Universal white master batch and preparation method thereof

A technology for white masterbatch and titanium dioxide, which is applied in the field of general white masterbatch and its preparation, can solve the problems of poor coloring ability of white masterbatch, unsuitable for large-scale production, and the coloring effect is not long-lasting, and achieves good coloring effect and coloring. Long-lasting, highly pigmented effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

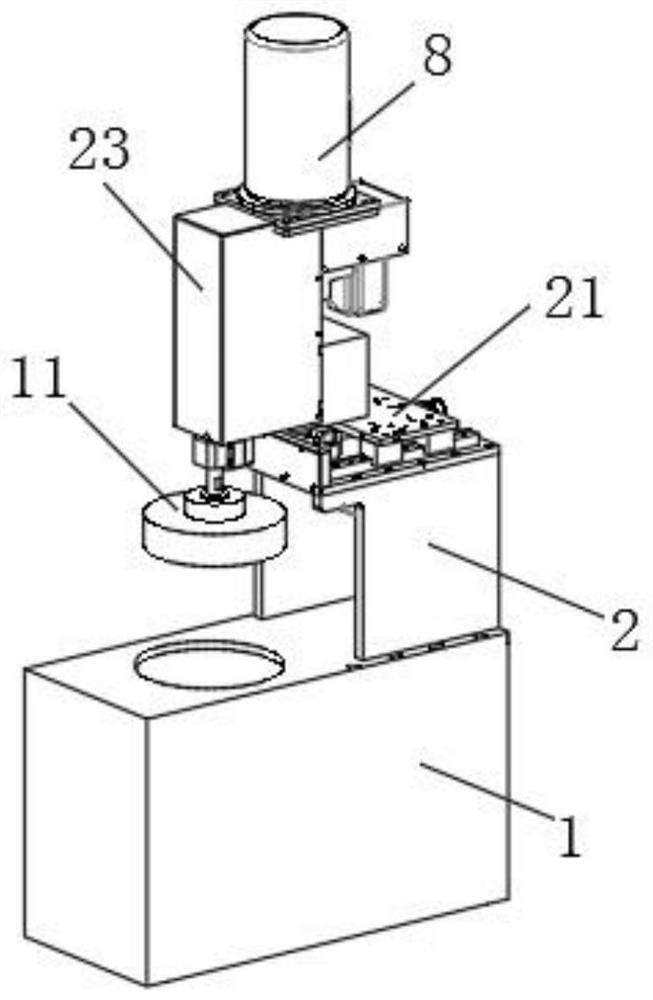

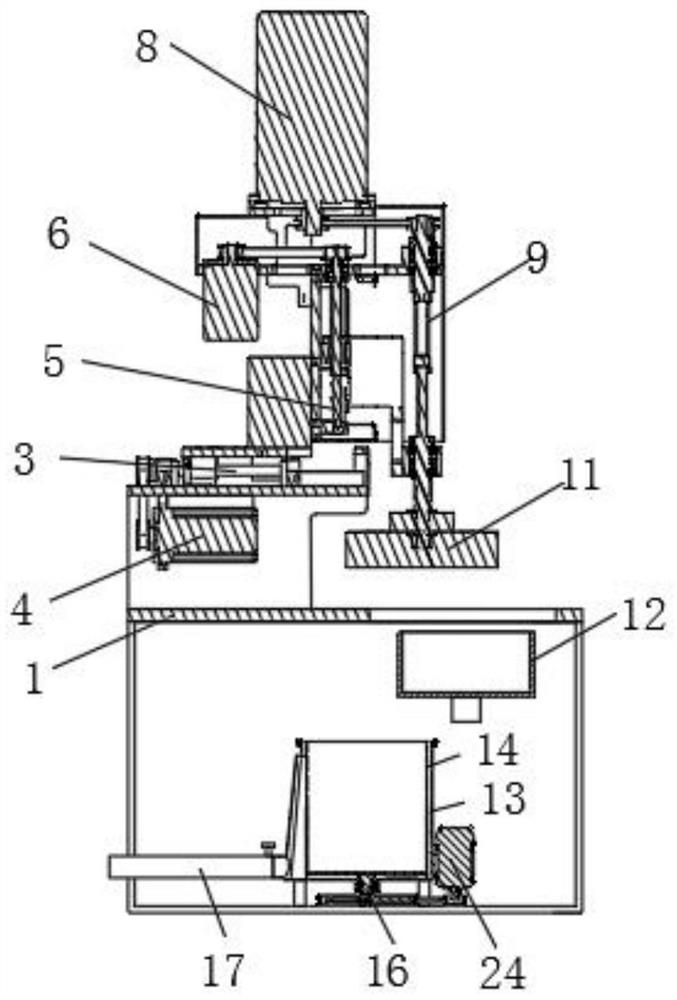

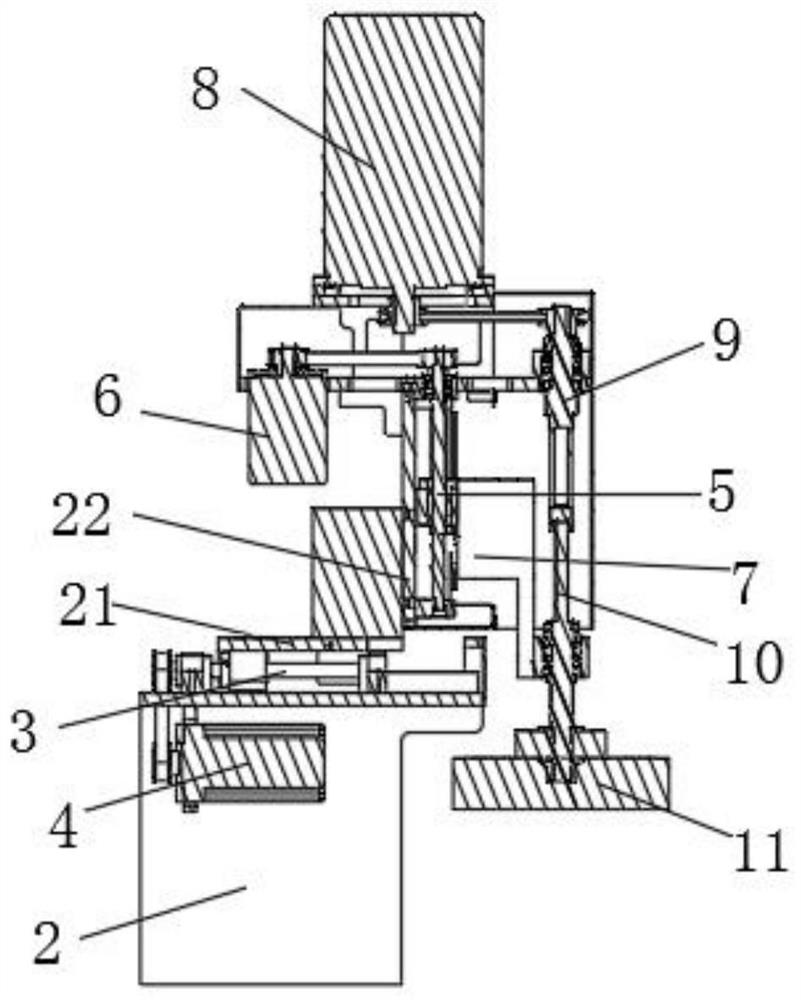

[0035] Such as Figure 1-5 As shown, a general-purpose white masterbatch, which is prepared by the following raw materials in parts by weight: 30 parts of carrier resin, 20 parts of titanium dioxide, 1 part of dispersant, 2 parts of antioxidant, 10 parts of desiliconized powder share.

[0036] The carrier resin is polyolefin.

[0037] The dispersant is polyethylene wax or polypropylene wax.

[0038] The antioxidant is a mixture of antioxidant 1010 and antioxidant 168, and the weight ratio of antioxidant 1010 to antioxidant 168 is 1.5:2.

[0039] A kind of preparation method of universal white masterbatch, this method specifically comprises the following steps:

