Double-layer filter material, preparation method thereof and multilayer product

A double-layer filter material and filter material technology, applied in the field of wet papermaking, can solve the problems of increased filtration efficiency, reduced resistance, increased fan consumption, etc., and achieve the effects of improved filtration efficiency, high yield, and simple operation

Active Publication Date: 2011-05-18

CHONGQING ZAISHENG TECH CORP

View PDF9 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Secondly, how to reduce resistance, increase filtration efficiency, and control costs through effective process and technological innovation is a technical problem existing in the domestic market. The increase in resistance means that under the same efficiency, the consumption of fans is greatly increased.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

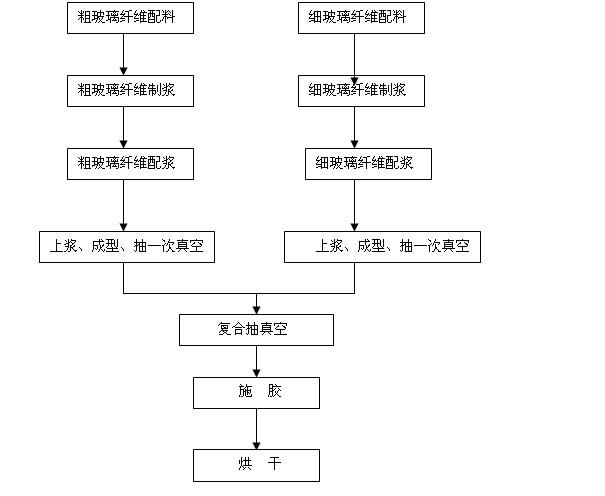

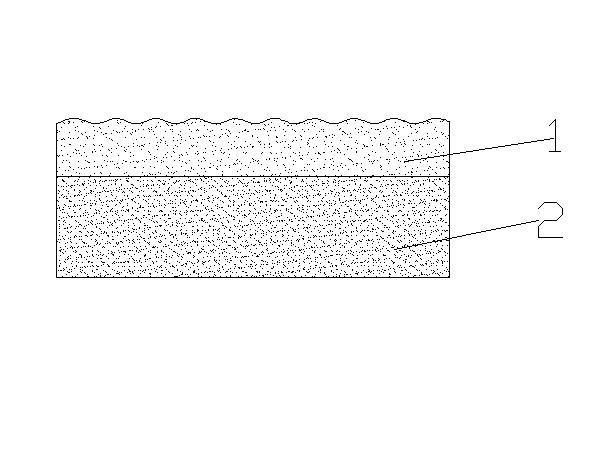

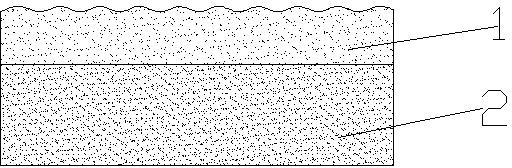

The invention relates to the field of wet paper making, in particular to a double-layer filter material, a preparation method thereof and a multilayer material. The double-layer filter material consists of a coarse glass fiber layer and a fine glass fiber layer, wherein the thickness of the double-layer filter material is between 0.35 and 0.45mm; and the double-layer filter materials are compounded to prepare a multilayer filter material, or are compounded with nonwoven fabrics for filtering liquid. The preparation method comprises the steps of preparation of a coarse fiber layer semi-finished product and a fine fiber semi-finished product, preparation of a composite fiber layer semi-finished product and drying. In the double-layer filter material, the service life is prolonged to 133 percent, the filter efficiency is improved by 50 percent, and the resistance is reduced by 10 percent. The double-layer filter material can be compounded with the nonwoven fabrics and other filter materials once more to prepare a filter material with better performance and effectively filter impurities and microorganisms in the liquid; and the preparation method is easy to operate, has high yield, and is suitable for scale production.

Description

technical field [0001] The invention relates to the field of wet papermaking, in particular to a double-layer filter material, a preparation method thereof and a multi-layer product. [0002] Background technique [0002] Air filtration refers to the use of micropores formed inside the glass fiber to intercept, absorb and block particles above 0.01 μm to reduce the entry of particles into the protected space; it mainly removes dust, viruses, harmful gases, large particles, etc. in the air. The products are mainly used in VLSI, atomic power stations, radiation medicine, genetic engineering, computer mainframe, food processing, pharmaceuticals, biological isolation of viruses and many other fields. At present, there are ultra-high-efficiency glass fiber filter materials and inorganic films that can achieve this filtration in air filtration, but their service life is short; The service life of the glass fiber composite filter material is doubled, and the strong dust holdin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D39/20B32B17/02

Inventor 郭茂刘军

Owner CHONGQING ZAISHENG TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com