Welding device and method for avoiding high-nitrogen steel welding air holes and improving connector strength

A joint strength and welding device technology, which is applied in the direction of welding/welding/cutting articles, welding equipment, laser welding equipment, etc., can solve the problems of coarse weld grains and easy precipitation of carbonitrides, etc., to improve mechanical properties and improve The effect of weld structure and grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

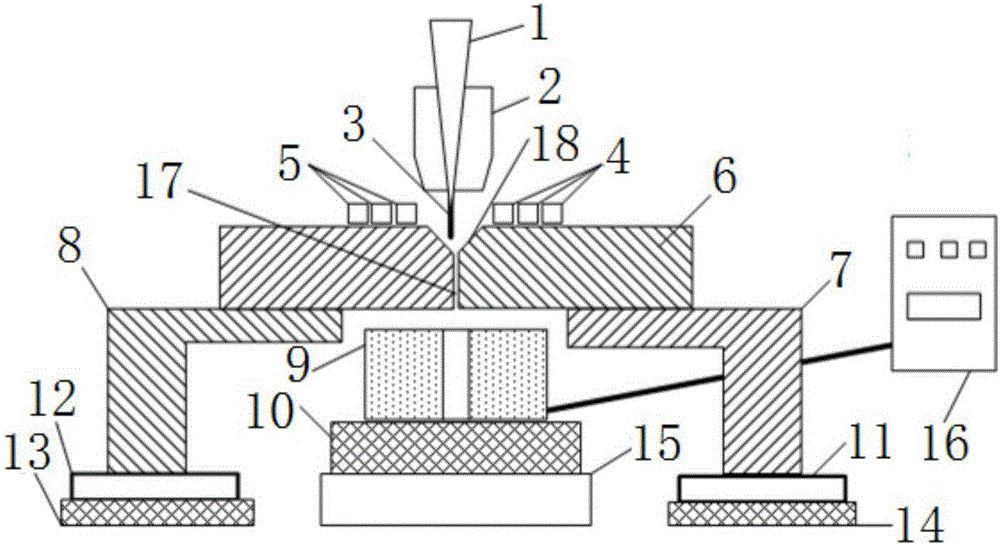

[0040] The welding method of the above-mentioned device is specifically carried out in accordance with the following steps:

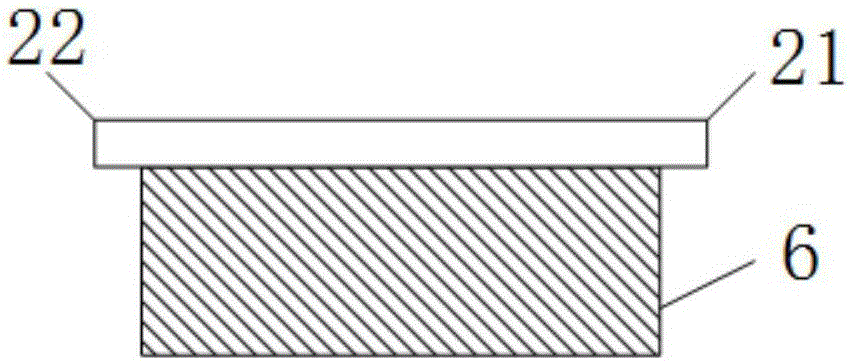

[0041] Step 1: Install and debug the device, clamp two welded workpieces 6 made of high-nitrogen steel with a thickness of 8.0mm and a nitrogen content of 0.5-0.7% on the first workpiece support plate 7 and the second On the workpiece support plate 8;

