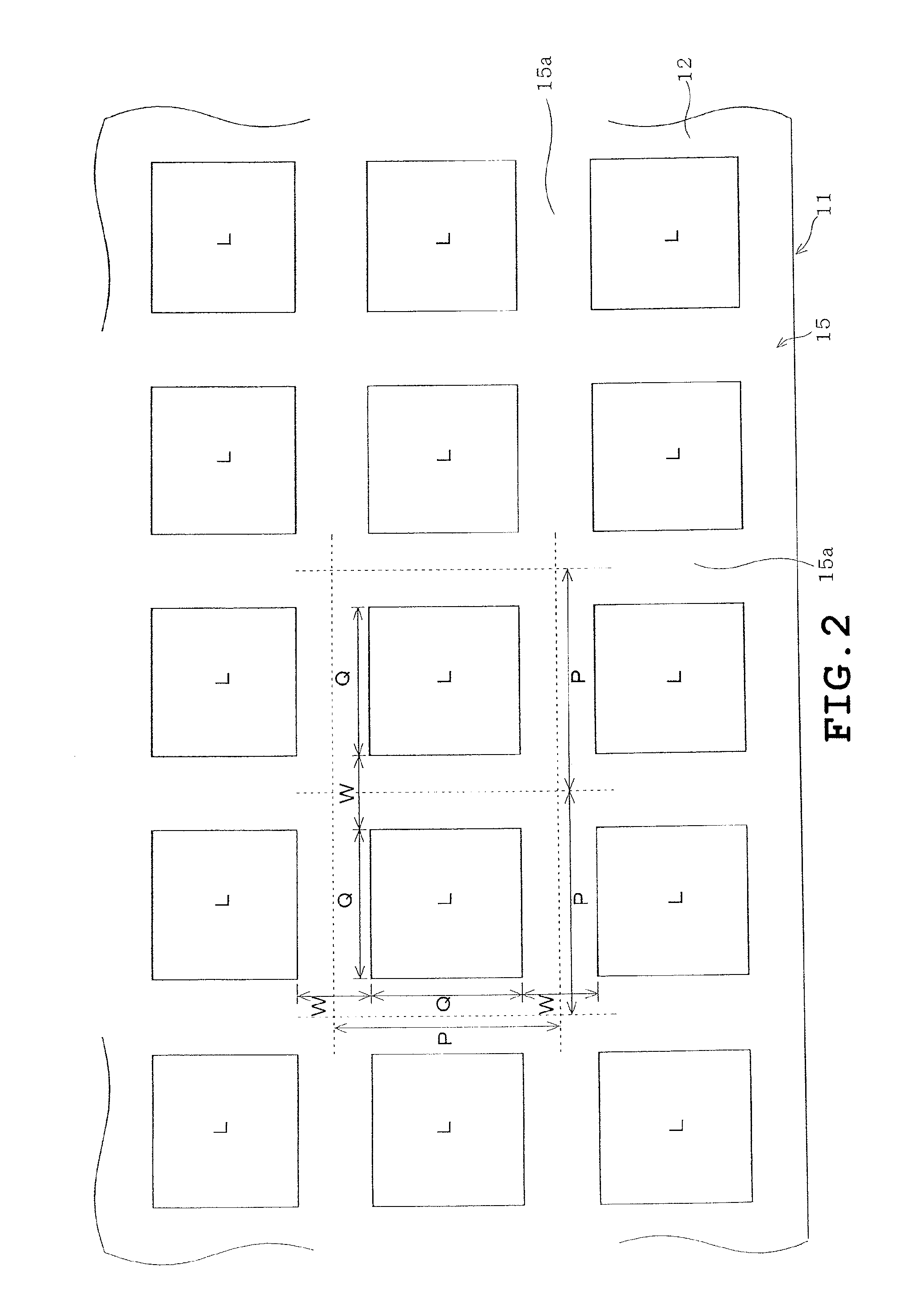

[0066]Next, an embodiment will be described with reference to FIGS. 1 to 3 and 7 and 8.

[0067]Slide member 11 of the present embodiment is obtained by preparing a base metal backing 12 made, for instance, of steel, providing impregnated layer 13 by forming recess 15 on surface portion 12b of base metal backing 12, and impregnating and covering impregnated layer 13 with resin layer 14 primarily composed of PEEK.

[0068]In order to verify the bonding force, in other words, the shearing stress of base 12 and resin layer 14 of slide member 11 of the present embodiment, EXAMPLES based on the embodiment and COMPARATIVE EXAMPLES based on conventional porous sintered configuration were prepared and were screened through a shear test.

[0069]More specifically, EXAMPLES were prepared as follows.

[0070]First, a steel backing plate serving as the base and having a thickness of 20 mm was prepared. Then, recesses were formed, by wire cut electrical discharge machining, on the surface portion of the bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com