Patents

Literature

85results about How to "Guaranteed gloss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Highlight water-based automobile paint

InactiveCN101104768AGuaranteed stabilityMiscibility guaranteedLiquid surface applicatorsPolyurea/polyurethane coatingsWater basedLacquer

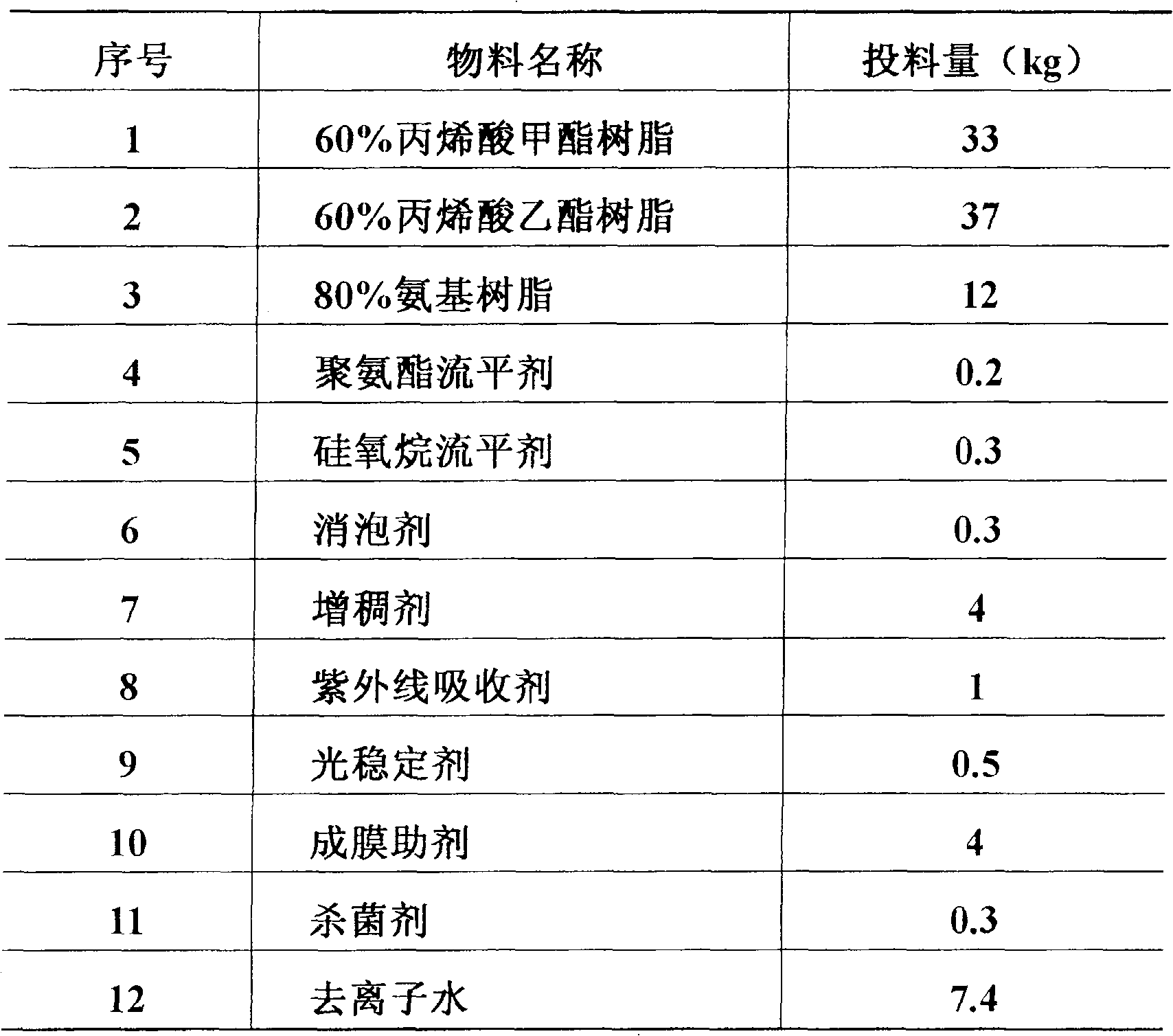

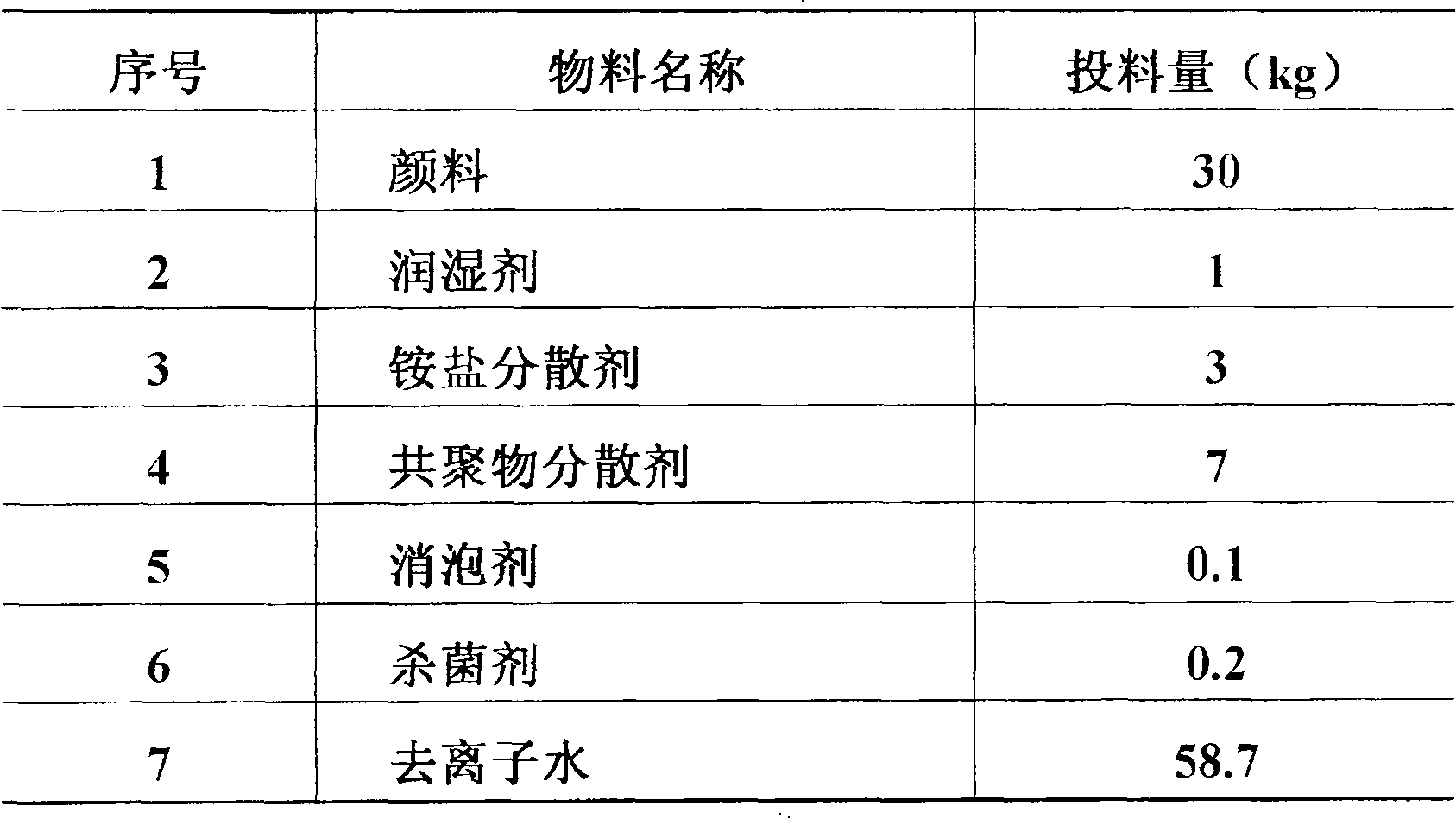

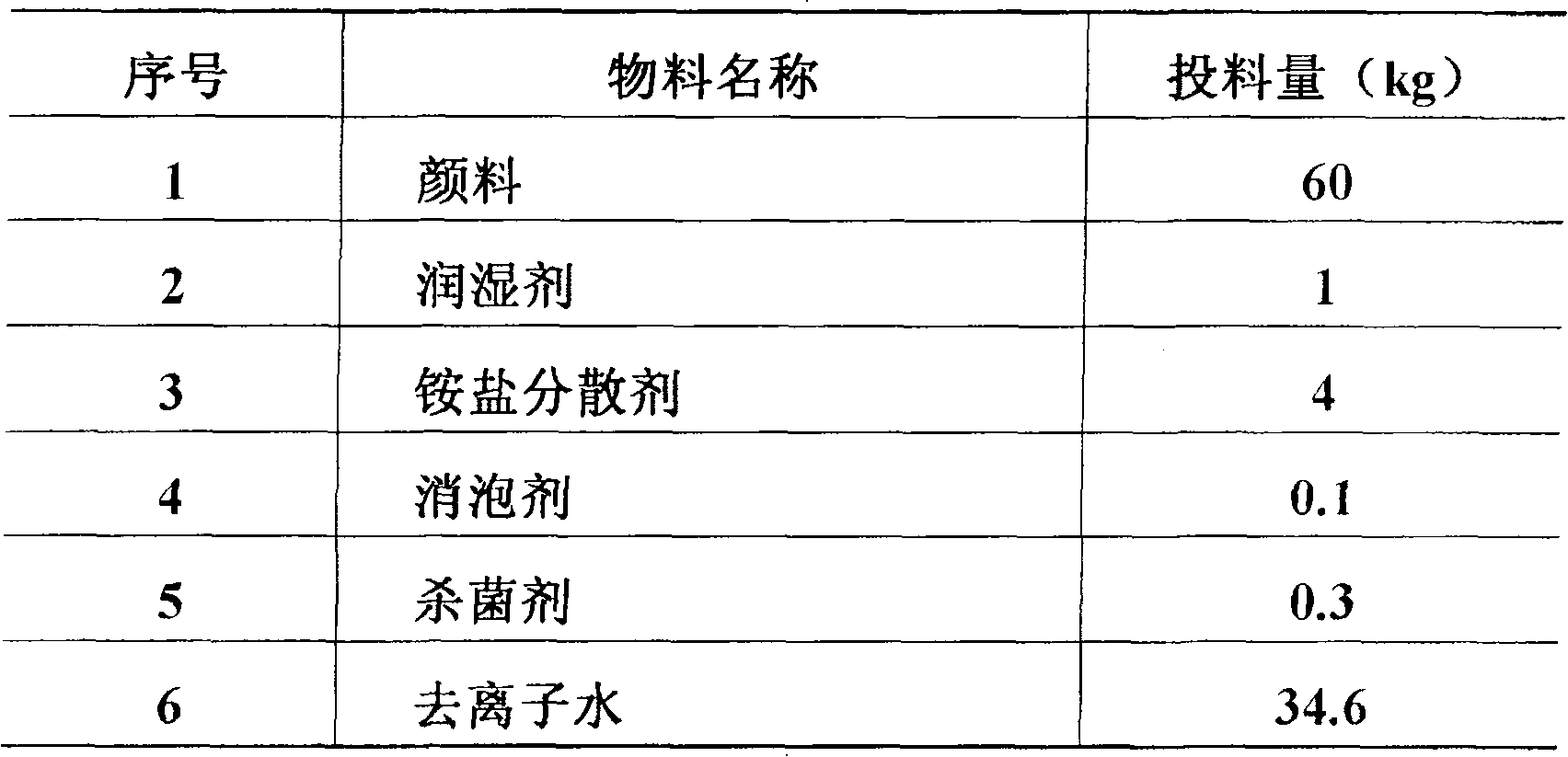

The invention discloses a high-gloss water-based paint for car. The finishing varnish is prepared by mixing methacrylate resin(27-36%), ethyl acrylate resin(31-41%), water-soluble methyl-etherifying amino resin(9-14%), water-soluble polyurethane rheological agent(0.1-0.3%) , water-based polyurethane thickening rheology agent(3-5%) and deionized water(3-18.5%) in a container. A colored paint can be made by adding pigment concentrates into the finishing varnish. The stabilities of pigment dispersing into tiny particles and the miscibility of different pigments are guaranteed by using blended dispersants to wet and disperse the pigment. Good film fullness and glossiness can be obtained due to a higher solid content of the water-based paint by a mixture of more than two high-solid basic resin. The specification of this paint reaches and surpasses the standard level of common solvent car varnish by reducing the pollution of the harmful volatile organic solvent.

