Shielded electronic components and method of manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

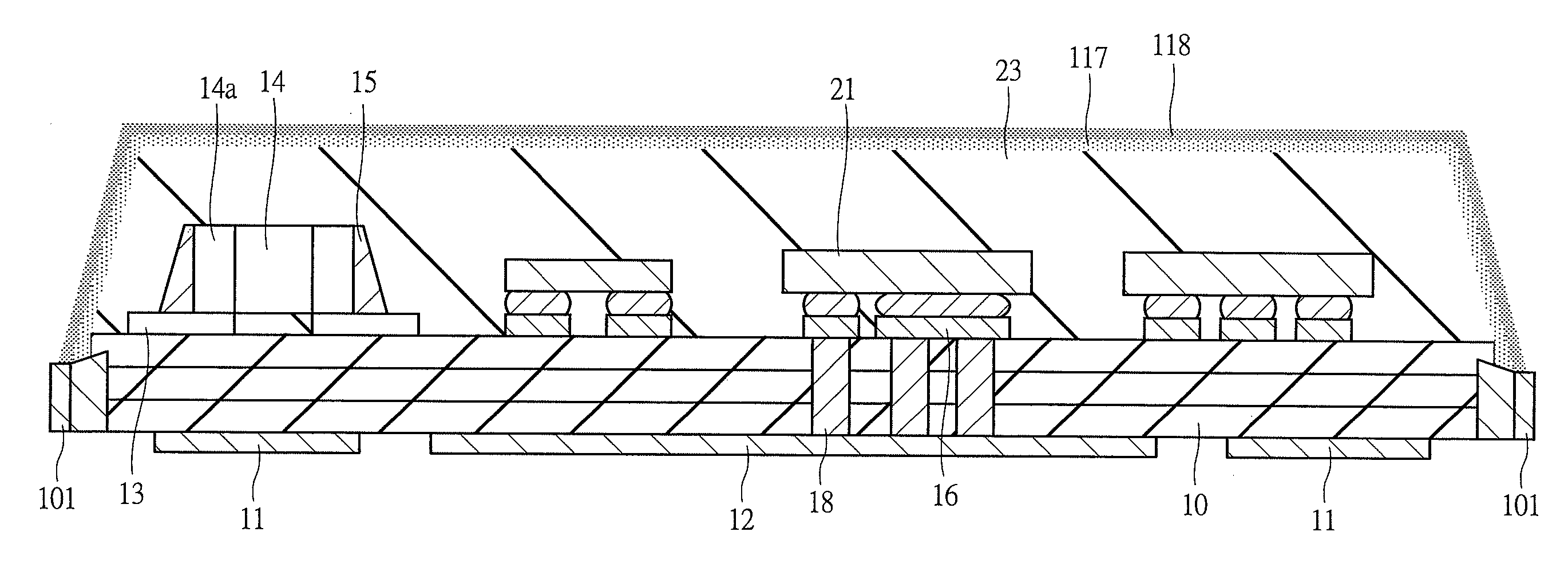

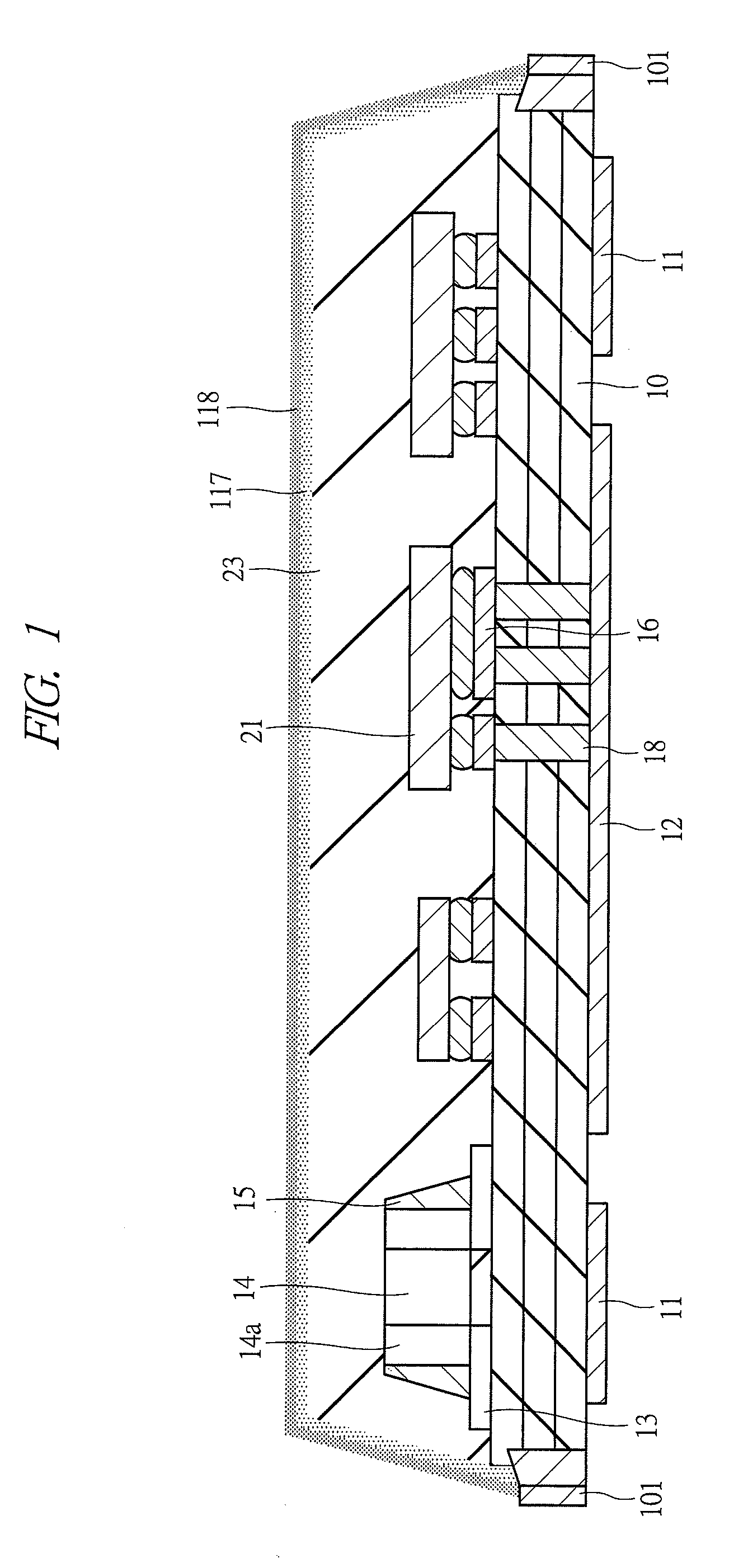

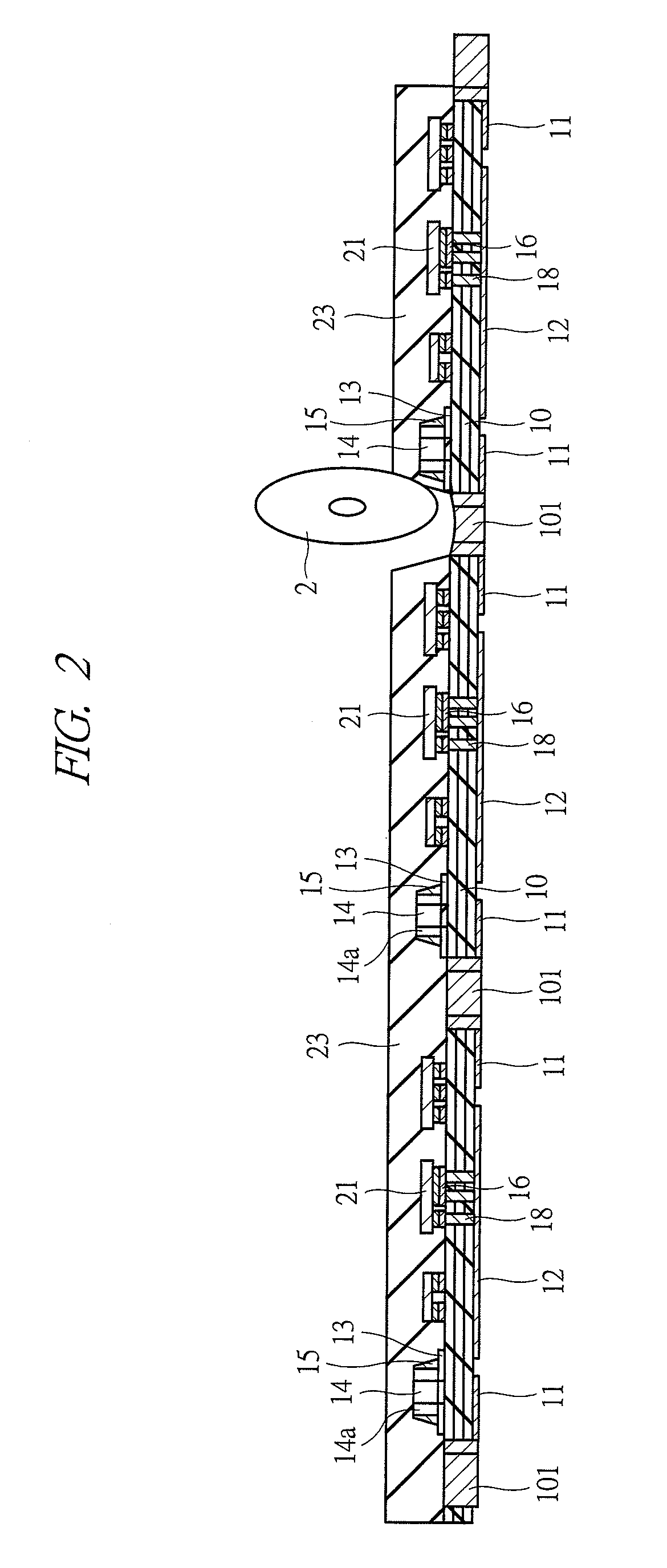

[0069]With reference to FIG. 1, a structure of a shielded electronic component according to a first embodiment of the present invention will be described. FIG. 1 is a cross-sectional view illustrating the structure of the shielded electronic component according to the first embodiment of the present invention and illustrating a structure of a power amplifier module.

[0070]In FIG. 1, a power amplifier module which is the shielded electronic component includes, when the external structure is viewed, a rectangular wiring board 10, a sealant 23 formed with overlapping on a surface (main surface) of the wiring board 10, a plurality of wirings 11 provided to a back surface of the wiring board 10, and a GND (ground) external wiring 12.

[0071]In addition, the sealant 23 is shielded by a Pd pretreatment layer 117 of a Pd complex and a Ni plating film 118. To edge portions of the wiring board 10, GND connection through-holes 101 for a GND wiring layer (not illustrated) or a shield connected to ...

