Printing drying device

A printing drying and drying box technology, applied in printing, printing machines, general parts of printing machinery, etc., can solve the problems of prolonging drying time, reducing product production efficiency, etc., to speed up the drying process, shorten the length, Guaranteed drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

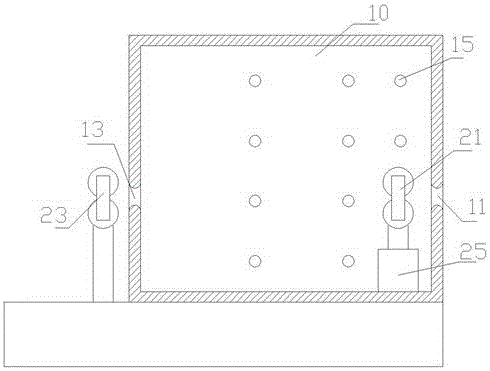

[0015] The reference signs in the drawings of the description include: drying box 10 , feed inlet 11 , discharge outlet 13 , heating mechanism 15 , feed pair rollers 21 , discharge pair rollers 23 , and air cylinder 25 .

[0016] Such as figure 1 The printing drying device shown includes a frame and a drying box 10 arranged on the frame. The drying box 10 is provided with an inlet 11 and an outlet 13, and the edges of the inlet 11 are rounded. Side; feeding port 11 is arranged relatively with discharging port 13, and the inner wall of drying box 10 is provided with heating mechanism 15, and heating mechanism 15 is arranged near feeding port 11, selects infrared heating tube as heating mechanism 15 in the present embodiment; A pair of feed rollers 21 is provided near the feed port 11 in the drying box 10, and one side of the pair of feed rollers 21 is connected with a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com