Owner:刘成金

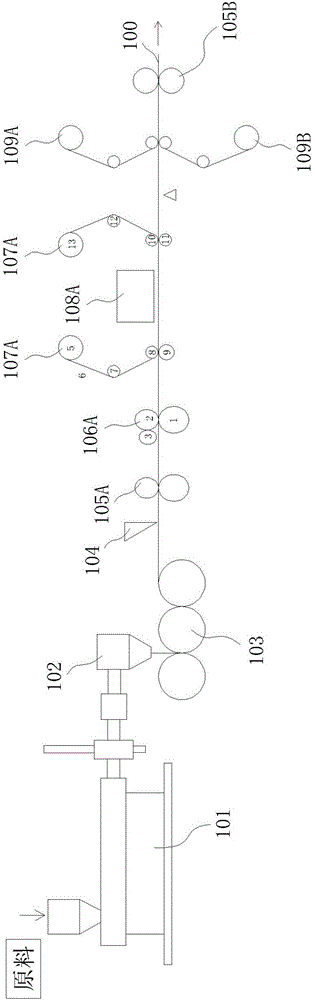

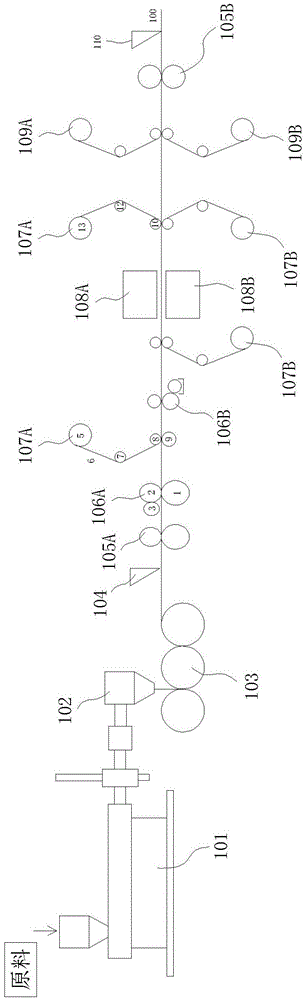

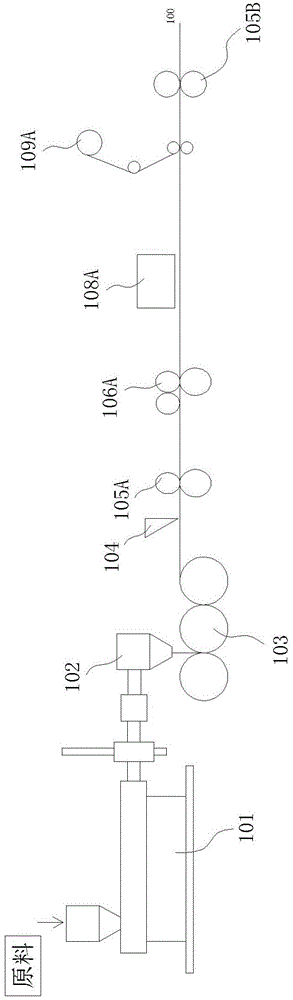

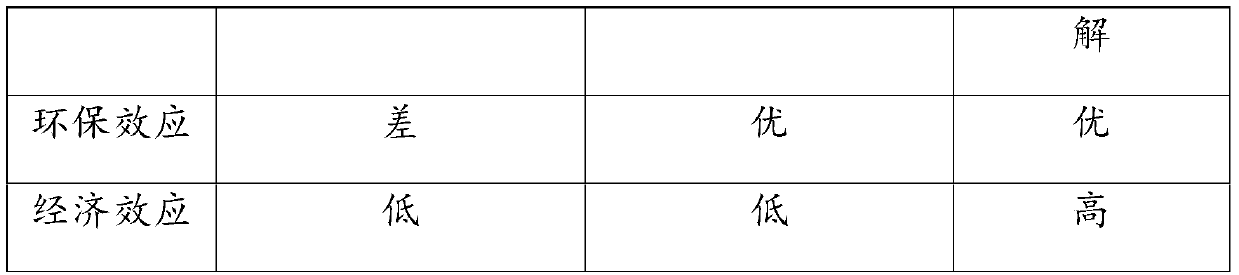

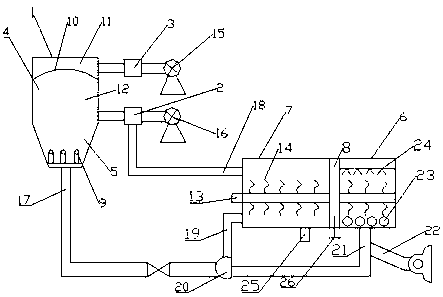

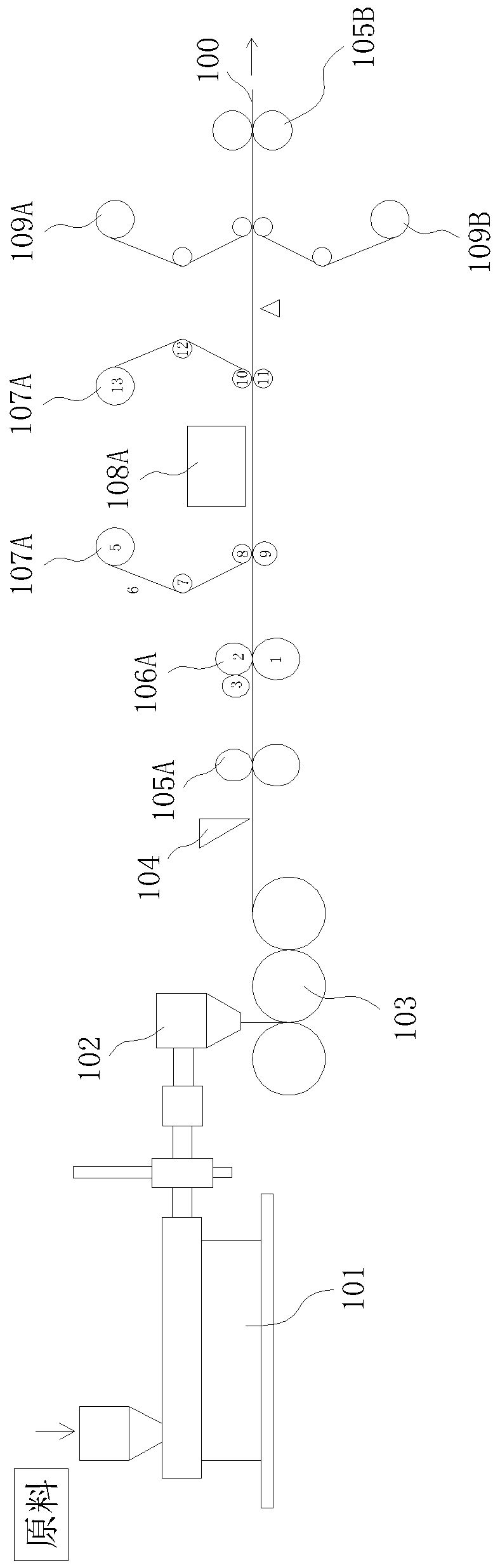

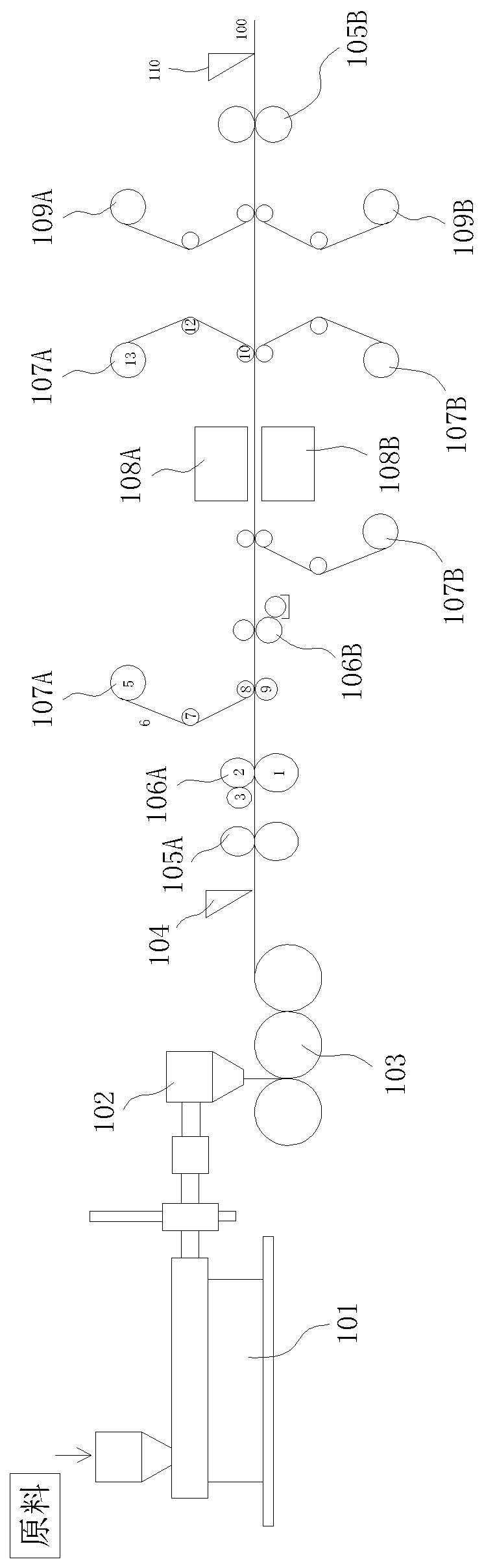

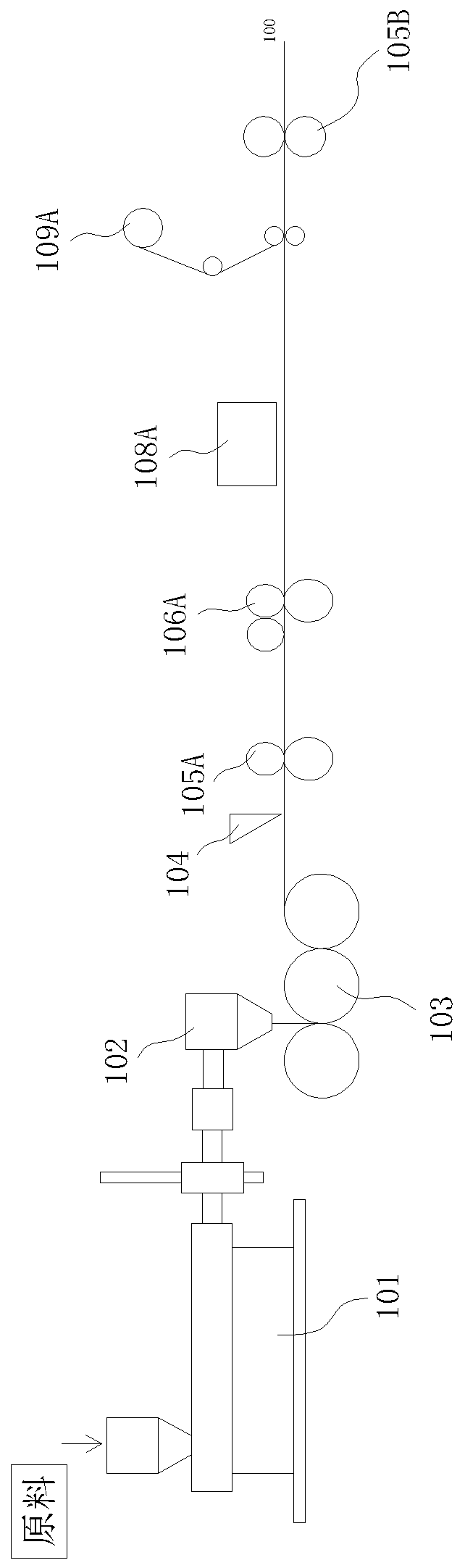

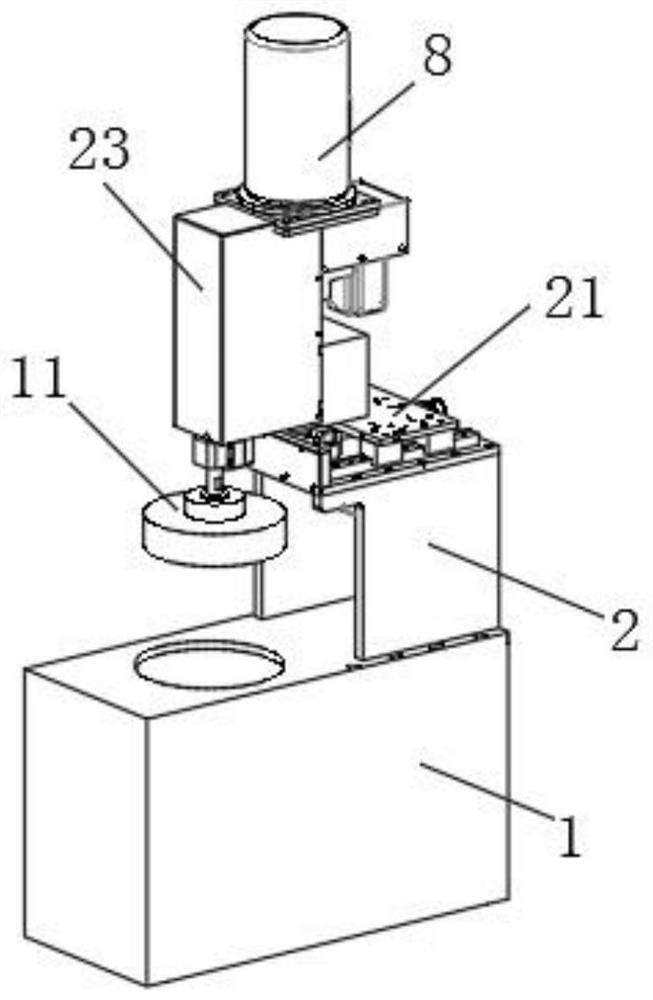

Online double-sided roller coating process and device for producing high-brightness panels by using solvent-free UV coating

ActiveCN104589677ASimple production processReduce material consumptionLiquid surface applicatorsLaminationThin membraneUV coating

