Telescopic spray booth

A paint spray booth and telescopic technology, applied in the paint spray booth, injection device, etc., can solve the problems of easy blockage of circulating water and high energy consumption, and achieve the effect of ensuring air tightness and avoiding gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

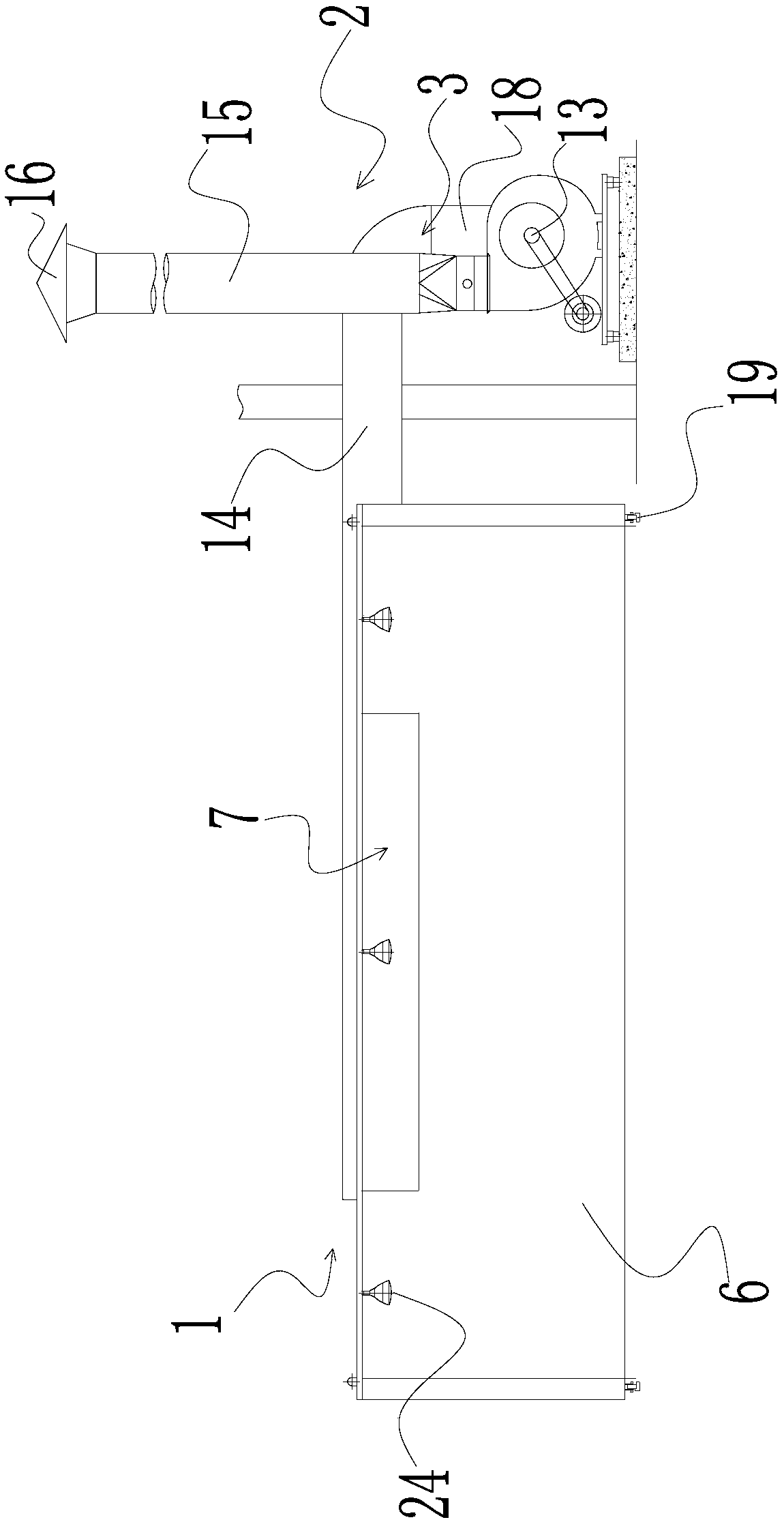

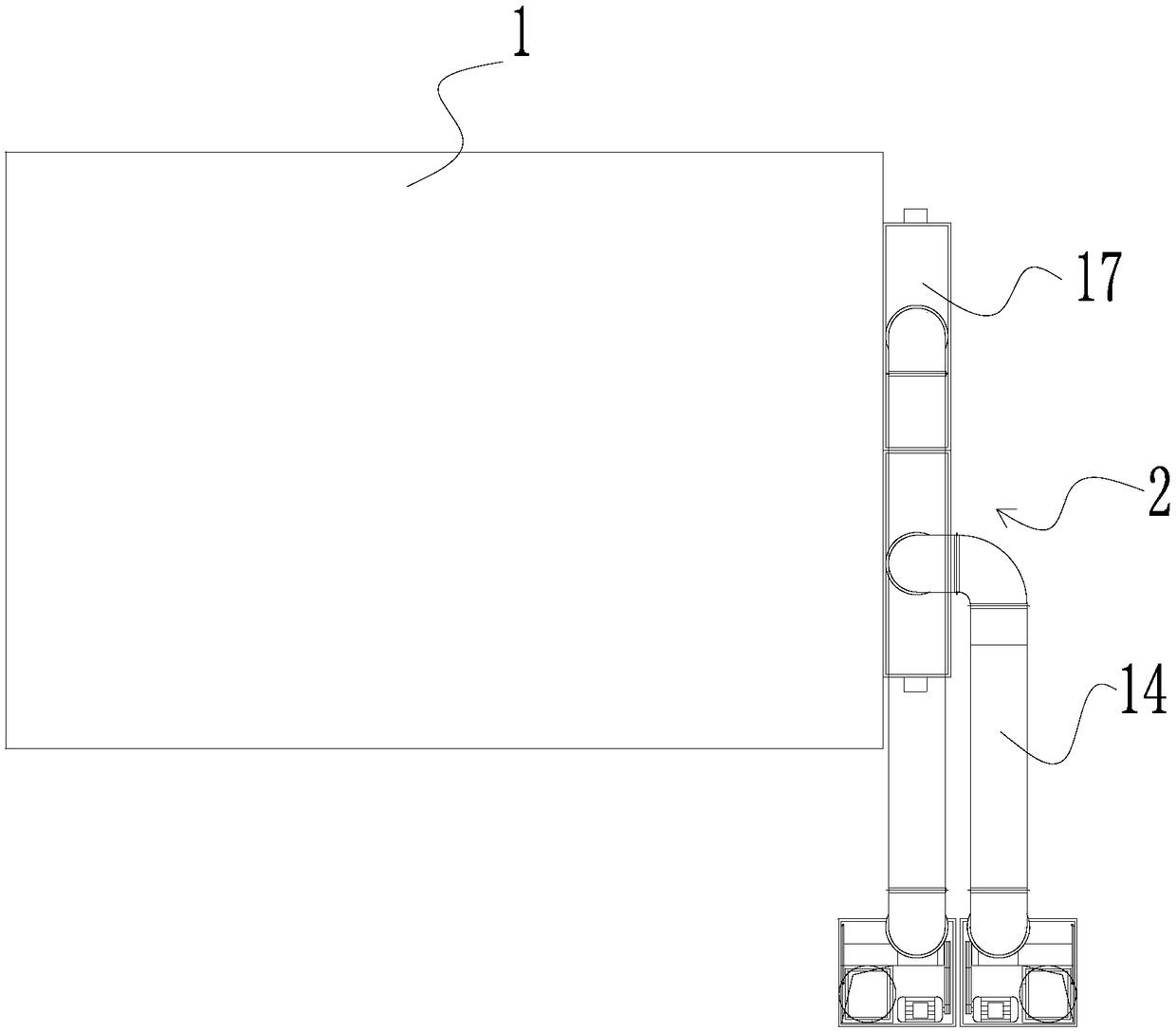

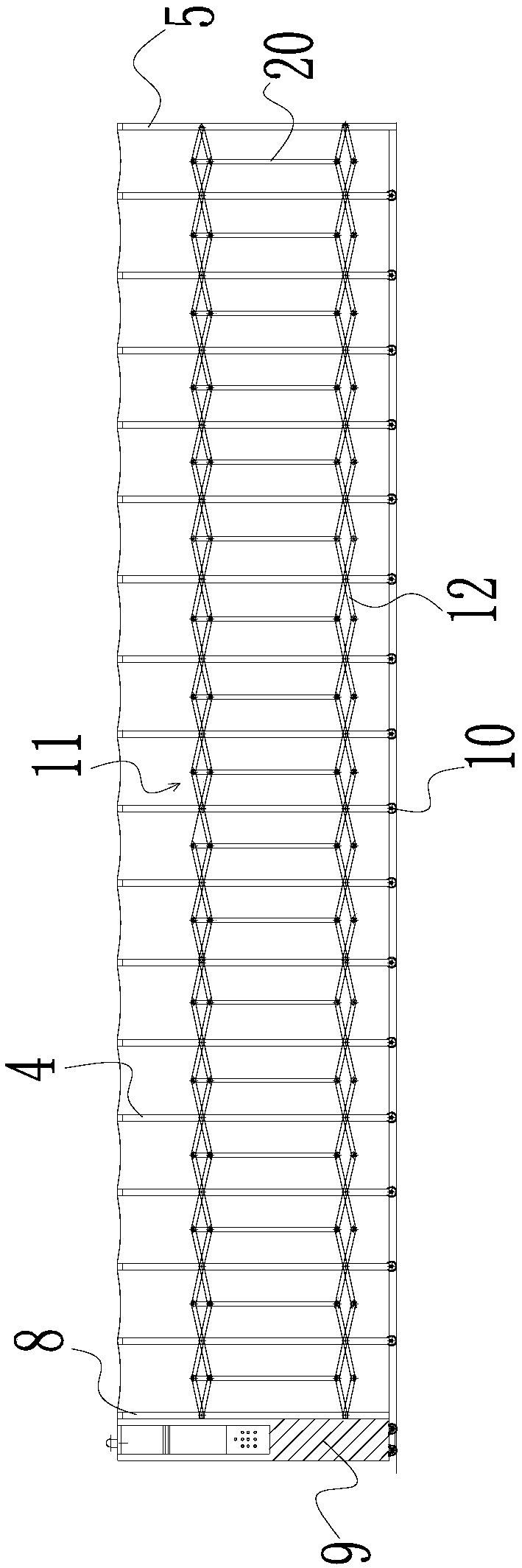

[0035] see Figure 1 to Figure 10, is a specific embodiment of a retractable spray booth. The retractable spray booth includes a spray booth body 1 , a paint mist discharge pipeline 2 communicating with the interior space of the paint spray booth body 1 , and a paint mist elimination system 3 arranged in the paint mist discharge pipeline 2 . The spray booth body 1 includes a number of n-shaped or Π-shaped support frames 4. In this embodiment, the number of support frames is eighteen, all of which are Π-shaped, and are formed by welding 60*40mm shaped steel. These support frames 4 are arranged in a row, and the support frame positioned at one end of the support frame column is a fixed frame 5, and an airtight baffle 6 that is covered with the inside of the fixed frame is arranged on the fixed frame 5, and the top of the airtight baffle 6 is provided with paint mist. The discharge hole 7, the support frame at the other end of the support frame row is a traction frame 8, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com