Temperature-sensitivity chitosan flocculating agent, preparation method and application thereof

A chitosan, sensitive technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water pollutants, etc. Achieve excellent flocculation ability, wide application range, and enhance the effect of flocculation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

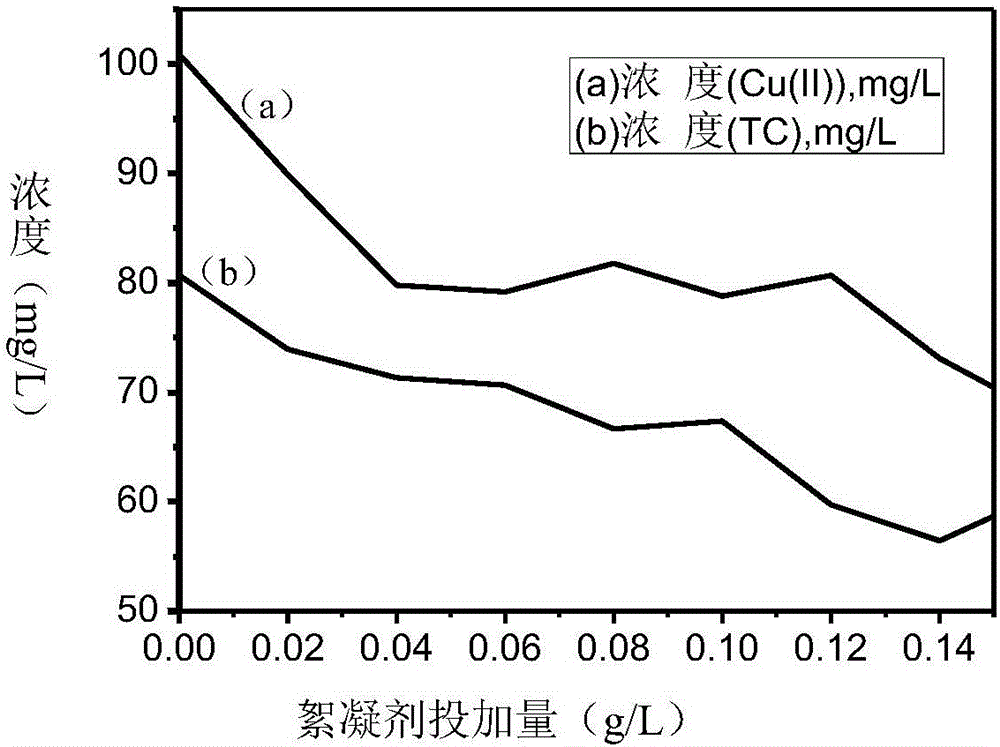

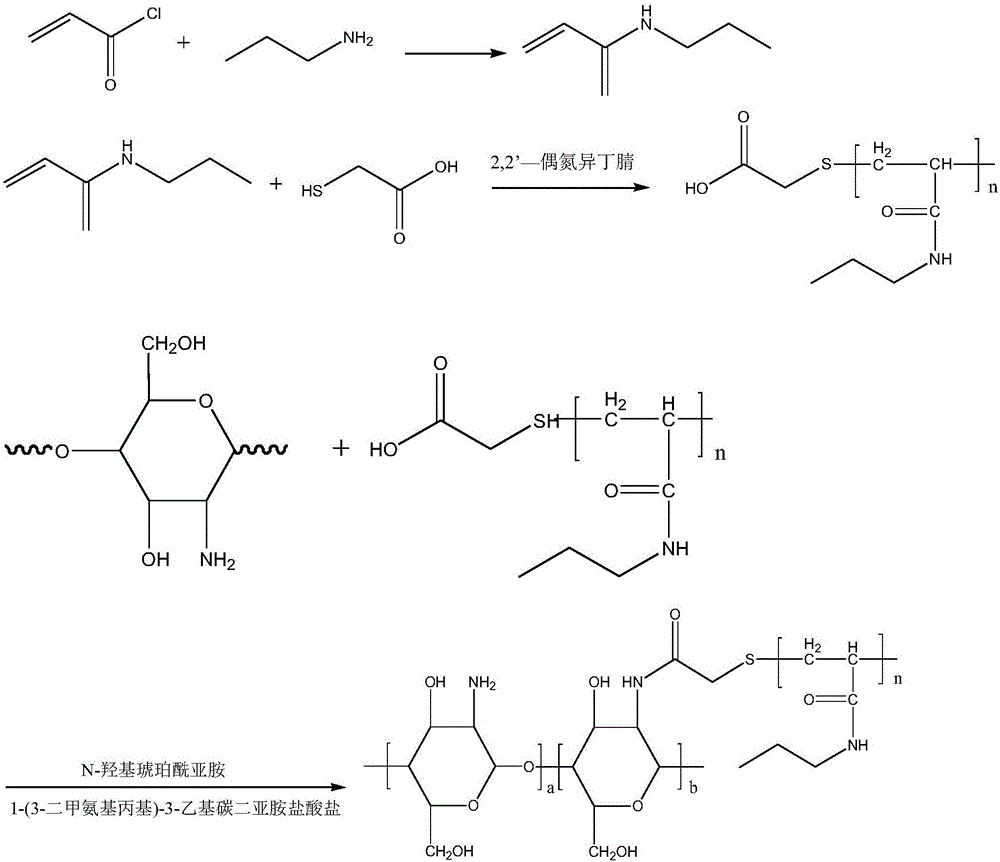

Embodiment 1

[0059] Dissolve acryloyl chloride, n-propylamine and triethylamine in toluene to prepare acryloyl chloride solution and a mixed solution of n-propylamine and triethylamine respectively (the molar ratio of acryloyl chloride, n-propylamine, triethylamine and toluene is 1:1.1 :1.2:10), for use. At 4°C, slowly add acryloyl chloride solution dropwise (drop rate: 1 drop / s) to the mixed solution of n-propylamine and triethylamine while stirring, dropwise for 1 hour, and then continue the mixture at 25°C. The reaction was stirred for 24 hours. The reaction mixture was filtered to remove the formed precipitate to obtain a monomer (in toluene) solution. Dissolve thioglycolic acid in toluene (the molar ratio of acryloyl chloride to thioglycolic acid is 20:1), place it in a round bottom flask, and stir to dissolve completely. The temperature was raised to 60° C., and nitrogen gas was passed through for 30 minutes to remove oxygen in the solution. Add 2,2'-azoisobutyronitrile (the solve...

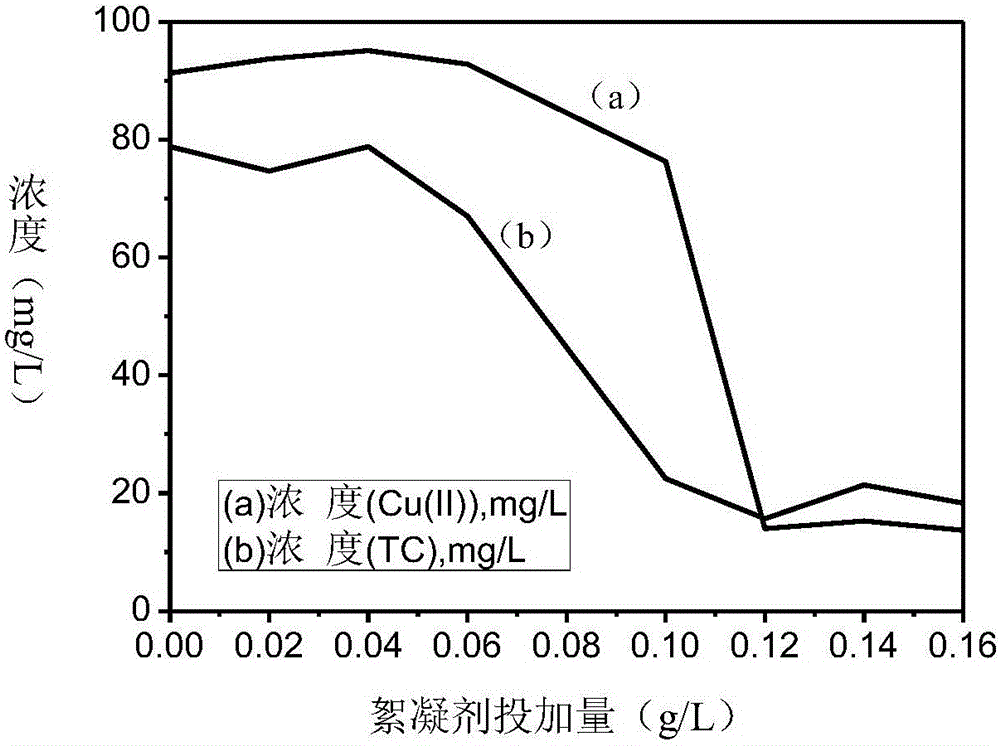

Embodiment 2

[0064] Dissolve acryloyl chloride, n-propylamine and triethylamine in toluene to prepare acryloyl chloride solution and a mixed solution of n-propylamine and triethylamine respectively (the molar ratio of acryloyl chloride, n-propylamine, triethylamine and toluene is 1:1 :5:10), for use. At 4° C., the acryloyl chloride solution was slowly added dropwise to the mixed solution of n-propylamine and triethylamine while stirring for 1 hour, and then the mixture was continuously stirred at 30° C. for 40 hours. The reaction mixture was filtered to remove the formed precipitate to obtain a monomer (in toluene) solution. Dissolve thioglycolic acid in toluene (the molar ratio of acryloyl chloride to thioglycolic acid is 38:1), place it in a round-bottomed flask, stir and dissolve completely. The temperature was raised to 70°C, and nitrogen gas was passed through for 30 minutes to remove the oxygen in the solution. Add 2,2'-azoisobutyronitrile (the solvent is diethyl ether, the molar r...

Embodiment 3

[0069] Dissolve acryloyl chloride, n-propylamine and triethylamine in toluene to prepare acryloyl chloride solution and a mixed solution of n-propylamine and triethylamine (the molar ratio of acryloyl chloride, n-propylamine, triethylamine and toluene is 1:5 :1:10), for use. At 0°C, the acryloyl chloride solution was slowly added dropwise to the mixed solution of n-propylamine and triethylamine while stirring for 1 hour, and then the mixture was continuously stirred at 25°C for 30 hours. The reaction mixture was filtered to remove the formed precipitate to obtain a monomer (in toluene) solution. Dissolve thioglycolic acid in toluene (the molar ratio of acryloyl chloride to thioglycolic acid is 8:1), place it in a round-bottomed flask, stir and dissolve completely. The temperature was raised to 85° C., and nitrogen gas was passed through for 30 minutes to remove oxygen in the solution. Add 2,2'-azoisobutyronitrile (the solvent is toluene, the molar ratio of 2,2'-azoisobutyron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com