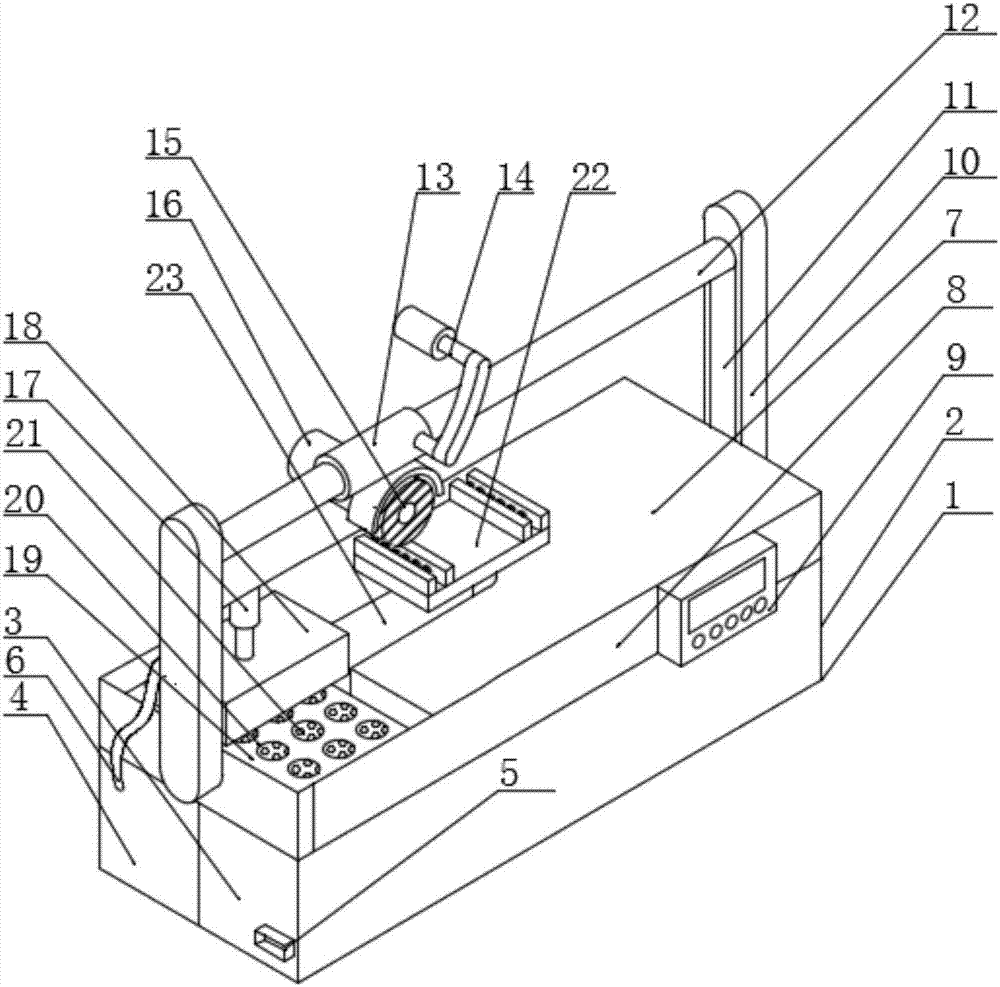

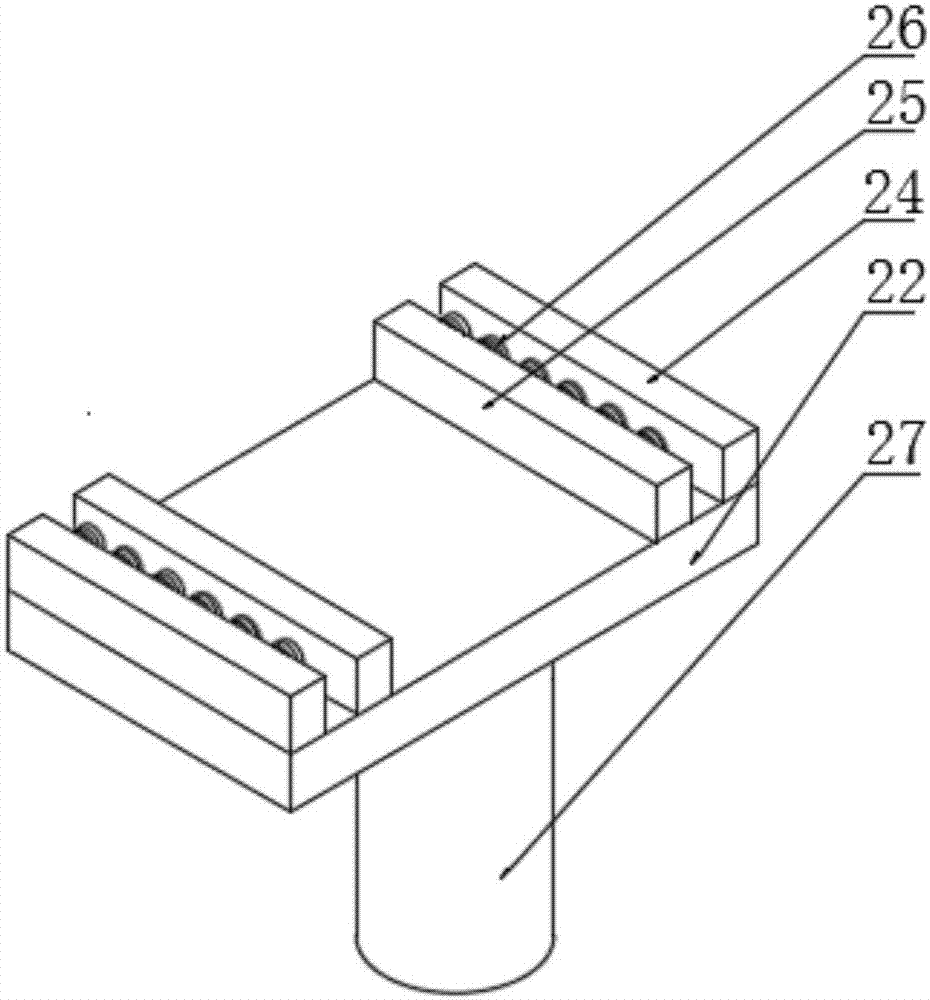

The invention discloses an online double-sided roller coating process and device for producing high-brightness panels by using a solvent-free UV coating. The process comprises the following steps: uniformly coating the solvent-free UV coating on plastic panels molded on an extruder by virtue of a roller coater, covering a release protection film on the surface with the coating on plastic panels by virtue of a laminating machine, flatly pressing, performing UV curing on the plastic panels, curing the coating by virtue of ultraviolet light penetrating through the protection film, cooling, stripping the surface release protection film and the panels, thereby obtaining the hardened wear-resistant coating layer with high glossiness and high flatness on the surface on the surface of the plastic panels. The process and the device disclosed by the invention are suitable for online double-sided roller coating or online single-sided roller coating, the PET films or other transparent and semi-transparent films serving as the release protection films are compounded with the panels, and the surface leveling problem generated by online roller coating of the plastic panels is solved.

Owner:厦门威亮光学涂层技术有限公司

Nano material modified fluorocarbon resin stone waterproof coating

The invention discloses a nano material modified fluorocarbon stone stone waterproof coating. The coating includes the following raw material components: resin raw material consisting of vinylidene fluoride resin and acrylic resin, multi-layer graphene oxide, a silane coupling agent, dibutyltin dichloride and solvent oil. The hardness, wear resistance and permeability resistance of the nano material modified fluorocarbon stone stone waterproof coating can be greatly improved by two-dimensional nanomaterial technology on the premise of guaranteeing of the transmittance and glossiness of the stone waterproof coating, and the protection life and the protection effect of the stone waterproof coating are greatly improved.

