Melt-extruded film

A technology of melt extrusion and extruder, which is applied in the field of melt extrusion film and its preparation, and can solve unsolved problems such as rapid release of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

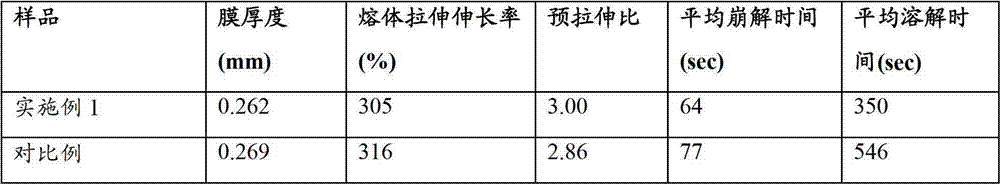

Embodiment 1

[0041] Component A is POLYOX WSR N-80NF (trademark of Dow Chemical Company). The substance is a polyethylene oxide polymer with a molecular weight of 200,000 g / mol. Component B is ibuprofen (Spectrum Chemical). Component C is Mannitol (SPI Polyols Inc.). These materials were blended at a ratio of 55 / 25 / 20 (POLYOX WSR N-80NF / Ibuprofen / Mannitol) for 10 minutes using a laboratory V-blender.

[0042] Film extrusion was performed using a Davis standard extruder equipped with a general purpose screw of 1.25 inch diameter (32 mm) and 24 / 1 length / diameter ratio. The extruder was equipped with an 8 inch (203 mm) wide cast film die with a die gap of about 0.025 inch (0.64 mm). The extruded film was pulled from the die using a vertical 3 roll stack and cooled. Steel casting rolls were controlled at 14.5°C using a Mokon Compu-Mate 100 controller. Extruder set points are: Barrel Zone 1 = 70°C, Barrel Zone 2 = 140°C, Barrel Zone 3 = 150°C, Die Zone 1 = 150°C, Die Zone 2 = 150 °C. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com