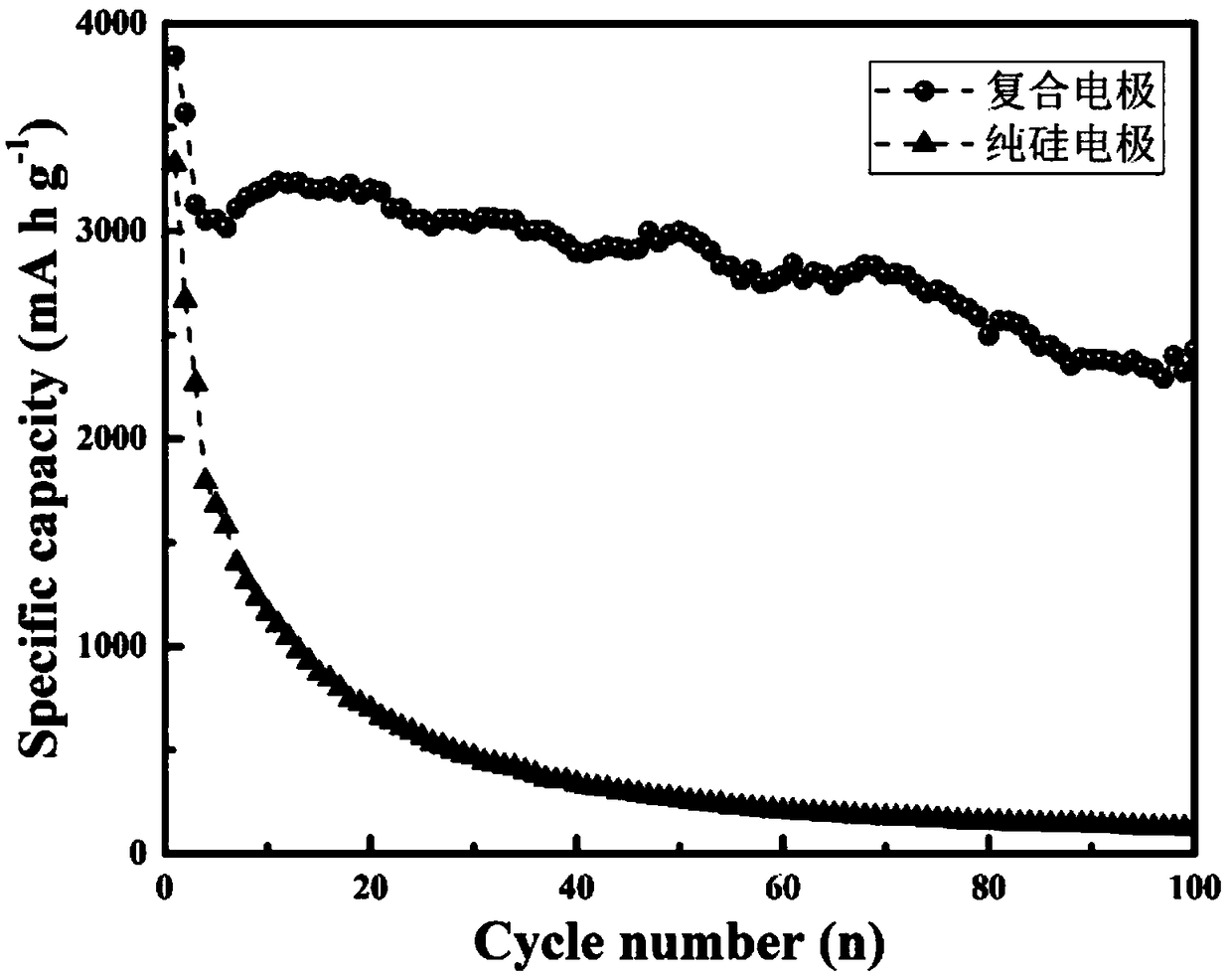

Lithium-ion-battery composite material and preparing method of composite electrode of lithium ion battery

A lithium-ion battery, composite electrode technology, applied in battery electrodes, nanotechnology for materials and surface science, negative electrodes, etc., to achieve the effects of improving stability, improving diffusion coefficient, and improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A lithium ion battery composite electrode, the preparation method comprising the following steps:

[0039] 1) Weigh 1g of graphite oxide powder and mix with 80ml of N,N-dimethylformamide, ultrasonically disperse for 1h, transfer to a 100ml reactor, and conduct a hydrothermal reaction at 220°C for 8h. After the mixture is cooled to room temperature, filter it with a microporous membrane to obtain a brown filtrate, remove the DMF solvent by rotary evaporation, then dissolve it in deionized water, dialyze it with a 3000Da molecular weight dialysis bag, and finally freeze-dry the solution in the bag to obtain a solid graphene quantum point;

[0040] 2) Disperse nano-silicon in a mixed solution of 100mL deionized water, 20mL hydrogen peroxide and 20mL ammonia water, heat and react in a water bath at 95°C for 30min, centrifuge and dry to obtain hydrophilic nano-silicon powder;

[0041] 3) Dissolve 0.5g of hydrophilic nano-silicon and 0.5g of dopamine hydrochloride in 100ml o...

Embodiment 2

[0051] 1) Weigh 1.6g of graphite oxide powder and mix with 80ml of N,N-dimethylformamide, ultrasonically disperse for 1h, transfer to a 100ml reactor, and conduct a hydrothermal reaction at 200°C for 8h. After the mixture is cooled to room temperature, filter it with a microporous membrane to obtain a brown filtrate, remove the DMF solvent by rotary evaporation, then dissolve it in deionized water, dialyze it with a 3000Da molecular weight dialysis bag, and finally freeze-dry the solution in the bag to obtain a solid graphene quantum point;

[0052] 2) Disperse nano-silicon in 100mL of deionized water, 40mL of hydrogen peroxide and 20mL of ammonia water, heat and react in a water bath at 95°C for 30min, centrifuge and dry to obtain hydrophilic nano-silicon powder;

[0053] 3) Dissolve 0.5g of hydrophilic nano-silicon and 0.5g of dopamine hydrochloride in 100ml of deionized water in turn, stir vigorously at room temperature for 2 hours, add 20ml of ammonium persulfate dropwise ...

Embodiment 3

[0058] 1) Weigh 1.6g of graphite oxide powder and mix with 80ml of N,N-dimethylformamide, ultrasonically disperse for 1h, transfer to a 100ml reactor, and conduct a hydrothermal reaction at 200°C for 8h. After the mixture is cooled to room temperature, filter it with a microporous membrane to obtain a brown filtrate, remove the DMF solvent by rotary evaporation, then dissolve it in deionized water, dialyze it with a 3000Da molecular weight dialysis bag, and finally freeze-dry the solution in the bag to obtain a solid graphene quantum point;

[0059] 2) Disperse nano-silicon in a mixed solution of 100mL deionized water, 40mL hydrogen peroxide and 20mL ammonia water, heat and react in a water bath at 95°C for 40min, centrifuge, and dry to obtain hydrophilic nano-silicon powder;

[0060] 3) Dissolve 0.5g of hydrophilic nano-silicon and 0.6g of dopamine hydrochloride in 100ml of deionized water in turn, stir vigorously at room temperature for 2 hours, add 20ml of ammonium persulfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com