[0040] Step 1. Add dispersant and antioxidant to the mixer, stir at 200r / min for 5min, add titanium dioxide and desiliconized powder, stir at 800r / min for 15min, then add carrier resin, stir at 500r / min The rotating speed of stirring 30min, obtains mixed material;

[0041] Step 2: Add the mixed material into the e...

Embodiment 2

[0048] Such as Figure 1-5 As shown, a general-purpose white masterbatch is prepared by the following raw materials in parts by weight: 35 parts of carrier resin, 25 parts of titanium dioxide, 3 parts of dispersant, 5 parts of antioxidant, 15 parts of desiliconized powder share.

[0049] The carrier resin is polyolefin.

[0050] The dispersant is polyethylene wax or polypropylene wax.

[0051] The antioxidant is a mixture of antioxidant 1010 and antioxidant 168, and the weight ratio of antioxidant 1010 to antioxidant 168 is 1.5:2.

[0052] A kind of preparation method of universal white masterbatch, this method specifically comprises the following steps:

[0053] Step 1. Add dispersant and antioxidant to the mixer, stir at 500r / min for 15min, add titanium dioxide and desiliconized powder, stir at 1200r / min for 30min, then add carrier resin, stir at 1500r / min The rotating speed of stirring 60min, obtains mixed material;

[0054] Step 2: Add the mixed material into the extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com