Antirust for reinforced concrete

A technology of reinforced concrete and rust inhibitor, applied in the field of rust inhibitor, can solve the problems of short action time, decrease of concrete compressive strength, local corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: a kind of reinforced concrete anticorrosion agent, each constituent optimal combination weight percentage is

[0016] Sodium molybdate 0.03%, diethylenetriamine 4.5%, propenylthiourea 0.15%, 1.4-butynediol 0.19%, and the rest is water.

[0017] When making concrete, add the raw materials into the mixer in sequence, but when adding water, add water to dissolve according to the requirements in the formula.

Embodiment 2

[0018] Embodiment 2: a kind of reinforced concrete rust inhibitor, each constituent is by weight percentage

[0019] Sodium molybdate 0.01%, diethylenetriamine 0.9%, propenylthiourea 0.08%, 1.4-butynediol 0.15%, and the rest is water.

[0020] When making concrete, add the raw materials into the mixer in sequence, but when adding water, add water to dissolve according to the requirements in the formula.

Embodiment 3

[0021] Embodiment 3: a kind of reinforced concrete rust inhibitor, each constituent is by weight percentage

[0022] Sodium molybdate 0.05%, diethylenetriamine 4.5%, propenylthiourea 0.19%, 1.4-butynediol 0.75%, and the rest is water.

[0023] When making concrete, add the raw materials into the mixer in sequence, but when adding water, add water to dissolve according to the requirements in the formula.

