Production line of modified plastic granules

A technology of plastic granules and production lines, applied in the field of plastic machinery manufacturing, can solve problems such as affecting production and cooling water tanks, untimely replacement of filters, uneven water temperature, etc., to ensure human health, good cooling effect, improve The effect of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

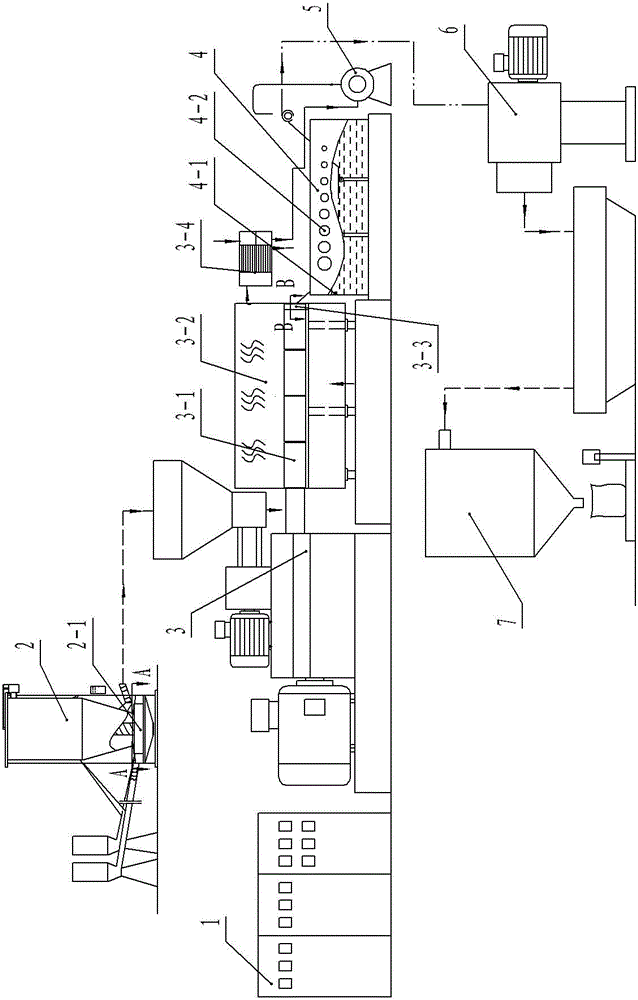

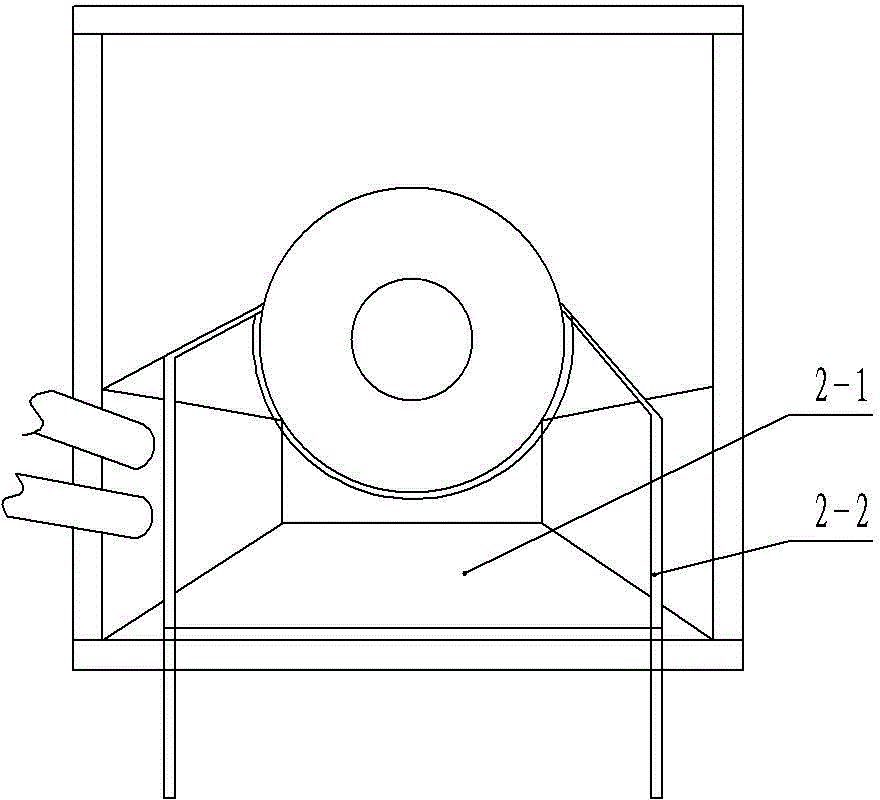

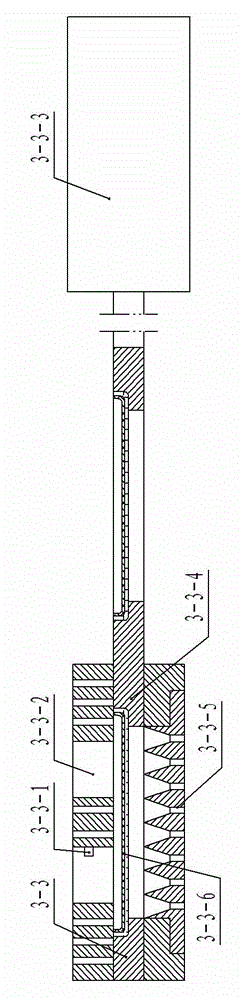

[0020] figure 1 The modified plastic granule production line shown includes a stirring feeder 2, an extruder 3, a cooling water tank 4, a drying fan 5, a traction pelletizer 6, and a packaging machine 7 connected in sequence and connected to each equipment. Electrical control cabinet 1. like figure 2 As shown, the stirring feeder 2 has a feeding port 2-1, the feeding port is rectangular, and the edges of the two opposite feeding ports are connected with retractable rails 2-2, and the dust cover slides on the rails to Feed port 2-1 is closed and opened. A smoke shield 3-2 is enclosed outside the heating unit 3-1 of the extruder 3, and the smoke outlet of the smoke shield 3-2 is connected to a heat exchanger 3-4 through an exhaust fan, and the heat exchanger 3- 4 is connected with the drying fan 5 through the outlet of the heated end; the heat source outlet end of the heat exchanger 3-4 is communicated with the waste gas treatment chamber; the air outlet of the drying fan 5 ...

Embodiment 2

[0023] The feed port is square, and the rest are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com