Patents

Literature

46results about How to "Consistent feel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

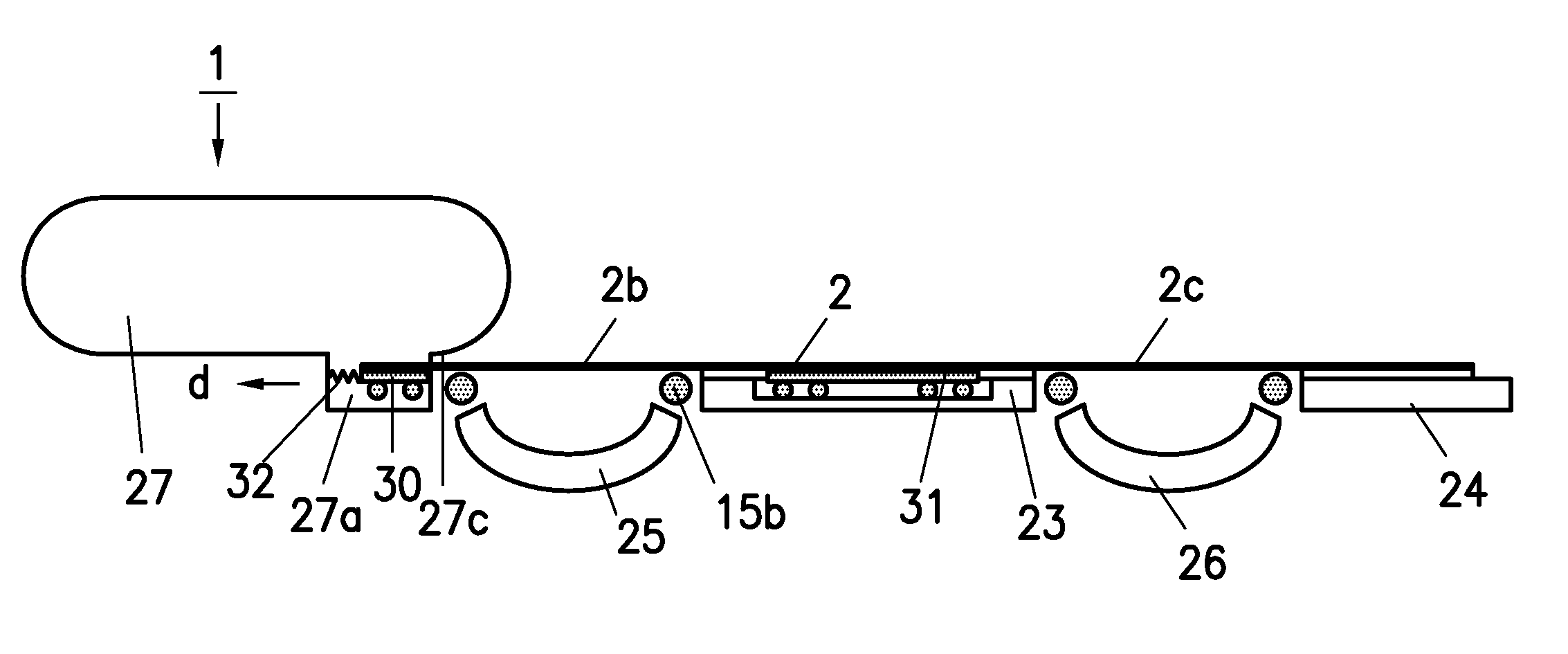

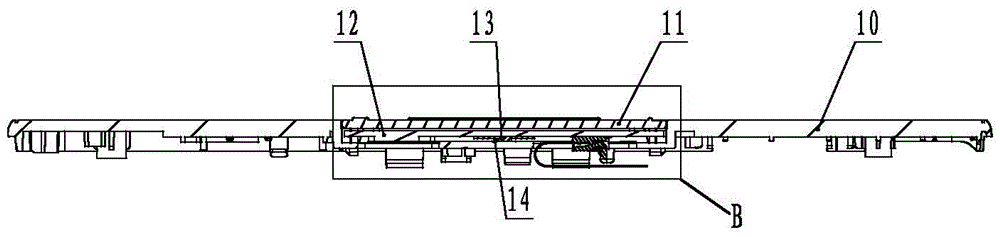

Display system having a continuous flexible display with display supports

InactiveUS20130342094A1Relieve stressKeep displayStatic indicating devicesAdvertisingDisplay deviceSpring force

A display system comprises a continuous flexible display and two main display supports being hingeably connected with respect to each other between a closed storage position and a planar open position for fixing the flexible display in an open position. Each of the supports is structurally configured to support respectively a first and a second portion of the flexible display, a segment of the flexible display is located between the said respective portions of the flexible display in the open position. The display system comprises a spring force biased mechanism operative in either the open or closed position or both the open and closed positions of the flexible display, biasing said segment of the flexible display in the respective position.

Owner:SAMSUNG ELECTRONICS CO LTD

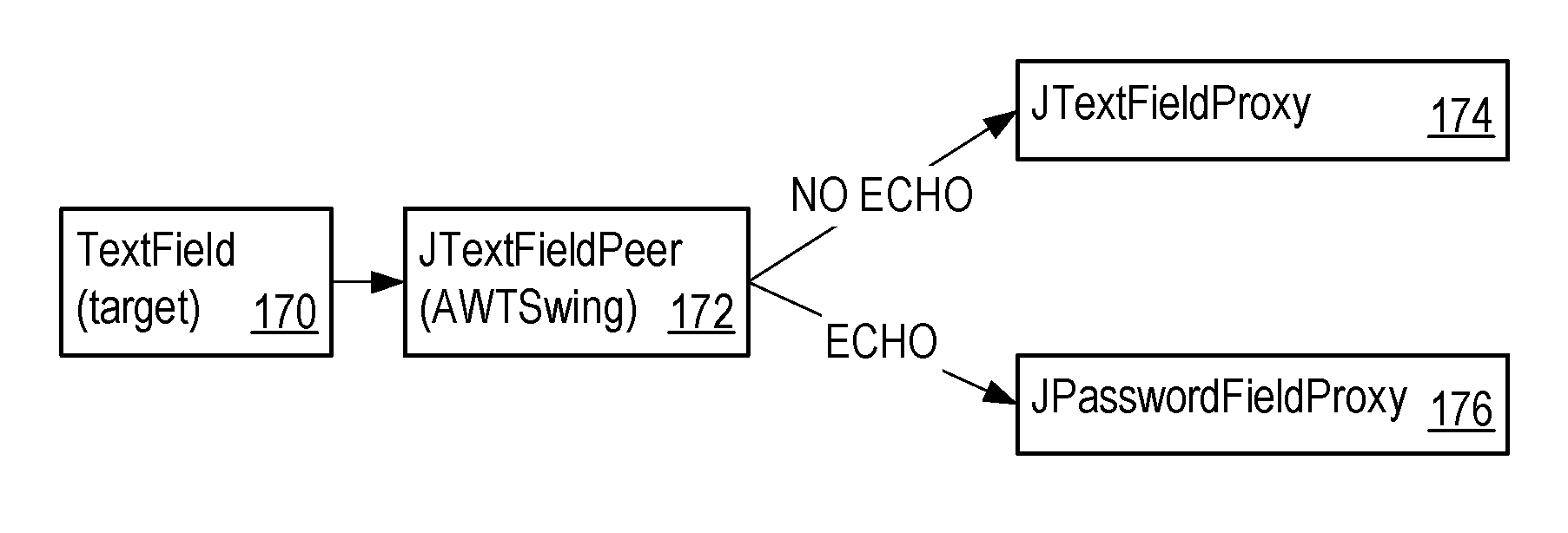

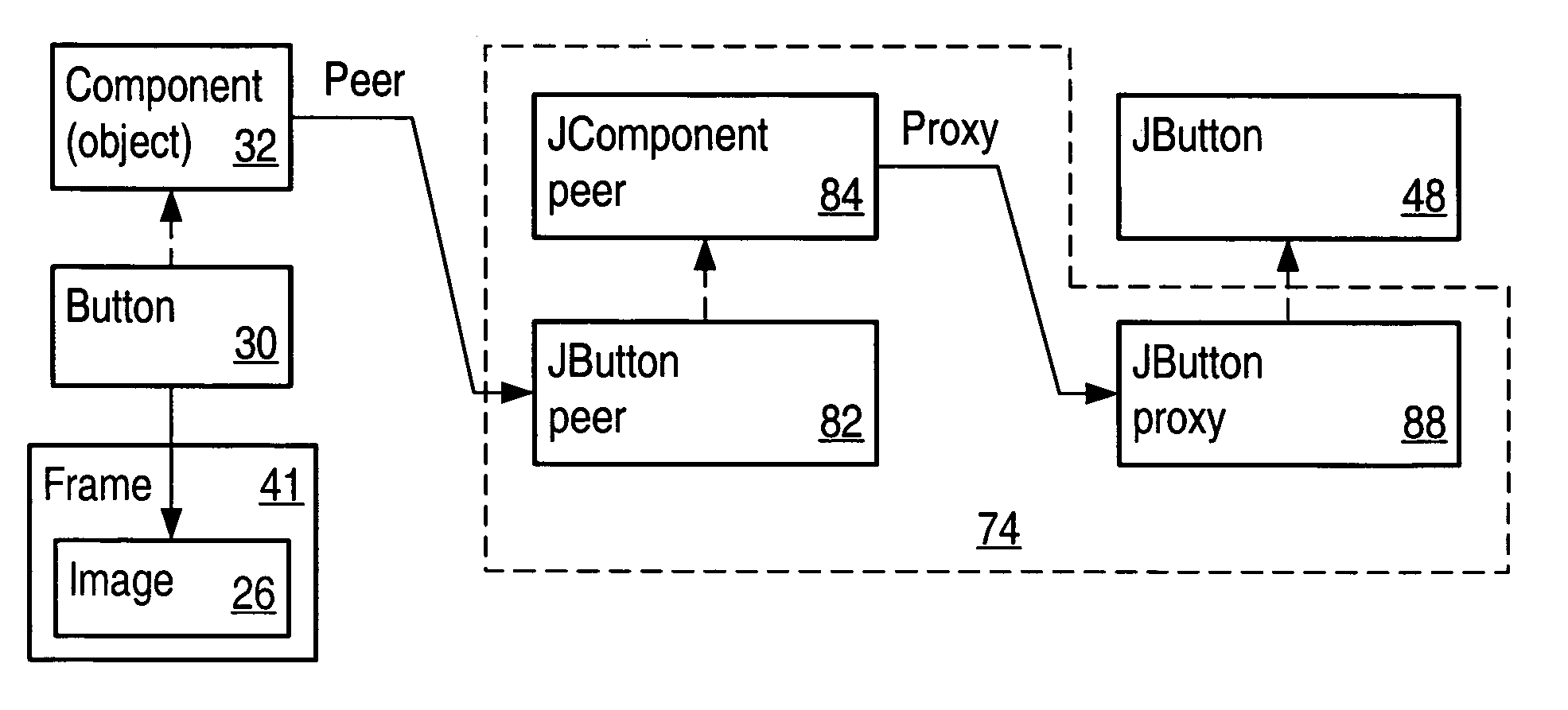

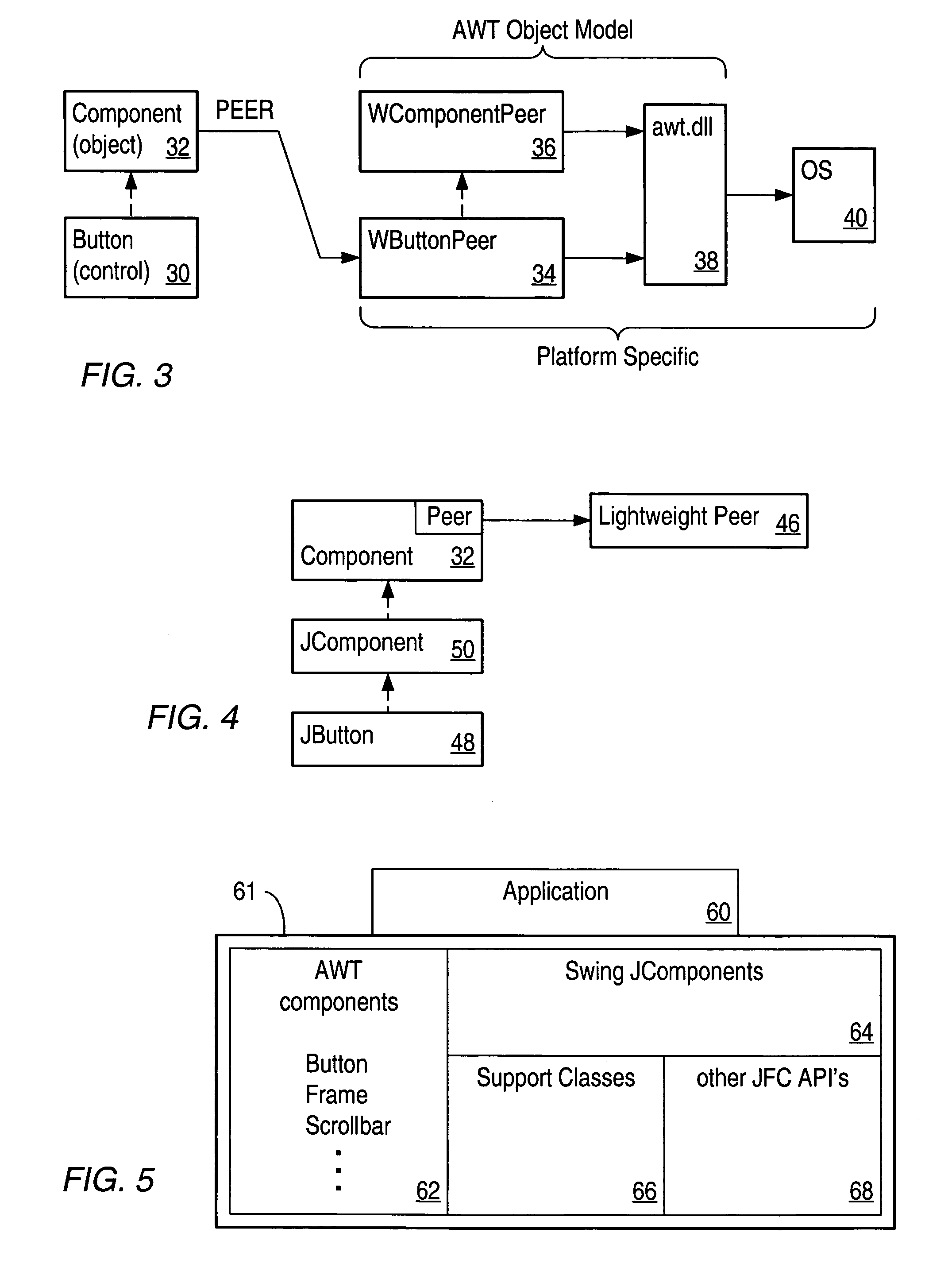

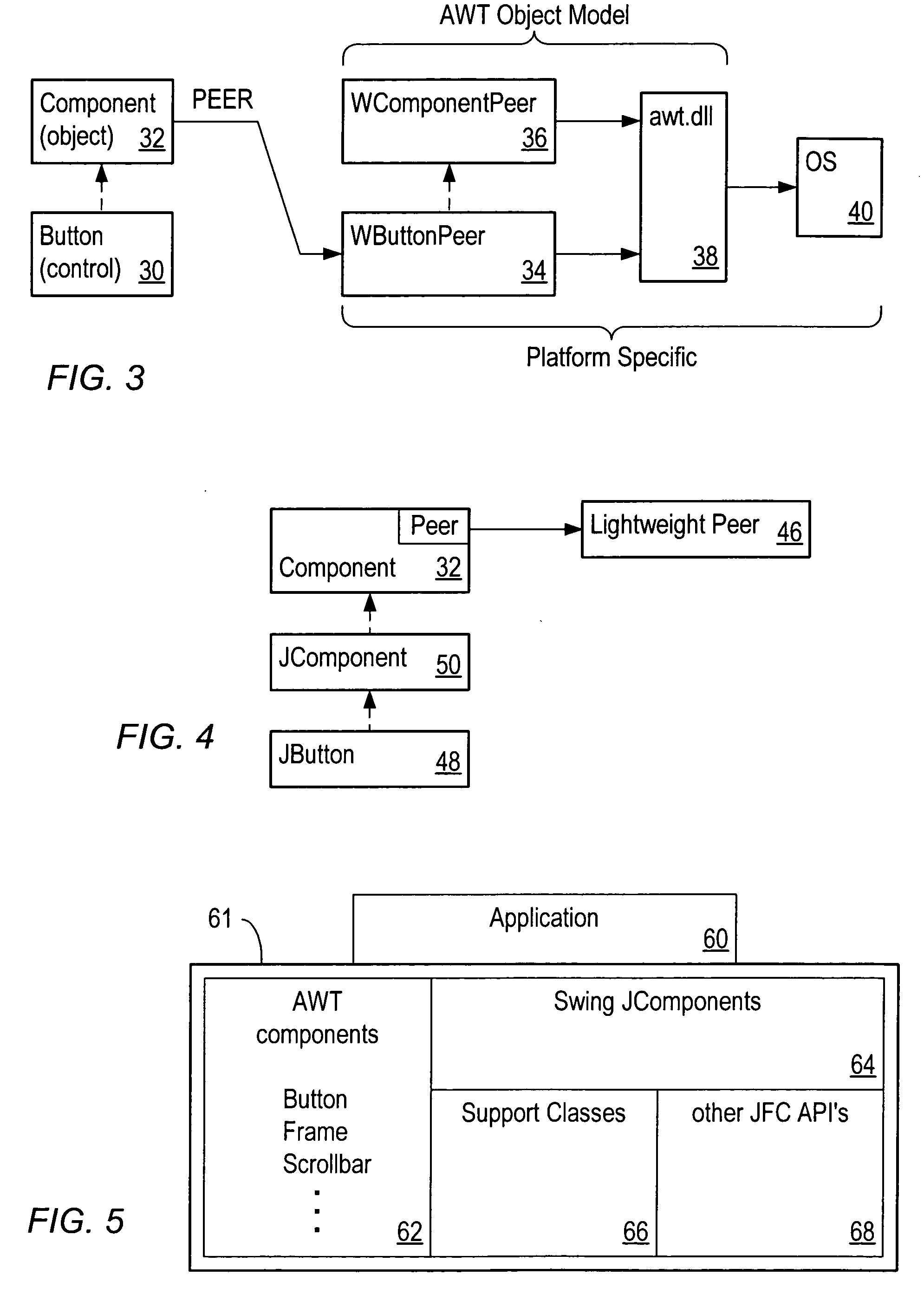

System, computer-readable storage device, and method for combining the functionality of multiple text controls in a graphical user interface

InactiveUS7571389B2Function increaseConsistent lookInput/output processes for data processingGraphicsGraphical user interface

A system and method are disclosed whereby two components within the Swing application program interface (API), JTextField and JPasswordField, are used to emulate the behavior of the TextField component in the abstract windowing toolkit (AWT). This allows legacy Java applications, based on the AWT, to be migrated to the platform-independent Swing API, without modification. In the AWT, a single TextField component could be used for ordinary text entry, as well as for password protected text entry. In the latter case, a prescribed echo character would be displayed as text was entered, to avoid displaying privileged information. According to the system and method disclosed herein, a JPasswordField component may be substituted for a JTextField component, or vice-versa, depending on whether an echo character has been specified. This substitution is performed at runtime, using an enhanced version of the Swing API, as disclosed herein. The enhanced version of Swing is referred to herein as AWTSwing.