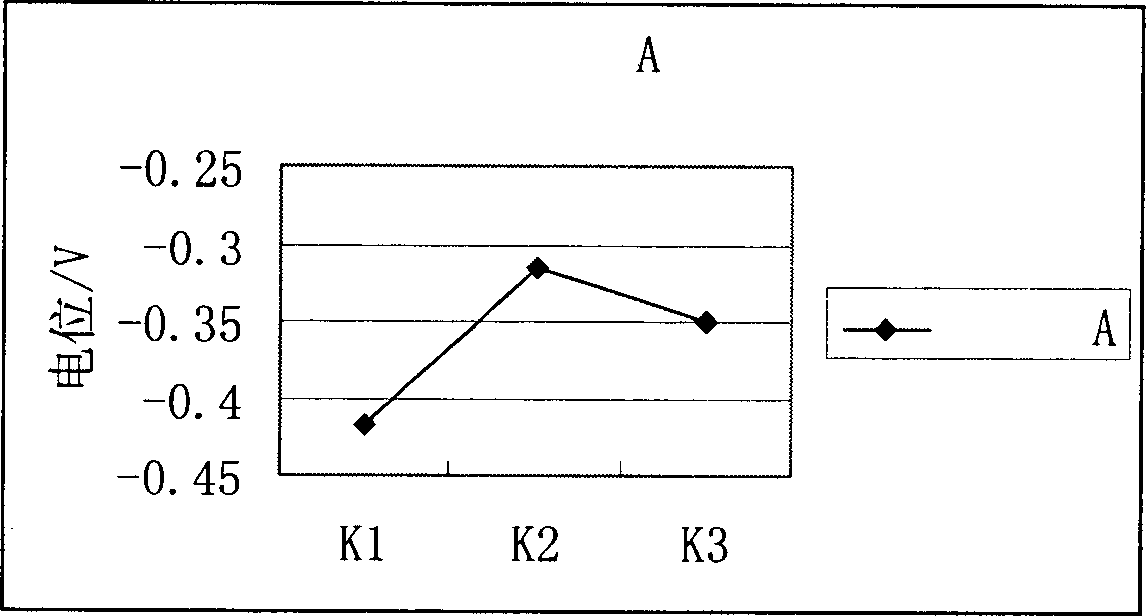

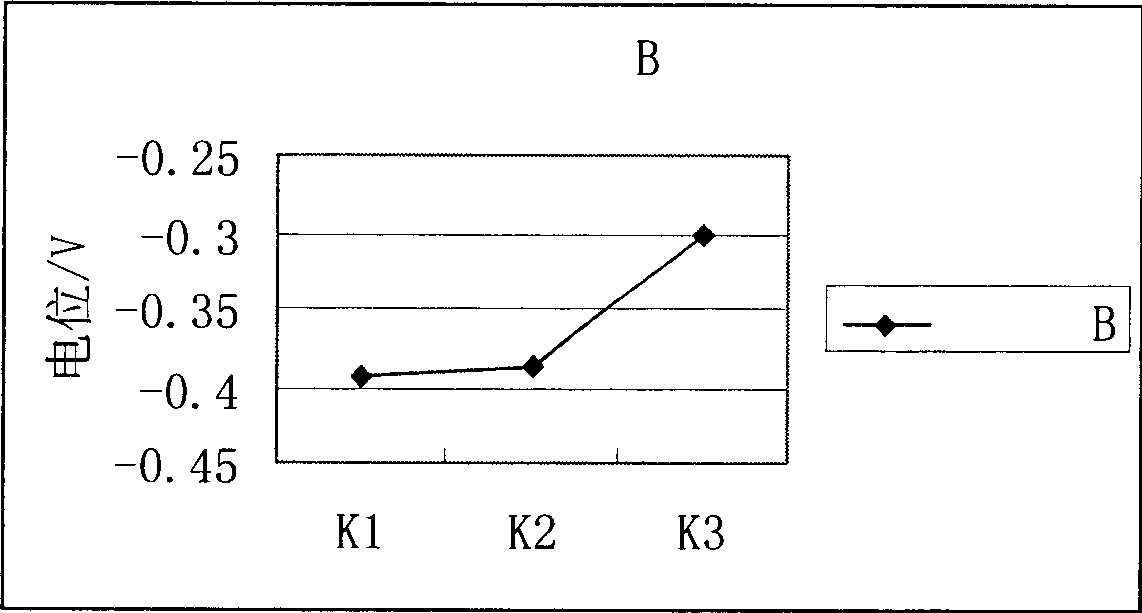

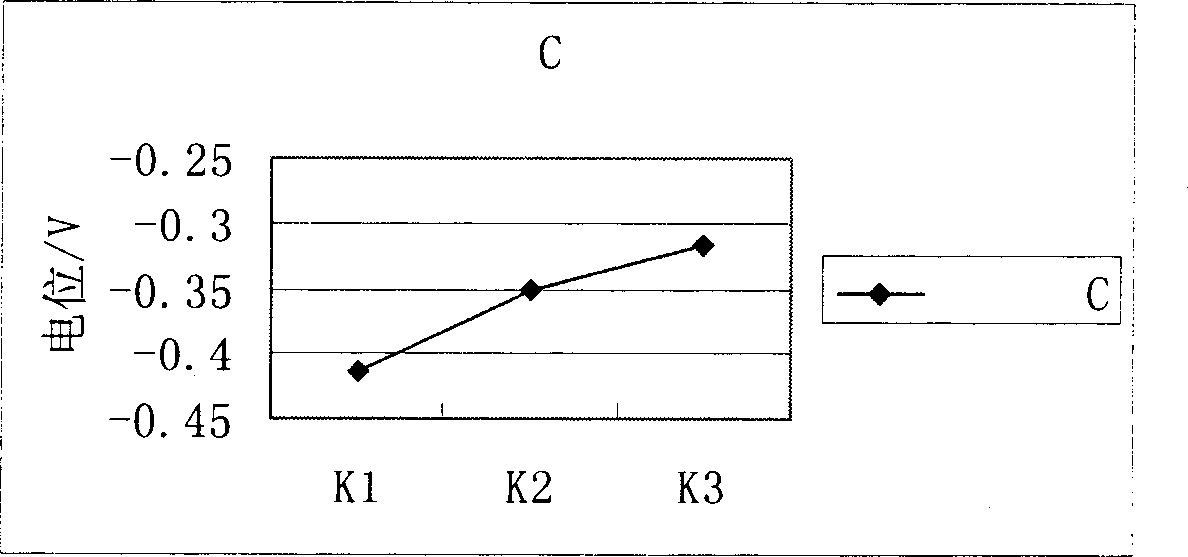

[0024] The present invention adopts four factors and three levels of orthogonal test formula, and each table is as follows

[0025] Table 1: Four-factor three-level orthogonal test formula

[0026]

[0027]

A

B

C

D

left after corrosion

side half cell

Potential (volts)

After corrosion

Q half battery

Potential (volts)

right after corrosion

side half cell

Potential (volts)

Z1

1

1

1

1

-0.481

-0.483

-0.485

Z2

1

2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com