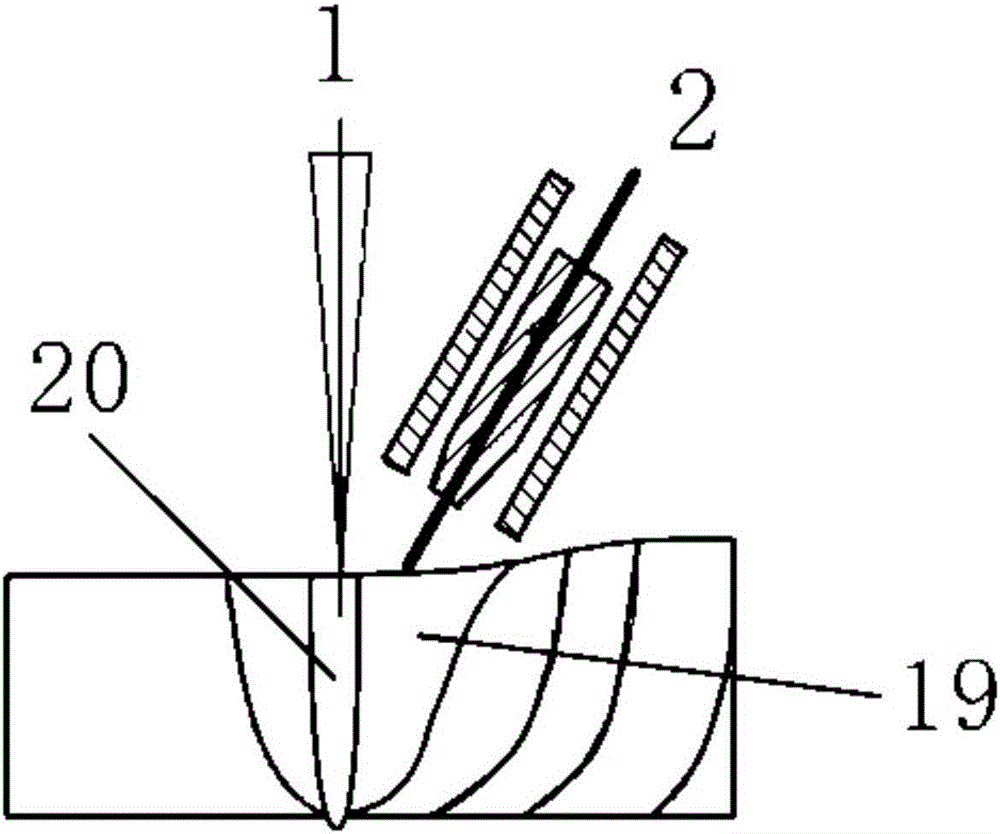

[0042] Step 2: Open the water inlet valves of the first water-passing copper pipe 4 and the second water-passing copper pipe 5, adjust the circulating water temperature in the first water-passing copper pipe 4 and the second water-passing copper pipe 5 to 15°C, and the circulating water flow rate 12L / min; turn on the excitation power supply 16, start the power supply of the CNC workbench, YAG laser and welding torch 2 synchronously, the YAG laser emits a laser beam 1, and the laser beam 1 is irradiated vertically on the front of the welding workpiece 6 to form a laser keyhole 20; welding torch 2 Welding...

Embodiment 2

[0045] The welding method of the above-mentioned device is specifically carried out in accordance with the following steps:

[0046] Step 1: Install and debug the device, clamp two welded workpieces 6 made of high-nitrogen steel with a thickness of 8.0mm and a nitrogen content of 0.5-0.7% on the first workpiece support plate 7 and the second On the workpiece support plate 8;

[0047] Step 2: Open the water inlet valves of the first water-passing copper pipe 4 and the second water-passing copper pipe 5, adjust the circulating water temperature in the first water-passing copper pipe 4 and the second water-passing copper pipe 5 to 10°C, and the circulating water flow rate 15L / min; turn on the excitation power supply 16, start the power supply of the CNC workbench, YAG laser and welding torch 2 synchronously, CO 2 The laser emits a laser beam 1, and the laser beam 1 is vertically irradiated on the front of the welding workpiece 6 to form a laser keyhole 20; the welding torch 2 pe...

Embodiment 3

[0050] The welding method of the above-mentioned device is specifically carried out in accordance with the following steps:

[0051] Step 1: Install and debug the device, clamp two welded workpieces 6 made of high-nitrogen steel with a thickness of 8.0mm and a nitrogen content of 0.5-0.7% on the first workpiece support plate 7 and the second On the workpiece support plate 8;

[0052] Step 2: Open the water inlet valves of the first water-passing copper pipe 4 and the second water-passing copper pipe 5, adjust the circulating water temperature in the first water-passing copper pipe 4 and the second water-passing copper pipe 5 to 20°C, and the circulating water flow rate 10L / min; turn on the excitation power supply 16, start the power supply of the CNC workbench, the YAG laser and the welding torch 2 synchronously, the semiconductor laser emits the laser beam 1, and the laser beam 1 is irradiated vertically on the front of the welding workpiece 6 to form a laser keyhole 20; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com