Owner:ACTIVISION PUBLISHING

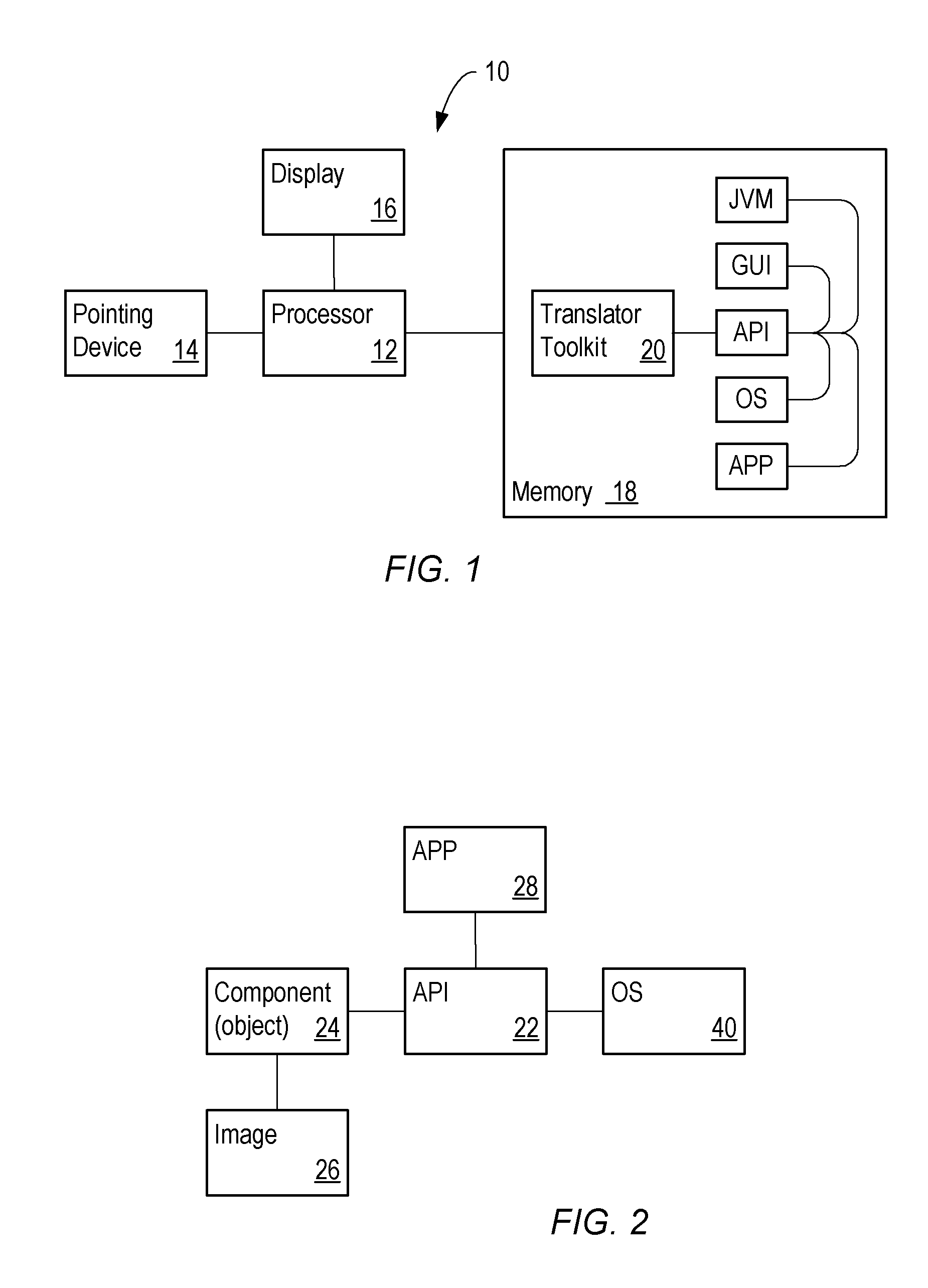

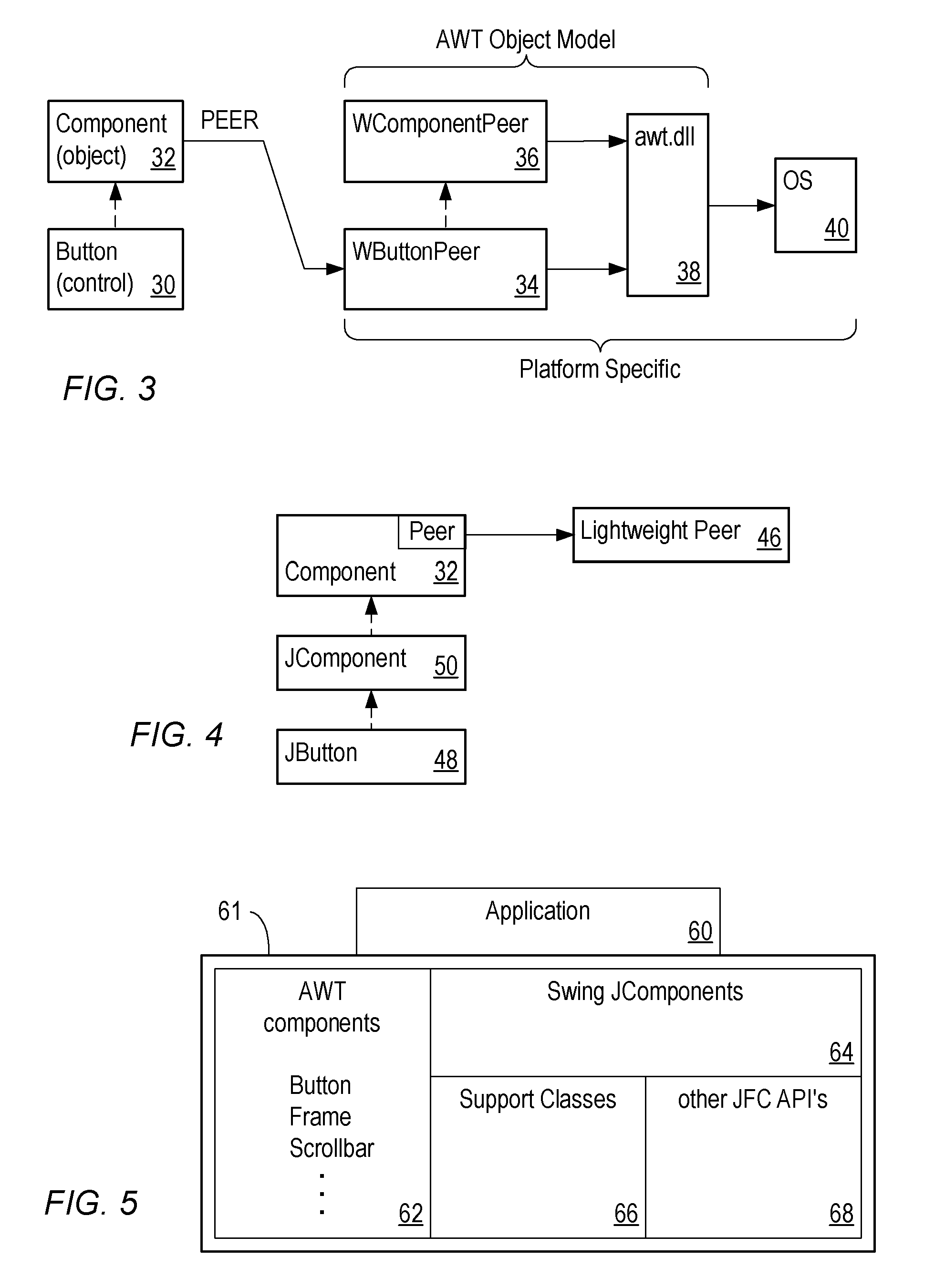

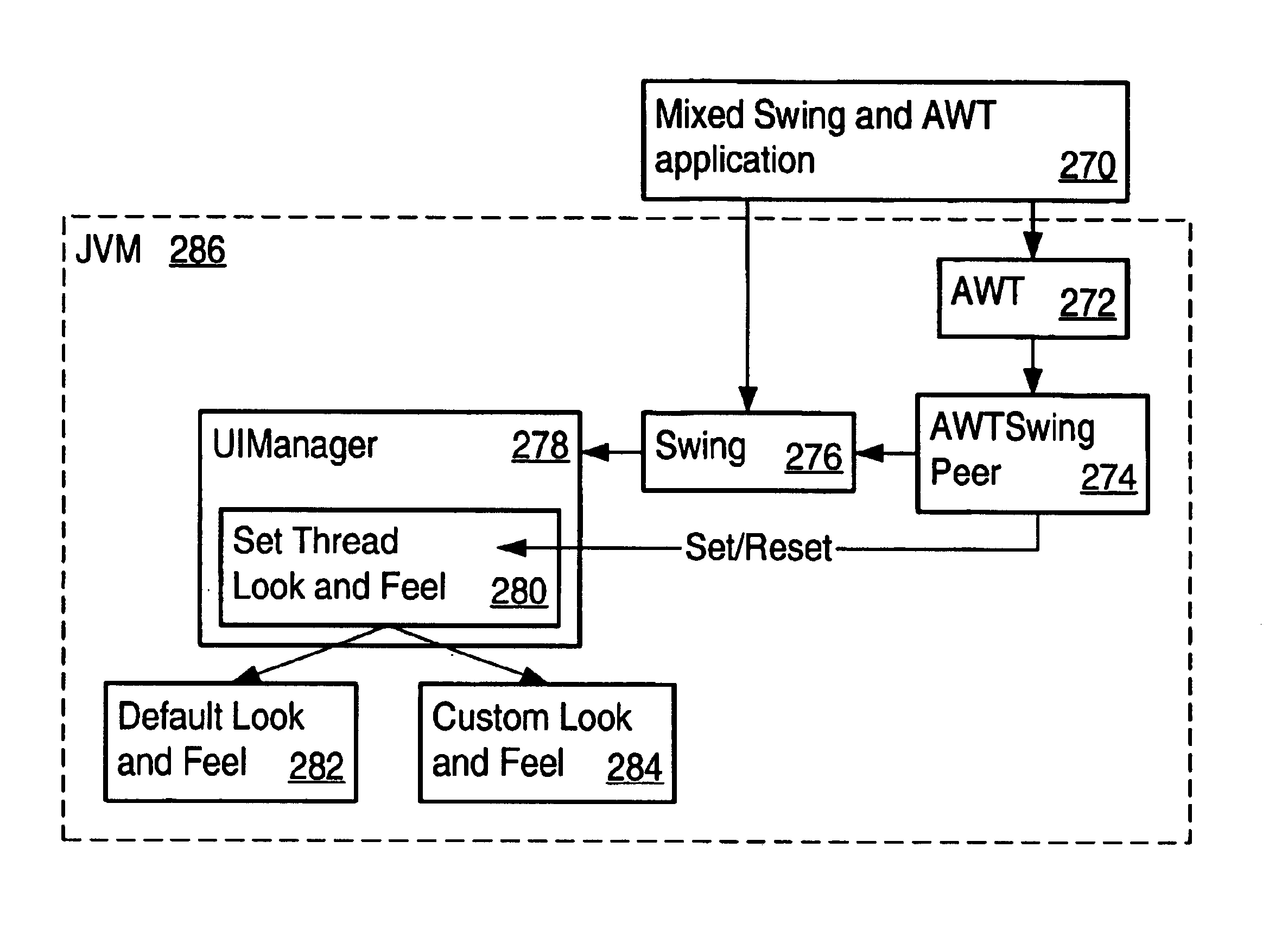

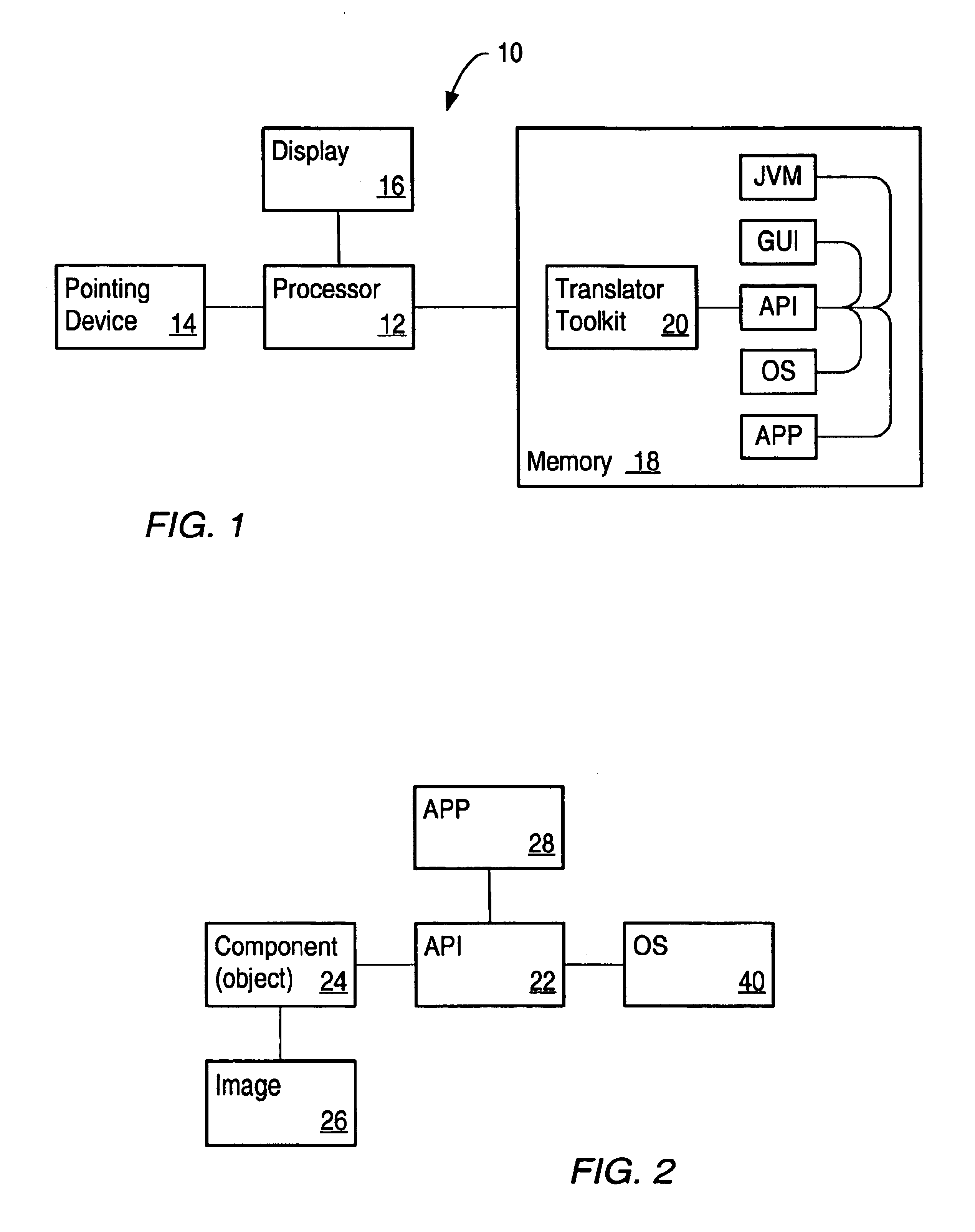

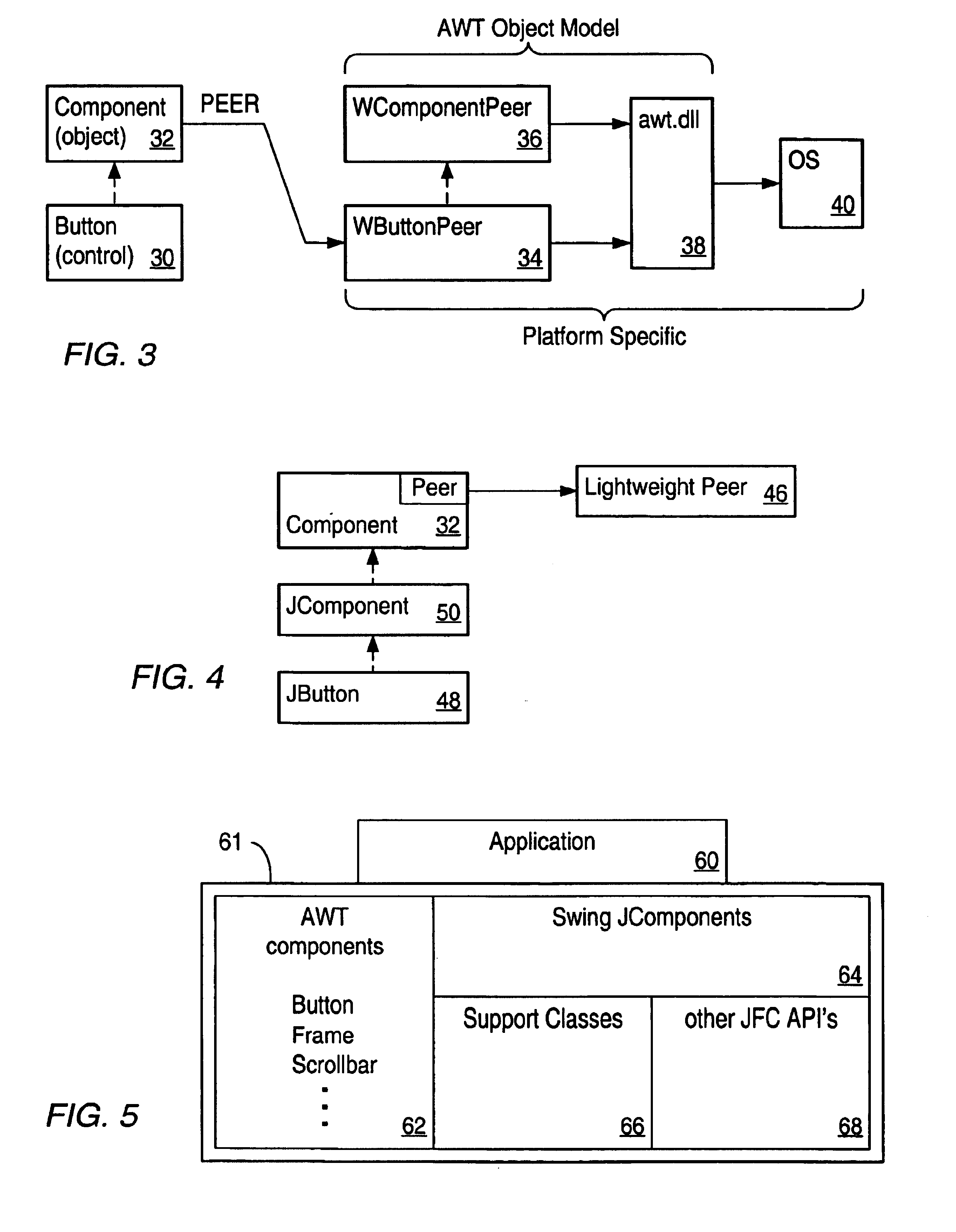

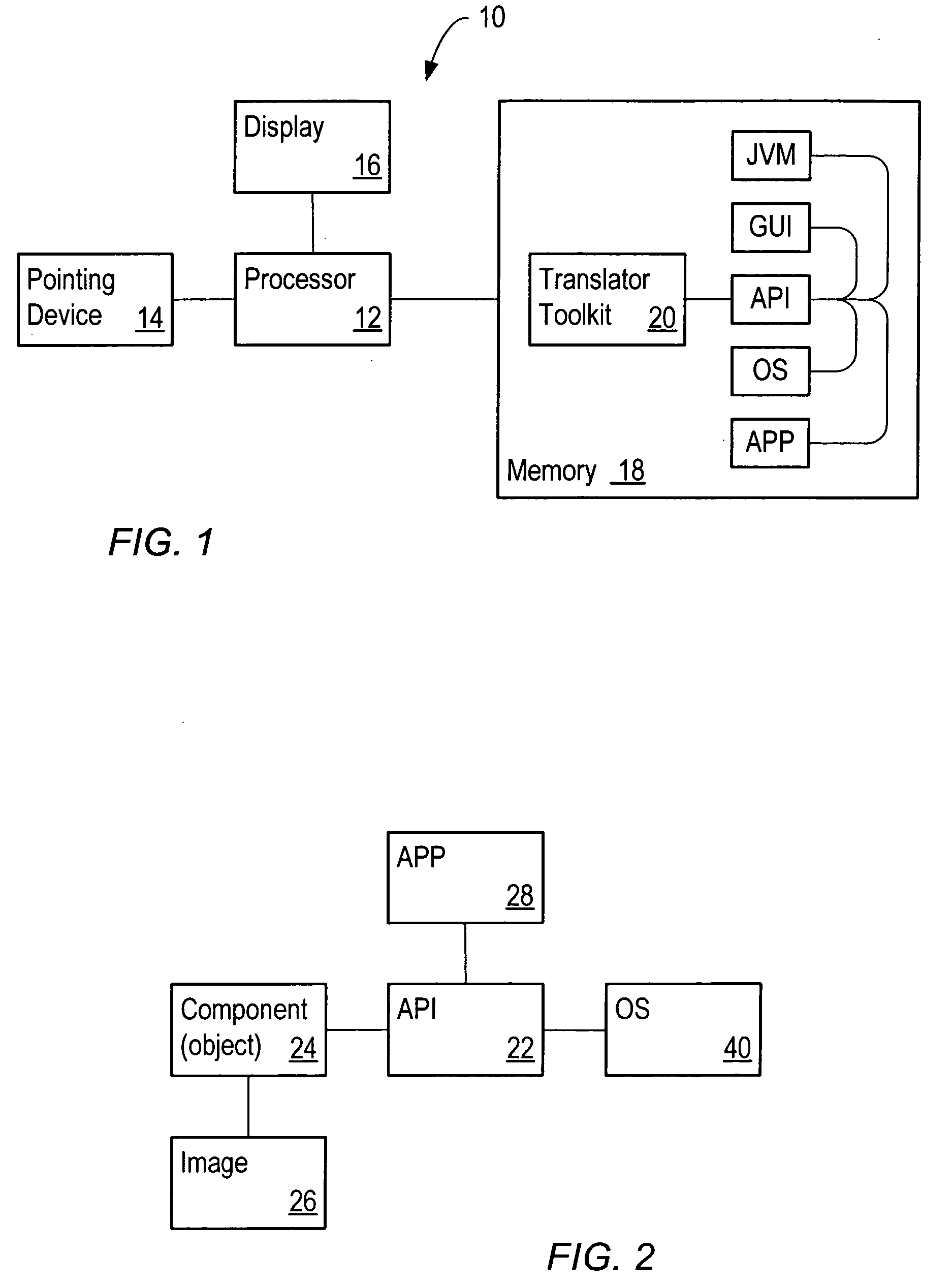

System and method for introducing enhanced features into a java swing application program interface

InactiveUS6993773B2Improve functionalityMore applicationSoftware engineeringMultiprogramming arrangementsUnicode fontApplication software

A system and method are disclosed for providing additional features in an enhanced version of the portable application program interface, Java Swing. The enhanced API can replace the first generation heavyweight abstract windowing toolkit used by legacy Java application programs, with no changes required to those programs. Thus, legacy applications running on various platforms can benefit from the improved functionality. Among the added features are a consistent, platform neutral GUI look and feel, Unicode font encoding for all text controls, and improved text drawing (based on the use of a high performance Java font rasterizer). The enhanced version of Swing is referred to herein as AWTSwing.

