A kind of ultra-thin layered v5s8 and its preparation method and its application in lithium-ion/sodium-ion batteries

An ultra-thin, layered technology, applied in battery electrodes, secondary batteries, circuits, etc., to achieve good application prospects, expand layer spacing, and high reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

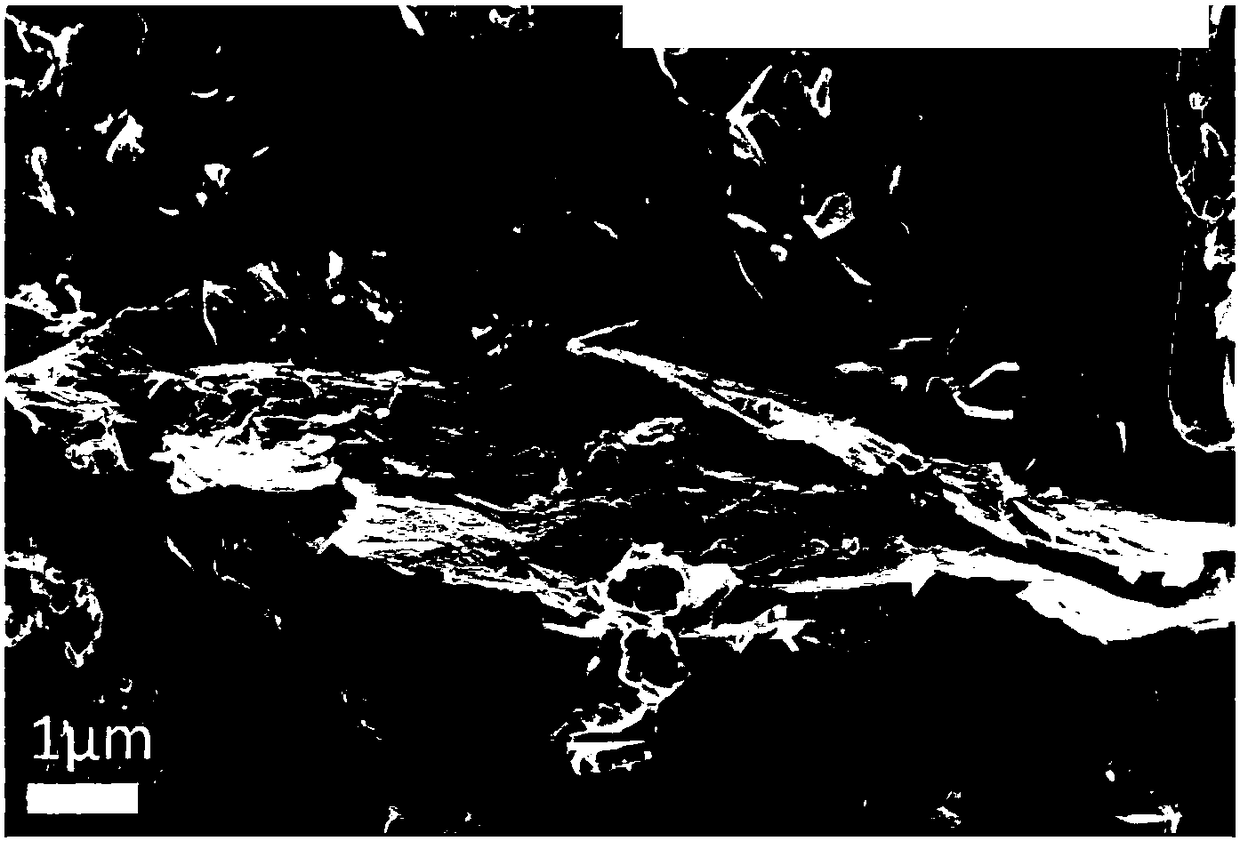

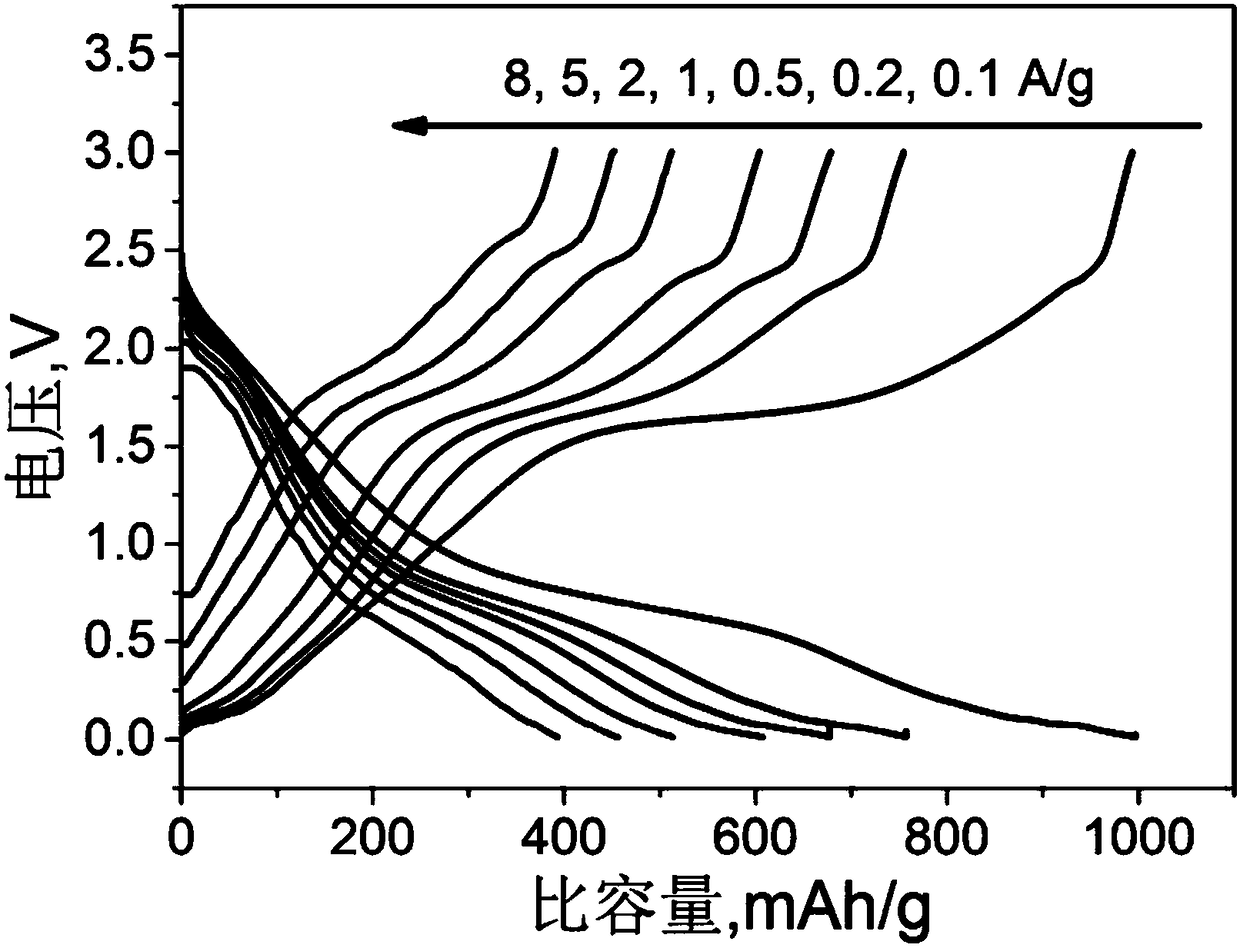

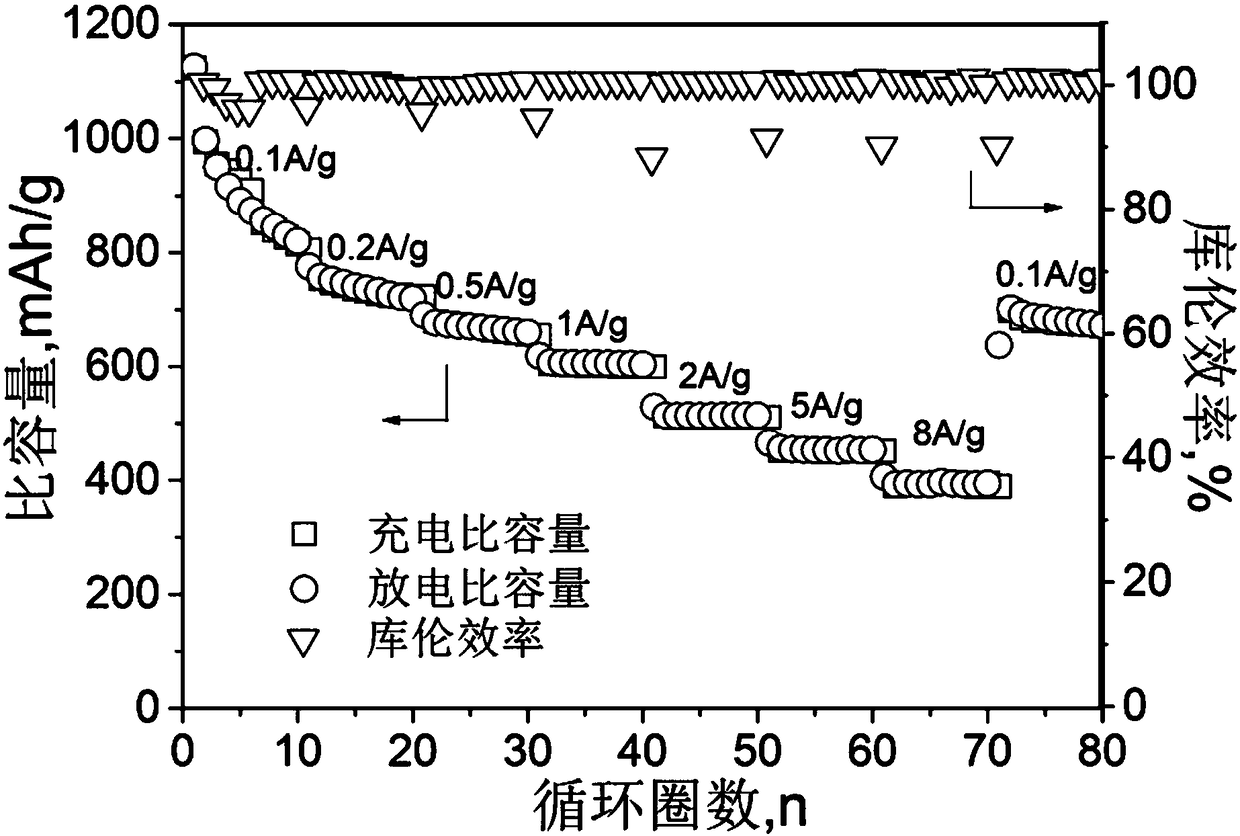

[0026] (1) Weigh 0.04 mol of vanadium pentoxide and 0.2 mol of sulfur powder, uniformly mix the raw materials with a ball mill, and press into tablets for calcination. The raw material after the tableting is in the mixed atmosphere of hydrogen and argon (H 2 The volume ratio to Ar is 5%) and sintered at 700° C. for 5 hours, and naturally cooled to room temperature to obtain product A. The product A and ethanol were uniformly mixed at a ratio of 1 g: 100 ml, ultrasonicated for 5 hours, and filtered to obtain precipitate B. Wash the precipitate B with deionized water and ethanol three times respectively, and dry it in vacuum at 60°C to obtain the finished ultra-thin layer V 5 S 8 . X-ray