Novel guardrail surface on-line treatment production technology

A production process and a technology for guardrails, which are applied in the field of production technology for on-line treatment of the surface of new guardrails, can solve problems such as affecting the appearance and service life of guardrails, the complexity of guardrail processing, and the need to improve the performance of guardrails. Maintenance workload, to ensure rigidity and gloss, to avoid the effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

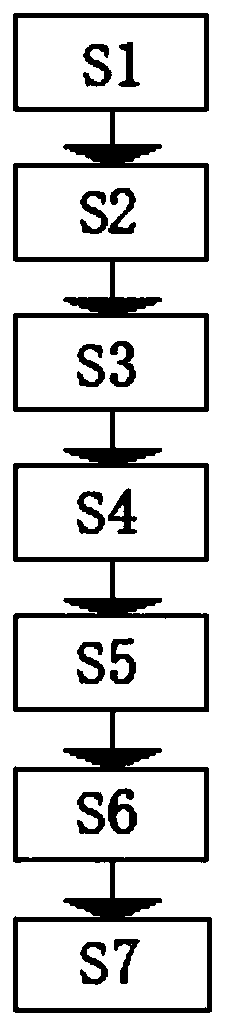

Method used

Image

Examples

Embodiment 1

[0024] 1) Steel pipe forming:

[0025] Cutting: select pipes of appropriate specifications for processing, inspect the raw materials before processing, and cut the pipes according to the required length by the cutting machine to ensure the flatness of the cross section;

[0026] Bending: The pipe fittings to be bent are processed by the pipe bender, and bent into the bend pipes of the required specifications, so as to avoid scratches on the pipe fittings during bending;

[0027] Punching: Put the truncated and bent pipe fittings on the punching machine to punch holes, including socket holes and bolt holes, to facilitate subsequent assembly and connection;

[0028] 2) Polishing treatment: firstly polish the surface and section of the pipe fittings to remove burrs on the surface and section of the pipe fittings, and then perform shot blasting treatment on the surface of the pipe fittings to remove scum and rust on the surface of the pipe fittings. During the shot blasting treatm...

Embodiment 2

[0036] 1) Steel pipe forming:

[0037] Cutting: select pipes of appropriate specifications for processing, inspect the raw materials before processing, and cut the pipes according to the required length by the cutting machine to ensure the flatness of the cross section;

[0038] Bending: The pipe fittings to be bent are processed by the pipe bender, and bent into the bend pipes of the required specifications, so as to avoid scratches on the pipe fittings during bending;

[0039] Punching: Place the cut and bent pipe fittings on the punching machine to punch holes, including socket holes and bolt holes, for subsequent assembly and connection;

[0040] 2) Polishing treatment: firstly polish the surface and section of the pipe fittings to remove burrs on the surface and section of the pipe fittings, and then perform shot blasting treatment on the surface of the pipe fittings to remove scum and rust on the surface of the pipe fittings. During the shot blasting treatment, For shot...

Embodiment 3

[0048] 1) Steel pipe forming:

[0049] Cutting: select pipes of appropriate specifications for processing, inspect the raw materials before processing, and cut the pipes according to the required length by the cutting machine to ensure the flatness of the cross section;

[0050] Bending: The pipe fittings to be bent are processed by the pipe bender, and bent into the bend pipes of the required specifications, so as to avoid scratches on the pipe fittings during bending;

[0051] Punching: Put the truncated and bent pipe fittings on the punching machine to punch holes, including socket holes and bolt holes, to facilitate subsequent assembly and connection;

[0052] 2) Polishing treatment: firstly polish the surface and section of the pipe fittings to remove burrs on the surface and section of the pipe fittings, and then perform shot blasting treatment on the surface of the pipe fittings to remove scum and rust on the surface of the pipe fittings. During the shot blasting treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com