Coating slurry for enhancing prestress of building ceramic and preparation method and building ceramic product of coating slurry

A technology of building ceramics and prestressing, which is applied in the field of building ceramic materials, can solve the problems that the prestressing enhancement method cannot meet the technical requirements of building ceramic materials, and it is difficult to control the force requirements of ceramic materials, so as to achieve simple and easy control of preparation, application and production , Accelerate the construction of ecological civilization and reduce the effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

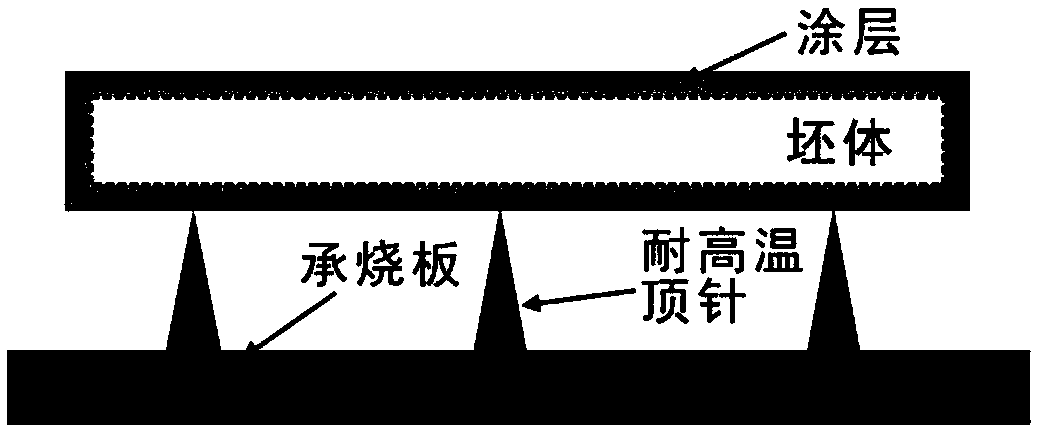

Method used

Image

Examples

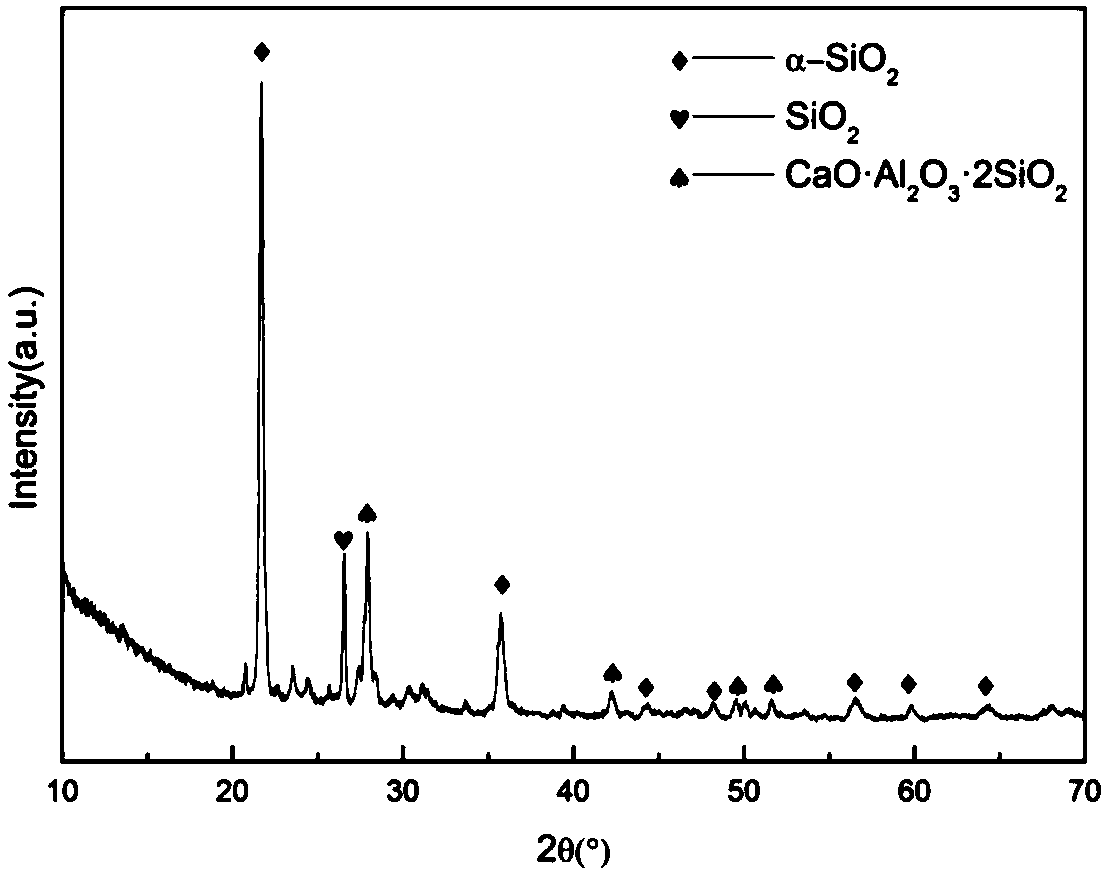

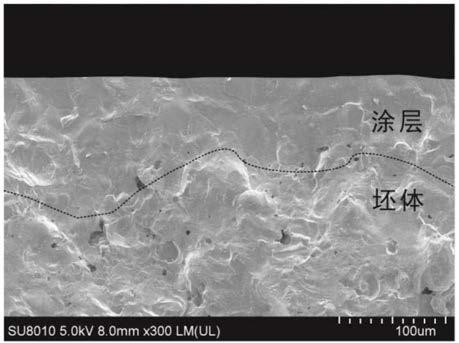

Embodiment Construction

[0030] An embodiment of the present invention is a coating slurry for prestressed reinforcement of architectural ceramics, which is composed of aggregate and binder according to the weight ratio of aggregate: binder = 1:4-8. Among them, the aggregate is a combination of oxides, hydroxides, and oxygen-containing salts of Si, Al, Mg, Ca, and Zn. Specifically, the composition of the aggregate is SiO in parts by weight. 2 Chemically pure and / or quartz 10-60, Al 2 o 3 Chemically pure 10~15, dolomite 0~45, CaCO 3 Chemically pure 0-35, calcite 0-35, calcined zinc oxide 1-5; the binder is one of CMC, PVA, PVB, water glass or a combination thereof. The composition of the coating slurry of each embodiment is shown in Table 1.

[0031] Table 1 Raw material composition (parts by weight) of the coating slurry of each embodiment of the present invention

[0032]

[0033] Note: SiO 2 、Al 2 o 3 , CaCO 3 , calcined zinc oxide are chemically pure

[0034] The preparation method of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com