powder diffraction (XRD) analysis showed that the resulting product was pure V 5 S 8 , without any other impurity phase, the sample has high crystallinity. Scanning electron microscopy analysis revealed that the product V 5 S 8 It has an ultra-thin sheet structure, the diameter of the sh...

Embodiment 2

[0029](1) Weigh 0.02 mol of vanadium trioxide, 0.2 mol of thiourea and 0.001 mol of glucose, uniformly mix the raw materials with a ball mill, and press into tablets for calcination. The raw material after the tableting is in the mixed atmosphere of hydrogen and argon (H 2 The volume ratio to Ar is 8%) and sintered at 750° C. for 3 hours, and cooled naturally to room temperature to obtain product A. The product A was mixed with ethanol at a ratio of 1 g: 200 ml, ultrasonicated for 7 hours, and filtered to obtain precipitate B. The precipitate B was washed 4 times with deionized water and ethanol respectively, and dried in vacuum at 80°C to obtain the finished ultra-thin V 5 S 8 . XRD analysis showed that the obtained product was pure V 5 S 8 , without any other impurity phase, high crystallinity. According to SEM analysis, the product V 5 S 8 Has an ultra-thin layered structure, the diameter of the flake layer is 500nm, the thickness is 50nm, and V 5 S 8 The flakes w...

Embodiment 3

[0032] (1) Weigh 0.04 mol of ammonium metavanadate, 0.8 mol of thioacetamide and 0.004 mol of graphene, uniformly mix the raw materials with a ball mill, and press into tablets to prepare for calcination. The raw material after the tableting is in the mixed atmosphere of hydrogen and argon (H 2 The volume ratio of Ar to 10%) was sintered at 800° C. for 8 hours, and naturally cooled to room temperature to obtain product A. Mix product A with acetone at a ratio of 1 g: 300 ml, sonicate for 10 hours, and filter to obtain precipitate B. The precipitate B was washed 5 times with deionized water and ethanol respectively, and dried in vacuum at 90°C to obtain the finished ultra-thin layer V 5 S 8 piece. XRD analysis showed that the obtained product was pure V 5 S 8 , without any other impurity phase, the sample has high crystallinity. According to SEM analysis, the product V 5 S 8 It has an ultra-thin sheet structure, the diameter of the sheet layer is 400nm, the thickness is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com