Owner:IBM CORP

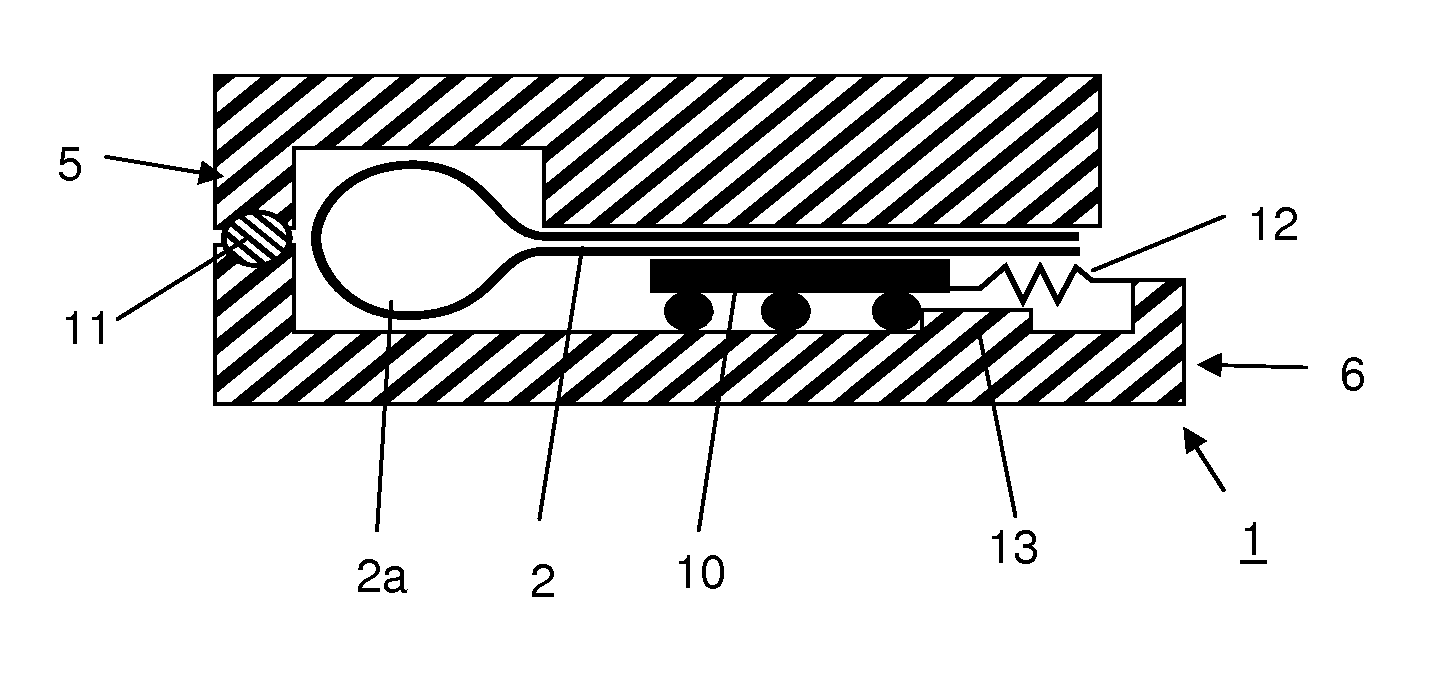

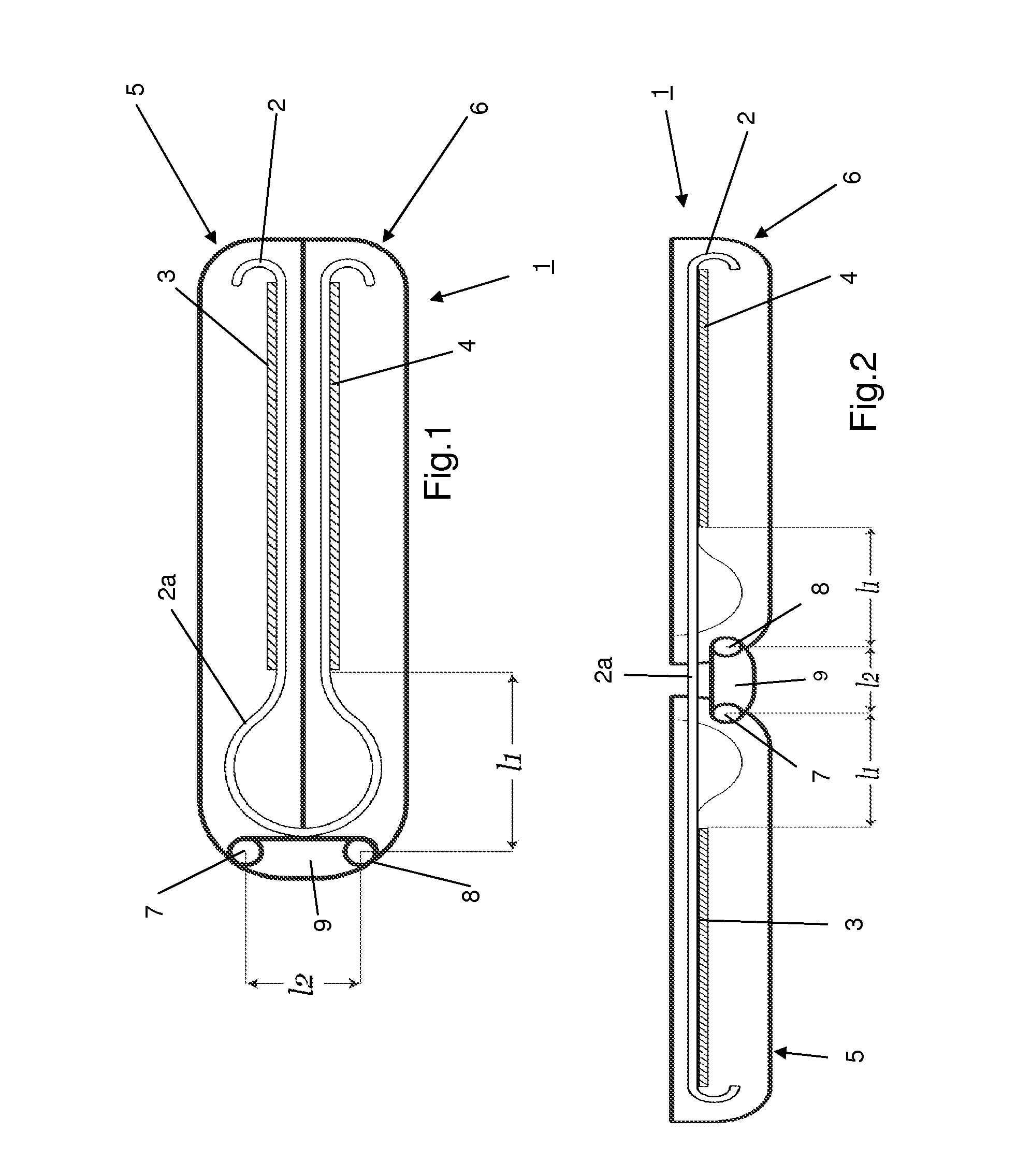

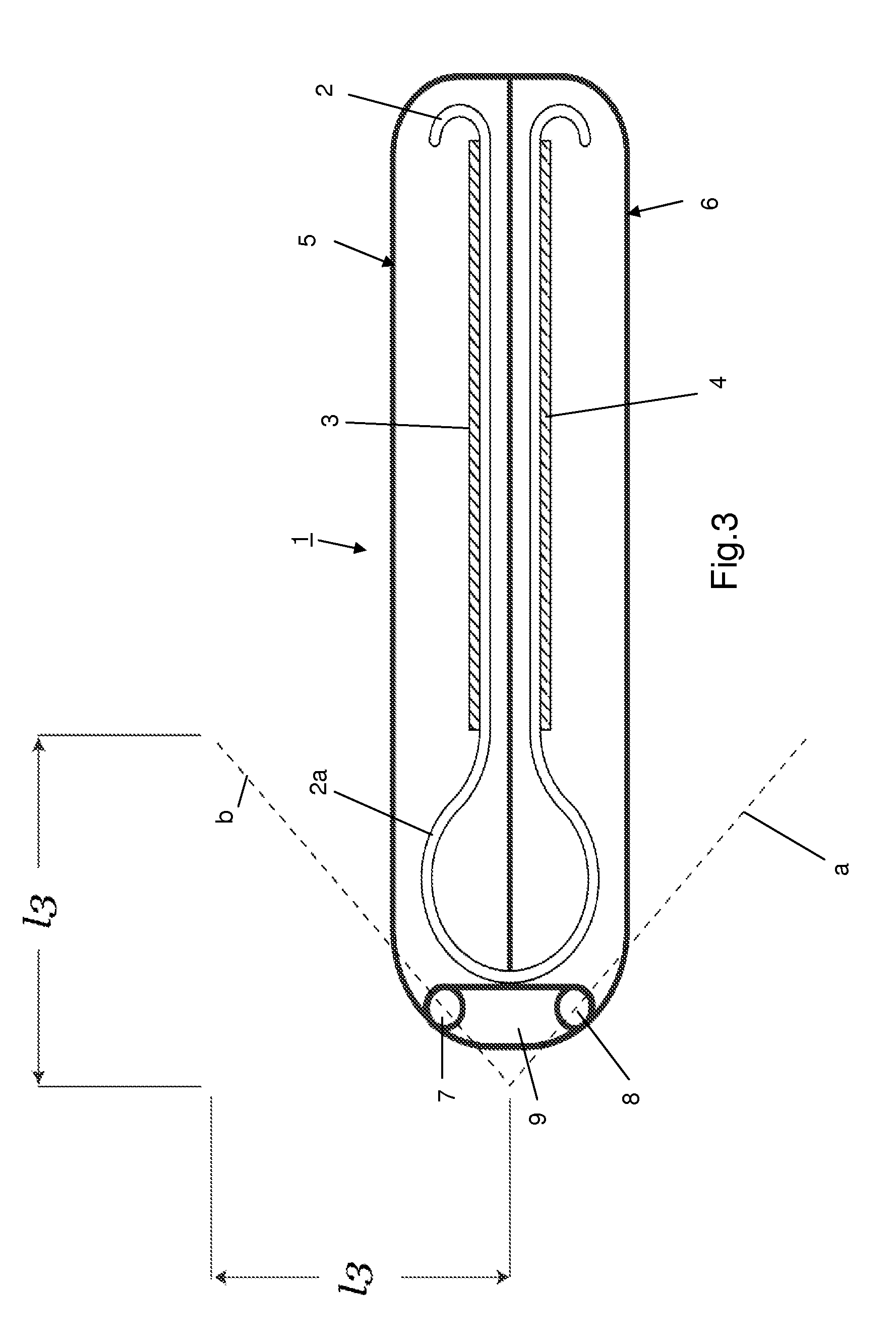

Display system having a continuous flexible display with display supports

InactiveUS8908365B2More roomPrevent saggingStatic indicating devicesAdvertisingDisplay deviceSpring force

A display system comprises a continuous flexible display and two main display supports being hingeably connected with respect to each other between a closed storage position and a planar open position for fixing the flexible display in an open position. Each of the supports is structurally configured to support respectively a first and a second portion of the flexible display, a segment of the flexible display is located between the said respective portions of the flexible display in the open position. The display system comprises a spring force biased mechanism operative in either the open or closed position or both the open and closed positions of the flexible display, biasing said segment of the flexible display in the respective position.

Owner:SAMSUNG ELECTRONICS CO LTD

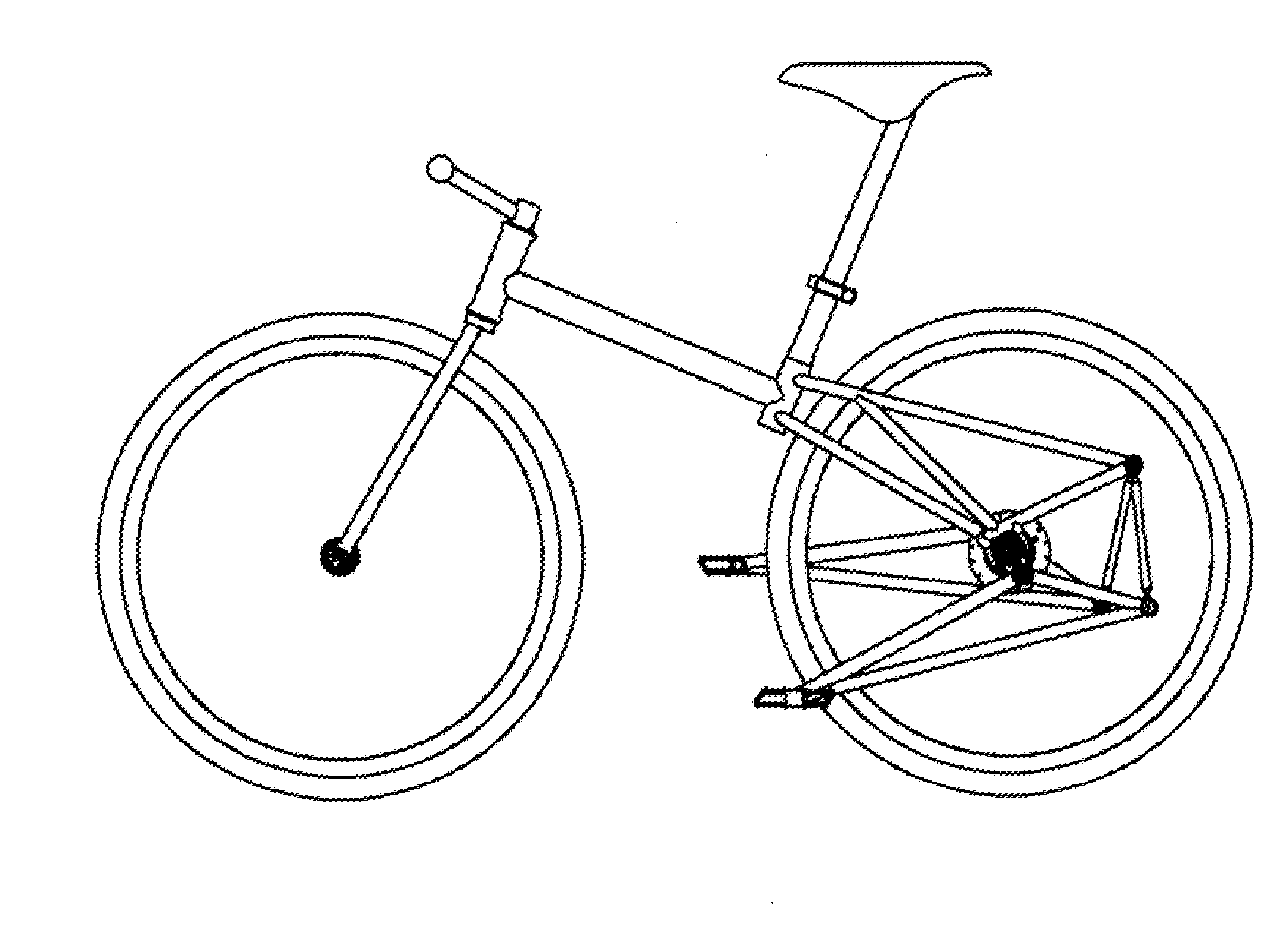

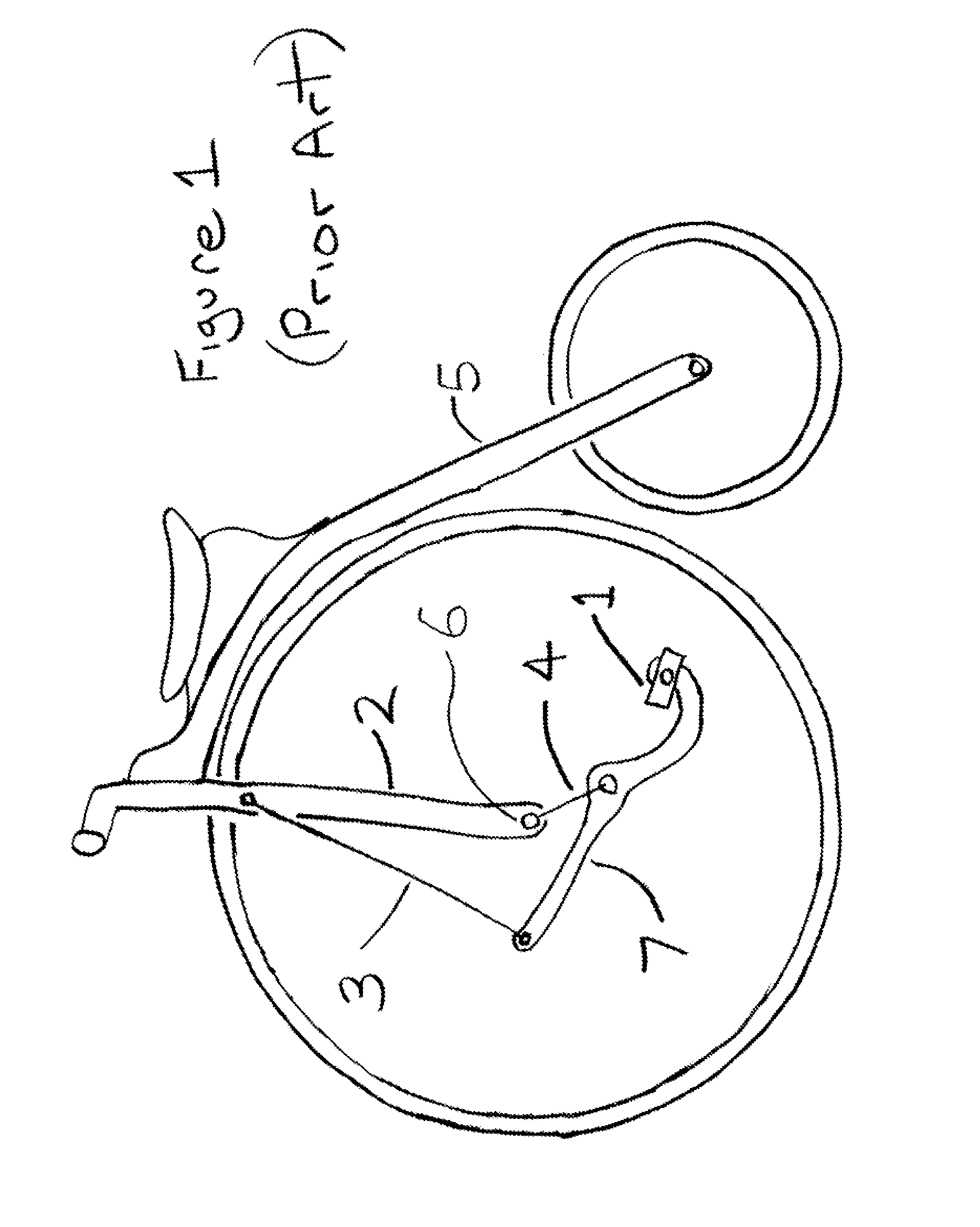

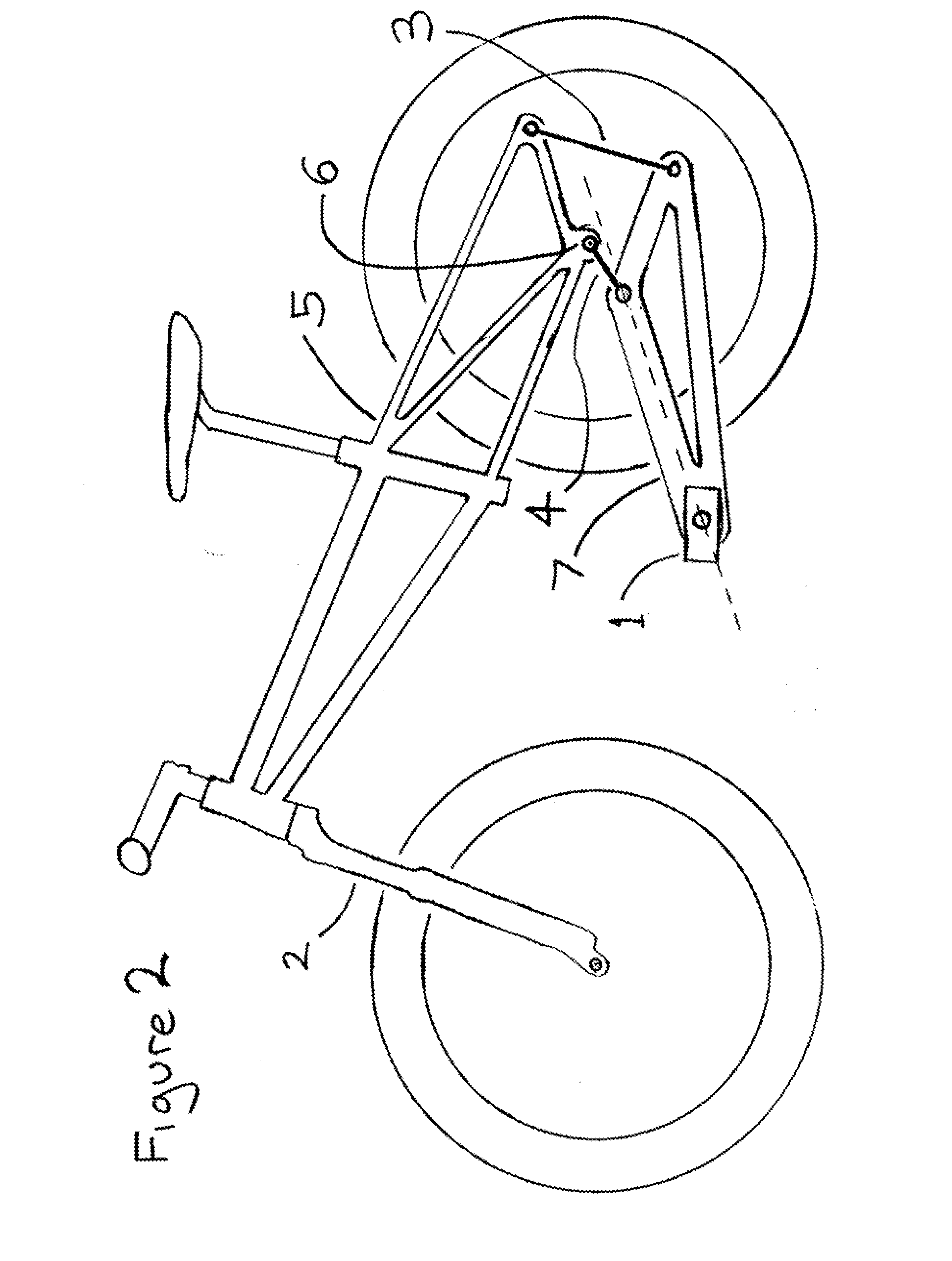

Bicycle transmission

InactiveUS20140361511A1High efficiency zero maintenance mechanismImprove sealingWheel based transmissionVehicle cranksDrive wheelEngineering

A chainless drive mechanism for a bicycle using pedal arms, one on each side of the bicycle, each pedal arm carrying a pedal engageable with a rider's foot. Each pedal arm is mounted to a crank by a rotating joint and connected to the frame of the bicycle by a link, each link having rotating joints at each end. The cranks are connected by a shaft passing through the hub of to the driven wheel of the bicycle. The cranks may be connected to the driven wheel by a multi ratio free wheeling gear mechanism.

