Molybdenum disulfide/mesoporous carbon composite electrode material as well as preparation method and application thereof

A technology of molybdenum disulfide and composite electrodes, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of limited electrochemical performance and low electronic conductivity, and achieve excellent electrochemical performance, improved conductivity, and excellent rate Effects on performance and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Dissolve 1.5g sodium oleate, 1.0g sodium molybdate, and 0.9g thiourea in a mixed solvent of 15ml deionized water, 15ml ethanol and 2ml oleic acid, adjust the pH value to less than 1 with nitric acid, stir evenly, and The hydrothermal reaction was carried out at ℃ for 24 h, and after cooling to room temperature, the reaction product was washed and collected.

[0024] Dissolve 0.2g of P123 in 200ml of water, then add 0.25g of tromethamine and stir evenly to obtain a buffer solution, then disperse the above reaction product in 200ml of the buffer solution, sonicate for 30min and cool to room temperature, then add 250mg of dopamine while stirring , stirred at 10°C for 3 h, and the reaction product was collected by filtration and centrifugation.

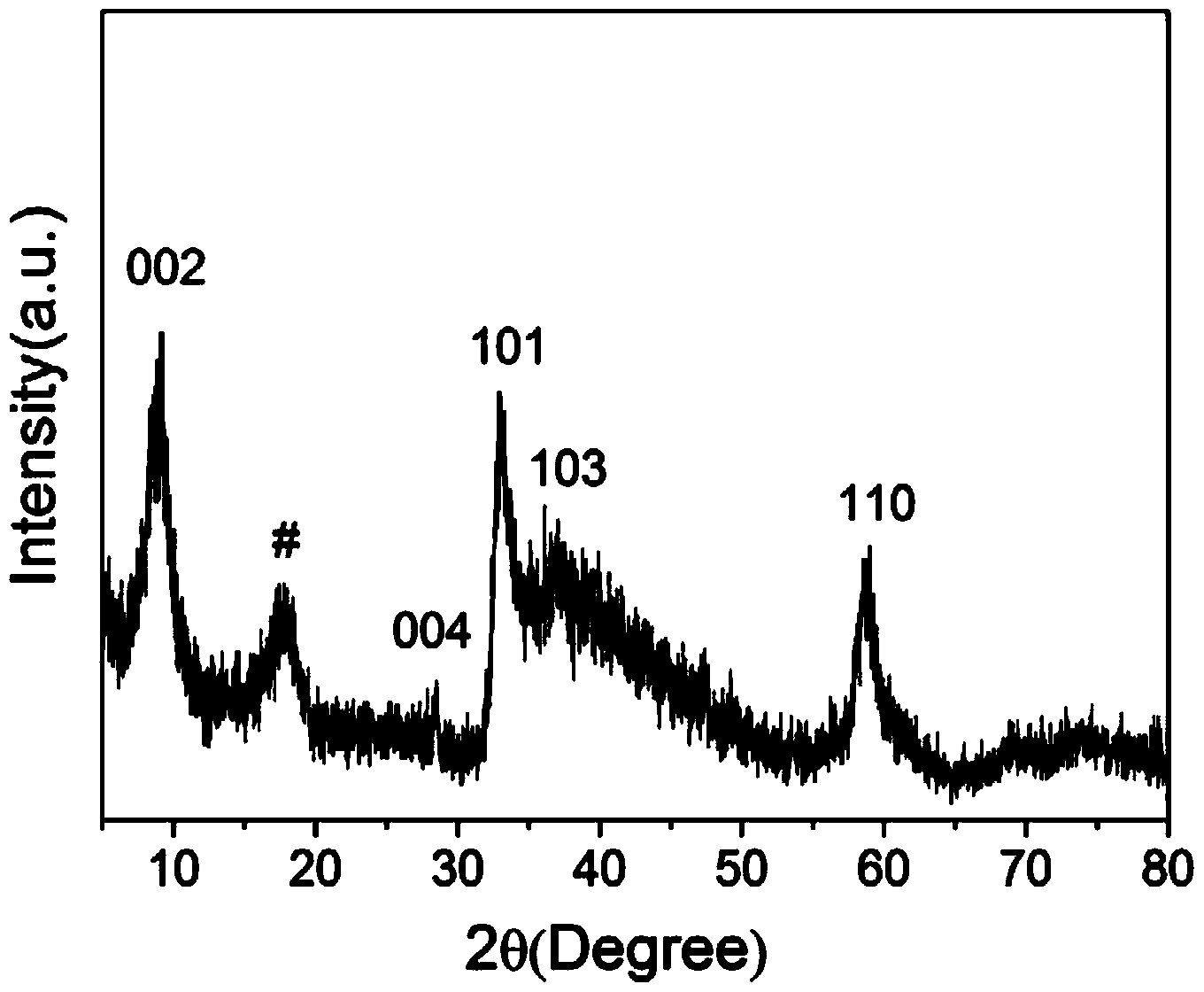

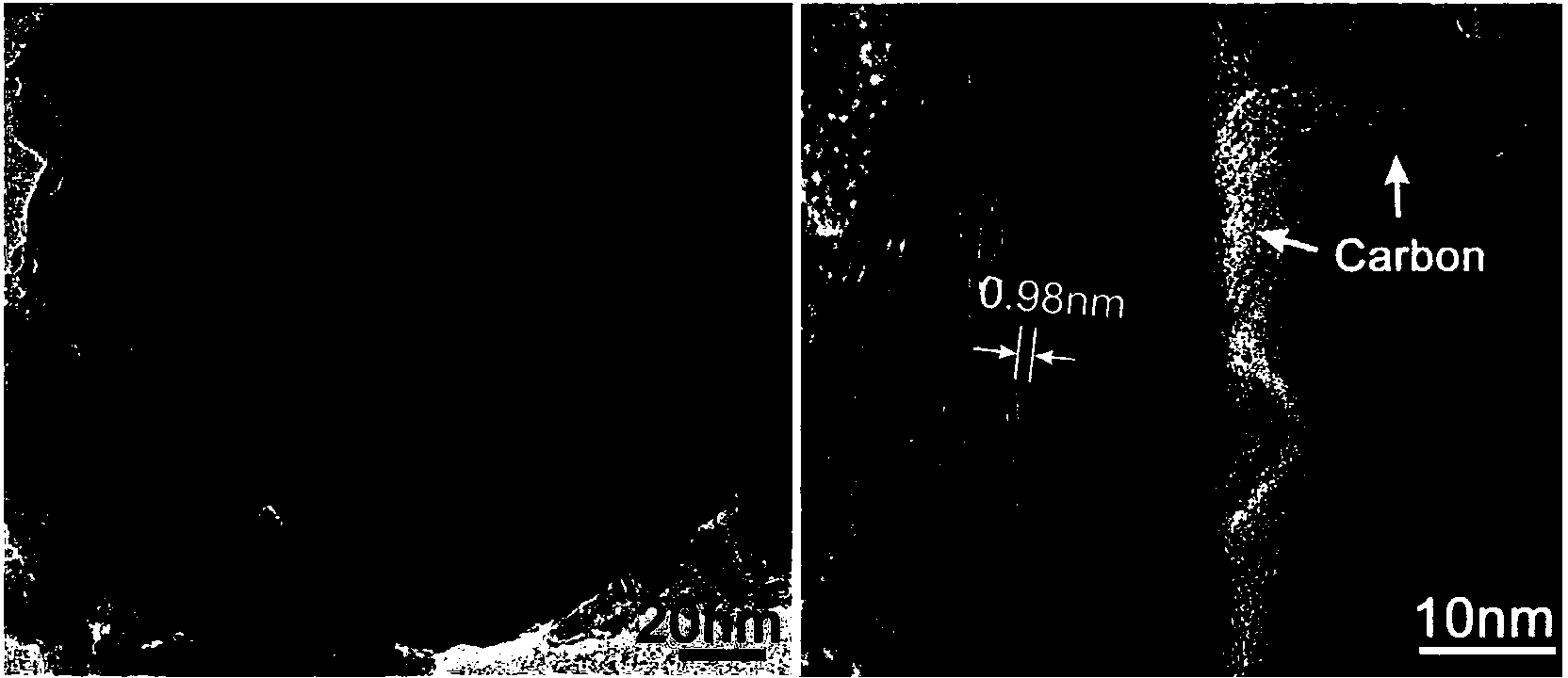

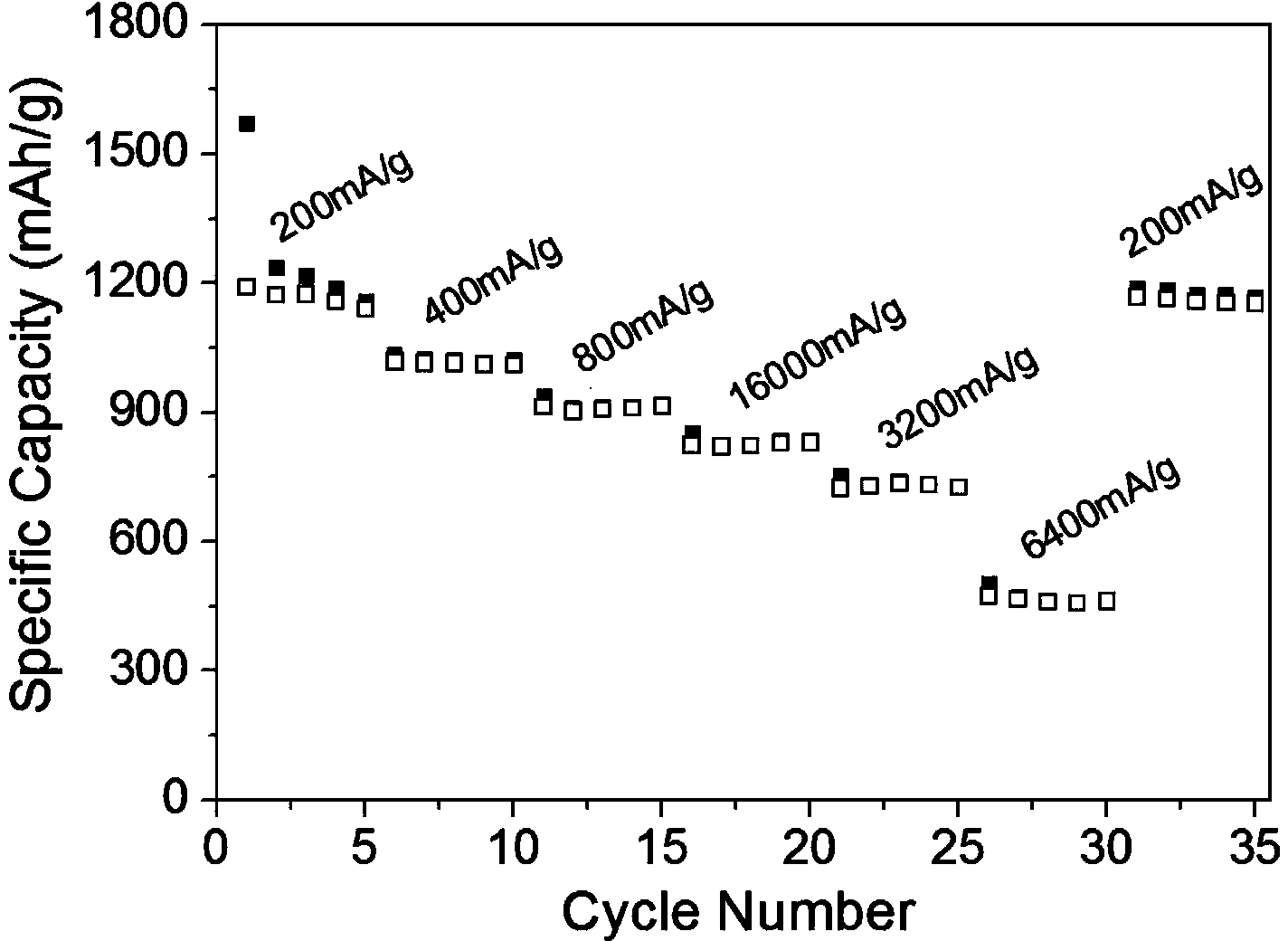

[0025] The obtained product was subjected to high-temperature carbonization in an argon atmosphere, and reacted at 600°C for 2 hours to obtain a molybdenum disulfide / mesoporous carbon composite electrode material, that is, a nano-h...

Embodiment 2

[0028] Dissolve 2g of sodium oleate, 1.5g of sodium molybdate, and 1.4g of thiourea in a mixed solvent of 20ml of deionized water, 20ml of ethanol, and 3ml of oleic acid, adjust the pH value to less than 1 with nitric acid, stir evenly, and heat at 160°C Carry out hydrothermal reaction for 30h, wash and collect the reaction product after cooling to room temperature.

[0029] Dissolve 0.3g of P123 in 300ml of water, then add 0.5g of trometamol and stir to obtain a buffer solution, then disperse the above-mentioned product in 100ml of the buffer solution, sonicate for 60min and cool to room temperature, then add 350mg of dopamine while stirring, The reaction was stirred at 250°C for 16 hours, and the reaction product was collected by filtration and centrifugation.

[0030] The obtained product was subjected to high-temperature carbonization in an argon atmosphere, and reacted at 850° C. for 34 hours to obtain a nano-hybrid material in which mesoporous carbon was embedded between...

Embodiment 3

[0032] Dissolve 3.0g sodium oleate, 2.0g sodium molybdate, and 2.0g thiourea in a mixed solvent of 30ml deionized water, 30g ethanol and 2ml oleic acid, adjust the pH value to less than 1 with nitric acid, stir evenly, and °C for hydrothermal reaction for 36 h, after cooling to room temperature, wash and collect the reaction product.

[0033] Dissolve 0.6g of P123 in 600ml of water, then add 0.75g of tromethamine and stir to obtain a buffer solution, then disperse the above-mentioned product in 200ml of the buffer solution, sonicate for 90min and cool to room temperature, add 500mg of dopamine while stirring, The reaction was stirred at 40°C for 24 hours, and the reaction product was collected by filtration and centrifugation.

[0034] The obtained product was subjected to high-temperature carbonization in an argon atmosphere, and reacted at 900° C. for 4 hours to obtain a nano-hybrid material with mesoporous carbon intercalated between molybdenum disulfide layers. The electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com