Extrusion grade aesthetical resin possessing metal color effect and its preparation method

A color effect, aesthetic resin technology, applied in the field of extrusion-grade aesthetic resin and its preparation, can solve the problems of damage to the surface of the aesthetic resin, poor coverage of the aesthetic resin, and poor metal color and texture, so as to reduce migration, ensure metal texture, and improve The effect of opacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

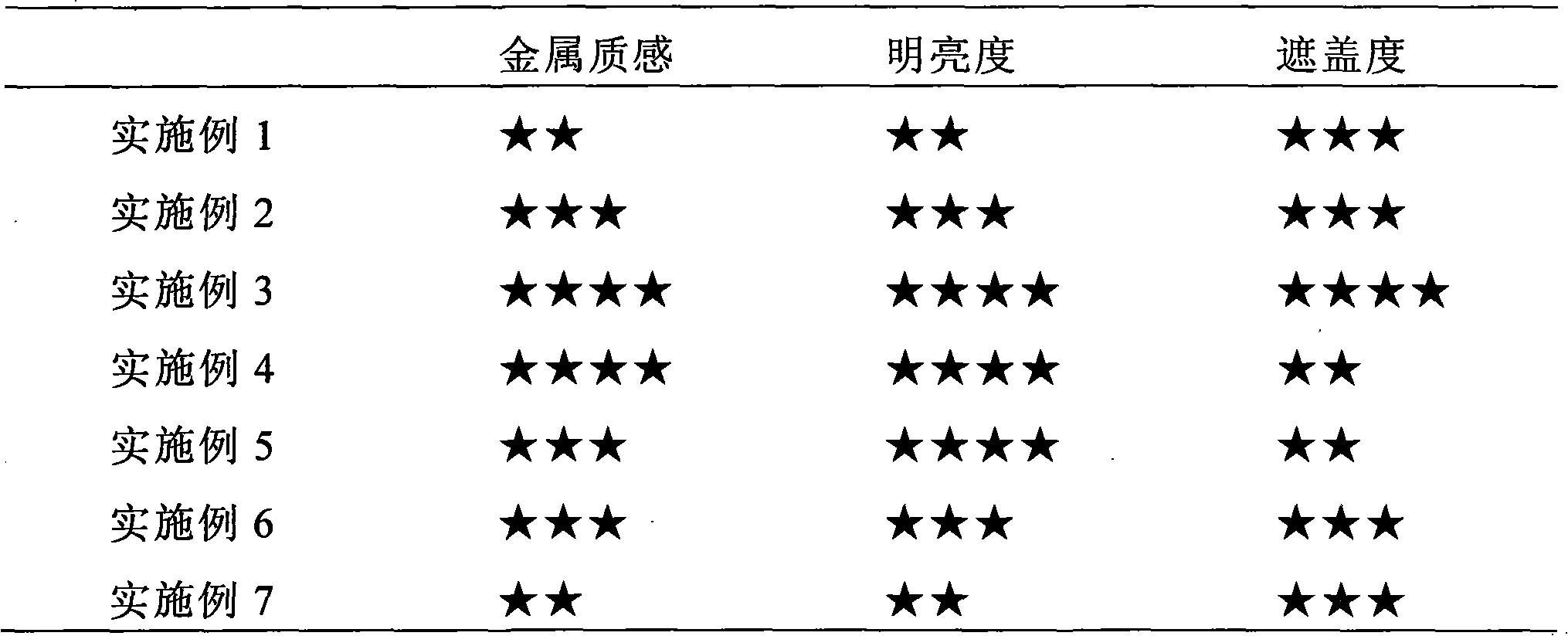

Examples

Embodiment 1

[0039] A kind of extrusion grade aesthetic resin with metallic color effect, the method comprises the following steps:

[0040] (1) Prepare materials according to the following components and contents:

[0041] Base resin 100;

[0042] Metallic pigments 0.5;

[0043] Pearlescent pigment 1.0;

[0044] Molecular sieve adsorbent 0.3;

[0045] Lubricant 0.5;

[0046] Antioxidant 0.3;

[0047] Among them, the matrix resin is the transparent modified grade ABS-TM of Shanghai Kumho Sunny Plastic Co., Ltd.;

[0048] The metal pigment is aluminum powder pigment with a particle size of 15 μm, polished cornflake type, and PE wax as a carrier;

[0049] The pearlescent pigment is TiO2-coated mica flakes with a particle size of 10 μm;

[0050] The molecular sieve adsorbent is natural zeolite with a particle size of 1000 mesh;

[0051] The lubricant is EBS;

[0052] The antioxidant is B900.

[0053] (2) Mix the base resin, metallic pigment, pearlescent pigment, molecular sieve adso...

Embodiment 2

[0055] A kind of extrusion grade aesthetic resin with metallic color effect, the method comprises the following steps:

[0056] (1) Prepare materials according to the following components and contents:

[0057] Base resin 100;

[0058] Metallic Pigments 1.0;

[0059] Pearlescent pigment 1.0;

[0060] Molecular sieve adsorbent 0.3;

[0061] Lubricant 0.5;

[0062] Antioxidant 0.3;

[0063]Among them, the matrix resin is the transparent modified grade ABS-TM of Shanghai Kumho Sunny Plastic Co., Ltd.;

[0064] The metal pigments are two kinds of aluminum powder pigments, both of which are PE wax as the carrier, and the particle diameters are respectively 15 μm and 40 μm in polished corn flake type, and the weight parts are 0.4 and 0.6 respectively;

[0065] Pearlescent pigments are mica flakes coated with TiO2 and Fe2O3 double layers, with a particle size of 20 μm;

[0066] The molecular sieve adsorbent is natural zeolite with a particle size of 1000 mesh;

[0067] The lu...

Embodiment 3

[0071] A kind of extrusion grade aesthetic resin with metallic color effect, the method comprises the following steps:

[0072] (1) Prepare materials according to the following components and contents:

[0073] Base resin 100;

[0074] Metallic Pigments 2.0;

[0075] Pearlescent Pigment 2.0;

[0076] Molecular sieve adsorbent 0.5;

[0077] Lubricant 0.5;

[0078] Antioxidant 0.3;

[0079] Among them, the matrix resin is ABS / PMMA alloy HAM8541 of Shanghai Kumho Sunny Plastic Co., Ltd.;

[0080] The metal pigments are two kinds of aluminum powder pigments, both of which are acrylate carriers, and the particle sizes are 15 μm and 50 μm respectively, the former is polished cornflake type, and the latter is silver dollar type, and the weight parts are 1.0 and 1.0 respectively;

[0081] The particle size of the pearlescent pigment is 20 μm, the mica sheet coated with Fe2O3 has a particle size of 40 μm, and the weight parts of the mica sheet coated with TiO2 and AL2O3 double la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com