Owner:云浮华云创新设计有限公司

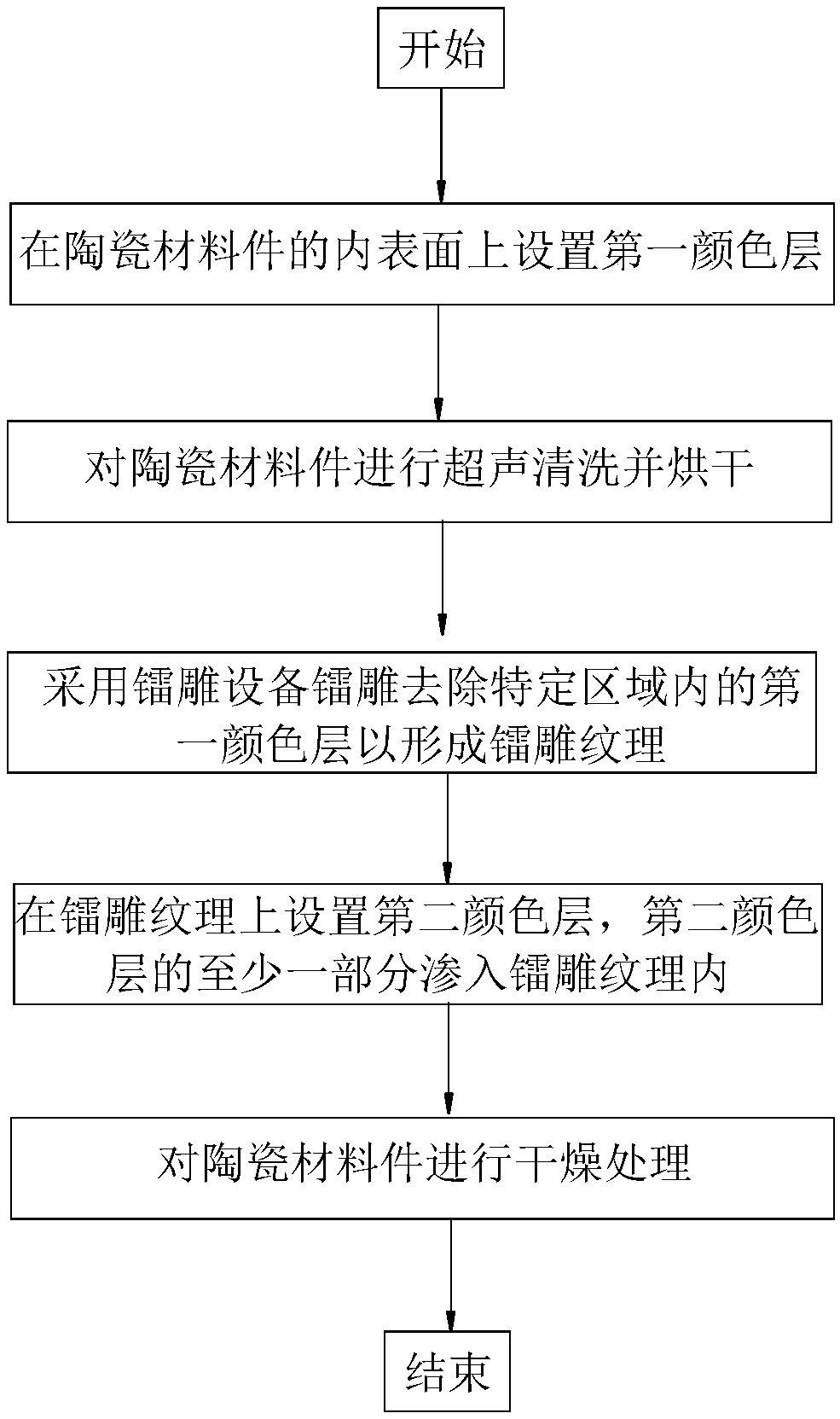

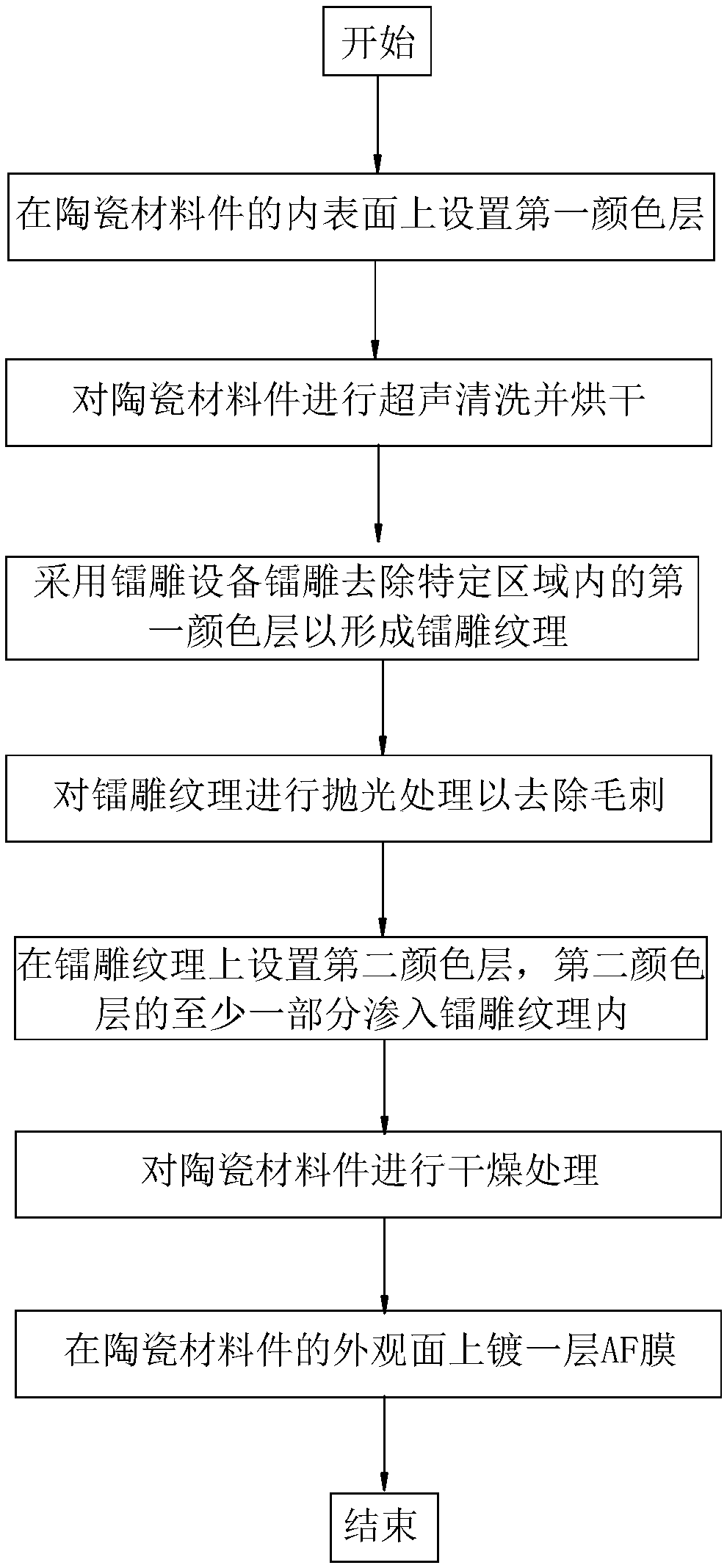

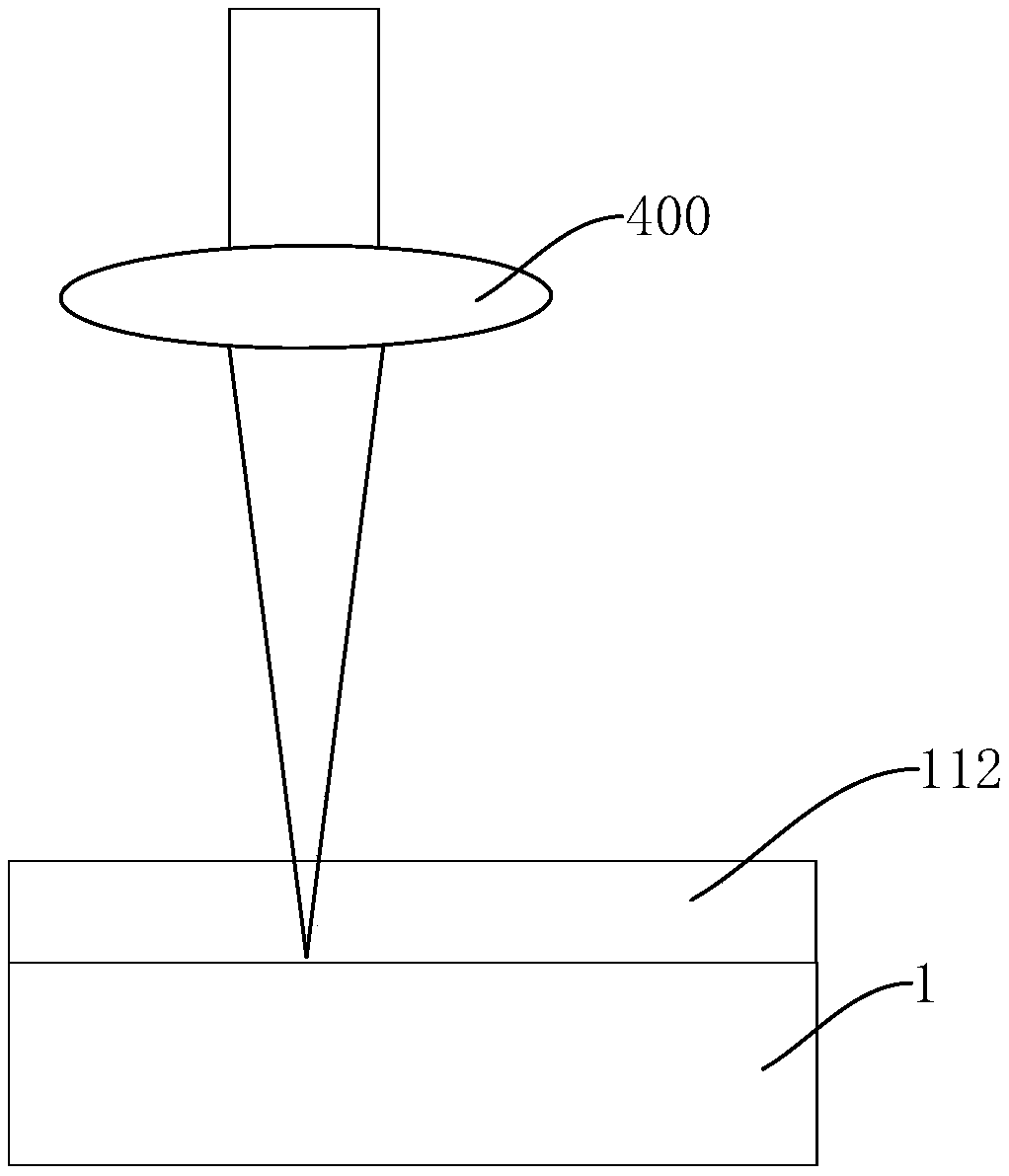

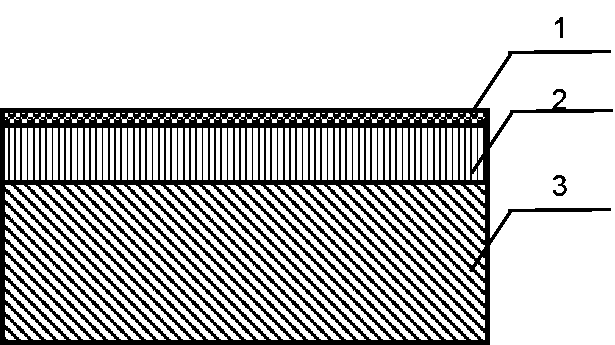

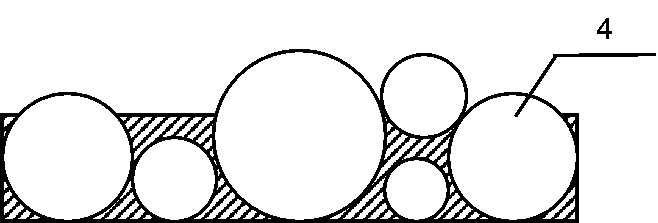

Surface treatment method for ceramic material piece, housing assembly and electronic device

InactiveCN109050139AImprove aestheticsGuaranteed glossDecorative surface effectsCasings/cabinets/drawers detailsLaser engravingPartial filling

The invention discloses a surface treatment method for a ceramic material piece, a housing assembly and an electronic device. The surface treatment method of the ceramic material piece comprises the following steps: providing a first color layer on the inner surface of the ceramic material piece; performing laser engraving on the first color layer by using a laser engraving device to remove the first color layer in a specific area to form a laser engraving texture; providing a second color layer on the laser engraving texture, filling at least a portion of the second color layer into the laserengraving texture; and drying the ceramic material piece. According to the surface treatment method of the ceramic material piece of the present application, by providing the first color layer and the second color layer on the inner surface of the ceramic material piece, at least a portion of the second color layer is filled into the laser engraving texture on the first color layer. Therefore, itis possible to present a clear, rounded and gradient laser engraved texture on the appearance of the ceramic material piece, improving the aesthetic appearance of the ceramic material piece.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Anti-scratching highlight RC printing paper and preparation method thereof

The invention discloses anti-scratching highlight RC printing paper and a preparation method thereof. The preparation method comprises the steps that highlight RC paper is coated with an ink absorption layer coating, and pre-coating RC printing paper is obtained after drying is performed; then, the pre-coating RC printing paper continues to be coated with an anti-scratch glossy layer coating, andthe anti-scratching highlight RC printing paper is obtained after drying; the ink absorption layer comprises nanometer aluminum oxide, an adhesive, a pH regulator, a silane coupling agent, a defoamingagent, a flatting agent and a cross-linking agent; the anti-scratch glossy layer comprises micro transparent powder, nanometer aluminum oxide, an adhesive, a pH regulator, a silane coupling agent, adye fixing agent, a flatting agent and a cross-linking agent. According to the anti-scratching highlight RC printing paper, the glossiness is higher than 50%, the surface hardness reaches up to 4H tothe minimum, the excellent scratch resistance is achieved, and the high glossiness and the imaging effect close to traditional photos are achieved.

Owner:GUANGDONG GLM DIGITAL TECH

Normal-temperature binding preparation method of powder coating

ActiveCN107353785AAvoid expensiveTo achieve the binding effectPowdery paintsPolyester coatingsHigh rateWater soluble

The invention discloses a normal-temperature binding preparation method of powder coating, and relates to the field of preparation of powder coating. The normal-temperature binding preparation method comprises the following steps of coating metal-effect pigments of metal powder or mica powder by water-soluble resin, adding into a powder coating system, and binding with the particles of the powder coating. Proofed by the testing results, the powder coating product bound by the method can reach the binding effect of the current industrial heat binding method, the film coating property exceeds the level of the current industrial heat binding product, and the metal powder and the powder coating are successfully bound at normal temperature. The normal-temperature binding preparation method has the advantages that by adopting the water-soluble resin to coat the metal-effect pigment, the pollution by solvent is avoided; the use of expensive heat binding equipment is avoided, the binding temperature is greatly lowered, the binding cost is reduced, and the problems of pre-curing, false binding between powder coatings, high rate of defective products, high cost and the like in the prior art are solved; the suitability is wide, and the method is widely applied to the binding of metal powder or non-metal powder and various powder coatings.

Owner:天津西敦粉漆科技有限公司

Method for preparing special material of recycled polyester for high-purity chemical fibers

InactiveCN103831911AExtended service lifeImprove cleanlinessPlastic recyclingMechanical material recoveryFiberPolyester

The invention discloses a method for preparing a special material of recycled polyester for high-purity chemical fibers. The method comprises the following eleven process steps: unpacking, removing metal impurities, performing rotary impurity removal, performing near-infrared separation, performing visible light separation, performing whole-bottle cleaning, performing fragment pre-cleaning, removing pre-cleaning impurities, performing main washing, separating and purifying, conveying bottle chips to a storage bin. According to the method for preparing the special material of recycled polyester for the high-purity chemical fibers, metal impurities in bottle bricks are removed by adopting a metal detection device, the service lives of mechanical screw, grinding tools and other equipment can be effectively prolonged, shear stress is generated to strong marks on the surfaces of the bottle chips by utilizing centrifugal force of turbo prop, buoyancy of water and gravity of bottle chips, and bottle marks on the bottle chips are removed, so that the bottle chips can keep high cleanliness and are subjected to the main washing process, and the liquid replacement frequency during main washing is reduced. Meanwhile, the cleaning time and pressure during main washing can be effectively reduced, and the glossiness and transparency of the bottle chips are ensured.

Owner:江苏中再再生资源有限公司

Bristle production technique

The invention relates to a bristle production technique which comprises the steps of (1) selection and separation, (2) immersing, (3) cleaning, (4) sun-drying, (5) fine hair absorption, (6) plate-binding, (7) stewing, (8) drying, (9) smoothing, (10) grading, (11) blending, (12) root trimming, (13) bundling, (14) repairing, and (15) acceptance inspection. The working pressure of water vapor is 0.5-0.9 MPa, and the water vapor is saturated vapor. Water used in the process contains deodorants. According to the bristle production technique, the abominable odor of bristles can be effectively eliminated, sterilization is achieved, impurities can be eliminated completely, straightness and glossiness of the bristles are guaranteed, and excellent natural characteristics of the bristles are reserved. The bristles manufactured with the technique can be directly used for manufacturing other products, treatment such as odor removing is not needed, and the problems of low efficiency and poor effect of traditional bristle production are solved.

Owner:WUWEI RONGHUA BRISTLE BRUSH PROD

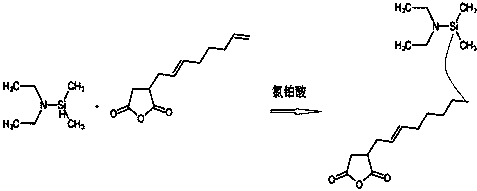

Preparation method of organic silicon-coated polytetrafluoroethylene anti-dripping agent

The invention relates to the field of chemical engineering, in particular to a preparation method of an organic silicon-coated polytetrafluoroethylene anti-dripping agent. The invention relates to a preparation method of an organic silicon-coated polytetrafluoroethylene anti-dripping agent. According to the method, a mixed solution of palladium chloride and stannous chloride is used for treating apolytetrafluoroethylene dry material under an ultrasonic condition to generate active groups on the surface of the polytetrafluoroethylene dry material, ultraviolet polymerization is performed at thesame time to graft amido bonds to the surface; and then organic silicon wraps the surface of polytetrafluoroethylene particles through hydrolysis polycondensation reaction of organic silicon, therebyobtaining the organic silicon coated polytetrafluoroethylene anti-dripping agent. By means of the anti-dripping agent, product particles and resin have better affinity, coating is more complete, thecompatibility between the material and resin is not affected, and the mechanical property and glossiness of the material are guaranteed.

Owner:QUZHOU ZHONGTONG CHEM

Production technique for copper ammonia fiber looped fabrics

InactiveCN103014996AHigh degree of automationEasy to operateBiochemical fibre treatmentDry-cleaning apparatus for textilesCotton fibreFiber loop

A production technique for copper ammonia fiber looped fabrics is characterized in that blended yarns blended by copper ammonia fibers and cotton fibers and / or 100% of copper ammonia yarns are used as weaving yarns, and are woven to obtain grey fabrics, wherein the weaving yarns are refined before the weaving, or the grey fabrics are refined after the weaving; and then the grey fabrics are softened to prepare the copper ammonia fiber looped fabrics. The technique is simple, reliable and convenient to implement; and prepared copper ammonia looped products have the characteristics of freshness, amenity, health, comfort, humidity absorption, breathability, natural color, soft texture, good skin friendliness and the like.

Owner:SUNVIM GROUP

Ceramic glazed tile glaze prepared from coal gangue, and preparation method and use method of ceramic glazed tile glaze

The invention relates to the technical field of ceramic glazed tiles, in particular to a ceramic glazed tile glaze prepared from coal gangue, and a preparation method and use method of the ceramic glazed tile glaze. The ceramic glazed tile glaze is prepared from 1-5 parts of zinc oxide, 4-10 parts of barium carbonate, 4-12 parts of zirconium silicate, 30-40 parts of potassium feldspar, 2-10 partsof desiliconized aluminum powder, 6-14 parts of calcined talc, 2-8 parts of calcite, 6-12 parts of kaolin, 6-12 parts of dolomite, 3-8 parts of quartz and 5-12 parts of coal gangue waste residues, wherein the fineness of the coal gangue waste residues is that screening residues of 60 meshes is 10-20%, and the mass content of water is 1-2%. According to the glaze, the cheap coal gangue waste residues are adopted to replace high-cost calcined kaolin, so that cost of the glaze is greatly reduced, and raw material cost per ton can be reduced by 60% or above. In addition, the texture and luster ofthe glaze surface are finally ensured to meet use requirements by controlling the glaze slurry performance, the glaze formula and the glazing conditions.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

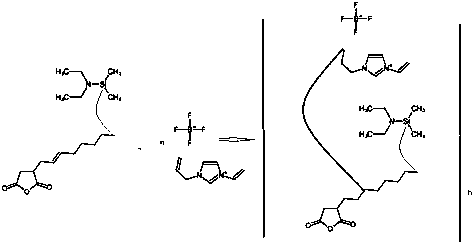

Nanometer material modified fluorocarbon resin stone material waterproof paint and preparation method thereof

ActiveCN107974141AImproved weather resistance and impermeabilityStrong applicabilityCoatingsPolyvinylidene fluorideSolvent

The invention discloses nanometer material modified fluorocarbon resin stone material waterproof paint. The paint is prepared from the following ingredients: a resin raw material composed of polyvinylidene fluoride resin and acrylic resin, a hexagonal phase boron nitride two dimension nanosheet, a silane coupling agent, dibutyltin dichloride and solvent oil. By two-dimensional nanometer material modification technology, on the premise of guaranteeing the light transmittance and glossiness of the stone material waterproof paint, the hardness, abrasive resistance and permeation resistance of thestone material waterproof paint are substantially improved, so that the protection lifetime and protection effect of the stone material waterproof paint are remarkably improved.

