Online double-sided roller coating process and device for producing high-brightness panels by using solvent-free UV coating

A solvent-free, plastic sheet technology, used in devices for coating liquid on surfaces, lamination devices, applications, etc., can solve the problems of not getting a uniform coating on the surface, and achieve less material consumption and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

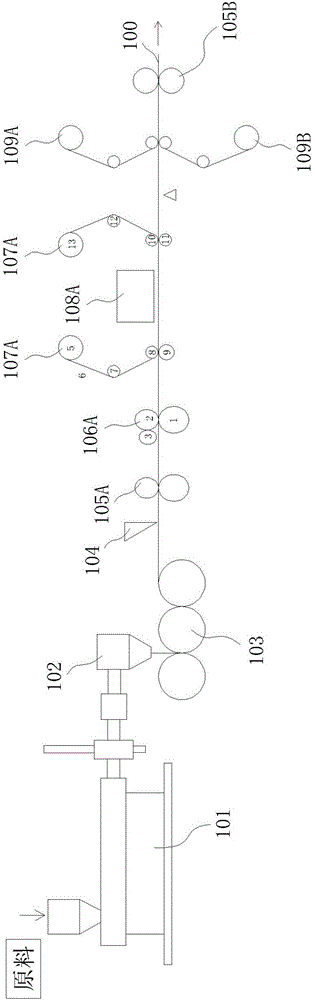

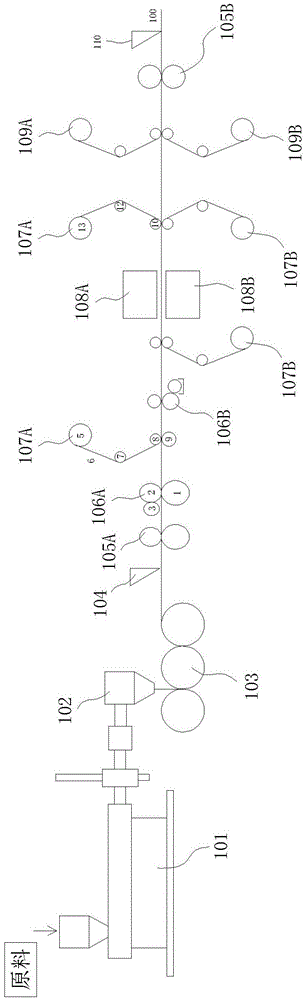

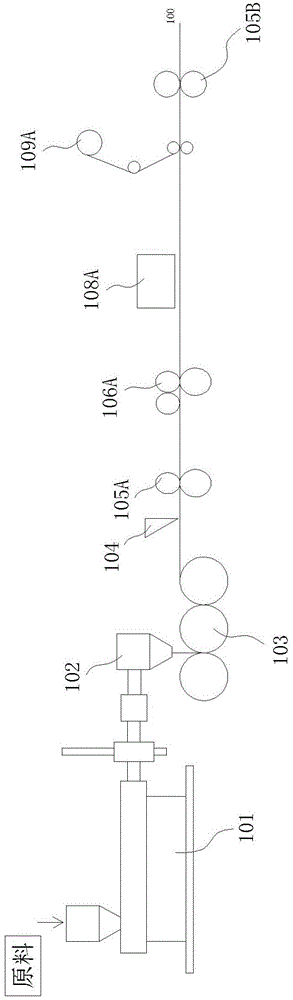

[0046] Example: see figure 1 , figure 2 , an online roller coating process for producing high-gloss panels with solvent-free UV coatings, comprising the following steps:

[0047] S1. After the plastic sheet is formed on the extruder, it passes through the roller coating machine, and the solvent-free UV coating is evenly rolled onto the plastic sheet by the coating roller;

[0048] S2. The plastic sheet passes through the laminating machine, and the release protective film covers the surface with the paint on the plastic sheet and is pressed flat. After that, the plastic sheet is cured by UV, and the paint is cured by the ultraviolet light that penetrates the protective film. After UV curing, the release protective film on the surface of the plastic sheet is peeled off from the sheet after cooling, and a hardened and wear-resistant coating layer with high gloss and high flatness can be obtained on the surface of the plastic sheet.

[0049] An online roll coating device for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Dominant wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com