Molybdenum disulfide/carbon black composite hydrogen-evolution electrocatalytic material and preparation method therefor

An electrocatalytic material, molybdenum disulfide technology, applied in the field of electrocatalytic hydrogen evolution, can solve the problems of high production cost of composite hydrogen evolution electrocatalytic materials, low yield of graphene oxide preparation, complicated preparation process, etc., to achieve good electrocatalytic performance, Ease of large-scale synthesis and simple method effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A kind of preparation method of molybdenum disulfide / carbon black composite hydrogen evolution electrocatalytic material provided by the present invention, the specific steps are as follows:

[0030] In the first step, the improved Hummer method prepares carbon black oxide with low oxidation degree;

[0031] Weigh carbon black, place it in a three-necked flask, add concentrated sulfuric acid with a mass concentration of 98%, and stir magnetically for 24 hours at room temperature; transfer the three-necked flask to an oil bath for heating in an oil bath, and after constant temperature, add Anhydrous sodium nitrate, potassium permanganate, and magnetically stirred for 30 minutes; the mass ratio of the anhydrous sodium nitrate, potassium permanganate, and carbon black is 0.1:0.3:1.

[0032] Add high-purity water into the three-necked flask (the high-purity water is added three times, and then adjust the reaction rate to make the reaction fully), stir; remove the three-neck...

