Spraying and falling film compound condensation apparatus for coal or biomass pyrolytic liquefaction

A biomass pyrolysis and condensation device technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems affecting the yield and quality of liquid products, slow cooling speed, incomplete condensation, etc., and achieve the cost of condensation Effects of low cost, improved yield and quality, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

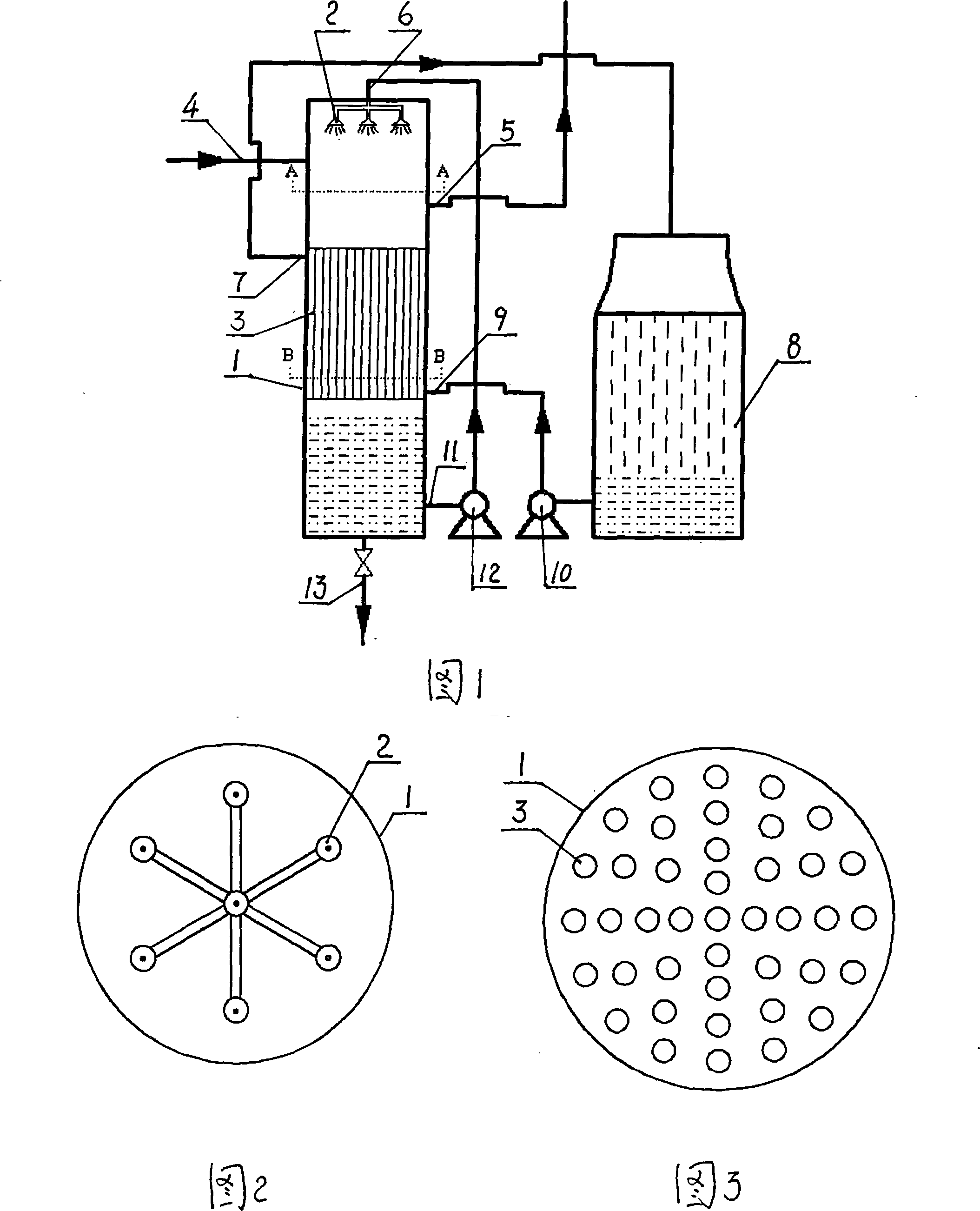

[0021] Taking the spray and falling film compound condensation device in the biomass pyrolysis liquefaction equipment with an oil production capacity of 500kg / h as an example, the condenser 1 has a diameter of 1.5m and a height of 4.5m, and its interior is divided into upper, middle, and The next three parts, see Figure 1:

[0022] The upper part is the spray condensation section with a height of 1.5 meters. There are 7 atomizing nozzles 2 installed in the middle of 150mm from the top. Figure 2, the nozzle diameter is 0.6mm, which is used to atomize the pyrolysis liquid into fine droplets, which are in direct contact with the high-temperature pyrolysis gas entering from the entrance of the side wall of the condenser (300mm from the top), so that it can be cooled rapidly and condensed ;

[0023] The middle part is the falling film condensation section, with a height of 1.8 meters. The built-in shell and tube indirect heat exchanger 3 is composed of 600 heat exchange tubes with...

Embodiment 2

[0032] Take the spray and falling film composite condensing device in the biomass pyrolysis liquefaction equipment with an oil production capacity of 50kg / h as an example. The diameter of the condenser is 0.8 meters and the height is 2.5 meters; the height of the spray condensation section in the condenser is 0.8 meters, the height of the falling film condensation section in the middle is 0.8 meters, and the height range of the lower liquid storage section is 0.8 meters.

[0033] The built-in shell and tube indirect heat exchanger is composed of 400 heat exchange tubes with a diameter of 25mm.

[0034] Other structures are with embodiment 1.

Embodiment 3

[0036] Taking the spray and falling film compound condensation device in the biomass pyrolysis liquefaction equipment with an oil production capacity of 800kg / h as an example, the condenser has a diameter of 2.0 meters and a height of 5.0 meters; the height of the spray condensation section in the condenser is 1.5 meters. The height of the falling film condensation section in the middle is 2.0 meters, and the height of the lower liquid storage section is 1.5 meters.

[0037] The built-in shell and tube indirect heat exchanger is composed of 800 heat exchange tubes with a diameter of 25mm.

[0038] Other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com