Owner:THOMPSON ROBERT WILLIAM

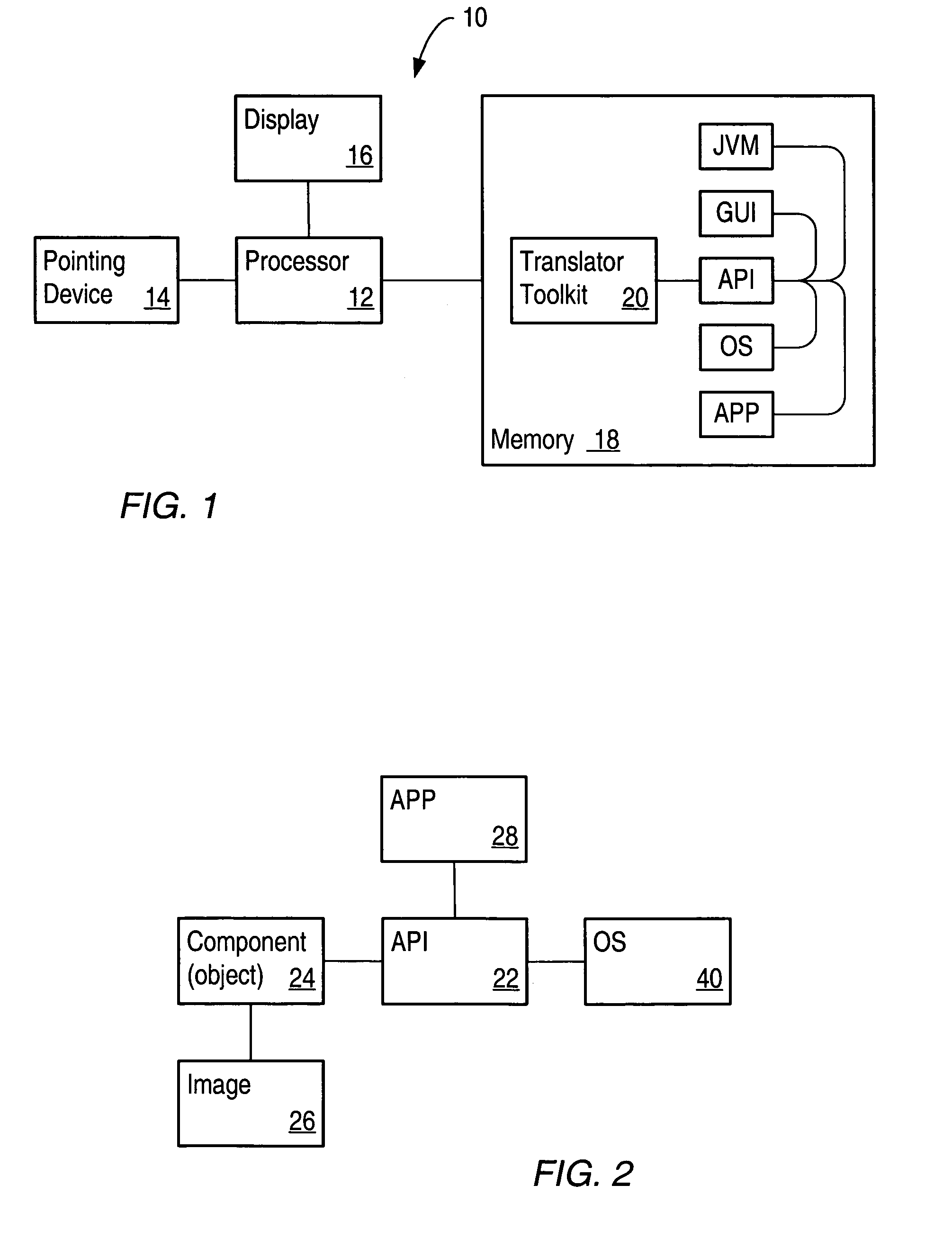

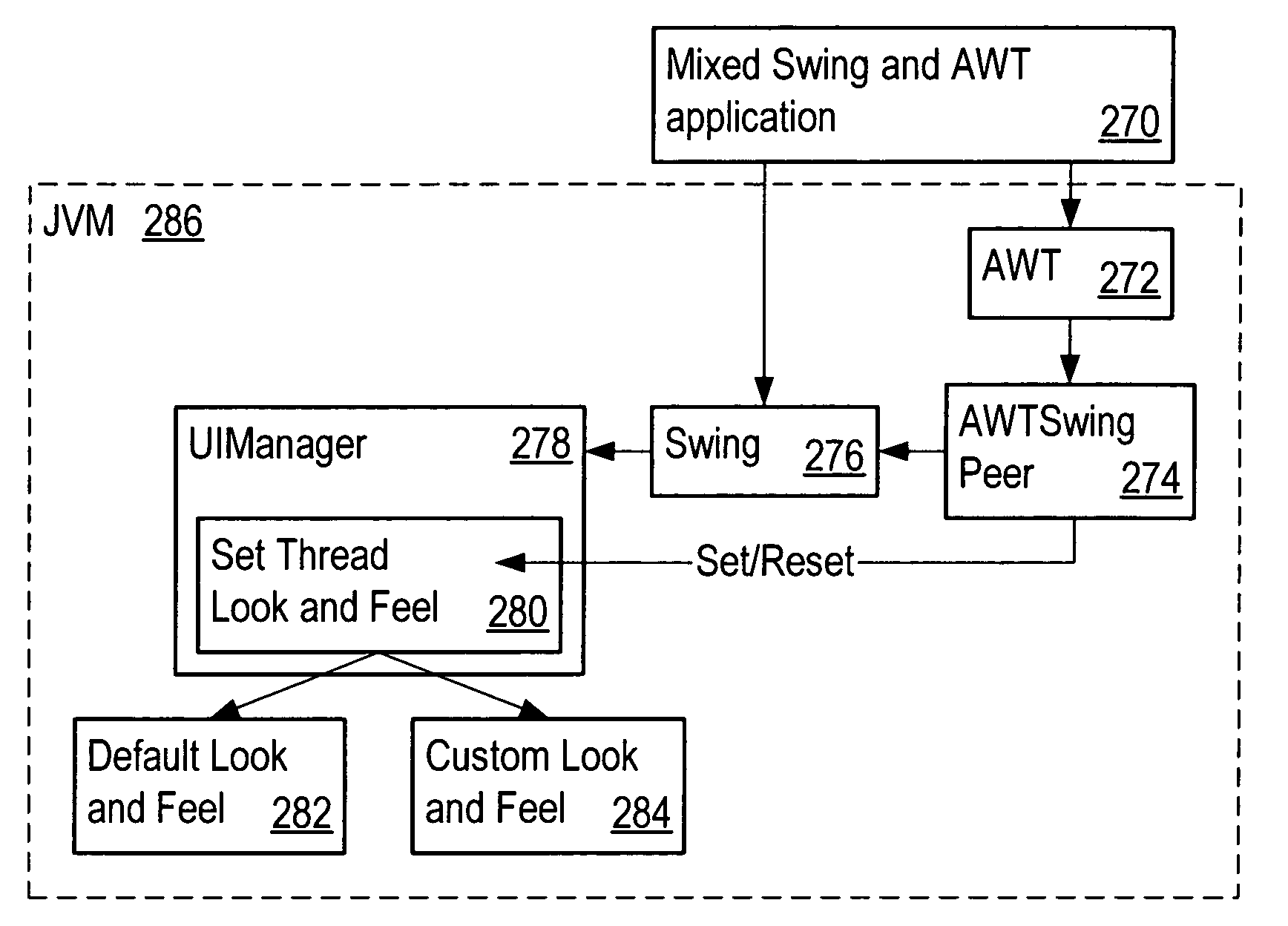

Application program interface that can maintain similar look and feel of a displayed image regardless of whether the interface is platform dependent or platform independent

InactiveUS6957391B2Improve functionalityMore applicationSoftware engineeringSpecific program execution arrangementsApplication softwareLook and feel

A system and method are disclosed whereby the look and feel of the OS / 2 operating system is added to the Swing application program interface (API), in an enhanced version of the API, referred to herein as AWTSwing. A further disclosure is the creation of a thread-relative setLookAndFeel method, which only accepts calls from a particular thread to adopt a prescribed look and feel. This makes it possible for an application to have a look and feel distinct from that of the platform, or of other concurrently executing applications. This capability is not present in the conventional version of the Swing API, which treats look and feel settings as global.

Owner:IBM CORP

Application program interface that can maintain similar look and feel of a displayed image regardless of whether the interface is platform dependent or platform independent

InactiveUS20050246644A1Function increaseConsistent lookSoftware engineeringSpecific program execution arrangementsOperational systemLook and feel

A system and method are disclosed whereby the look and feel of the OS / 2 operating system is added to the Swing application program interface (API), in an enhanced version of the API, referred to herein as AWTSwing. A further disclosure is the creation of a thread-relative setLookAndFeel method, which only accepts calls from a particular thread to adopt a prescribed look and feel. This makes it possible for an application to have a look and feel distinct from that of the platform, or of other concurrently executing applications. This capability is not present in the conventional version of the Swing API, which treats look and feel settings as global.

