Preparation method of high-gloss bulk ABS resin

An ABS resin, high gloss technology, applied in the field of preparation of high gloss bulk ABS resin, can solve the problems of inaccurate control of raw materials and additives, demanding process conditions, affecting the service life of products, etc., to ensure mechanical properties and gloss. The effect of high degree, simple process flow and excellent product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific embodiments.

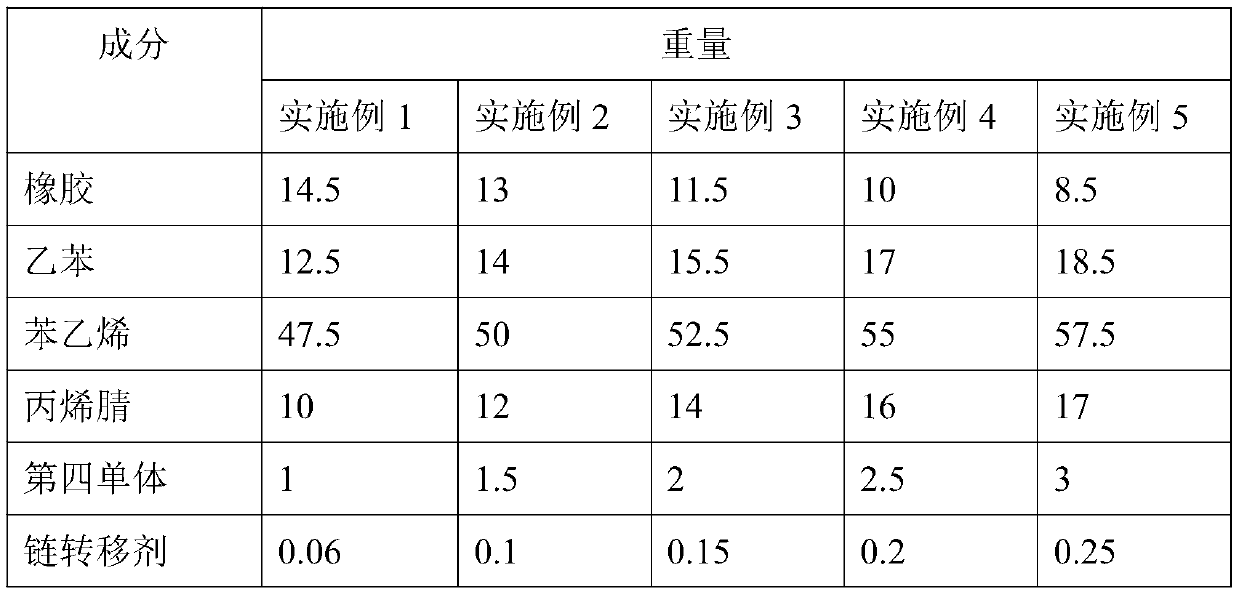

[0016] Carry out each composition of original glue solution proportioning by the weight shown in table 1.

[0017] Each component weight of table 1 embodiment 1-5

[0018]

[0019] Remarks: The compounding ratio of star-shaped low-cis rubber and styrene-butadiene rubber is 1:1, 1:2, 1:3, 2:1 and 3:1 respectively. The star-shaped low-cis rubber is preferably LANXESS 565T, and the styrene-butadiene rubber is self-made , the fourth monomer is preferably butyl acrylate.

[0020] Wherein, the preparation process is as follows:

[0021] 1. Add rubber, ethylbenzene, styrene, acrylonitrile and the fourth monomer into the liquid mixing tank according to the glue formula, and dissolve in the liquid mixing tank until the original glue is uniform;

[0022] 2. The raw glue solution is transported to four parallel plug-flow tube reactors connected in series through the feed pump; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com