Microbial flocculant as well as preparation method and application thereof

A technology of microbial flocculants and floc-producing bacteria, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of unclear straw resources, high collection and transportation costs, and low degree of industrialization, and reach the source Wide range of effects with high flocculation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

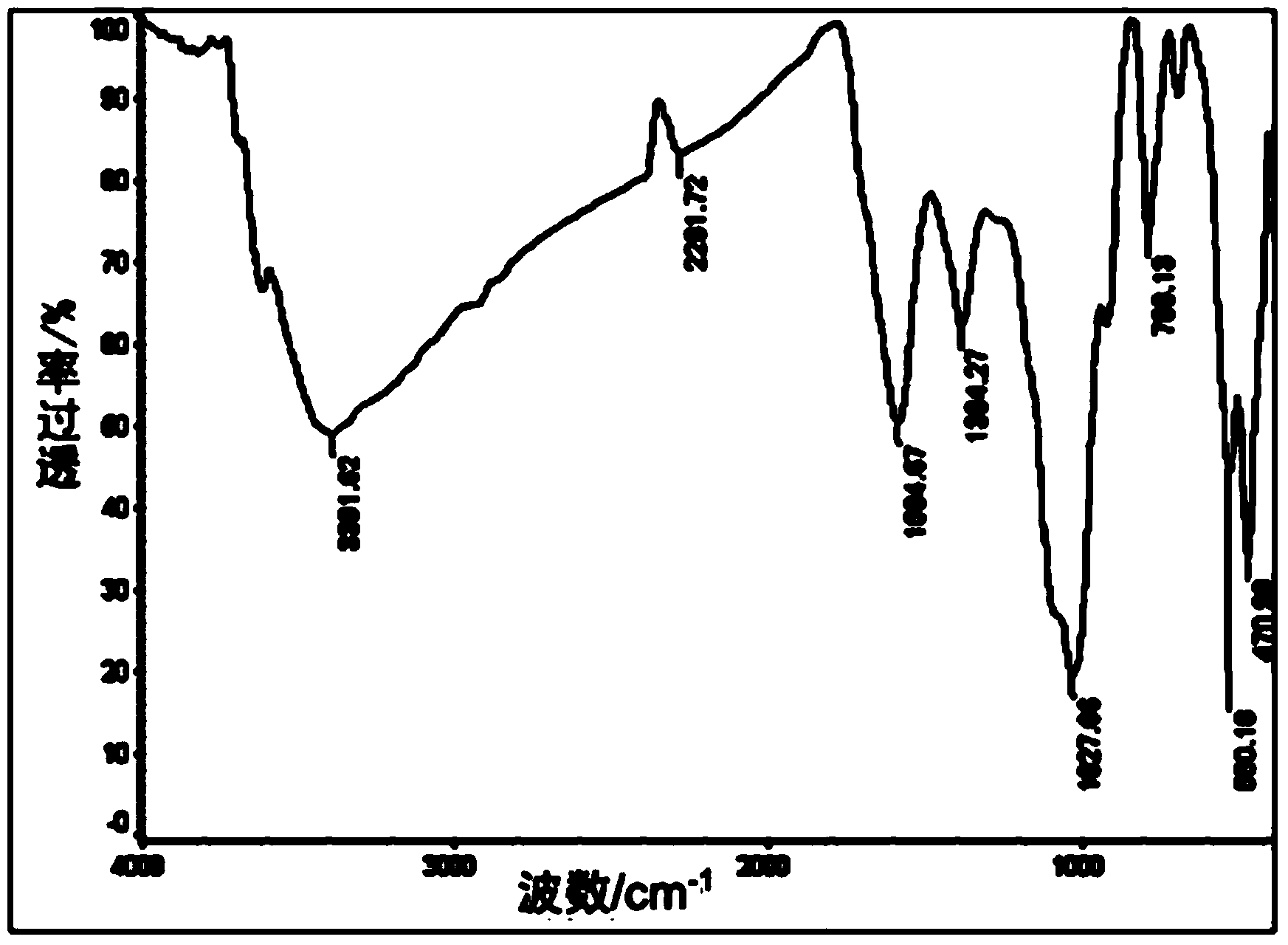

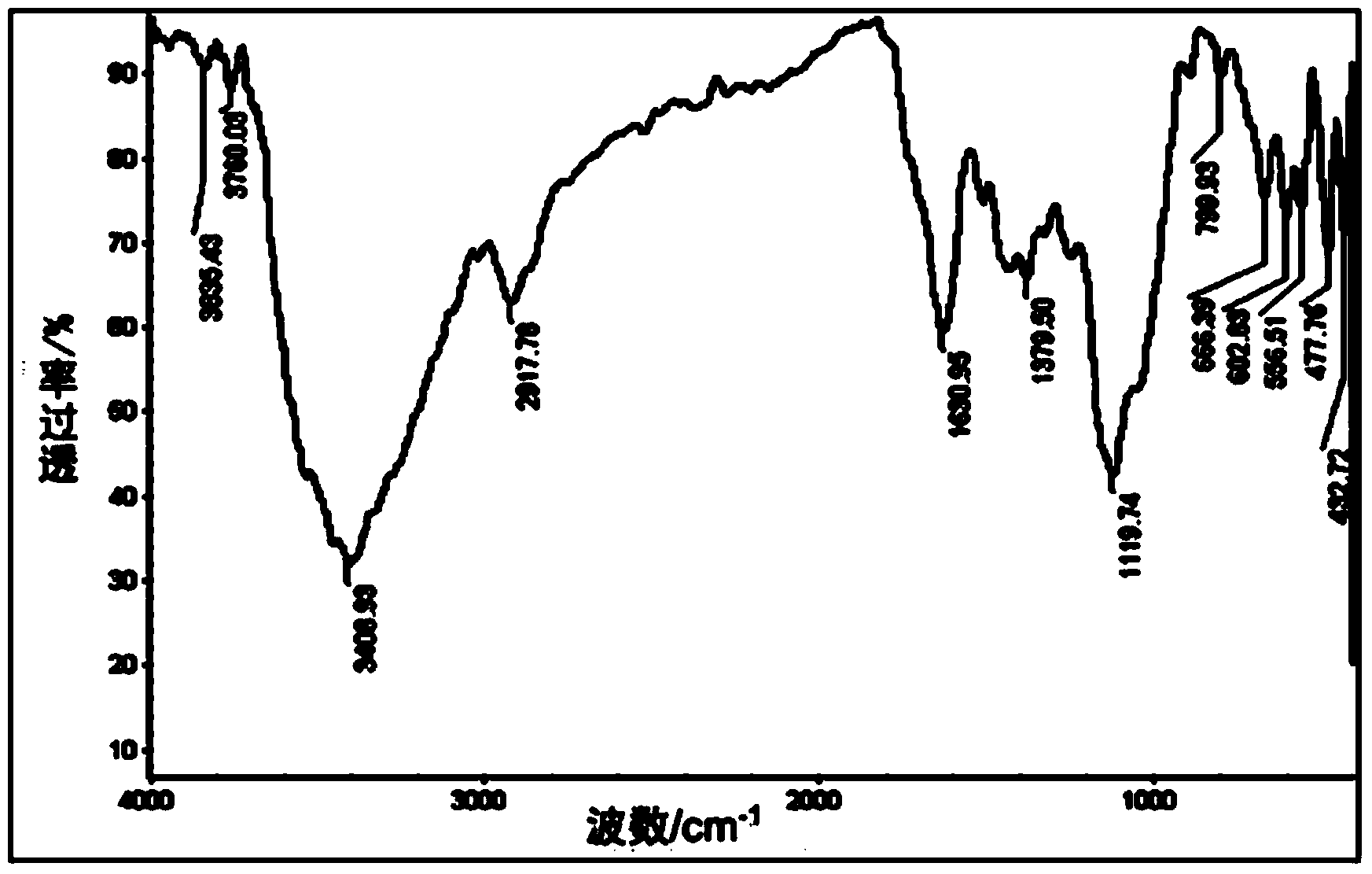

Image

Examples

Embodiment 1

[0042] 1 Preparation of fermentation agent

[0043] Trichoderma koningii CGMCC3.2774 and Aspergillus niger CGMCC3.06194 were inoculated in sterilized straw bran medium, cultured at 28°C for 7 days, and the number of spores in the solid substrate exceeded 10 10 spores / g to obtain the fermentation inoculum.

[0044] The formula of the straw bran medium is: 700g of wheat straw powder, 300g of bran, 2500mL of water, natural pH; after mixing, sterilize at 126°C for 2 hours.

[0045] 2 Preparation of microbial flocculant

[0046] Take 10kg each of fresh beets and fresh rice straws, put them into a blender after pulverization by a pulverizer, add water while stirring until the water content of the substrate is about 60%, add concentrated nitric acid by spraying, when the pH of the substrate is 3-4 Stop adding concentrated nitric acid, and continue to add water until the water content of the matrix reaches 65%. Add 40 g of the above-mentioned fermentation agent, stir evenly, take o...

Embodiment 2

[0058] 1 Preparation of fermentation agent

[0059] Trichoderma viride (Trichoderma viride) CGMCC3.5455 and Aspergillus tubingensis (Aspergillus tubingensis) CGMCC3.06402 were respectively inoculated in sterilized straw bran medium, cultured at 28°C for 5 days, and the number of spores in the solid substrate exceeded 10 9 spores / g to obtain the fermentation inoculant.

[0060] The formula of the straw bran medium is: 700g of wheat straw powder, 300g of bran, 2500mL of water, natural pH; after mixing, sterilize at 126°C for 2 hours.

[0061] 2 Preparation of microbial flocculant

[0062] Take 10kg each of fresh beet and air-dried rice straw, put them into a mixer after pulverization by a pulverizer, add water while stirring until the water content of the substrate is about 60%, add concentrated nitric acid by spraying, when the pH of the substrate is 3-4 Stop adding concentrated nitric acid, and continue to add water until the water content of the substrate reaches 65%. Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com