Owner:云浮华云创新设计有限公司

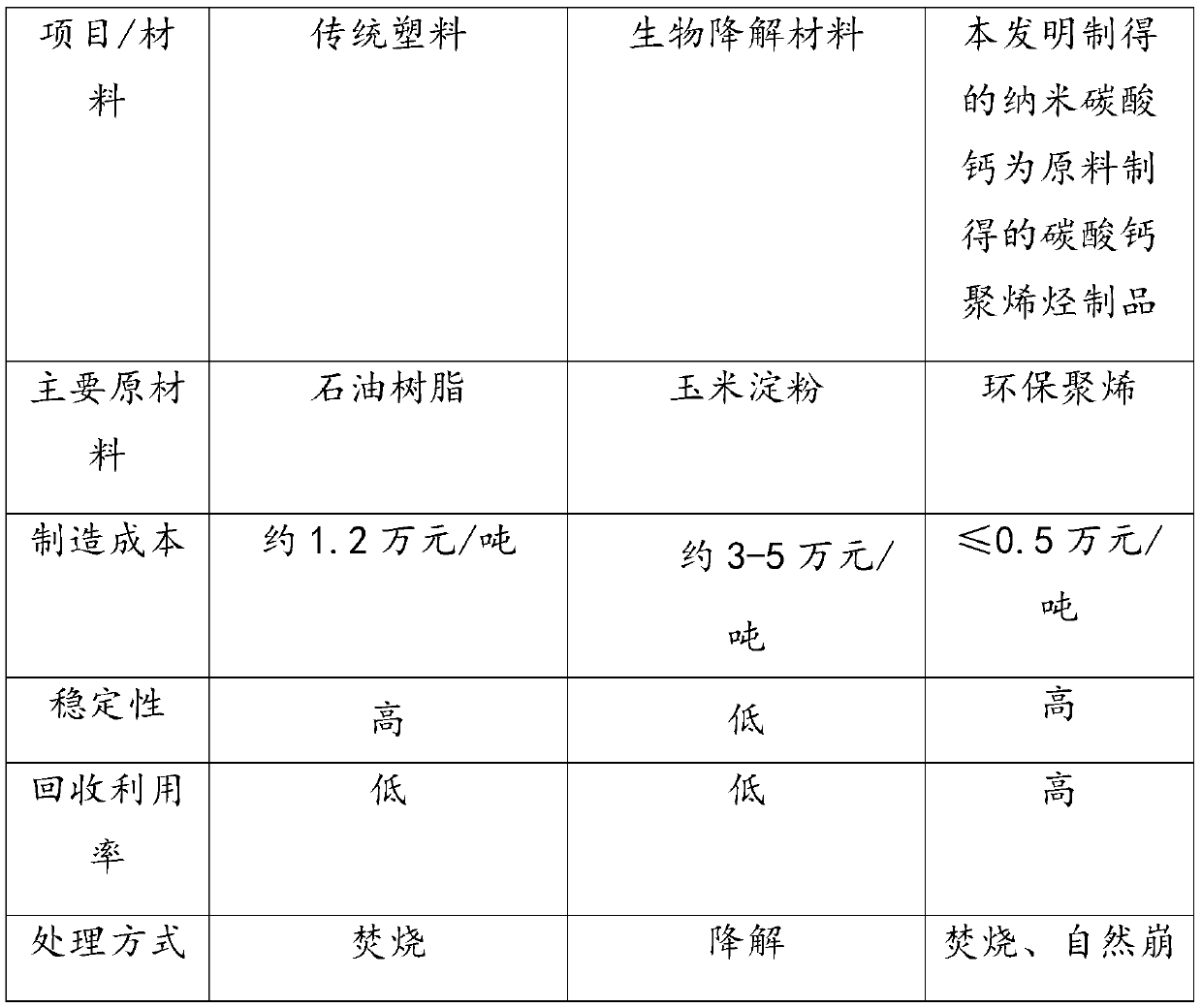

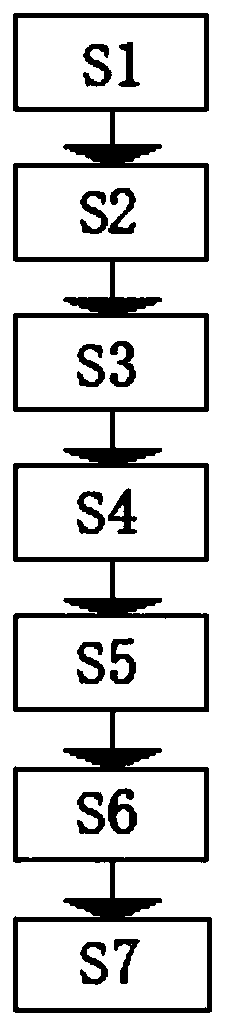

Production method of nanometer calcium carbonate for PE direct film blowing

InactiveCN111559752AImprove bindingImprove mechanical propertiesCalcium/strontium/barium carbonatesCalcium hydroxideCarbonization

The invention discloses a production method of nanometer calcium carbonate for PE direct film blowing. The production method comprises the following steps: S1, preparing raw slurry of calcium hydroxide; S2, preparing a solution of a crystal form control agent a; S3, after step S2 is finished, adding the raw slurry obtained in step S1 and a crystal form control agent b into a carbonization tower, and carrying out carbonization treatment; S4, aging the slurry obtained by carbonization, detecting the pH value, and if the pH value is greater than 7.0, introducing carbon dioxide until the pH valueis less than 7.0; S5, carrying out surface activation treatment on the aged slurry; S6, cooling the activated slurry, carrying out filter pressing, and drying; and S7, adding a heat stabilizer in thedrying process of the product, and crushing and depolymerizing to obtain the product. The nanometer calcium carbonate prepared by the production method disclosed by the invention can omit a granulation process in a PE film blowing process, and meets the requirements of energy conservation, environmental protection and consumption reduction.

Owner:建德市双超钙业有限公司

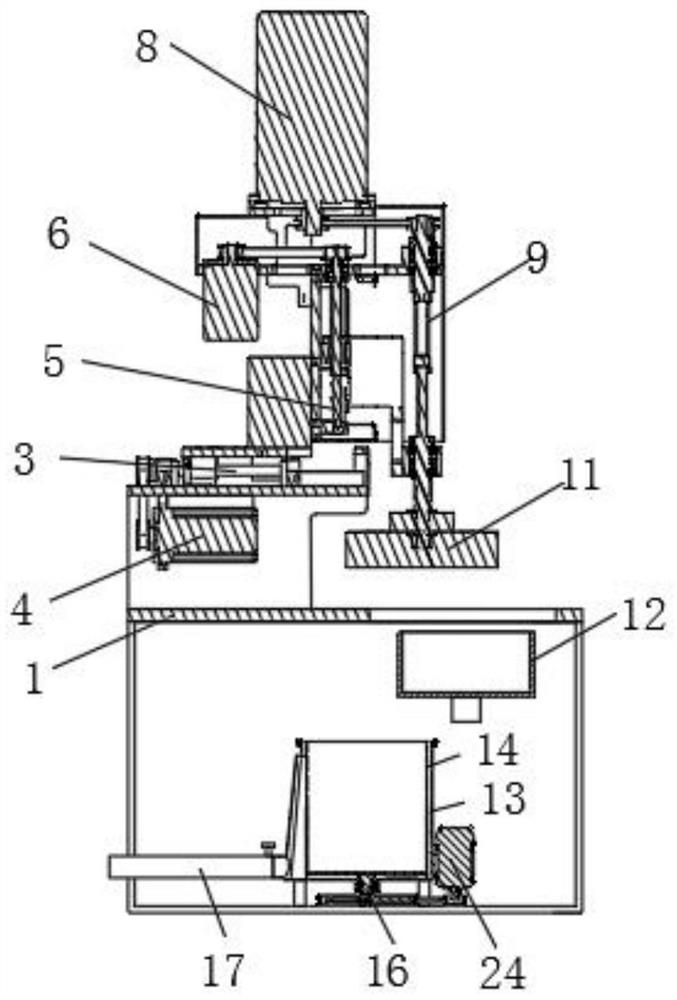

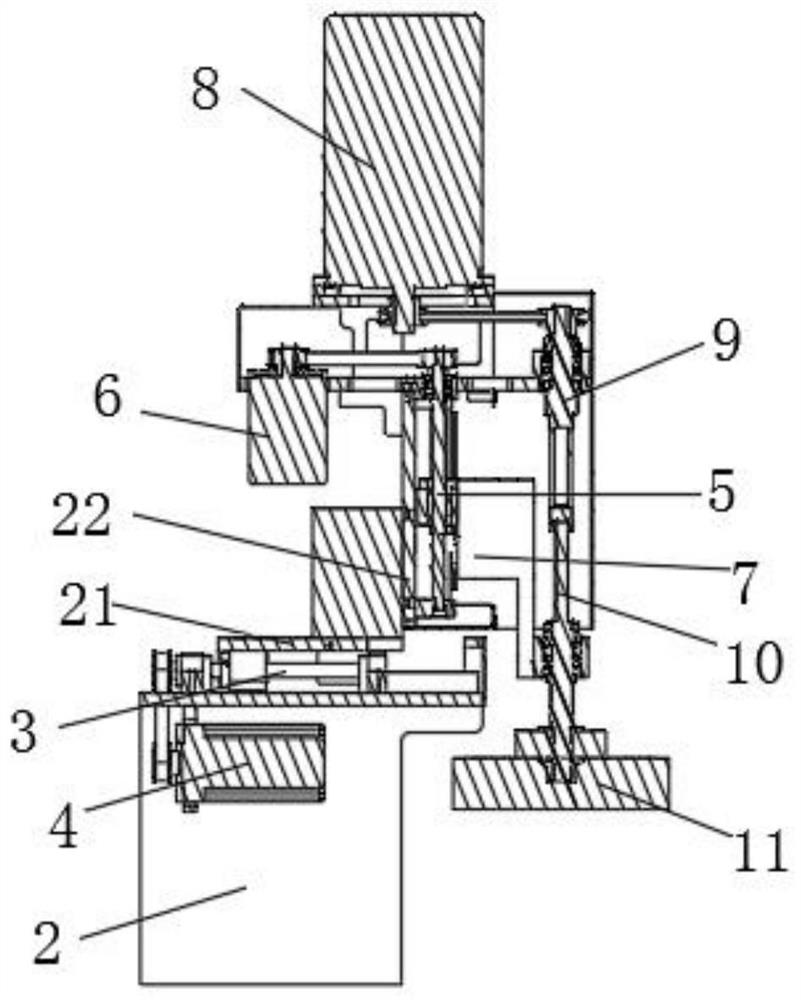

Sesame seed stir-frying device with preheating

The invention discloses a sesame frying device with preheating, which includes a preheating drying device and a roasting device. The preheating drying device includes a drying barrel, a collection chamber and an impurity chamber. The drying barrel includes a fixedly connected drying chamber and a drying chamber. Drying cone, the drying cone is located at the lower part of the drying chamber; the roasting device includes a frying device and a cooling drum, the frying device includes a drum, the cooling drum is arranged at the outlet end of the drum, and the cooling drum passes through the intermediate piece and the drum Connected, the cooling cylinder is provided with a cooling outlet. The sesame frying device with preheating of the present invention has wide applicability, preheating and drying can greatly improve the efficiency of sesame frying, the frying device ensures that the sesame is evenly fried, and the frying situation can be monitored at any time during the frying process, At the same time, the excess high temperature during the frying process can be used to fry the sesame seeds at a low temperature. The fried sesame seeds can be cooled in time, and the entire processing process can also ensure continuity.