second embodiment

[0091]A shielded electronic component according to a second embodiment has the semiconductor chip 21 of the first embodiment mounted by face-up mounting.

[0092]With reference to FIG. 10, a structure of a shielded electronic component according to the second embodiment of the present invention will be described. FIG. 10 is a cross-sectional view illustrating a structure of the shielded electronic component according to the second embodiment of the present invention, and illustrates a structure of a power amplifier module.

[0093]In FIG. 10, a wiring 13 is formed to a surface of a wiring board 10 in the power amplifier module, and a chip component 14 is formed to be connected to the wiring 13. The chip component 14 is configured by a passive component such as a resistor or capacitor, and an electrode 14a of the chip component 14 and the wiring 13 formed to the wiring board 10 are electrically connected by a solder 15.

[0094]Also, a wiring 16 is connected to a GND external wiring 12 formed...

third embodiment

[0099]A shielded electronic component according to a third embodiment has the semiconductor chip 21 formed with a plurality of stacked semiconductors and mounted by face-up mounting.

[0100]With reference to FIG. 11, a structure of the shielded electronic component according to the third embodiment of the present invention will be described. FIG. 11 is a cross-sectional view illustrating the structure of the shielded electronic component according to the third embodiment of the present invention, and illustrating a generally used package. The package is a package of only for a memory, and / or a semiconductor package composed of an ASIC and a memory etc., for example.

[0101]In FIG. 11, the semiconductor chip 21 composed of a plurality of stacked semiconductors attached by a die-attach film 233 having its device forming surface facing upwards (face-up) is stacked on a wiring board 10.

[0102]The semiconductor chip 21 and the wiring board 10 are electrically connected to a wiring 13 on a sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com