Owner:IBM CORP

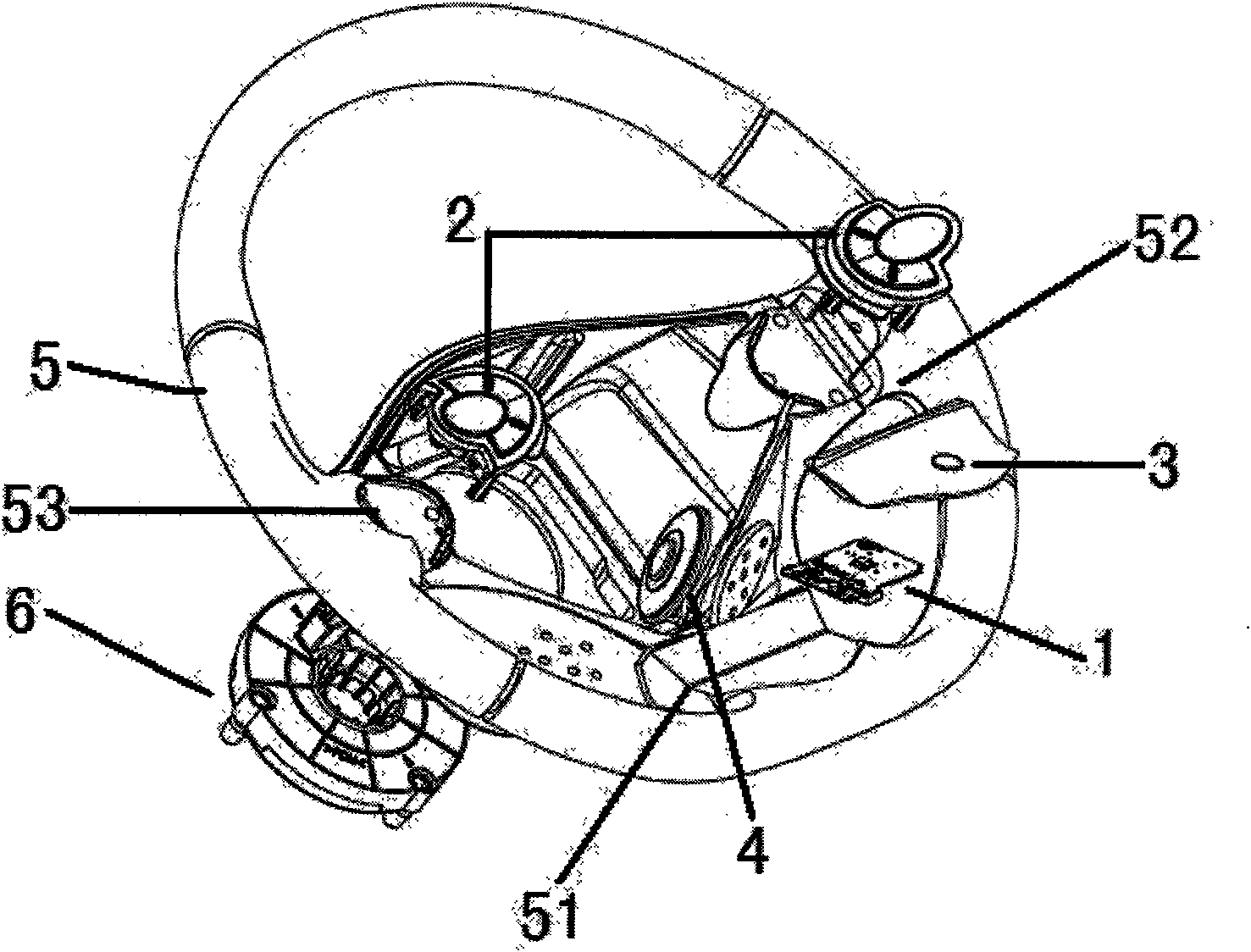

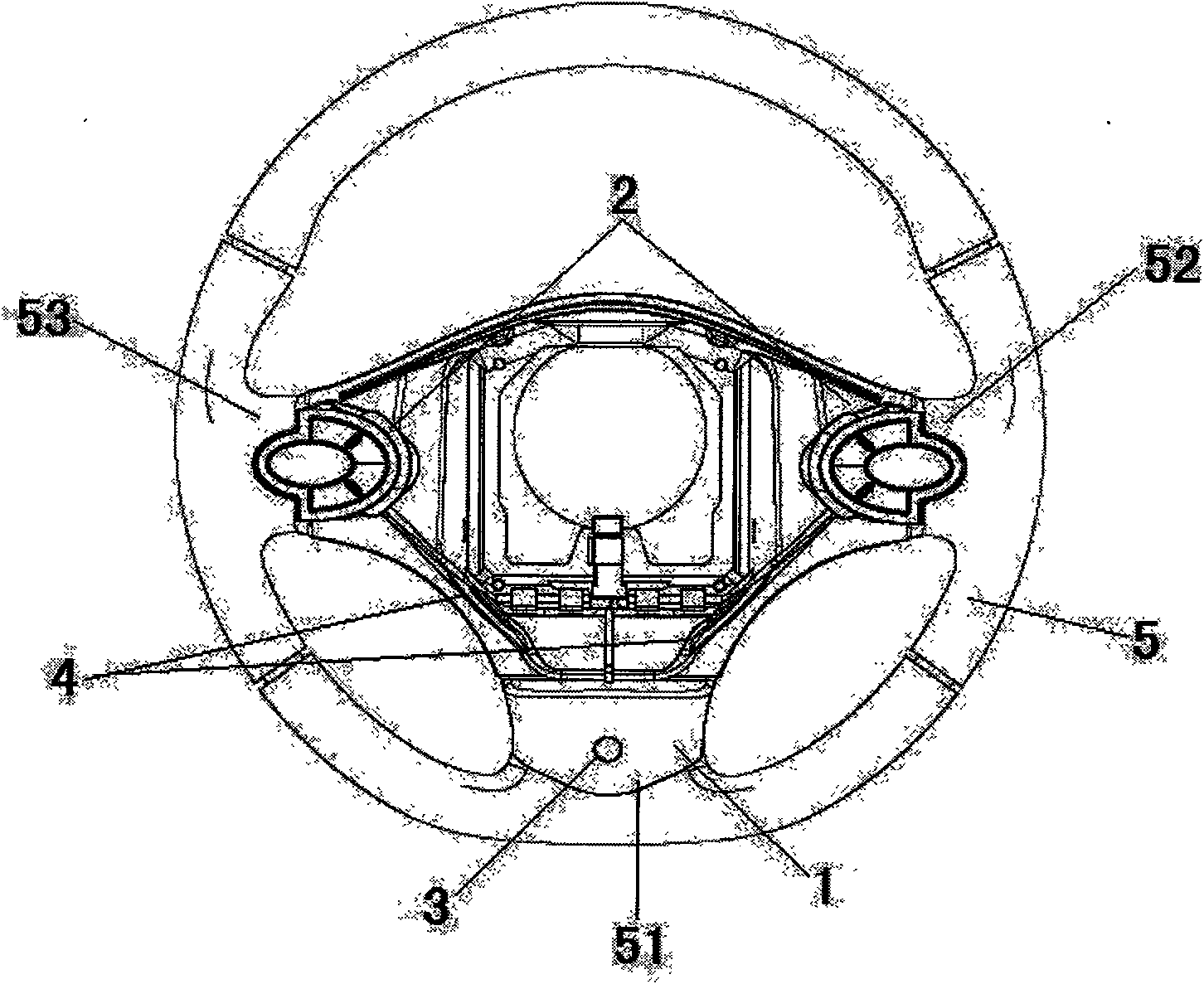

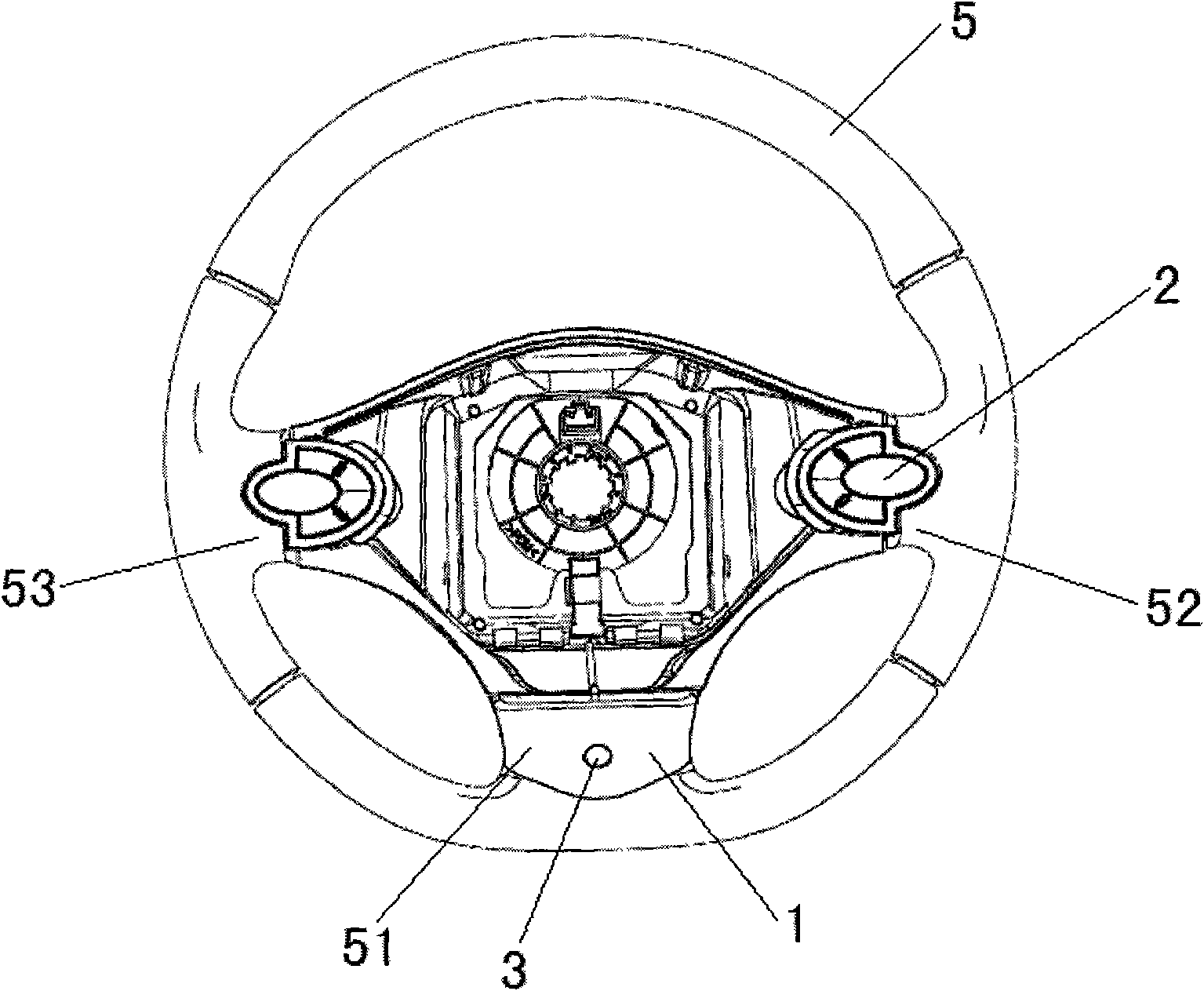

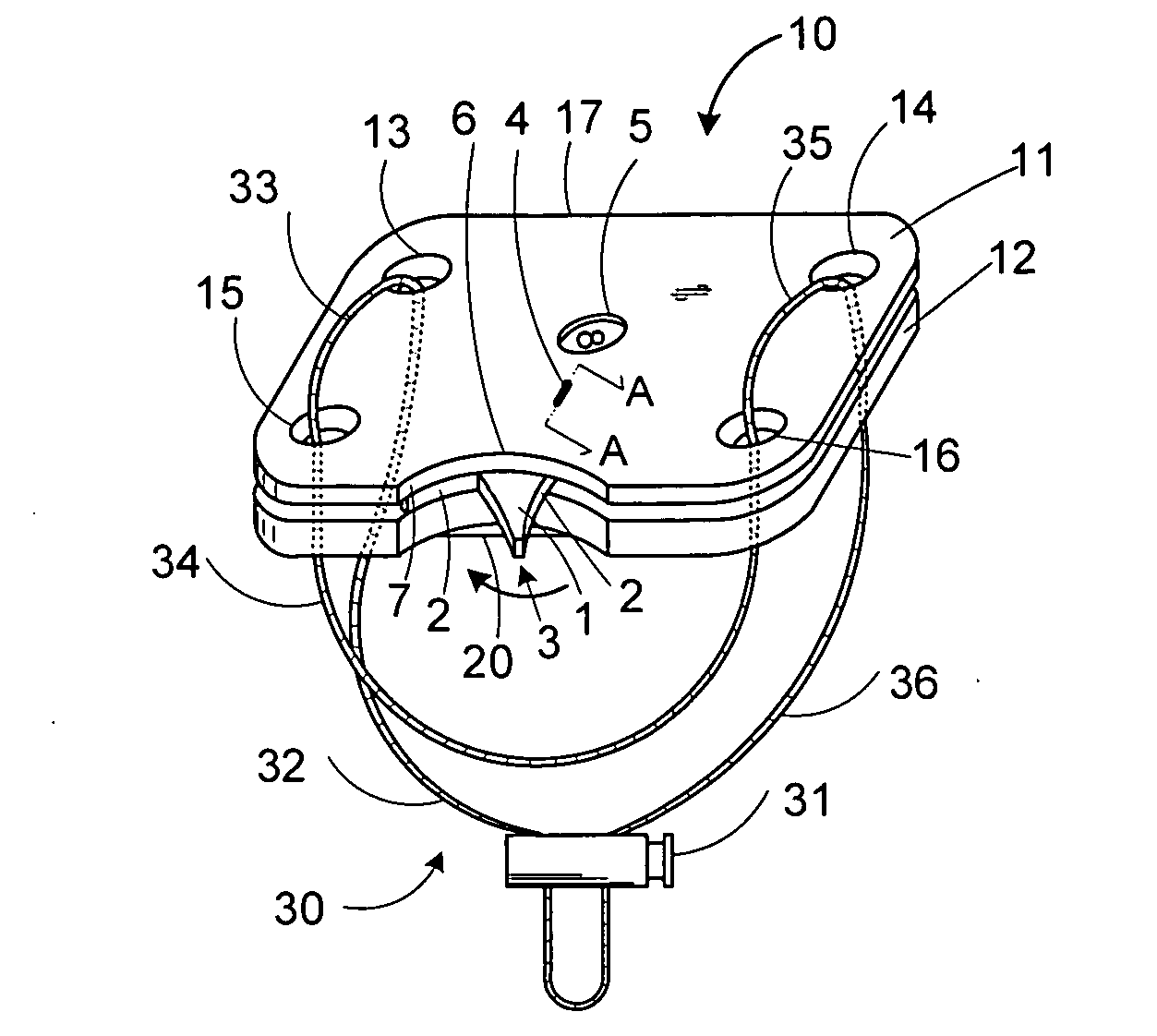

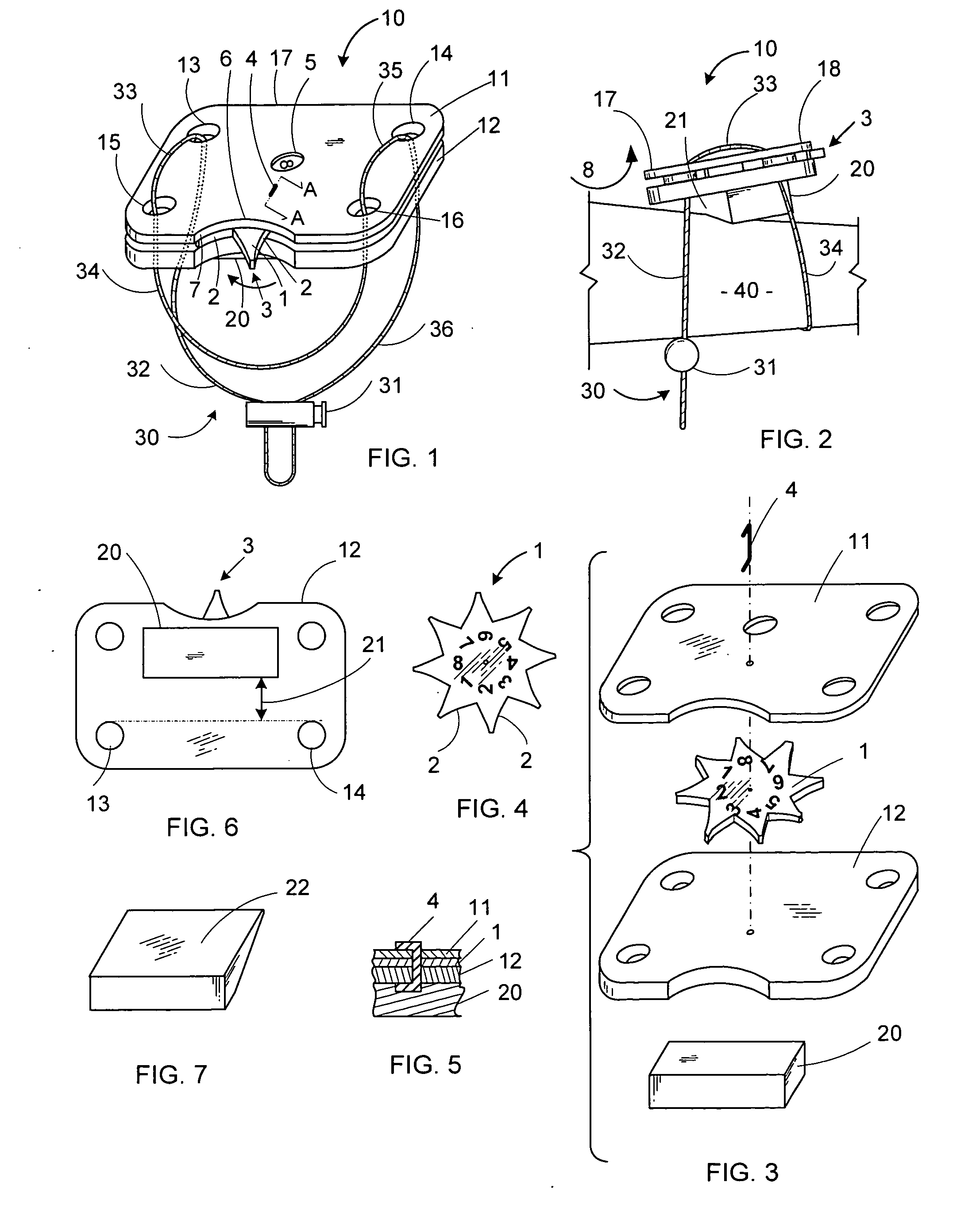

Steering wheel with voice acquisition system

ActiveCN101594409ALow costWill not affect the feelSubstation speech amplifiersHand wheelsShielded cableSteering wheel

The invention provides a steering wheel with a voice acquisition system, which comprises a steering wheel and the voice acquisition system, wherein the voice acquisition system can be a blue-tooth hands-free system comprising a blue-tooth hands-free control module, a microphone, control keys and a loudspeaker; the microphone is embedded in the steering wheel and positioned on a position which is close to the speaking direction of a driver and suitable for the mounting of the microphone; and the blue-tooth hands-free control module, the control keys and the loudspeaker can be also embedded in the steering wheel. The steering wheel solves the problems of poor received audio signals, bigger noise in sound effect and the like existing in the prior blue-tooth hands-free device, achieves the best speech quality, and simultaneously saves cost because an audio shield cable is not used; and because the voice acquisition system is completely integrated in the steering wheel, mounting places on other parts of a vehicle and special mounting devices are not needed.

Owner:YANFENG AUTOMOTIVE SAFETY SYST CO LTD +1

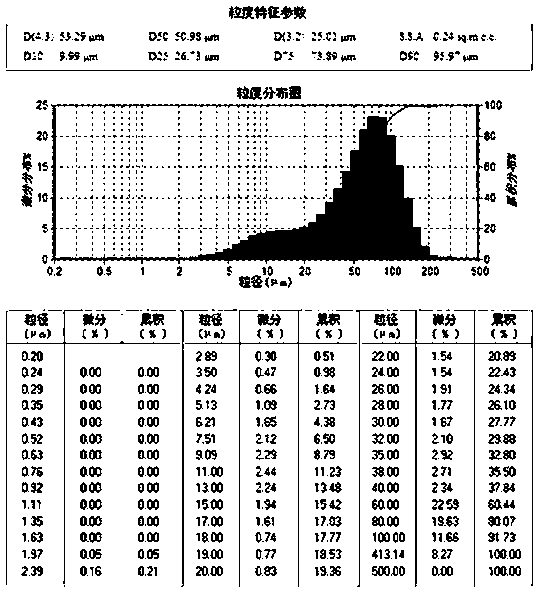

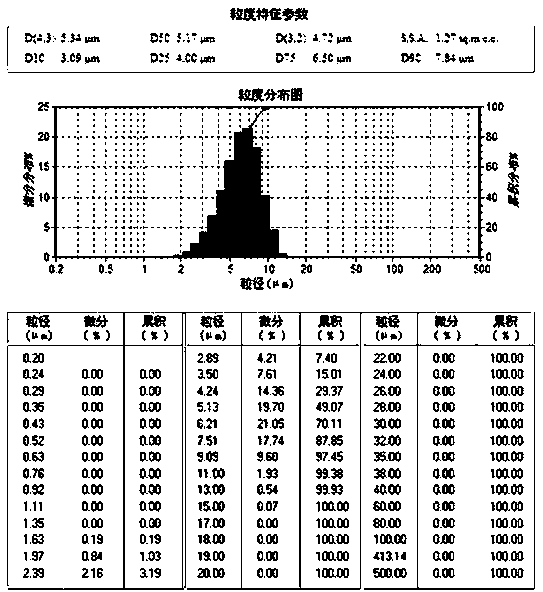

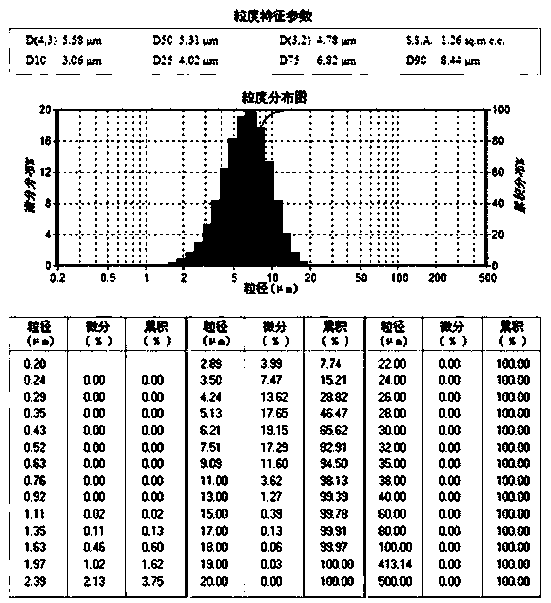

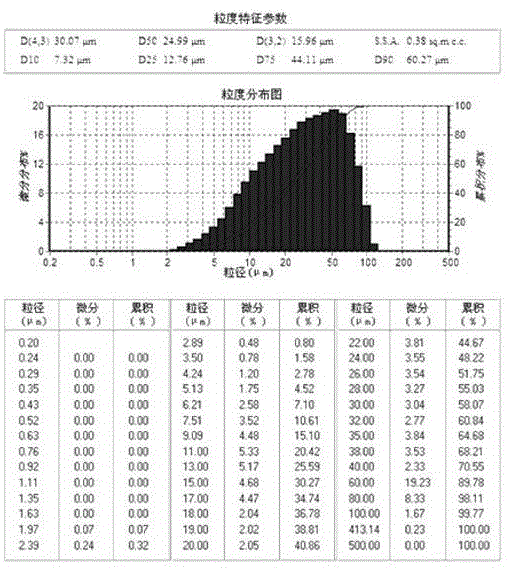

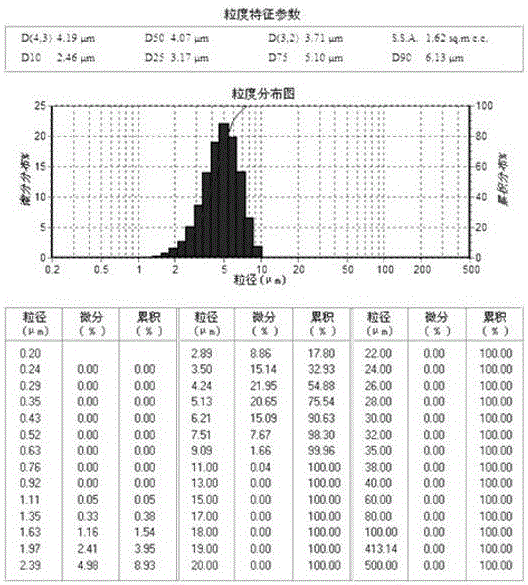

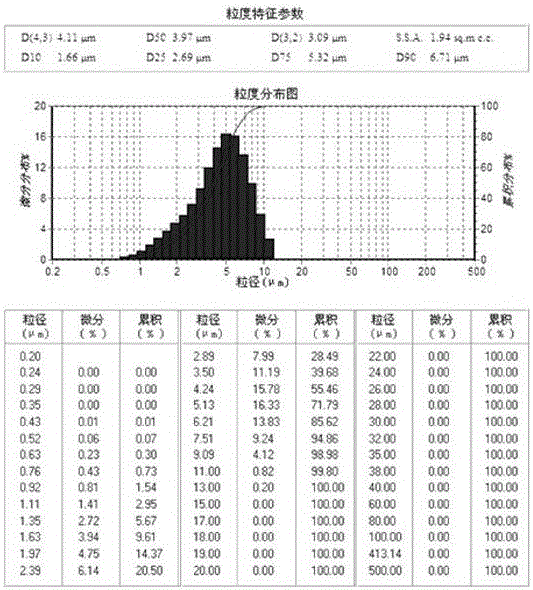

Particle size controllable nano silica and preparation method thereof

ActiveCN103911022AConcentrated particle size distributionThe proportion of large particles is reducedPigment treatment with organosilicon compoundsPigment physical treatmentMasterbatchSodium metasilicate

The invention discloses particle size controllable nano silica and a preparation method thereof, relating to a granulating technology for silica. The particle size of nano silica prepared according to currently known preparation technologies is difficult to control, and distributed within a relatively large range of 1-30mu m. The invention discloses particle size controllable nano silica and a preparation method thereof which are used for solving the defects. According to the invention, slurry is prepared by using sodium metasilicate and sulfuric acid, a master batch is prepared by using an atomizer, and the master batch is crushed by using a fluidization crusher so as to obtain a finished product. The granularity of the finished product is 4-6mu m, the granularity is distributed in a concentrated mode, and large particles are significantly decreased.