Owner:黄林海

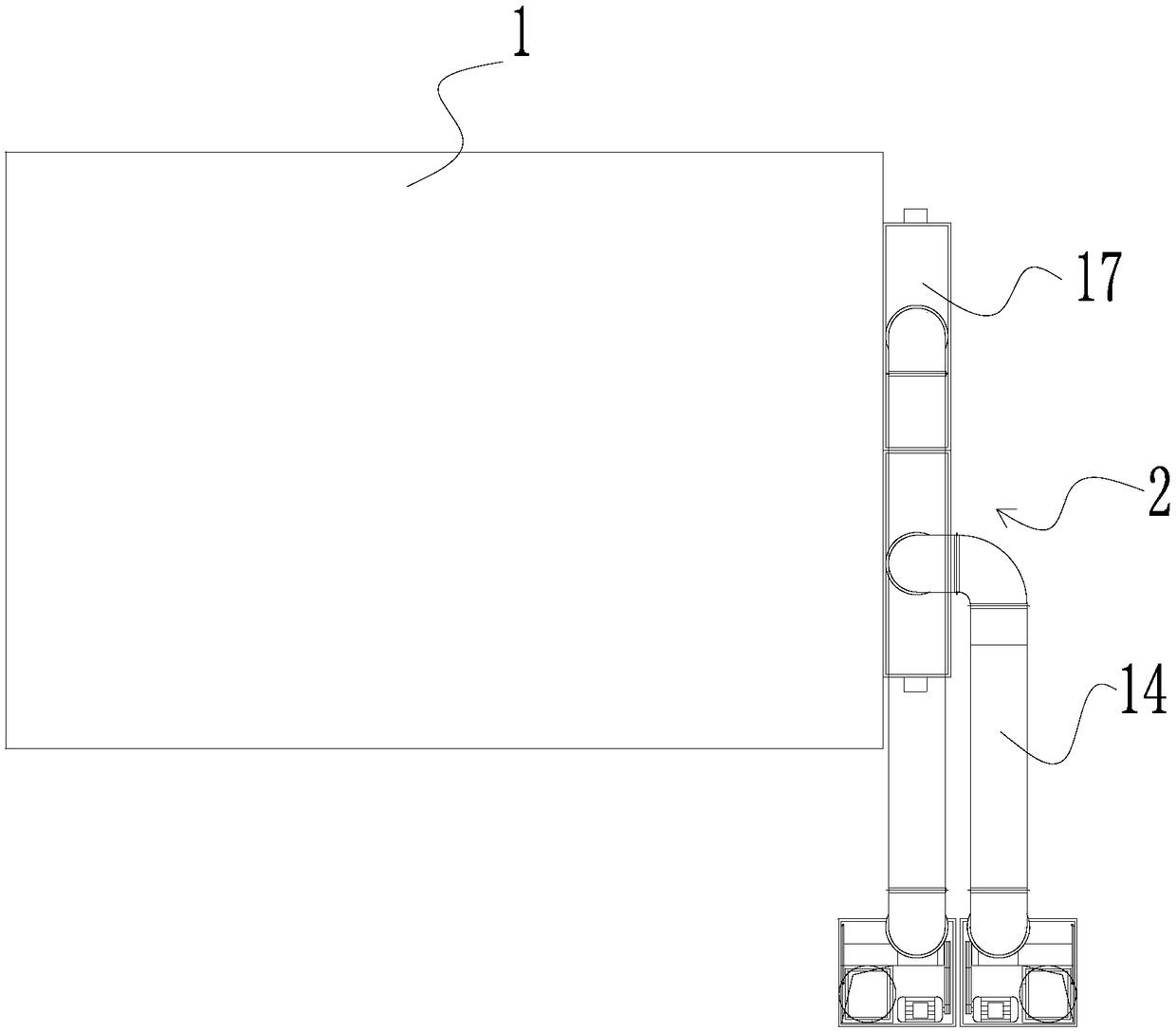

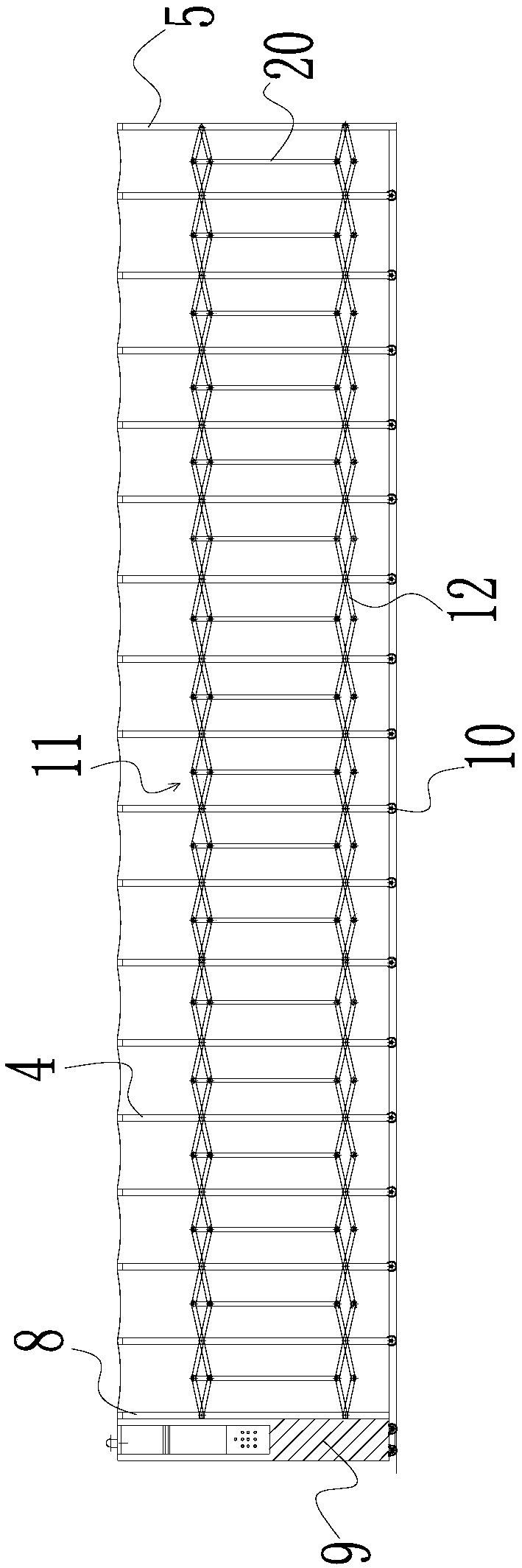

Telescopic spray booth

ActiveCN108855731AGuaranteed normal expansionAvoid unexpected situations of skidding and derailmentSpray boothsActivated carbonLacquer

The invention relates to a telescopic spray booth, which comprises a spray booth body, a paint mist discharging pipeline and a paint mist elimination system, wherein the spray booth body comprises a supporting skeleton of the spray booth body, which is formed by a plurality of supporting frames and connecting pieces; flame-retardant PVC (polyvinyl chloride) cloth is arranged on the supporting skeleton; the flame-retardant PVC cloth covers the top and the side wall of the supporting skeleton so as to form the spray booth body of which a traction frame end is an open end; the paint mist discharging pipeline comprises an exhaust fan and first and second discharging pipelines; the paint mist elimination system comprises a water curtain paint removal device and an activated carbon paint removaldevice; an air inlet of the water curtain paint removal device is communicated with a paint mist discharging hole; the lower end of a barrel of the activated carbon paint removal device is in interference fit into an air inlet pipe section of the exhaust fan; the upstream end of the first discharging pipeline is communicated with an air outlet of the water curtain paint removal device; the downstream end of the first discharging pipeline is communicated with the upper end of the barrel of the activated carbon paint removal device; the upstream end of the second discharging pipeline is communicated with an exhaust pipe section of the exhaust fan; the downstream end of the second discharging pipeline vertically extends upwards to form a chimney.

Owner:重庆建杰建筑工程有限公司

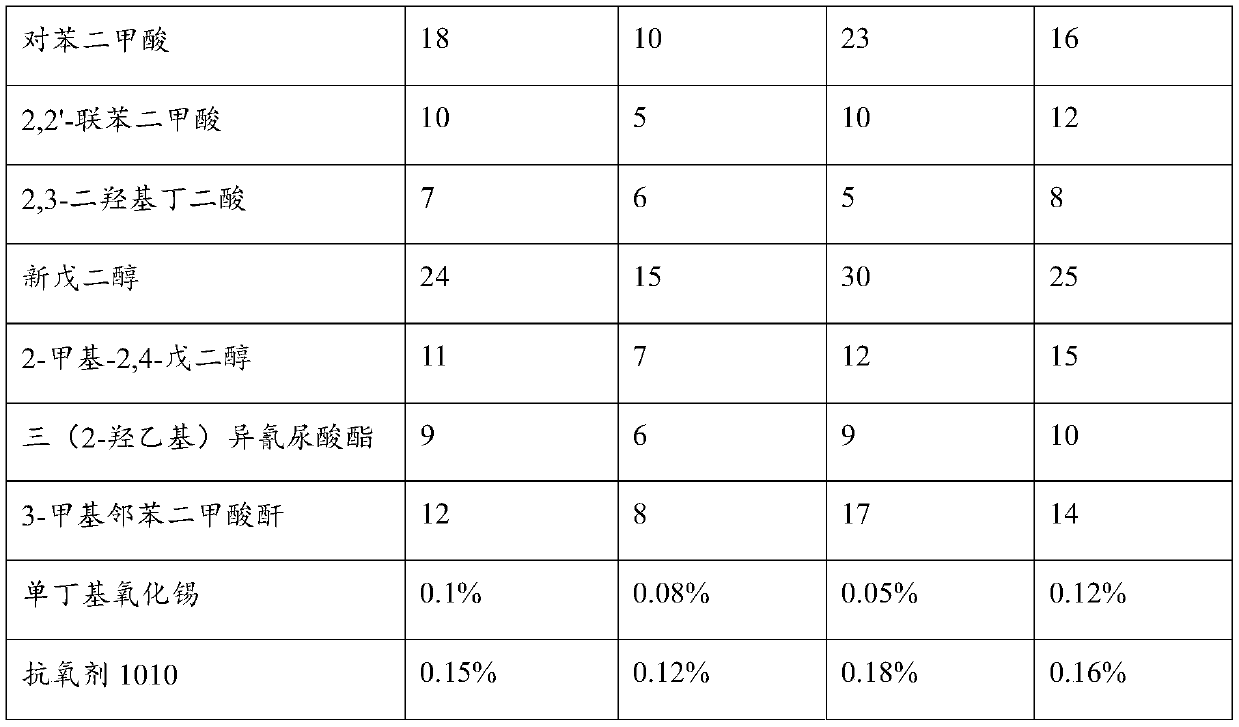

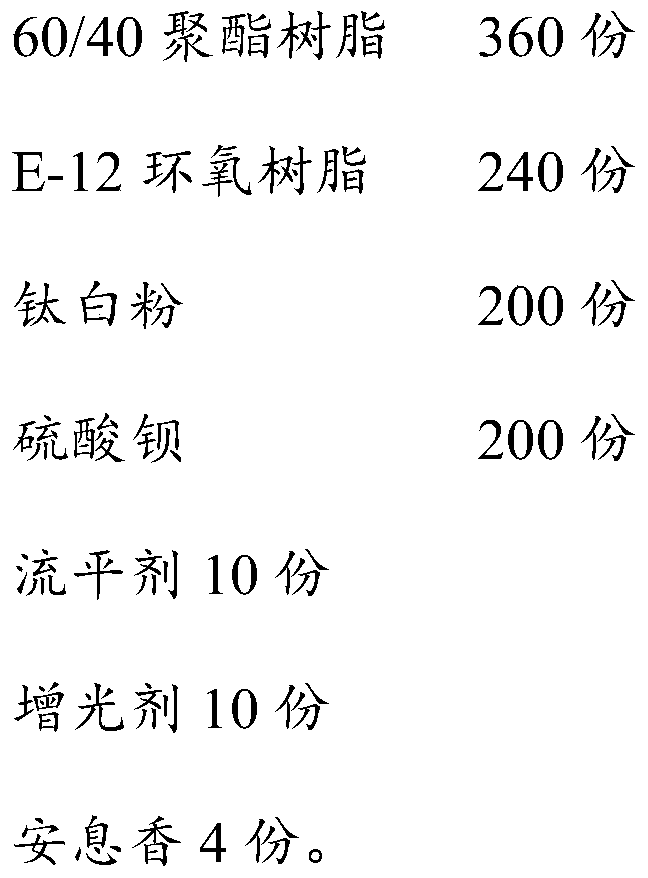

Polyester resin with high hardness and high storage stability for 60/40 mixed powder and preparation method thereof

ActiveCN111333827AHigh hardnessGood storage stabilityPowdery paintsPolyester coatingsPolymer scienceButanedioic acid

The invention, which belongs to the technical field of preparation of polyester resin, particularly relates to polyester resin with high hardness and high storage stability for 60 / 40 mixed powder anda preparation method thereof. According to the polyester resin for 60 / 40 mixed powder, the polyester resin is characterized by being prepared from the following main raw materials: terephthalic acid,2, 2 '-biphenyldicarboxylic acid, 2, 3-dihydroxy succinic acid, neopentyl glycol, 2-methyl-2, 4-pentanediol, tris (2-hydroxyethyl) isocyanurate and 3-methyl phthalic anhydride. According to the invention, the performances such as impact resistance, coating film appearance, caking resistance, hardness, gloss and the like of polyester resin products are guaranteed, the influence on subsequent spraying use and coating film quality due to crosslinking of the powder coating in the storage period is eliminated, the polyester resin can be stored in an environment of 45 DEG C for a long time without influencing subsequent use, and the polyester resin has excellent high storage stability.

Owner:黄山市源润新材料科技有限公司

Wear-resistant antibacterial ceramic and processing method thereof

InactiveCN111792913AImprove quality requirementsGood antibacterial effectClaywaresAir atmospherePyrophyllite

The invention relates to wear-resistant antibacterial ceramic and a processing method thereof. The processing method includes the steps that a body material is fired for the first time to form a plainbody, then glaze is applied to the two faces of the plain body to form glaze layers, and firing is conducted for the second time, and then the wear-resistant antibacterial ceramic is obtained, wherein the body material is made of raw materials such as sodium bentonite, coke gemstone, pyrophyllite, dolomite, and the like, the glaze is prepared from silicon dioxide, potassium fluoroaluminate, boronoxide, barium oxide, yttrium oxide, titanium-silicon co-doped graphene, large ball mud and other raw materials. Wherein the second firing comprises three-stage heating and heat preservation and three-stage cooling, each heating and heat preservation is sequentially carried out in an air atmosphere, a nitrogen atmosphere and a hydrogen atmosphere, and the three-stage cooling is natural cooling, rapid cooling and natural cooling. The obtained ceramic product has excellent antibacterial performance and wear resistance, and meets the high-quality requirements of ceramics.

Owner:许洁

Polymer wear-resistant PP composite material for eyeliner tube and preparation method thereof

The invention discloses a polymer wear-resistant PP composite material for an eyeliner tube. The polymer wear-resistant PP composite material comprises the following raw materials by weight: 65 to 85parts of polypropylene powder, 5 to 8 parts of silicone rubber, 0.5 to 1 part of tungsten carbide powder, 1 to 3 parts of nanometer toughened aluminum oxide, 0.5 to 0.8 part of an aluminum-based adhesive, 5 to 10 parts of sepiolite fiber, 5 to 10 parts of a compatibilizing and toughening agent, 1 to 3 parts of a lubricant and 0.1 to 0.7 part of an antioxidant. The invention relates to the technical field of polymer composite materials. The polymer wear-resistant PP composite material for the eyeliner tube and the preparation method thereof have the following advantages: improvement of the manufacturing materials of the eyeliner tube can be realized to increase the wear-resisting effect of the eyeliner tube; the wear resistance of the eyeliner tube can be greatly improved; the frequent situations of surface abrasion and edge peeling of the eyeliner tube after long-term use are avoided from occurrence; the glossiness and smoothness of the surface of the eyeliner tube are guaranteed; theinfluence on the appearance of the eyeliner tube is prevented; the purpose of prolonging the service life of the eyeliner tube is well achieved; and normal use of the eyeliner tube for people is guaranteed.

Owner:邵成杰

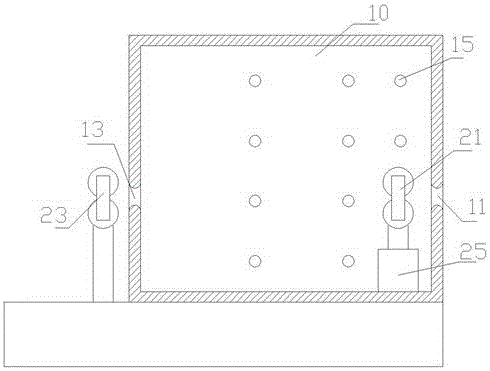

Printing drying device

ActiveCN106696453AAchieve movementSpeed up dryingPrinting press partsReciprocating motionEngineering

The invention discloses the field of packaging bag processing, and particularly relates to a printing drying device. The printing drying device comprises a machine frame and a drying oven arranged on the machine frame. The drying oven is provided with a feeding inlet and a discharging outlet which are arranged oppositely, and a heating mechanism is arranged on the inner wall of the drying oven, wherein a feeding roller pair is arranged in the drying oven and located close to the feeding inlet, and the feeding roller pair is connected with a driving part used for driving the feeding roller pair to do reciprocating motion in the vertical direction; and a discharging roller pair is arranged outside the drying oven and located close to the discharging outlet, and cooling rollers are used as the discharging roller pair. The printing drying device is provided to solve the problems that as for exiting devices, the drying time for products is prolonged in order to guarantee the drying effect on packaging films, and consequently the production efficiency of the products is reduced.

