A kind of natural food preservative of light bamboo leaf extract and preparation method thereof

A technology of natural food and pale bamboo leaves, which is applied in the fields of food preservation, food science, and application, can solve the problems of adverse effects of food flavor, toxic and side effects, and achieve the effect of obvious bacteriostatic effect, long shelf life and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

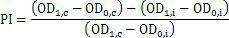

Method used

Image

Examples

Embodiment 1

[0026] Embodiment one: Preparation of preservative 1

[0027] (1) Weigh 20 kg of dried Pachyphyllum basil leaves, wash and crush them;

[0028] (2) Put the crushed bamboo leaves into the extraction tank, add 3% sodium hydroxide solution, soak the bamboo leaves completely, and soak overnight;

[0029] (3) adjust to pH value 7.0 with the hydrochloric acid of volume percent concentration 1%;

[0030] (4) Then add cellulase with a mass percentage concentration of 1%, and hydrolyze for 4 hours at 40°C;

[0031] (5) Then add ethyl acetate (calculated as dry bamboo leaves) that is 5 times the mass of bamboo leaves, adjust the pressure of the extraction tank to 1.5MPa, and the temperature to 30-40°C, extract twice, each time for 2 hours, and combine the extractions liquid;

[0032] (6) After the extract was left to stand for 2 hours, the supernatant was passed through multilayer screen filters with pore sizes of 60 mesh, 100 mesh and 200 mesh in turn;

[0033] (7) Put the filtrat...

Embodiment 2

[0037] Embodiment two: Preparation of preservative 2

[0038] (1) Weigh 20 kg of dried Pachyphyllum basil leaves, wash and crush them;

[0039] (2) Put the crushed bamboo leaves into the extraction tank, add 3% sodium hydroxide solution, soak the bamboo leaves completely, and soak overnight;

[0040] (3) adjust to pH value 7.0 with the hydrochloric acid of volume percent concentration 1%;

[0041] (4) Then add cellulase with a mass percentage concentration of 1%, and hydrolyze for 4 hours at 40°C;

[0042] (5) Then add ethyl acetate (calculated as dry bamboo leaves) that is 5 times the weight of the bamboo leaves, adjust the pressure of the extraction tank to 1.5MPa, and the temperature to 30-40°C, extract twice, each time for 2 hours, and combine the extractions liquid;

[0043] (6) After the extract was left to stand for 2 hours, the supernatant was passed through multilayer screen filters with pore sizes of 60 mesh, 100 mesh and 200 mesh in turn;

[0044] (7) Put the ...

Embodiment 3

[0048] Embodiment three: Preparation of preservative 3

[0049] (1) Weigh 20 kg of dried Pachyphyllum basil leaves, wash and crush them;

[0050] (2) Put the crushed bamboo leaves into the extraction tank, add 3% sodium hydroxide solution, soak the bamboo leaves completely, and soak overnight;

[0051] (3) adjust to pH value 7.0 with the hydrochloric acid of volume percent concentration 1%;

[0052] (4) Then add cellulase with a mass percentage concentration of 1%, and hydrolyze for 4 hours at 40°C;

[0053] (5) Then add ethyl acetate (calculated as dry bamboo leaves) that is 5 times the weight of the bamboo leaves, adjust the pressure of the extraction tank to 1.5MPa, and the temperature to 30-40°C, extract twice, each time for 2 hours, and combine the extractions liquid;

[0054] (6) After the extract was left to stand for 2 hours, the supernatant was passed through multilayer screen filters with pore sizes of 60 mesh, 100 mesh and 200 mesh in turn;

[0055] (7) Put th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com