Owner:FUJIAN SHUNCHANG XINHE NANO SILICON IND

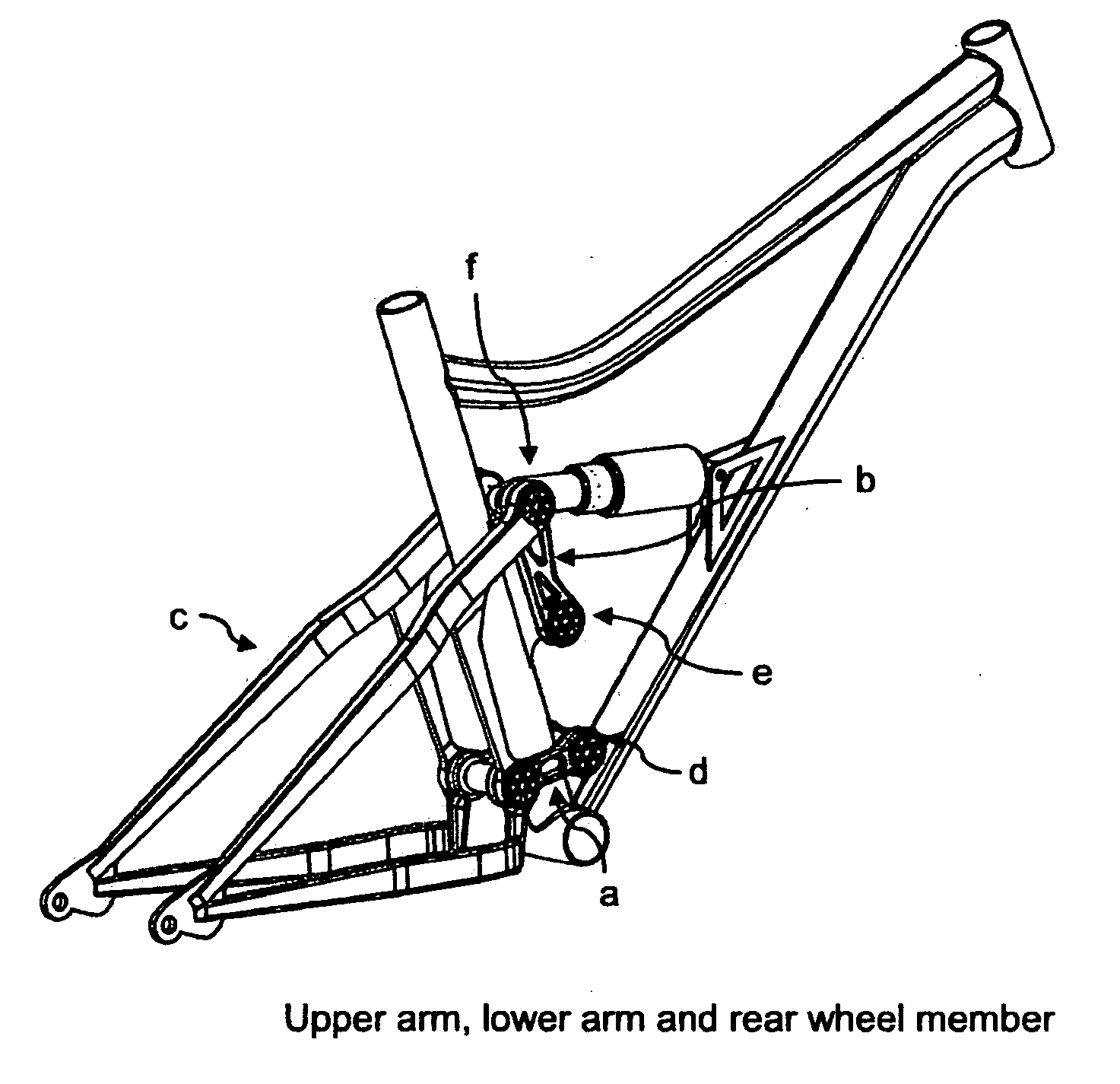

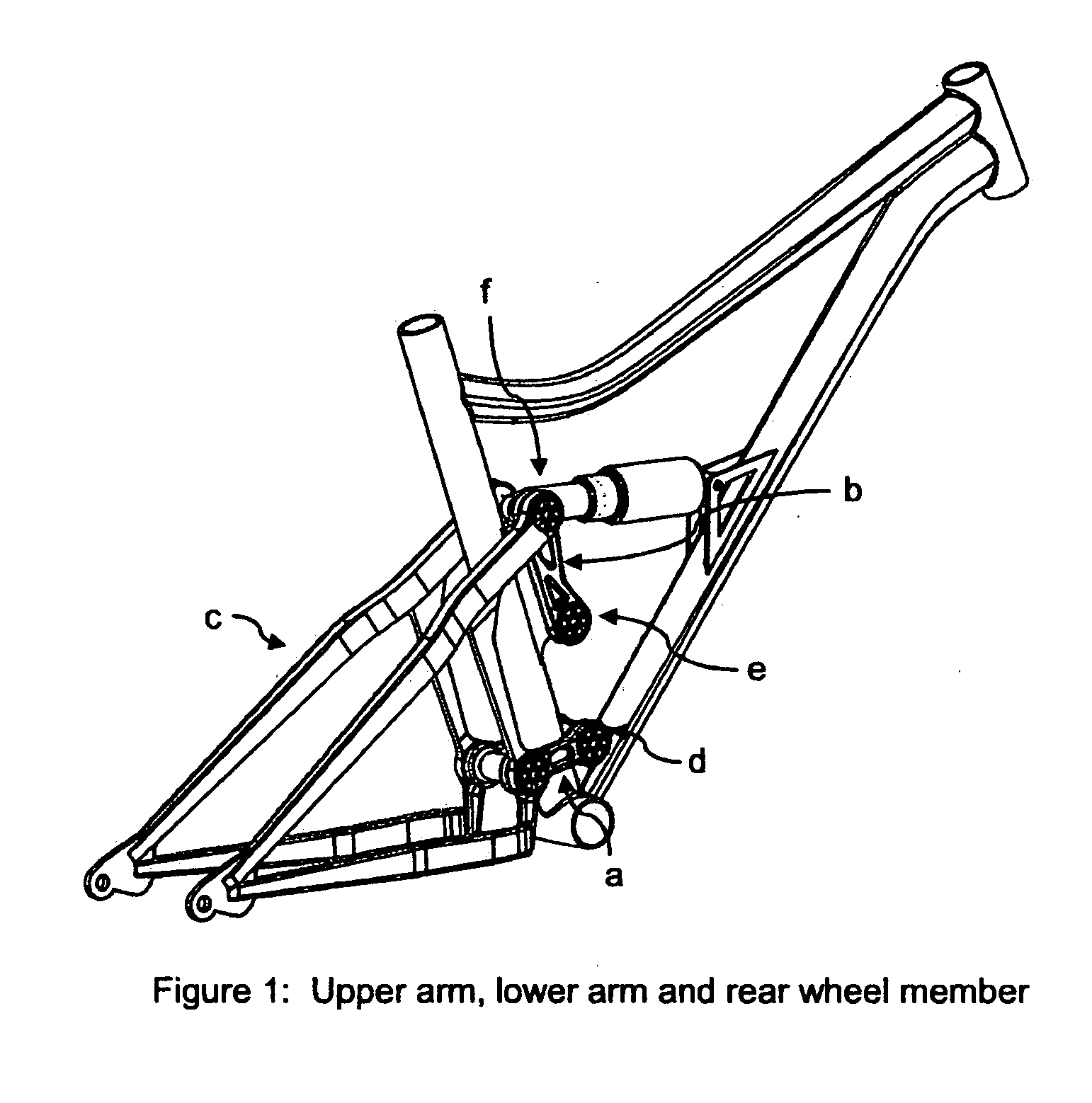

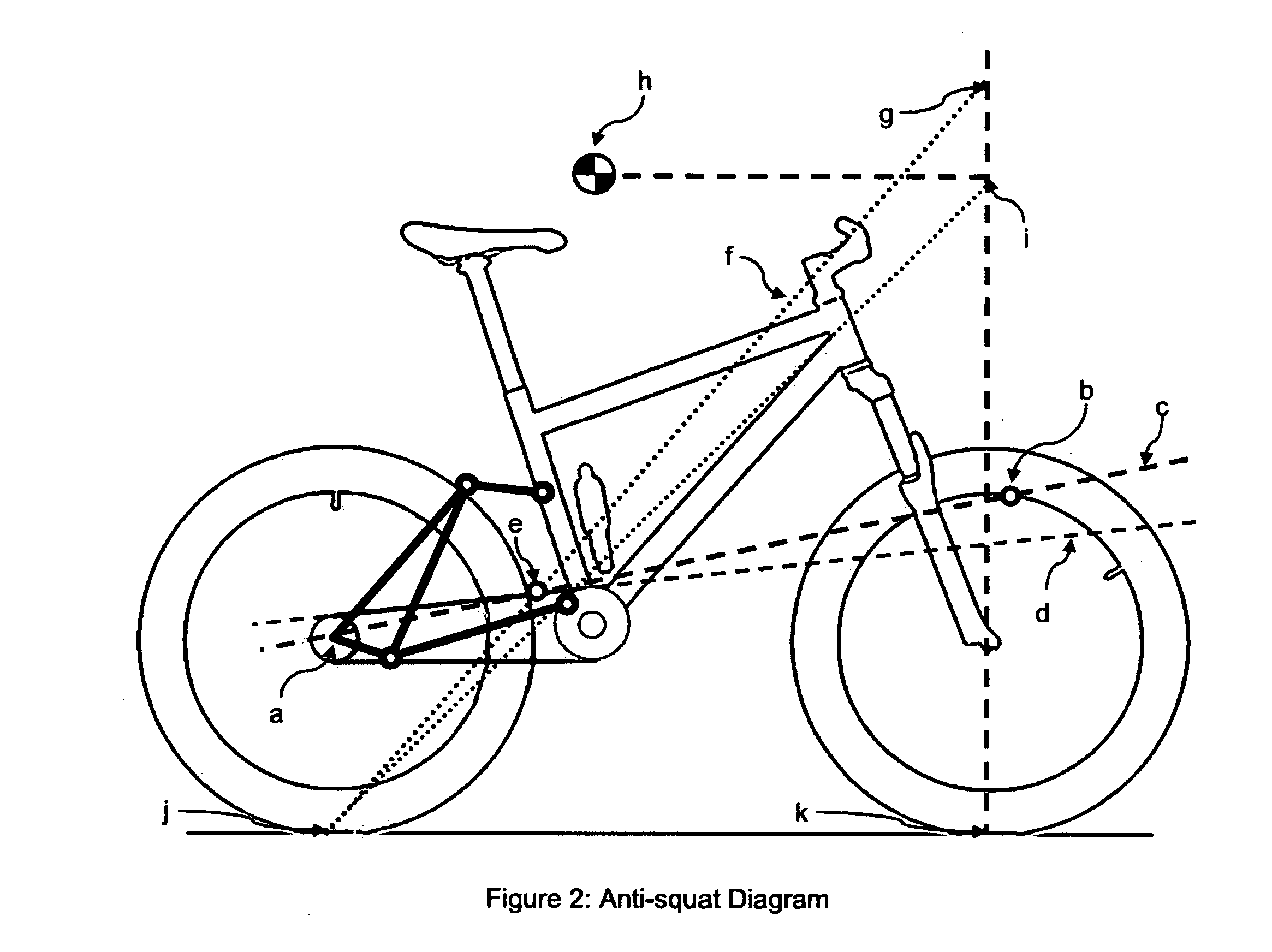

Suspension System for Chain-Driven or Belt-Driven Vehicles

InactiveUS20110140387A1Different pedaling feelConsistent feelAxle suspensionsResilient suspensionsChain driveLeather belt

Owner:ANDAL ARNEL MARCELO +2

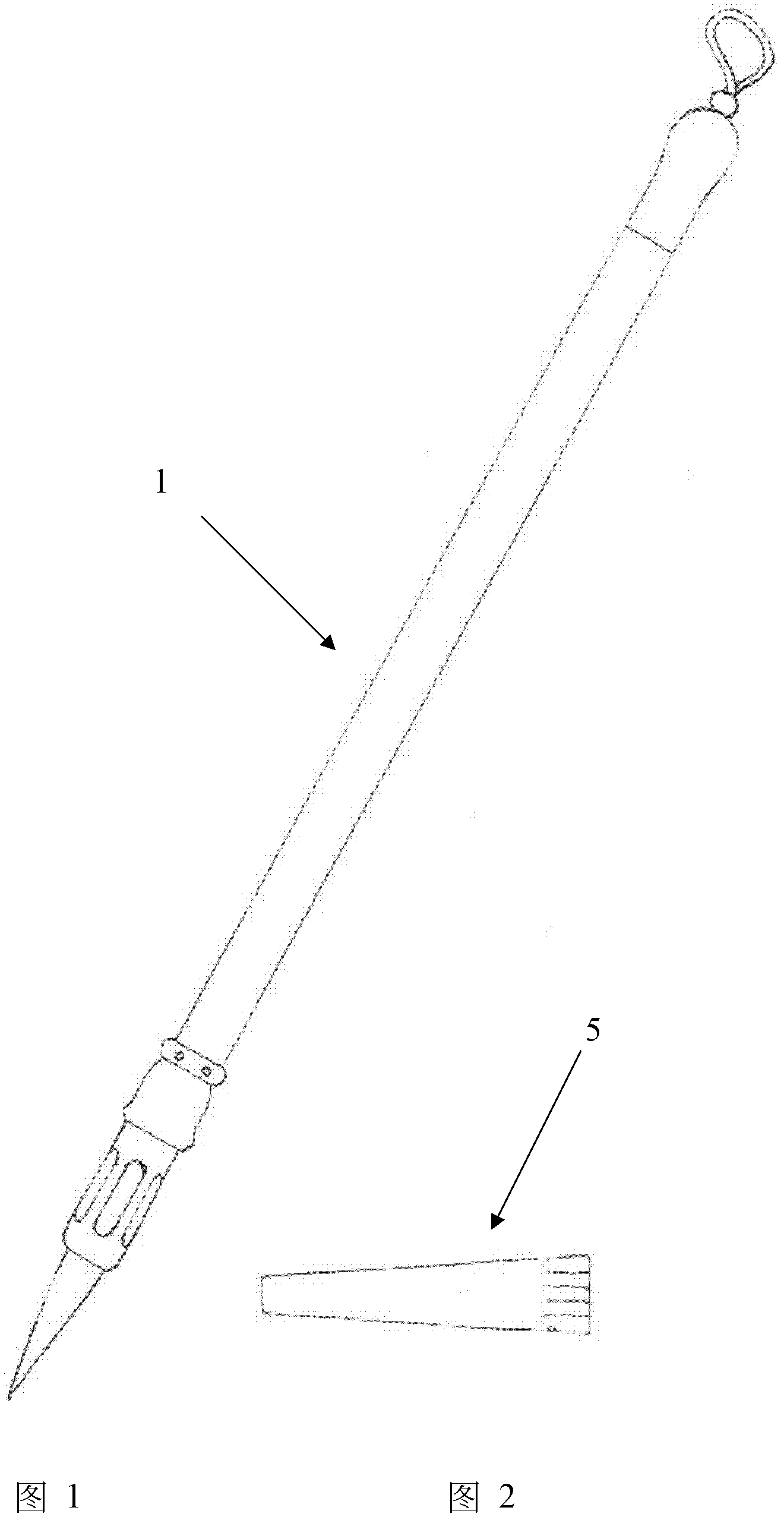

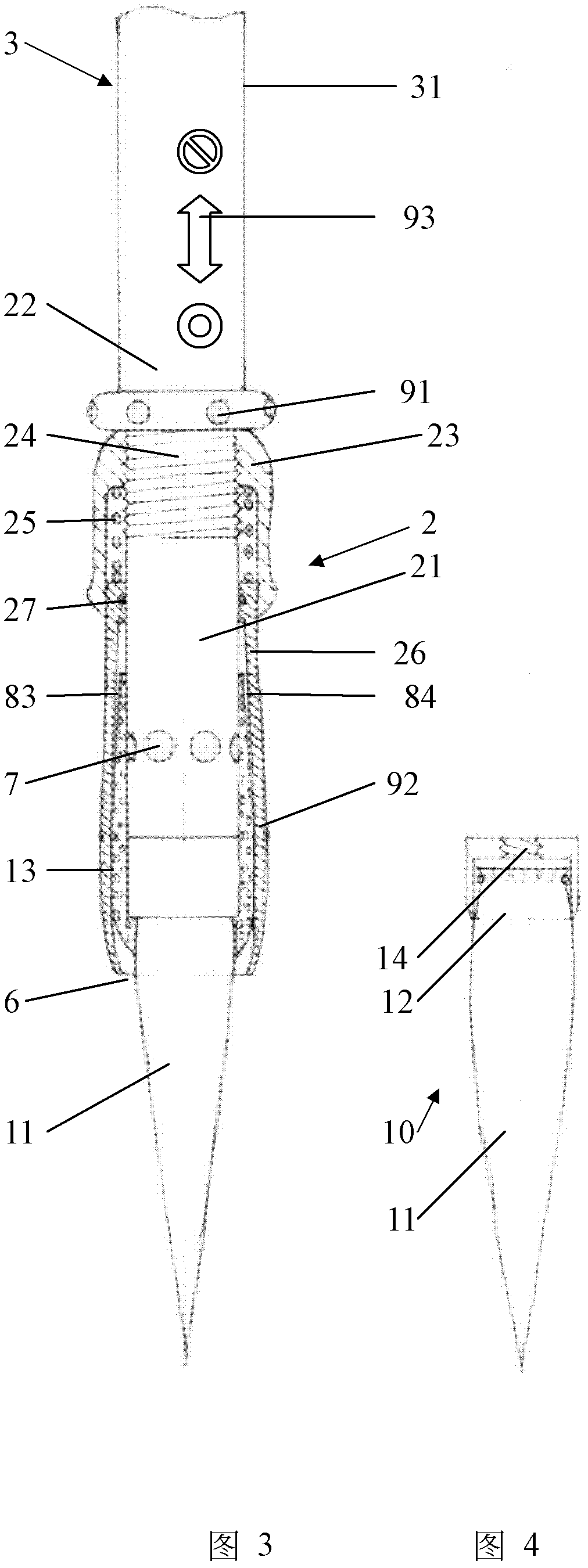

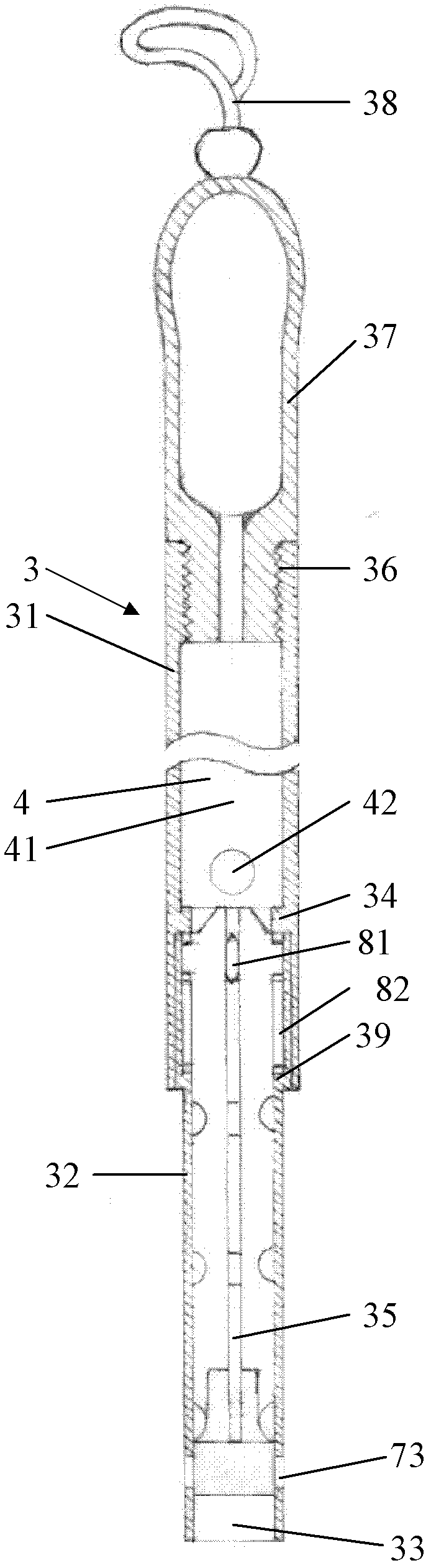

Automatic ink feeding writing brush

The invention provides an automatic ink feeding writing brush, which comprises a stem component, a head component, an ink adsorbing part, a bulb component and a fluid passage for circulation of ink and air. The bulb component comprises a bulb holder and a rotary jacket, and the bulb holder is in detachable connection with a stem. The head component comprises a head connector and a head fixed to the head connector, and the head connector is connected with the bulb holder. The ink adsorbing part is attached to the upper portion of the head component and wraps the lower portion of the bulb holder, and the ink adsorbing part is positioned between the inner wall of the rotary jacket and the bulb holder. An adjustable air inlet passage which can be selectively opened or closed according to ink adsorption quantity of the ink adsorbing part is arranged between the ink adsorbing part and the inner wall of the rotary jacket and selectively communicated with the fluid passage. Using the automatic ink feeding writing brush can reveal effect of classical painting and calligraphy artworks, the automatic ink feeding writing brush is fashionable, and further, storage, transport, carrying, manufacturing and the like of the automatic ink feeding writing brush are also given consideration.