Owner:DINGSHENG CORP

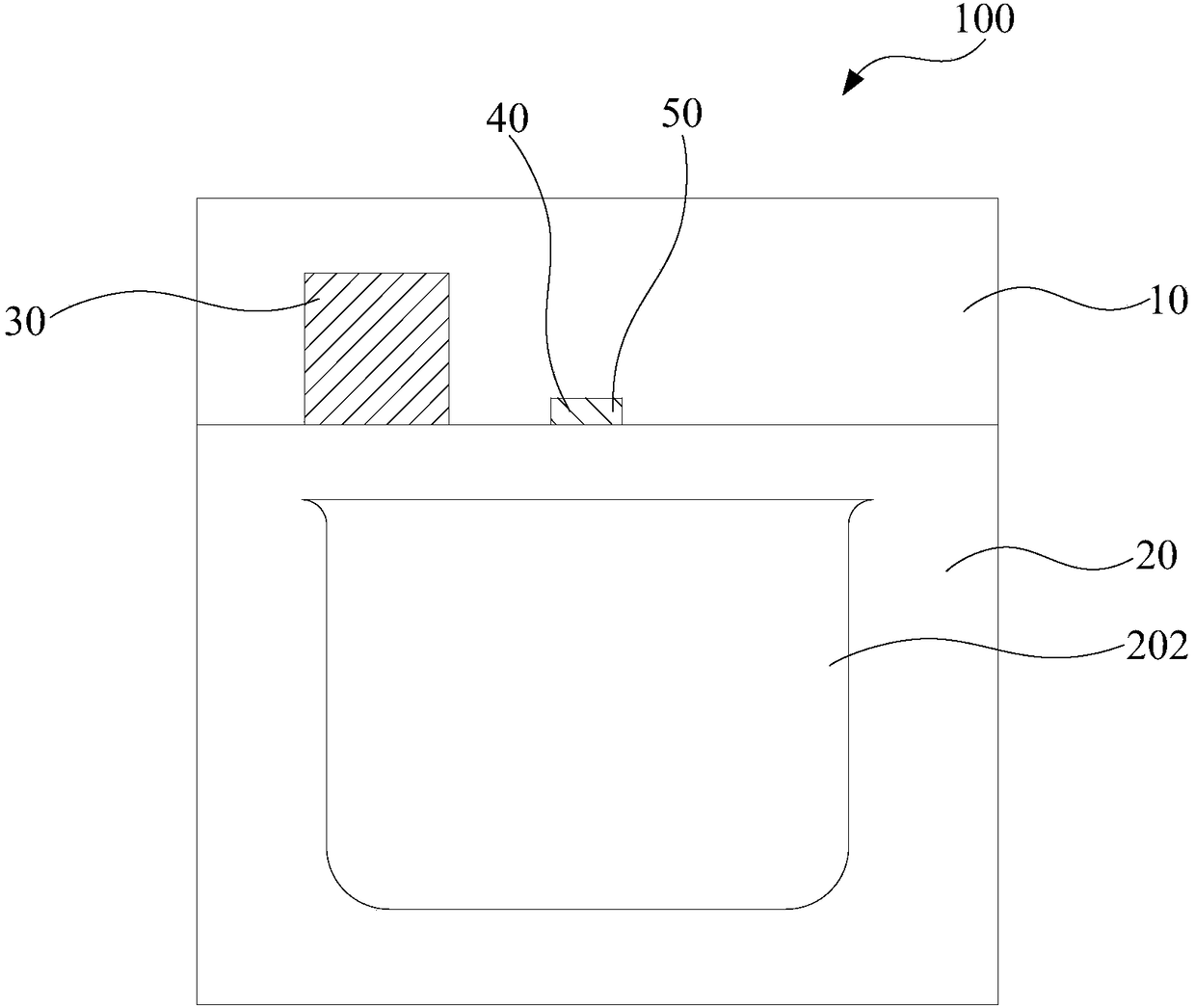

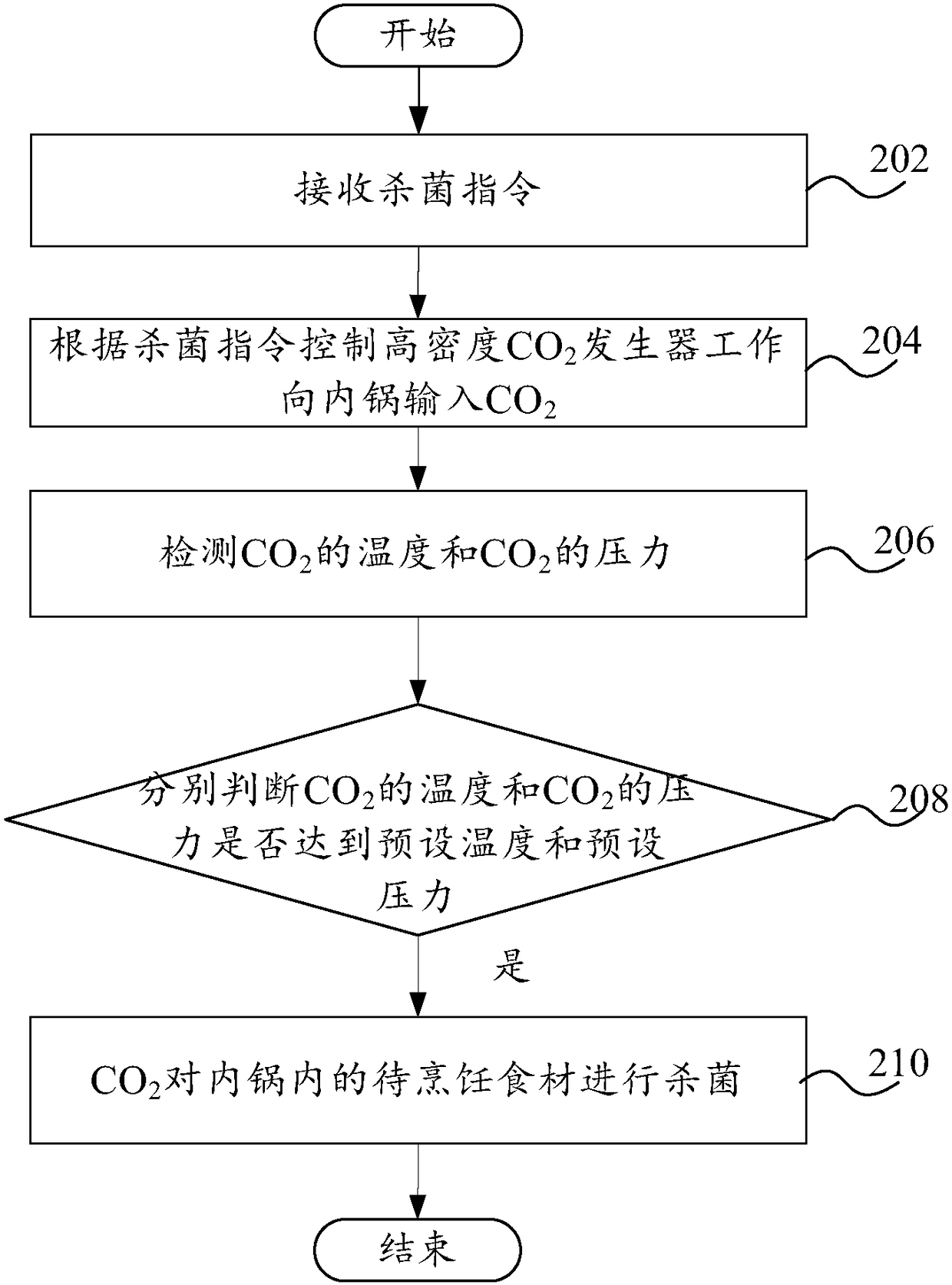

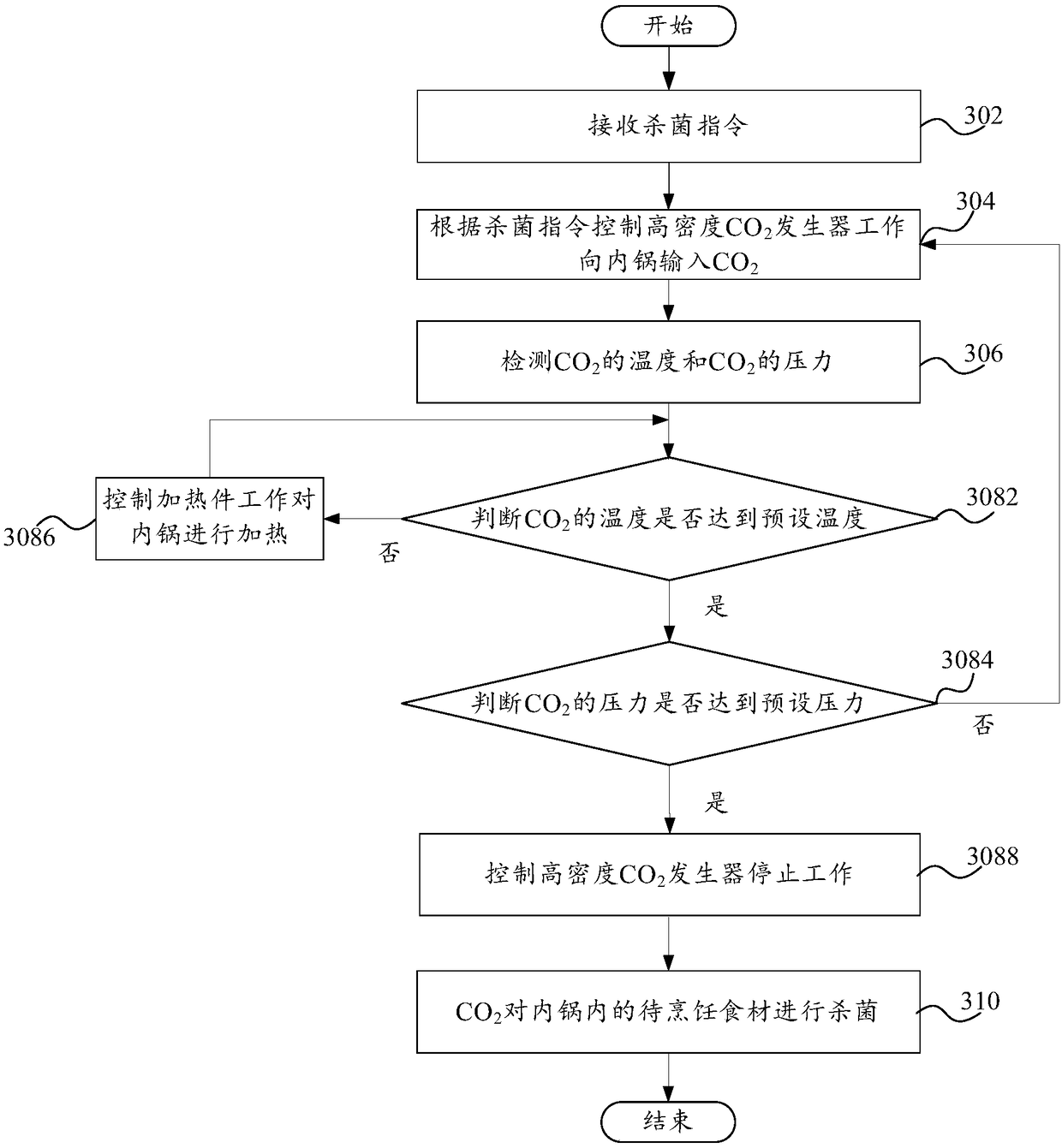

Cooking utensil and sterilization control method

InactiveCN108618564AGuaranteed qualityGuaranteed nutritionFood preservationVessels with intergral heatingHigh densityAdditive ingredient

The invention provides a cooking utensil and a sterilization control method. The cooking utensil comprises an upper cover and a machine body, an inner pot is arranged in the machine body, and the upper cover is arranged on the machine body in a fastened mode. The cooking utensil comprises a high-density CO2 generator, a temperature sensor, a pressure sensor and a heating part, wherein the high-density CO2 generator is detachably arranged on the upper cover for inputting CO2 into the inner pot; the temperature sensor is arranged on the upper cover or the machine body to detect the temperature of CO2; the pressure sensor is arranged on the upper cover to detect the pressure of CO2; and the heating part is arranged on the machine body and is connected with the temperature sensor. According tothe cooking utensil, when the temperature of CO2 reaches the preset temperature of the temperature sensor, and the pressure of CO2 reaches the preset pressure of the pressure sensor, the CO2 kills the microorganism and bacteria which are bred by the food materials to be cooked in the inner pot, the freshness, sterility nutritional ingredient, and color of the food materials to be cooked are guaranteed, then the quality, nutrition and taste of the food after cooking are guaranteed, and the use experience of a user is improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