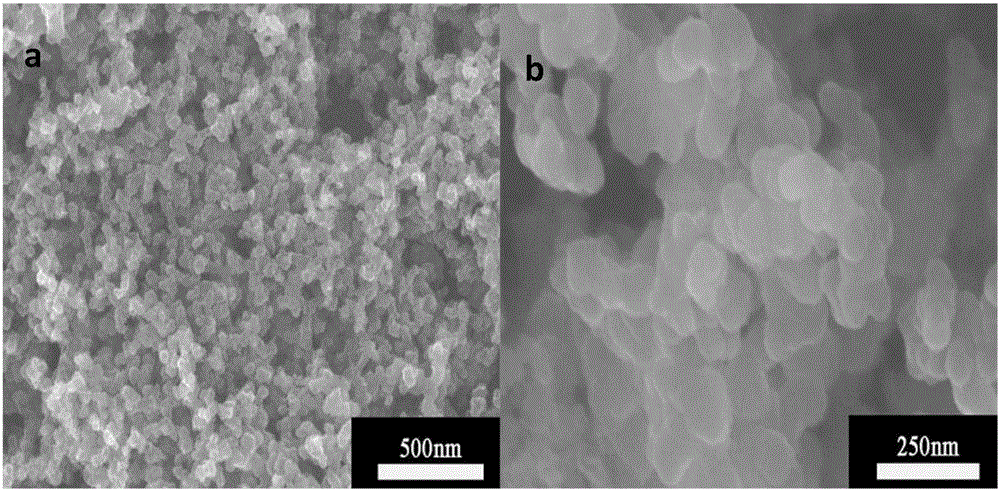

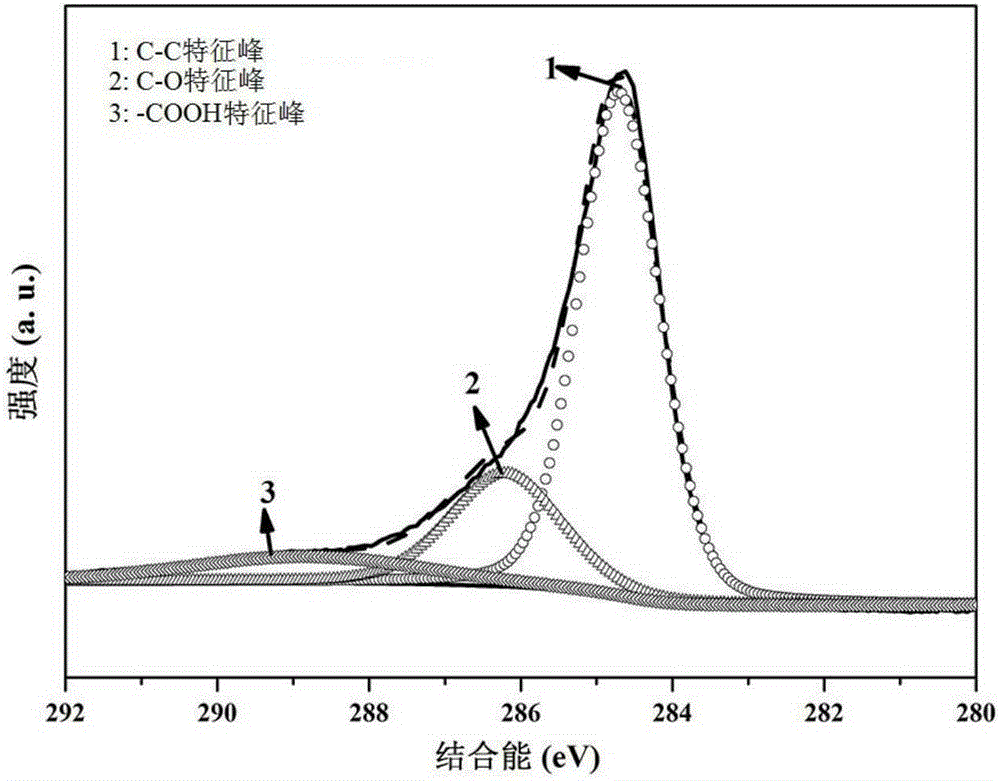

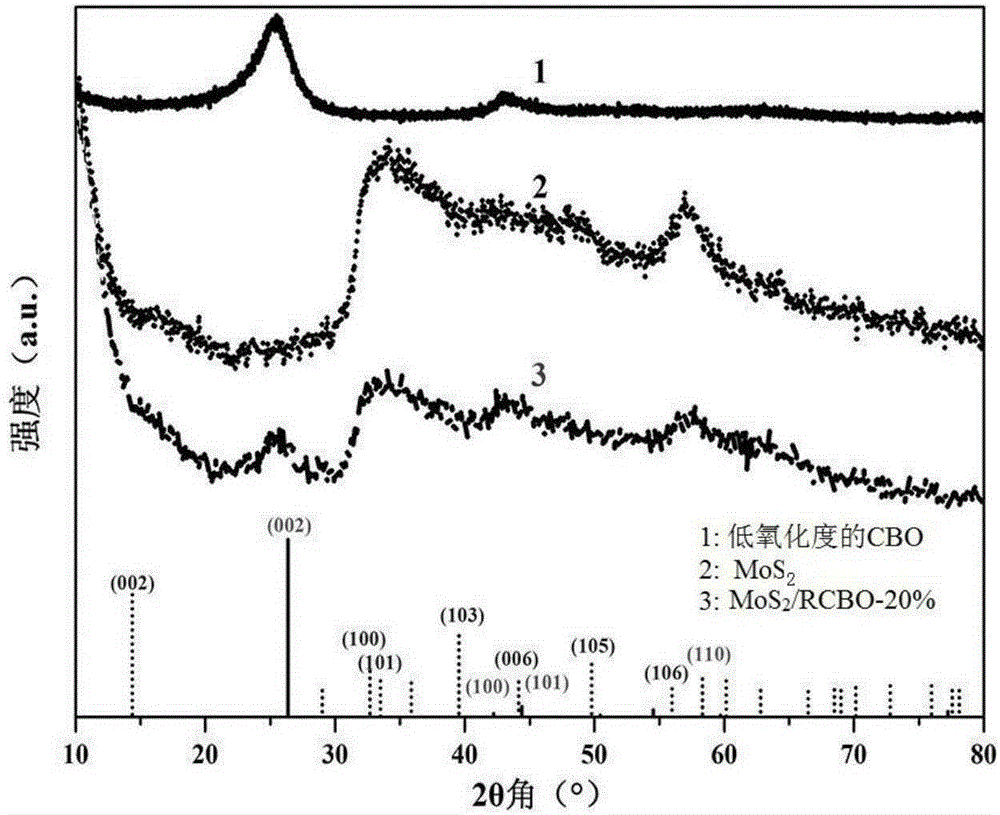

Embodiment 1

[0040] In the first step, the improved Hummer method prepares carbon black oxide with low oxidation degree;

[0041] Weigh 1.0g of carbon black into a 250ml three-necked flask, add 23ml of concentrated sulfuric acid with a mass concentration of 98% to the three-necked flask, and stir magnetically for 24 hours at room temperature; transfer the three-necked flask to an oil bath at 50-55°C for heating in an oil bath After constant temperature, add 100 mg of anhydrous sodium nitrate into the three-necked flask; add 300 mg of potassium permanganate after 5 minutes, control the temperature of the oil bath at 50-55 ° C, and stir for 30 minutes by magnetic force; add 3 ml of high-purity water into the three-necked flask, and re- Add 3ml of high-purity water, add 40ml of high-purity water after 5 minutes, and continue stirring for 15 minutes; remove the three-necked flask from the oil bath, add 140ml of high-purity water, 6ml of hydrogen peroxide solution with a mass concentration of 30...

Embodiment 2

[0054] In the first step, the improved Hummer method prepares carbon black oxide with low oxidation degree;

[0055] Weigh 1.0g of carbon black into a 250ml three-necked flask, add 23ml of concentrated sulfuric acid with a mass concentration of 98% to the three-necked flask, and stir magnetically for 24 hours at room temperature; transfer the three-necked flask to an oil bath at 50-55°C for heating in an oil bath After constant temperature, add 100 mg of anhydrous sodium nitrate into the three-necked flask; add 300 mg of potassium permanganate after 5 minutes, control the temperature of the oil bath at 50-55 ° C, and stir for 30 minutes by magnetic force; add 3 ml of high-purity water into the three-necked flask, and re- Add 3ml of high-purity water, add 40ml of high-purity water after 5 minutes, and continue stirring for 15 minutes; remove the three-necked flask from the oil bath, add 140ml of high-purity water, 6ml of hydrogen peroxide solution with a mass concentration of 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com