Method for preparing gold nanoparticles based on environmentally-friendly chemical method

A technology of gold nanoparticles and green chemistry, which is applied in the field of green chemistry to prepare gold nanoparticles with various shapes, can solve the problems of complex overall process, environmental toxicity, etc., and achieve the effect of high purity, less impurities and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

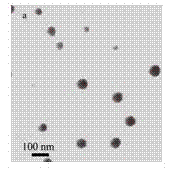

[0018] Embodiment 1 Preparation of spherical gold nanoparticles

[0019] Add a certain amount of CMC into water, heat it to 50°C to fully dissolve it, and then mix it with the aqueous solution containing chloroauric acid, so that the final concentrations of each component in the solution are: chloroauric acid 0.5mmol / L, CMC 25g / L . The above solution was heated to 80°C for reduction reaction for 8h. After the reaction, the reaction solution was centrifuged with a high-speed centrifuge (12,000 r / min) to separate the product, and the precipitate was washed with water three times to obtain spherical gold nanoparticles with an average particle size of 50 nm.

Embodiment 2

[0020] Embodiment 2 Preparation of multipod shape gold nanoparticles

[0021] Add a certain amount of CMC into water, heat it to 50°C to fully dissolve it, and mix it with the aqueous solution containing auric acid chloride, so that the final concentrations of the components in the solution are: 1mmol / L auric acid chloride and 15g / L CMC. The above solution was heated to 80°C for reduction reaction for 8h. After the reaction, the reaction solution was centrifuged in a high-speed centrifuge (10,000 r / min) to separate the product, and the precipitate was washed three times with water to obtain multipod-shaped gold nanoparticles with an average particle size of 100 nm.

Embodiment 3

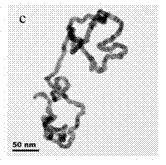

[0022] Example 3 Preparation of linear gold nanoparticles

[0023] Add a certain amount of CMC into water, heat it to 50°C to fully dissolve it, and then mix it with the aqueous solution containing chloroauric acid, so that the final concentrations of each component in the solution are: chloroauric acid 0.2mmol / L, CMC 2g / L . The above solution was heated to 80°C for reduction reaction for 8h. After the reaction, the reaction solution was centrifuged with a high-speed centrifuge (11,000 r / min) to separate the product, and the precipitate was washed three times with water to obtain linear gold nanoparticles with a width of about 10 nm and a length of more than 400 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com