Method for preparing natural color bamboo pulp fiber household paper

A technology for natural bamboo pulp and household paper, applied in natural cellulose pulp/paper, fiber raw material processing, papermaking, etc., can solve the problems of hair loss, powder loss, fiber strength damage, wet strength reduction, etc. The effect of compact, slender fibers and high wet strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

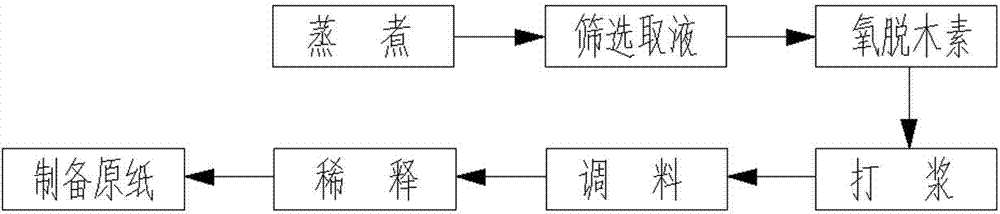

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] see figure 1 , a kind of preparation method of natural color bamboo pulp fiber household paper, its process step is:

[0020] The first step: steaming, put the natural clustered bamboo slices into a special cooking container, and add NaOH at the same time: 3.8 tons / pot to 5.0 tons / pot, NaOH 2 S: 0.9 tons / pot to 1.2 tons / pot, and steam is introduced to make the temperature reach 150°C-155°C, the pressure reach 0.7Mpa, and the treatment lasts for 280 minutes to 350 minutes;

[0021] Step 2: Screen and extract the liquid, remove undigested large pieces of bamboo, bamboo joints, coarse fibers, and sand and stones in the raw materials through screening and purification equipment, and then extract the coarse pulp through the pulp washing equipment and dissolve it in the cooking process The black liquor of black liquor, preliminary obtains the bamboo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com