Preparation method of manganese dioxide/carbon material/conducting polymer composite material

A conductive polymer, manganese dioxide technology, applied in the direction of hybrid capacitor electrodes, etc., can solve problems such as poor cycle performance, and achieve the effect of improving rate characteristics and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Under ice bath conditions, add 15g potassium permanganate to 130mL concentrated sulfuric acid and graphite mixture, then raise the temperature to 37°C for half an hour, then transfer to ice bath, slowly add 230mL deionized water dropwise, and then in 98°C React for 15 minutes, then add 700mL of 3% hydrogen peroxide and stir for 2 hours; graphite oxide can be obtained.

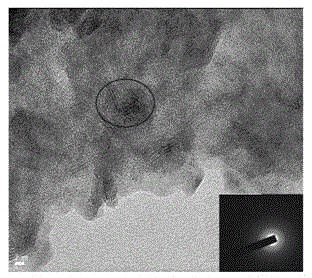

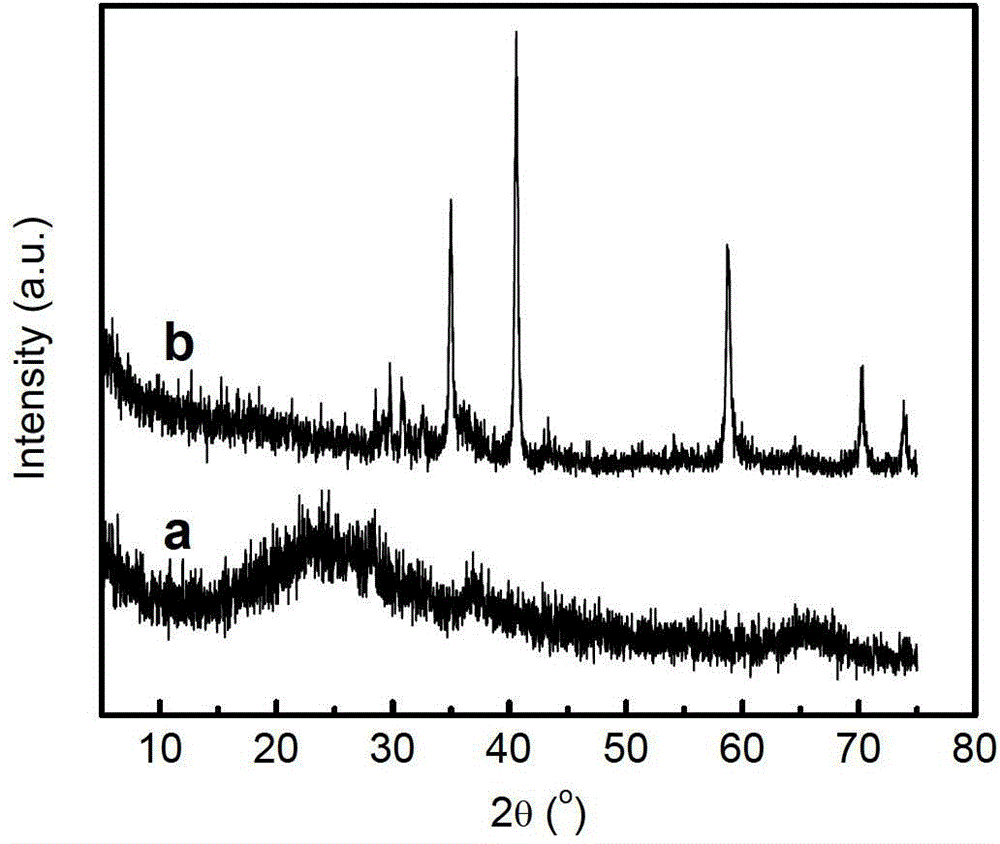

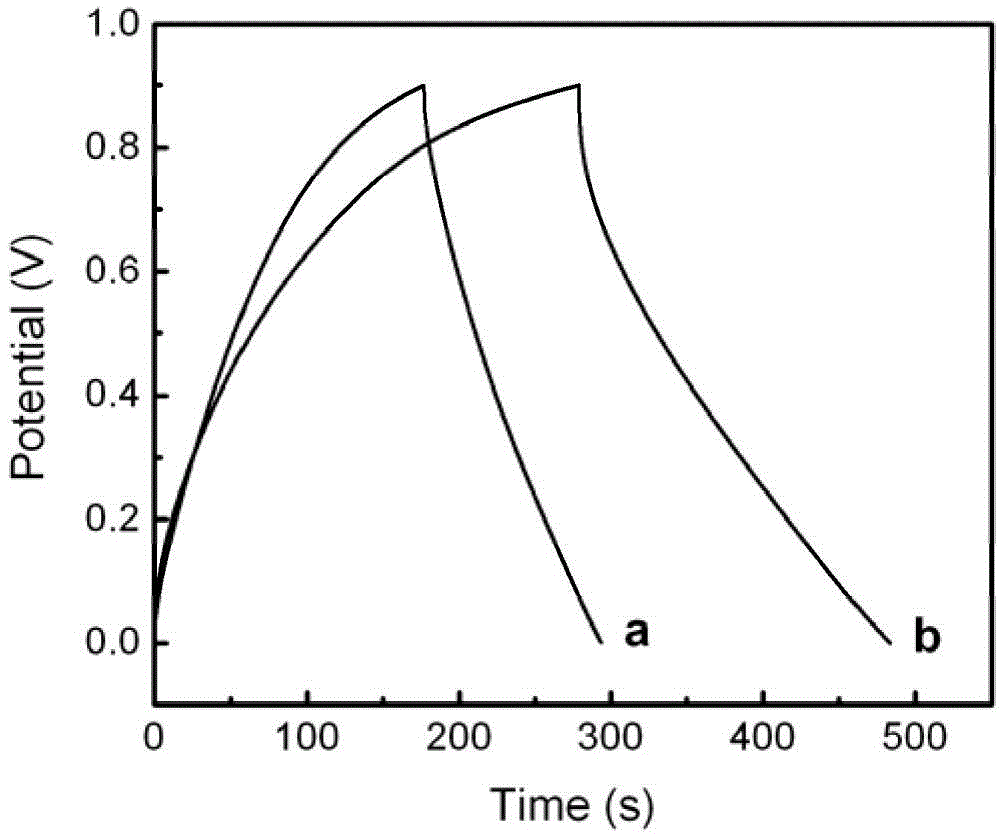

[0038] Disperse 0.47g of aniline monomer in 200mL of chloroform, place in an ice-water bath to cool to 0~5°C; dissolve 0.4g of potassium permanganate in 50mL of deionized water, and disperse 0.06g of graphite oxide in 150mL of deionized water, Add ammonia water to adjust pH=10, stir for three days and sonicate for 40 minutes at intervals to obtain a graphene oxide colloidal solution, both of which are cooled to 0~5°C in an ice-water bath, and then slowly add potassium permanganate dropwise to the graphite oxide dispersion , stirred mechanically for 1 hour, then carefully transferred the mixed solutio...

Embodiment 2

[0054] Disperse 0.47g of aniline monomer in 200mL of dichloromethane, place in an ice-water bath to cool to 0~5°C; dissolve 0.79g of potassium permanganate in 50mL of deionized water, and dissolve 0.06g of graphite oxide (the graphite oxide For the preparation, see Example 