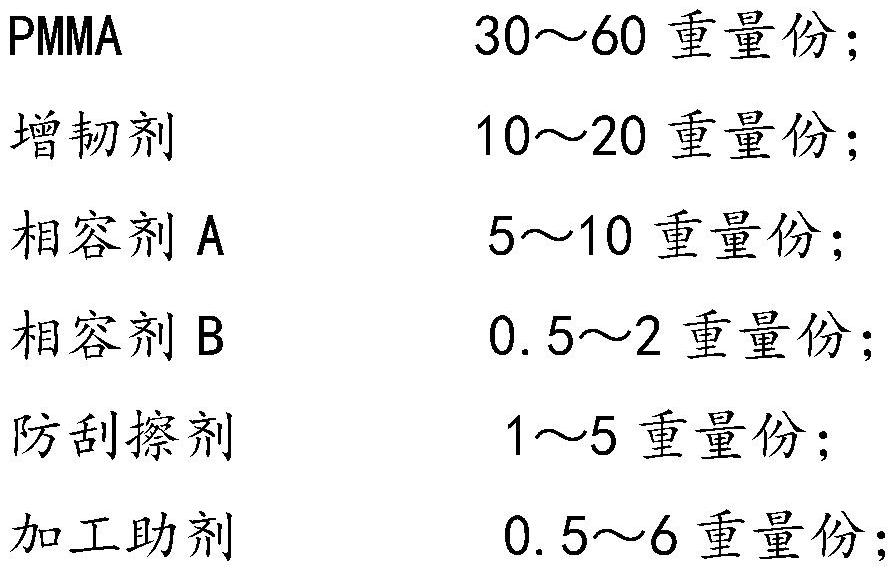

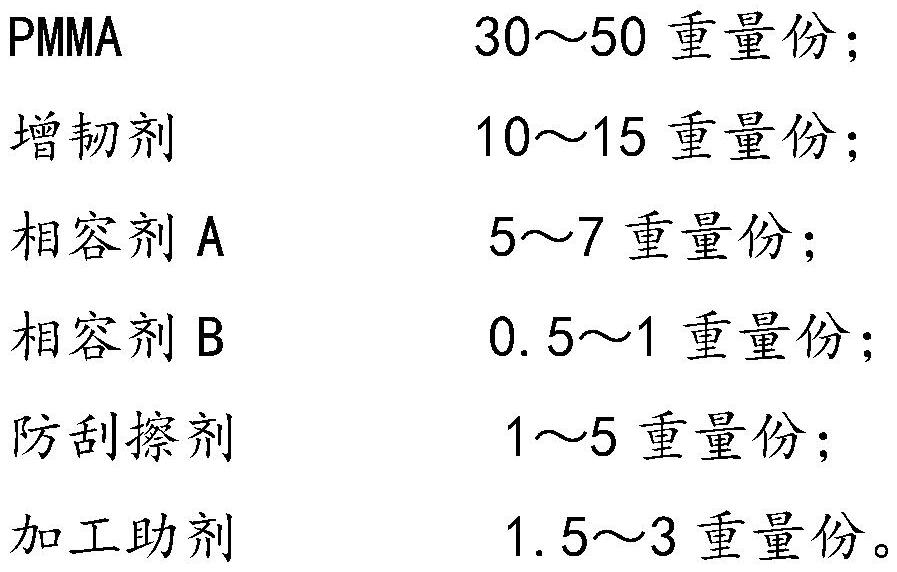

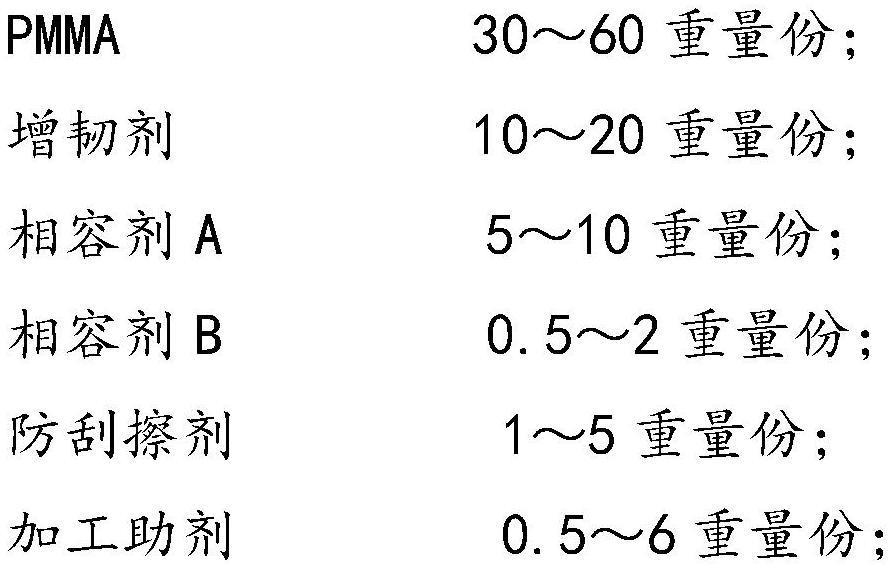

Modified acrylate polymer composition

The invention provides a modified PMMA / ASA polymer composition. The modified PMMA / ASA polymer composition is prepared from the following components in parts by weight: 30-60 parts of PMMA; 10-20 parts by weight of a toughening agent; 5-10 parts by weight of a compatilizer A; 0.5-2 parts by weight of a compatilizer B; 1-5 parts by weight of an anti-scratch agent; and 0.5-6 parts by weight of a processing aid. The invention also provides a preparation method of the modified PMMA / ASA polymer composition. The PMMA / ASA / MBS alloy resin composition with greatly improved impact strength, excellent scratch resistance, good surface gloss and good weather resistance is obtained by introducing two compatilizers with a synergistic effect.

Owner:CHINA CHEM TECH RES INST

On-line double-sided roller coating process and its device for producing high-gloss panels with solvent-free uv coatings

ActiveCN104589677BRealize online double-sided roller coating production processReduce insecurityLiquid surface applicatorsLaminationTectorial membraneProduction line

The invention discloses an online double-sided roller coating process and device for producing high-brightness panels by using a solvent-free UV coating. The process comprises the following steps: uniformly coating the solvent-free UV coating on plastic panels molded on an extruder by virtue of a roller coater, covering a release protection film on the surface with the coating on plastic panels by virtue of a laminating machine, flatly pressing, performing UV curing on the plastic panels, curing the coating by virtue of ultraviolet light penetrating through the protection film, cooling, stripping the surface release protection film and the panels, thereby obtaining the hardened wear-resistant coating layer with high glossiness and high flatness on the surface on the surface of the plastic panels. The process and the device disclosed by the invention are suitable for online double-sided roller coating or online single-sided roller coating, the PET films or other transparent and semi-transparent films serving as the release protection films are compounded with the panels, and the surface leveling problem generated by online roller coating of the plastic panels is solved.

Owner:厦门威亮光学涂层技术有限公司

High-rigidity high-gloss modified polystyrene material

The invention specifically relates to a high-rigidity high-gloss modified polystyrene material, which belongs to the technical field of modified polystyrene materials. The material comprises the following raw materials: high impact polystyrene, general-purpose polystyrene, a stabilizing agent, white oil and a dye. According to the invention, high impact polystyrene is modified, and the performances of high rigidity and high gloss are obtained.

Owner:QINGDAO DADU NEW MATERIAL TECH

High-stability water-based ink

The invention discloses high-stability water-based ink, and particularly relates to the technical field of ink. Deionized water is added into a dispersion kettle, the mixture is heated to 80 DEG C, then acrylic resin, a defoaming agent and isopropanol are added and stirred for 10 min to be uniformly dispersed, finally, a mixed solution of ammonia water and ethanolamine is added, the mixture is stirred until the resin is dissolved, the proportion of the ammonia water is adjusted, after mixing is completed, phthalocyanine blue, filler, a dispersing agent, a thickening agent and an anti-corrosion and anti-mildew agent are added into the solution to be dispersed in a high-speed dispersion machine in advance, the stirring speed is 900-1100 rpm, the stirring time is 1-2 h, then standing is conducted to the normal temperature, then grinding is conducted, the fineness is detected, the water-based ink can effectively overcome the defects of low drying speed, poor water resistance and low glossiness of the current water-based ink for flexible board printing, and the raw materials adopted in the preparation process of the water-based ink are cheap and easy to obtain, the production process is simple, the ink stability is high, and the water-based ink has very high popularization value in the field of the water-based ink for flexible board printing.

Owner:湖北绿新环保包装科技有限公司

Highlight water-based automobile paint

InactiveCN101104768BGuaranteed stabilityMiscibility guaranteedLiquid surface applicatorsPolyurea/polyurethane coatingsAutomotive paintPigment dispersion

The invention discloses a high-gloss water-based paint for car. The finishing varnish is prepared by mixing methacrylate resin(27-36%), ethyl acrylate resin(31-41%), water-soluble methyl-etherifying amino resin(9-14%), water-soluble polyurethane rheological agent(0.1-0.3%) , water-based polyurethane thickening rheology agent(3-5%) and deionized water(3-18.5%) in a container. A colored paint can be made by adding pigment concentrates into the finishing varnish. The stabilities of pigment dispersing into tiny particles and the miscibility of different pigments are guaranteed by using blended dispersants to wet and disperse the pigment. Good film fullness and glossiness can be obtained due to a higher solid content of the water-based paint by a mixture of more than two high-solid basic resin. The specification of this paint reaches and surpasses the standard level of common solvent car varnish by reducing the pollution of the harmful volatile organic solvent.

Owner:刘成金

Intelligent robot beneficial for cutting plastic mould rim charge of mould cleaning

InactiveCN107511958AStable cutting levelAvoid misalignmentCleaning using liquidsMetal working apparatusEngineeringElectrical and Electronics engineering

The invention discloses an intelligent robot for cutting plastic mold side material which is beneficial to mold cleaning. It comprises a device body, the surface of the device body is provided with a base, the base includes a battery box and a water tank, and the bottom side of the surface of the battery box is provided with a charging port and a water tank. The surface is provided with a connecting pipe, the connecting pipe is a corrugated pipe, the top of the base is provided with a working platform, the surrounding of the working platform is provided with a fixed plate, the surface of the fixed plate is provided with a control panel, and the two sides of the working platform are symmetrically provided with support columns. The inner side of the support column is provided with a height adjustment chute, and the inside of the height adjustment chute is provided with a horizontal connecting column. However, the existing plastic molds cannot wash the cut mold in time after cutting the edge material, which makes the mold production process more complicated. For the problem of inconvenience, we provide an intelligent robot for cutting plastic mold trim that is beneficial to mold cleaning.

Owner:王佳锋

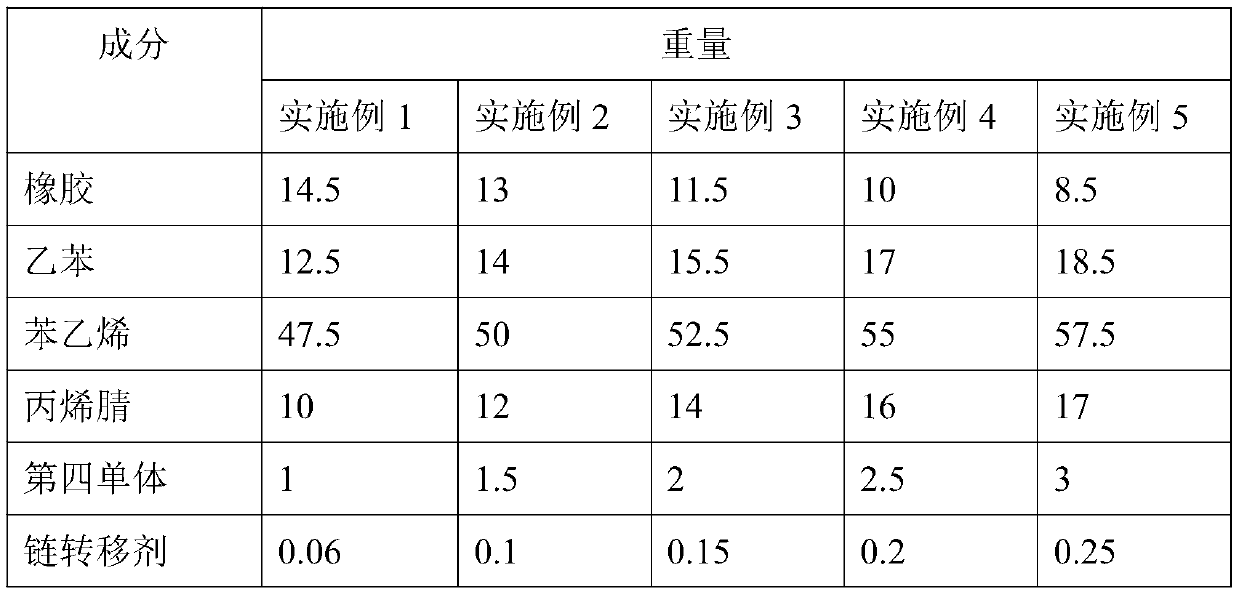

Preparation method of high-gloss bulk ABS resin

PendingCN111057190AGuaranteed gloss and mechanical propertiesHigh grafting ratePolymer chemistryButadiene-styrene rubber

The invention belongs to the field of polymer materials, and in particular, relates to a preparation method of high-gloss bulk ABS resin. The high-gloss ABS resin is prepared by using a bulk ABS device, star-shaped low-cis rubber and butadiene styrene rubber are compounded to form rubber, the proportion of an original rubber solution and the addition amount of a chain transfer agent are adjusted,a fourth monomer is added to prepare the high-gloss bulk ABS resin, and the glossiness of the product reaches 85 or above. The preparation method disclosed by the invention is simple in process, low in production cost and good in product stability, and can meet the requirement of daily supplies such as household appliances, electronic appliances and automobiles on high glossiness of a resin material.

Owner:NORTH HUAJIN CHEM IND CO LTD

Small-block-shaped nickel-copper alloy preparation method based on water washing technology

InactiveCN107321939AShorten the production cycleReduce segregation coefficientElectricityIntermediate frequency

The invention discloses a method for preparing a small block nickel-copper alloy based on a water washing process, which specifically includes the following steps: calculating the nickel-copper ratio according to the requirements for producing the nickel-copper alloy, then weighing the raw materials, putting them into an intermediate frequency furnace in batches, and energizing the melt , after all the materials are melted, inject the alloy solution into the ladle; move the ladle to the side of the cooling water pool, pour the alloy solution into the cooling water pool, the pouring speed is 100kg / min, and the temperature of the water in the cooling water pool is 70 ‑100℃; After all the alloy solution in the ladle is poured into the cooling water pool, it will be a small piece of nickel-copper alloy finished product when picked up. The invention is used to prepare the nickel-copper alloy of small block, the size of the block is uniform, no mold is needed in the production process, the cost is low, the production cycle of the nickel-copper alloy is shortened, and the production efficiency and product quality are improved.

Owner:HEBEI CHENGDA METAL GROUP

Novel guardrail surface on-line treatment production technology

The invention discloses a novel guardrail surface on-line treatment production technology. The production technology comprises the following step that steel pipe forming is carried out, wherein pipeswith appropriate specifications are selected for machining, raw materials are detected before machining, the pipes are cut off according to the required length by using a cutting-off machine, and thesections of the pipes are guaranteed to be flat. According to the novel guardrail surface on-line treatment production technology, the technological process is simple, firstly, steel pipe forming machining is carried out, the steel pipes are formed through cutting-off, bending and punching so that the pipes can be conveniently assembled into a guardrail in the sequent process, then polishing and grinding are carried out so as to removal floating slag and burrs on the surfaces of the pipes, then the surface treatment of the pipes is carried out through water washing and mixed washing so that stains on the surfaces of the pipes can be completely removed, then subsequent coating can be conveniently carried out on the pipes, the pipes and the guardrail can be isolated from air during use through coating, oxidation is avoided, the subsequent maintenance workload is reduced, then passivation and wax permeation treatment are carried out in the sequent processes, then the rigidity and the glossiness of the guardrail are guaranteed, and the product quality is improved.

Owner:山东伟达交通设施有限公司

Universal white master batch and preparation method thereof

The invention discloses a universal white master batch and a preparation method thereof. The white master batch is prepared from the following raw materials in parts by weight: 30-35 parts of carrierresin, 20-25 parts of titanium dioxide, 1-3 parts of a dispersing agent, 2-5 parts of an antioxidant and 10-15 parts of desilicication powder. The white master batch is good in dispersity, the preparation method is simple and suitable for large-scale production, the desilicication powder is added into the preparation raw materials of the white master batch, and the porous structure on the surfaceof the desilicication powder has relatively high adsorption capacity on the titanium dioxide, so that the titanium dioxide is not prone to falling off, the coloring capacity of the white master batchis high, and the coloring effect is good and lasting; as fired diatomite is ground through a grinding wheel, it is guaranteed that the subsequently-prepared desilicication powder is finer, and accordingly the glossiness and coloring capacity of the white master batch are guaranteed; and a desilicication solution can be rapidly produced through a desilicication solution production device, and the production efficiency is high.

Owner:方少山

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com