Owner:谢庆

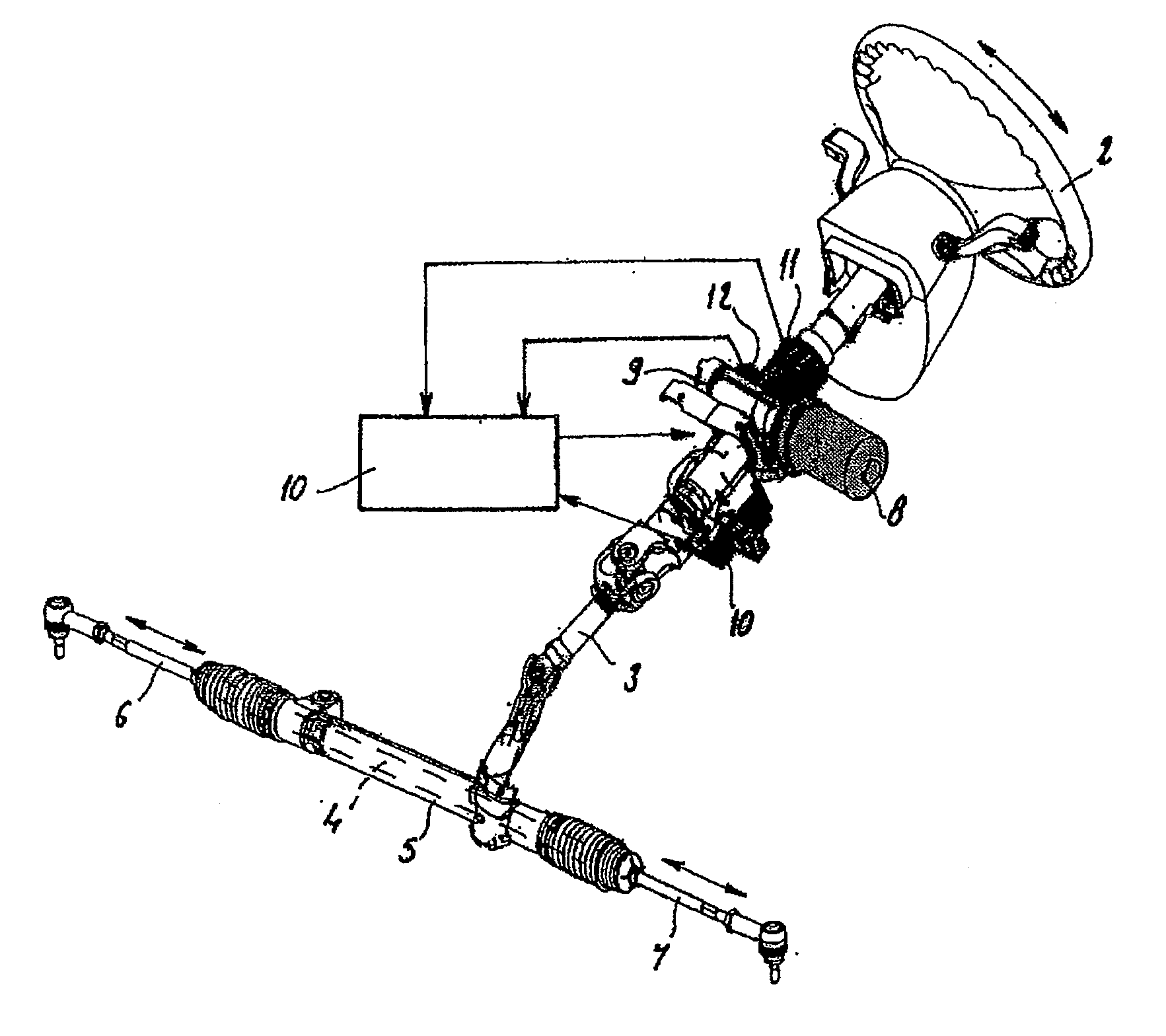

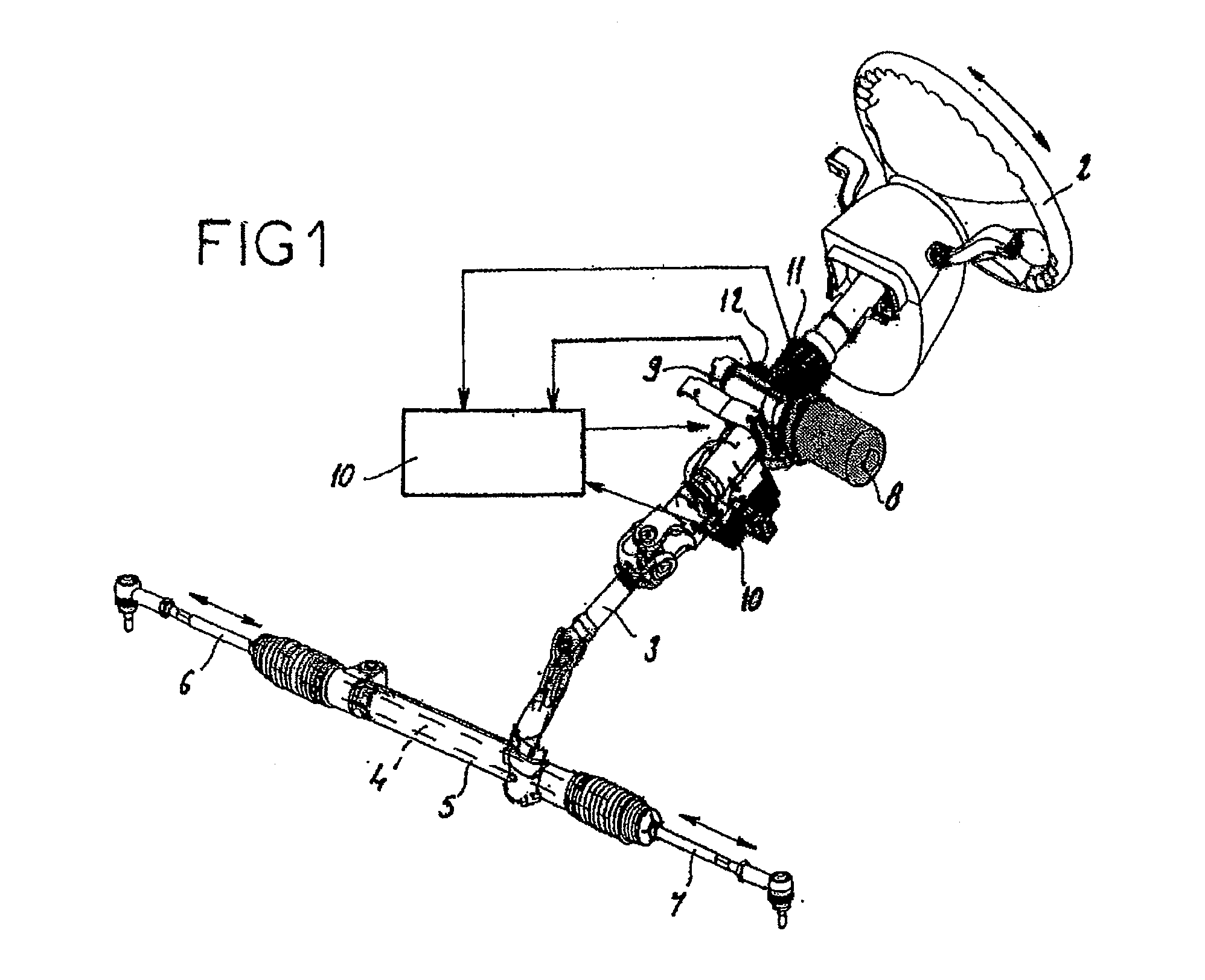

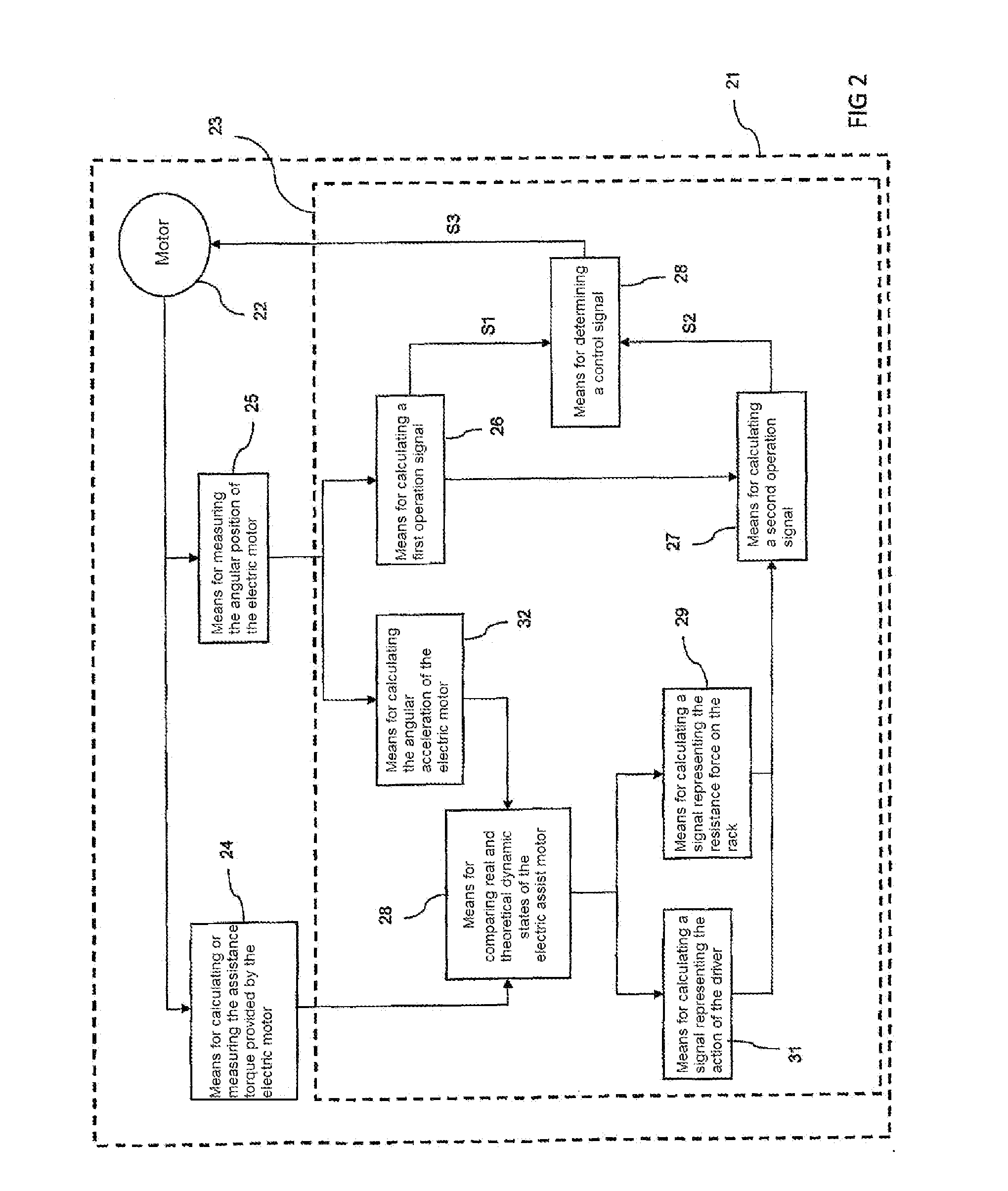

Power assisted steering for an automobile

ActiveUS20110184609A1Consistent feelSteering initiationsDigital data processing detailsSteering wheelDriver/operator

The invention relates to a power assisted steering system (21) that includes an electric assist motor (22) arranged to assist the manual force exerted by a driver on the steering wheel of the automobile, a processing means (23) arranged to control the electric assist motor (22), the processing means (23) including a means (28) for predetermining a signal (S3) for controlling the electric assist motor on the basis of a first operation signal (S1) determined on the basis of the angular position of the electric assist motor, and a second operation signal (S2) determined on the basis of the measurement or calculation of the angular acceleration of the electric assist motor and the measurement or calculation of the assistance torque output by the electric assist motor.

Owner:BERLIN PACKAGING +1

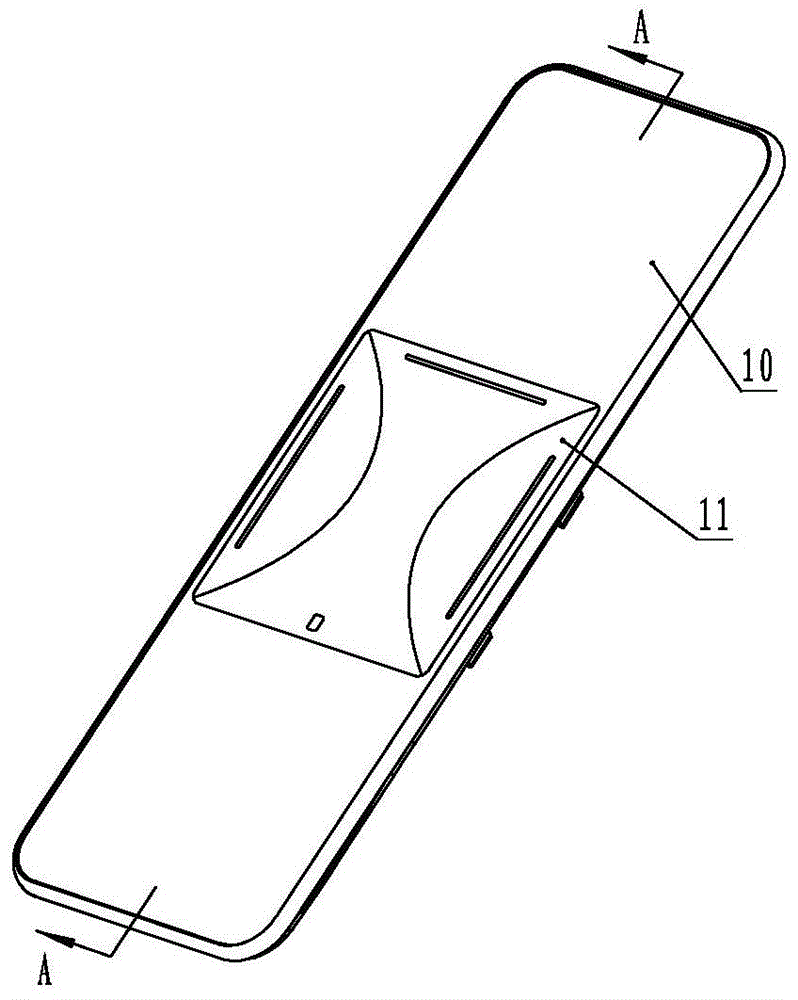

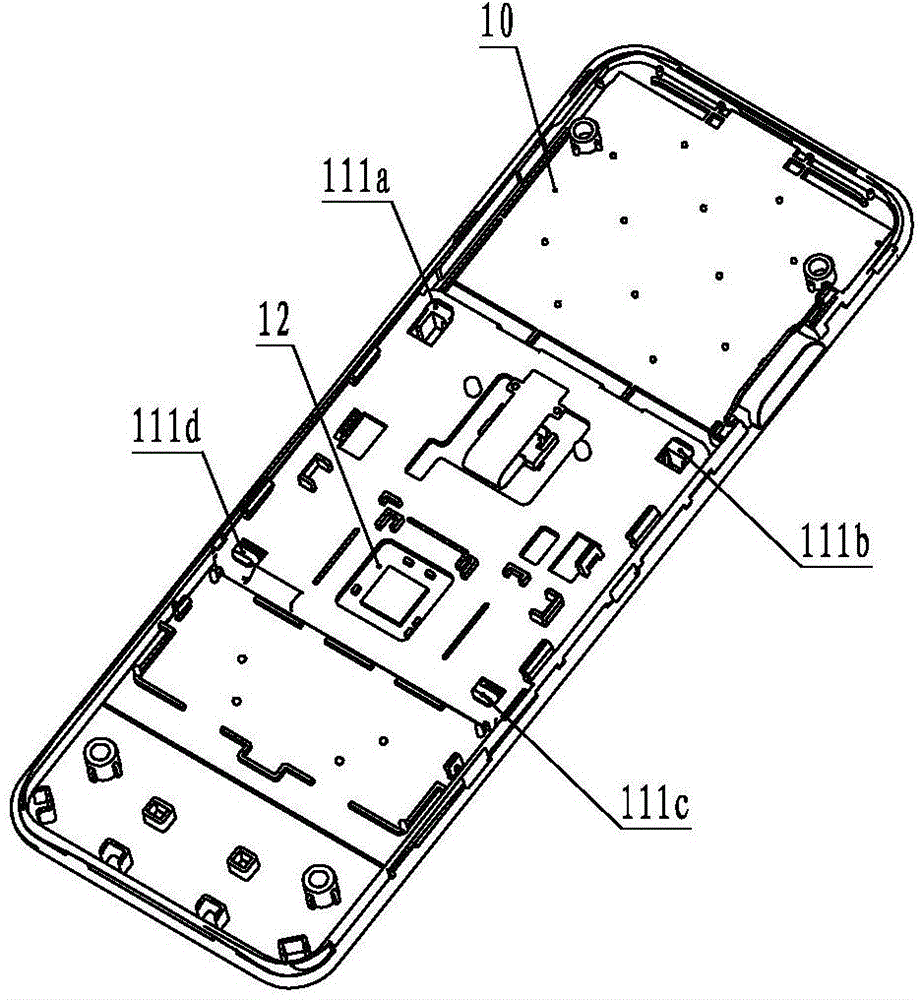

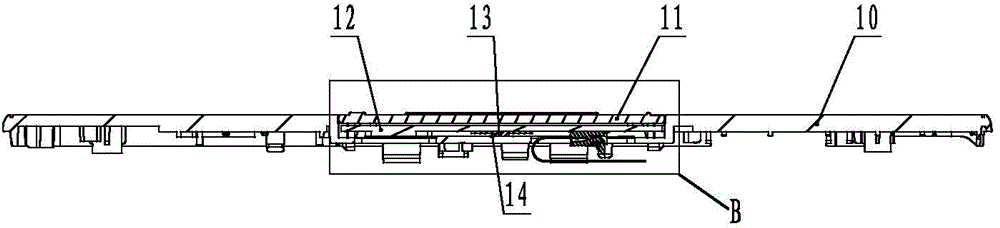

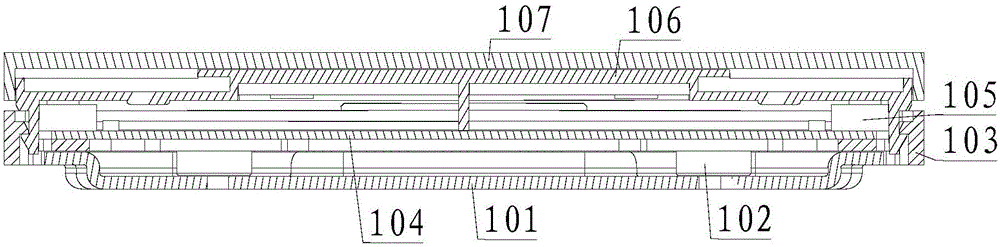

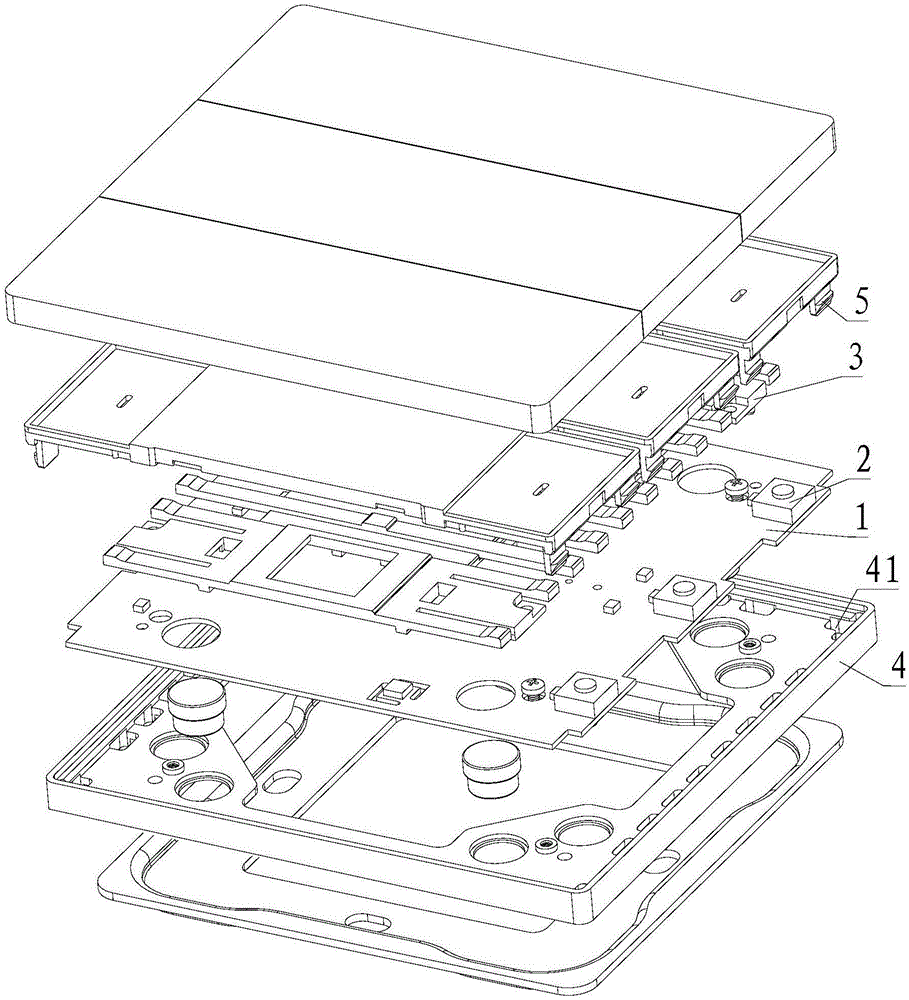

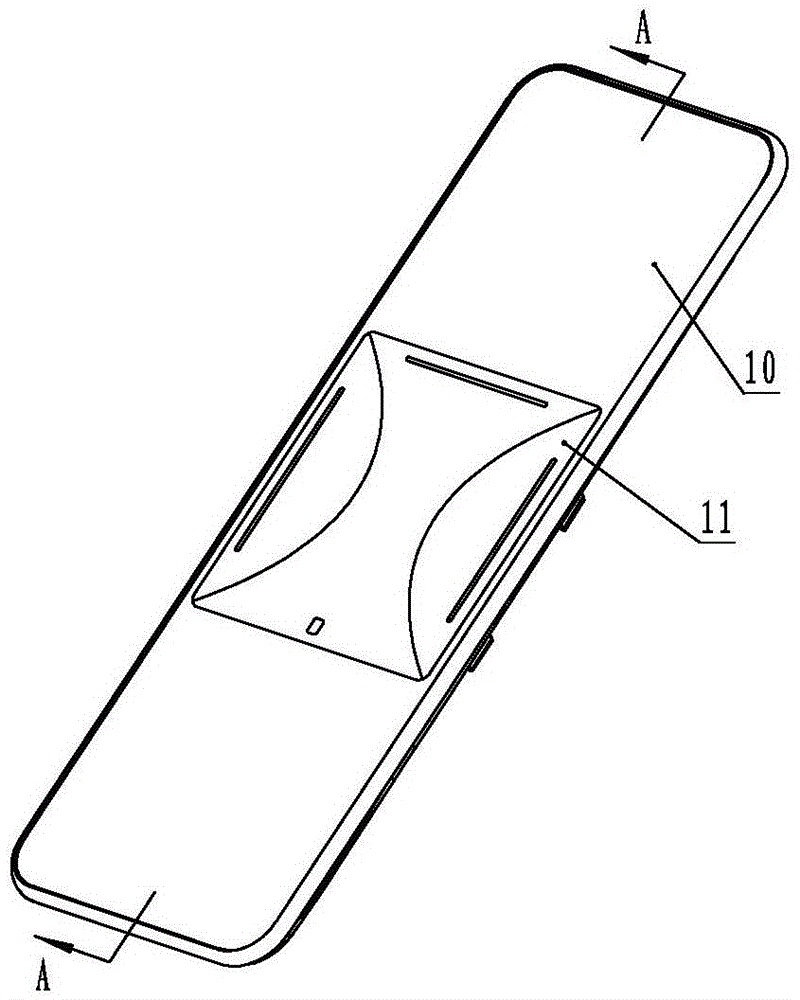

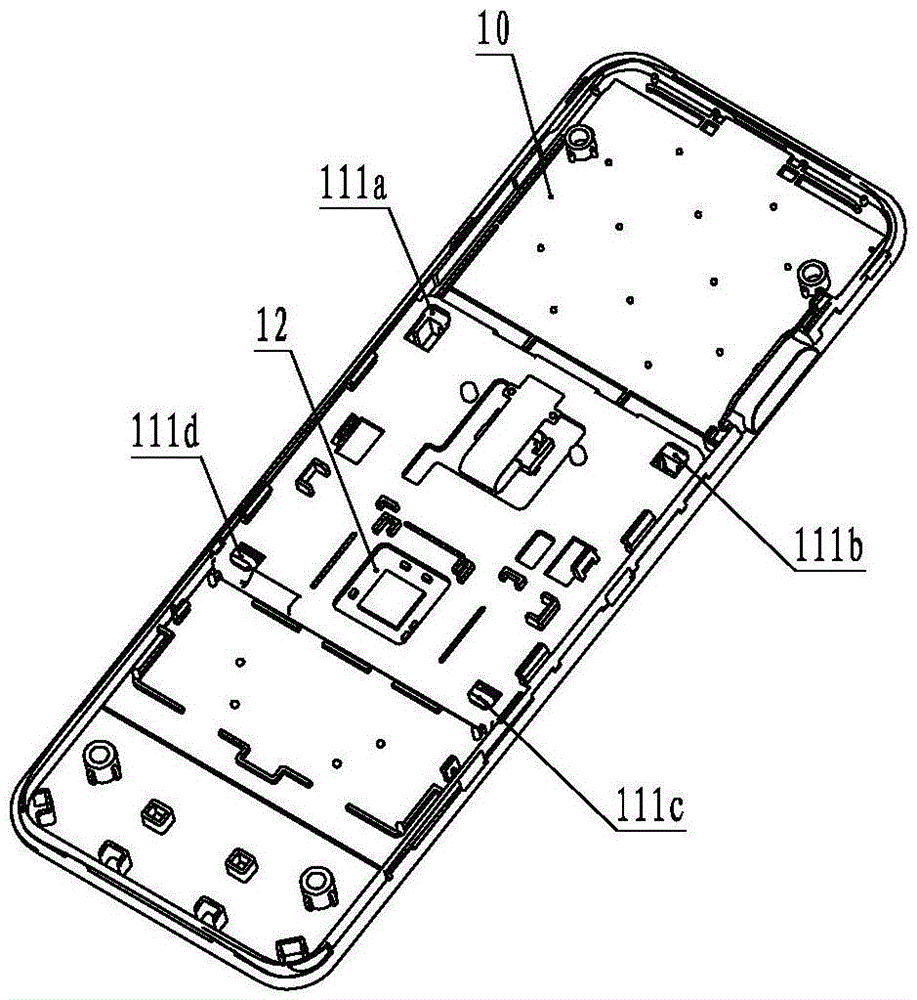

Electronic terminal product touch button structure and remote control

ActiveCN103560034ARealize the pressing functionConsistent feelElectric switchesKey pressingRemote control

The invention belongs to the technical field of buttons, and particularly relates to an electronic terminal product touch button structure. The electronic terminal product touch button structure comprises a touch panel, a PCBA circuit board and a dome button, wherein the touch panel is arranged at the front face of a front shell of an electronic terminal product, and the edge of the touch panel is tightly connected with the front shell; the PCBA circuit board is arranged between the touch panel and the front shell, and one side face of the PCBA circuit board is firmly connected with the touch panel; the dome button is arranged between the PCBA circuit board and the front shell, and the dome button is arranged at the central position of the other side face of the PCBA circuit board, the dome piece of the dome button is in contact with the PCBA circuit board, and a gap where the touch panel and the PCBA circuit board move perpendicular to the front face of the front shell is arranged between the touch panel and the front shell. Due to the fact that the edge of the touch panel is firmly connected with the front face of the front shell, and the dome button is arranged between the PCBA circuit board and the front shell, the touch panel and the PCBA circuit board have a certain movable space relative to the front face of the front shell, pressing on any area of the touch panel can press down the dome button, so that the electronic terminal product touch button structure can be used as a pressing type button to achieve the pressing function.