1) Disperse in 150mL deionized water, add ammonia water to adjust pH = 10, stir for three days and ultrasonically for 40min intervals to obtain a graphene oxide colloidal solution, both of which are cooled to 0~5°C in an ice-water bath , and then slowly add potassium permanganate dropwise to the graphite oxide dispersion, mechanically stir for 1 hour, then carefully transfer the mixture to the aniline dispersion to form a two-phase interface, stand in an ice-water bath for 24 hours, and the reaction is complete , the organic phase was carefully sucked out with a dropper and filtered, and the filter cake was washed and dried to obtain a graphene oxide-modified polyaniline / manganese dioxide ternary composite. ...

Embodiment 3

[0057] Disperse 1.86g of aniline monomer in 200mL of carbon tetrachloride, place in an ice-water bath to cool to 0~5°C; dissolve 3.16g of potassium permanganate in 50mL of deionized water, and dissolve 0.8g of graphite oxide (the Preparation of graphite, see Example 1) Disperse in 150mL deionized water, add ammonia water to adjust pH = 10, stir for three days and interval ultrasonic 40min to obtain graphene oxide colloidal solution, both are cooled to 0~5 in an ice water bath ℃, then slowly add potassium permanganate dropwise to the graphite oxide dispersion, mechanically stir for 2 hours, then carefully transfer the mixture to the aniline dispersion to form a two-phase interface, and stand in an ice-water bath for 72 hours to react. After completion, the organic phase was carefully sucked out with a dropper and filtered, and the filter cake was washed and dried to obtain a graphene oxide-modified polyaniline / manganese dioxide ternary composite.

[0058] 0.5 g of the obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com