Owner:QINGDAO GOERTEK

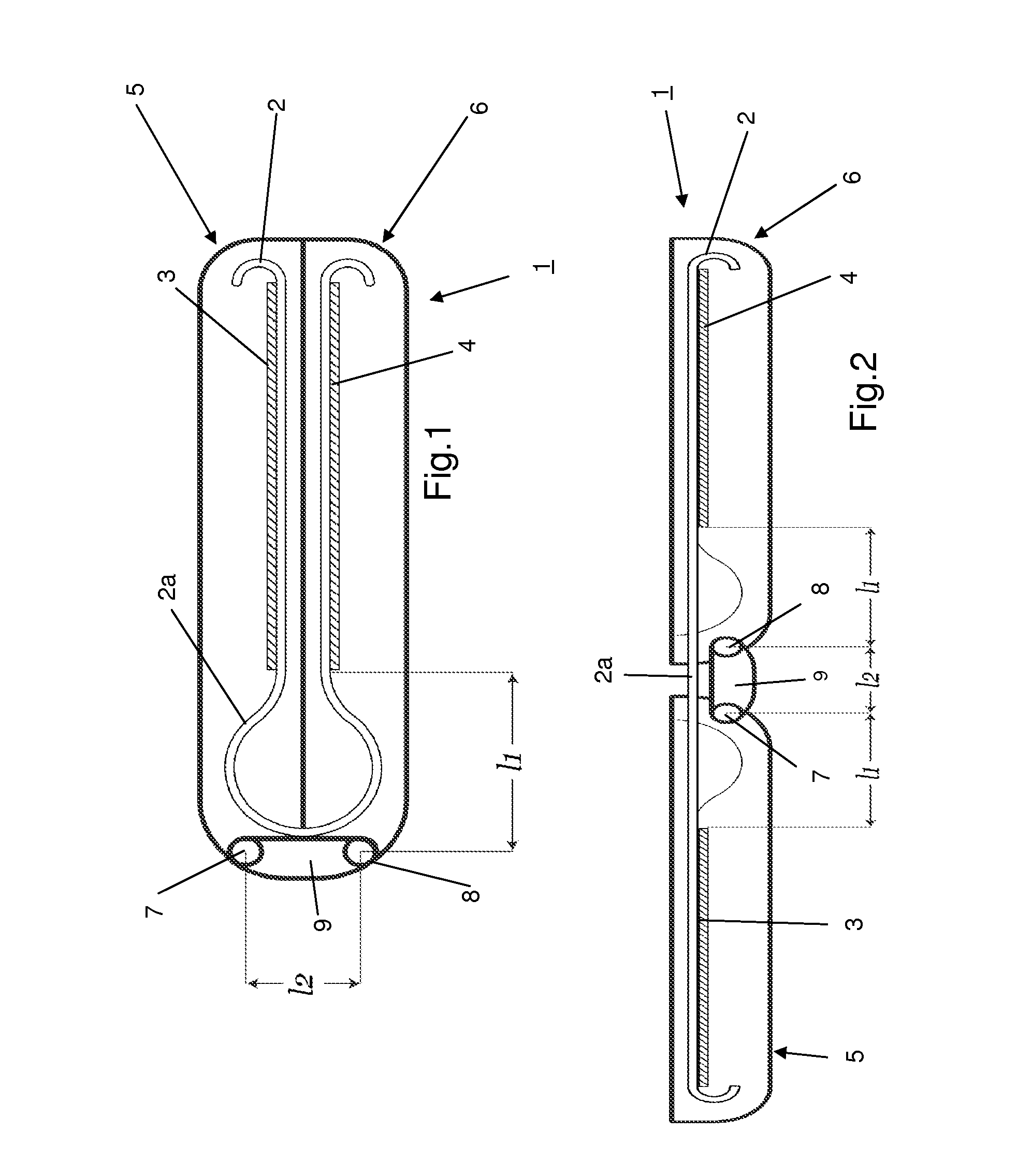

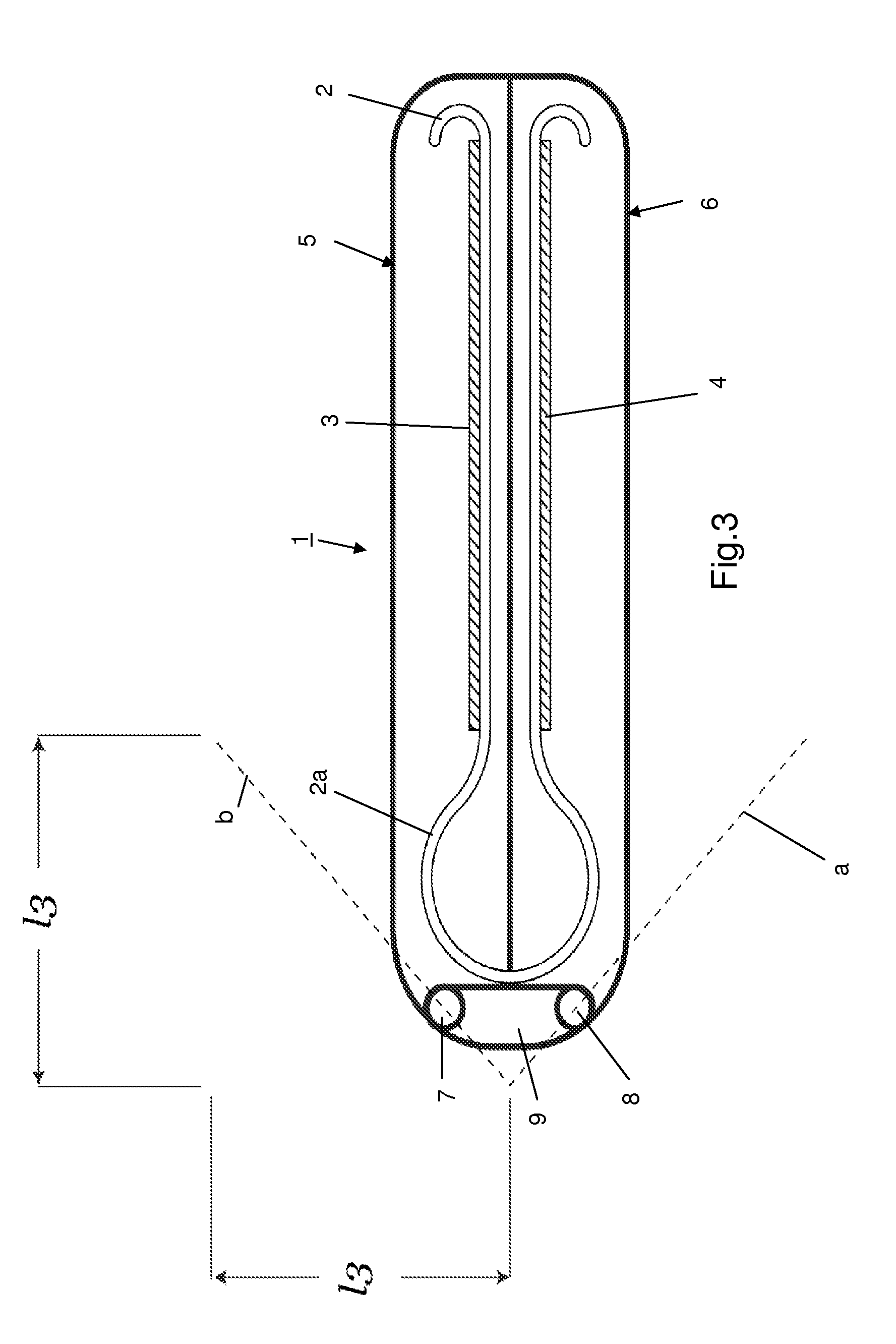

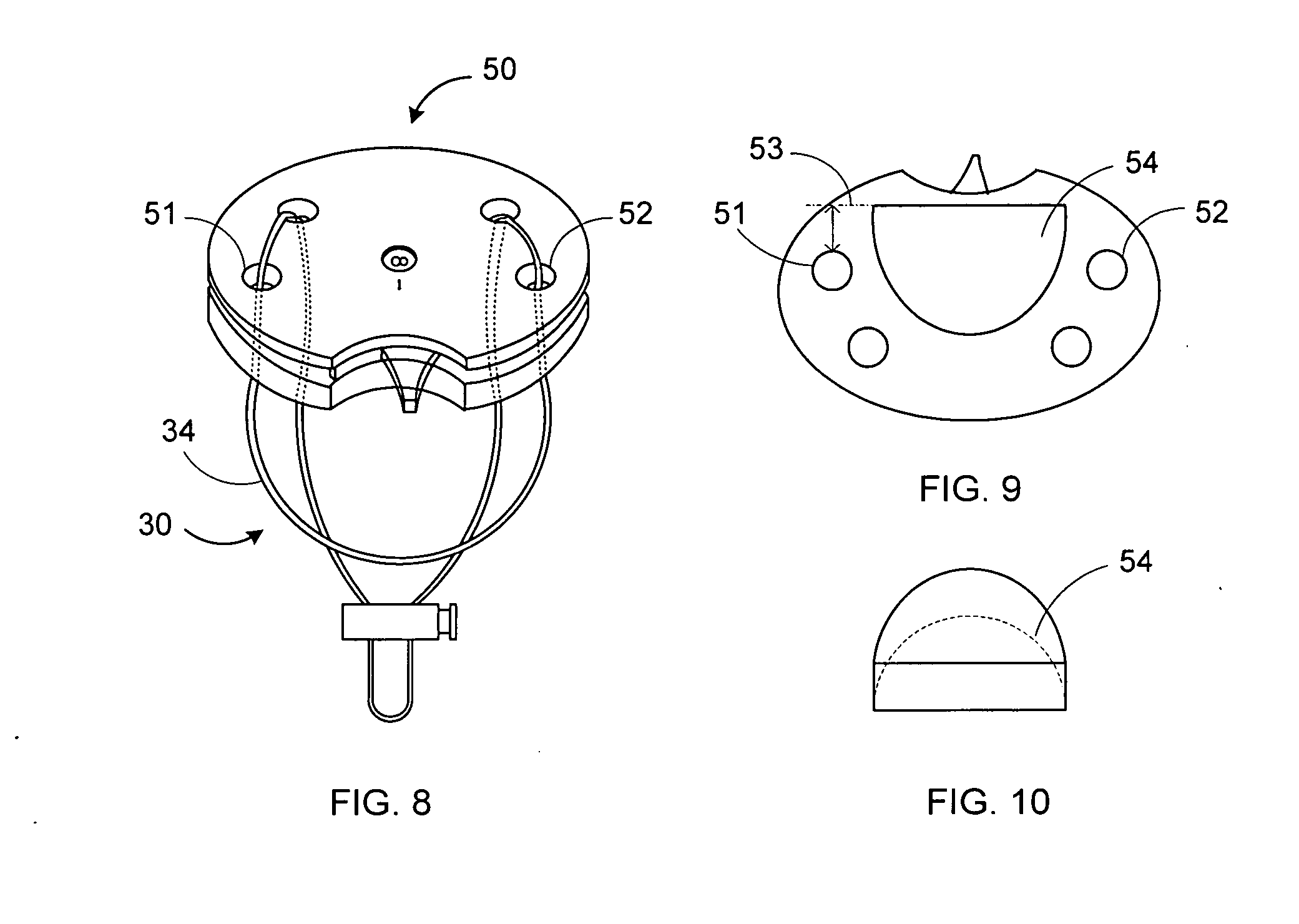

Wrist swim lap counter

InactiveUS20070076529A1Cheap wrist lap counterPrevent wrist lap counters from flippingSwimming detailsElectromechanical unknown time interval measurementGear wheelEngineering

The invention provides a cheap mechanical wrist swim lap counter for counting the number of laps traversed by a swimmer in a swimming pool. The lap counter consists of a front and a rear covers, a finger gear wheel and a pad. The lap counter uses the friction force between surfaces of gear wheel and covers to prevent gear wheel from rotating in swimming, and to provide a consistent feeling when the swimmer dials the gear wheel. The invention also provides a design to prevent lap counter from flipping in swimming.

Owner:LIN FENG

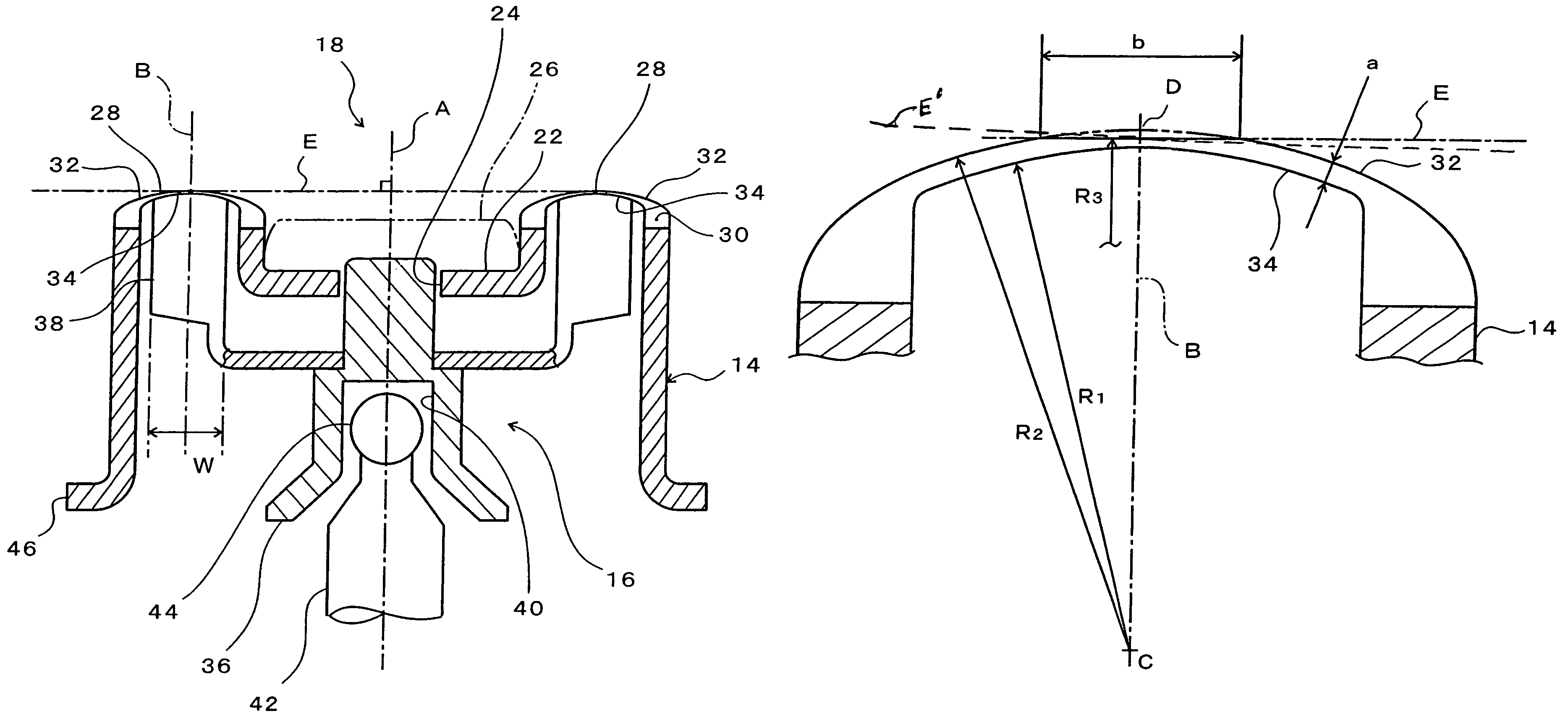

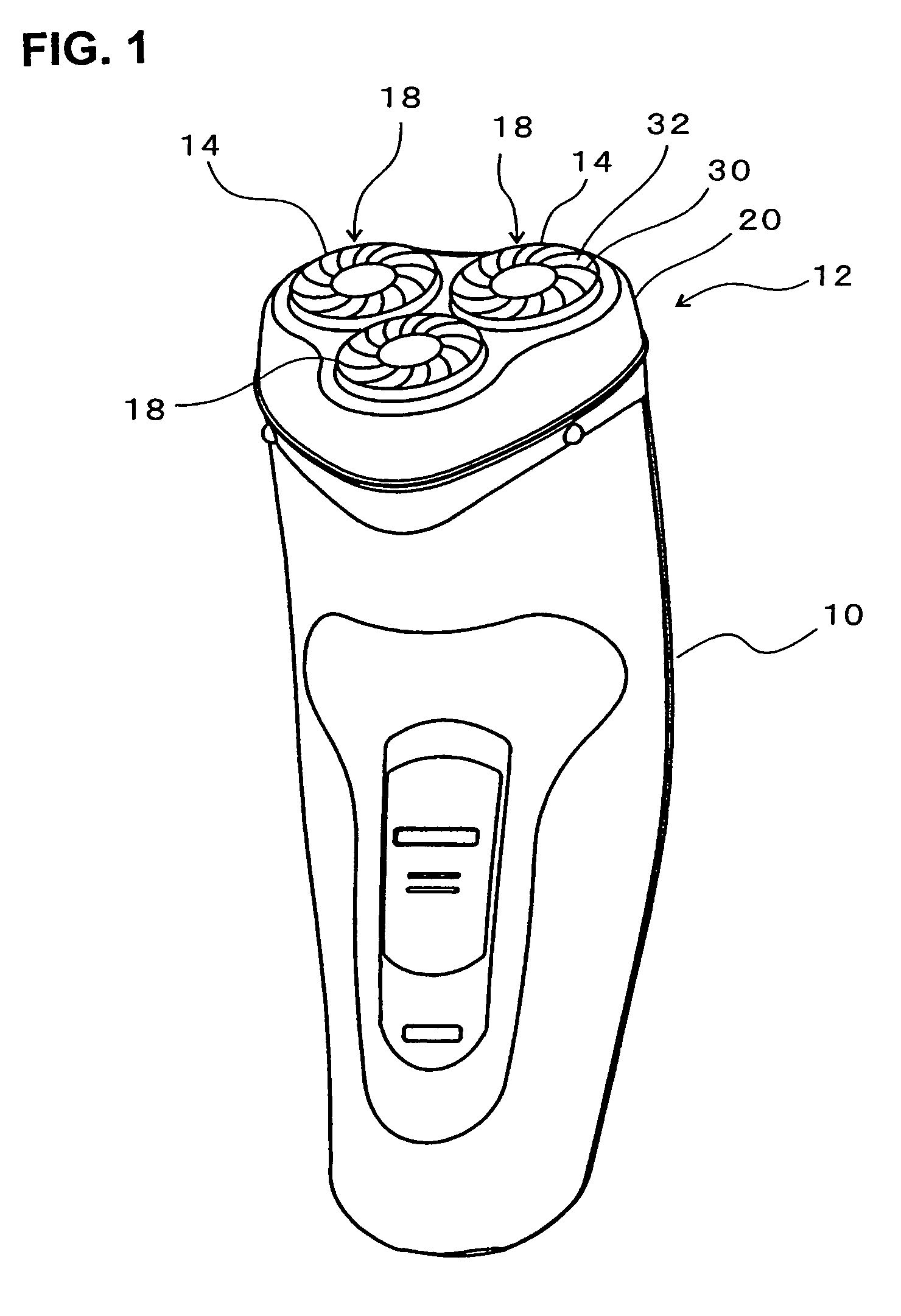

Rotary type electric shaver

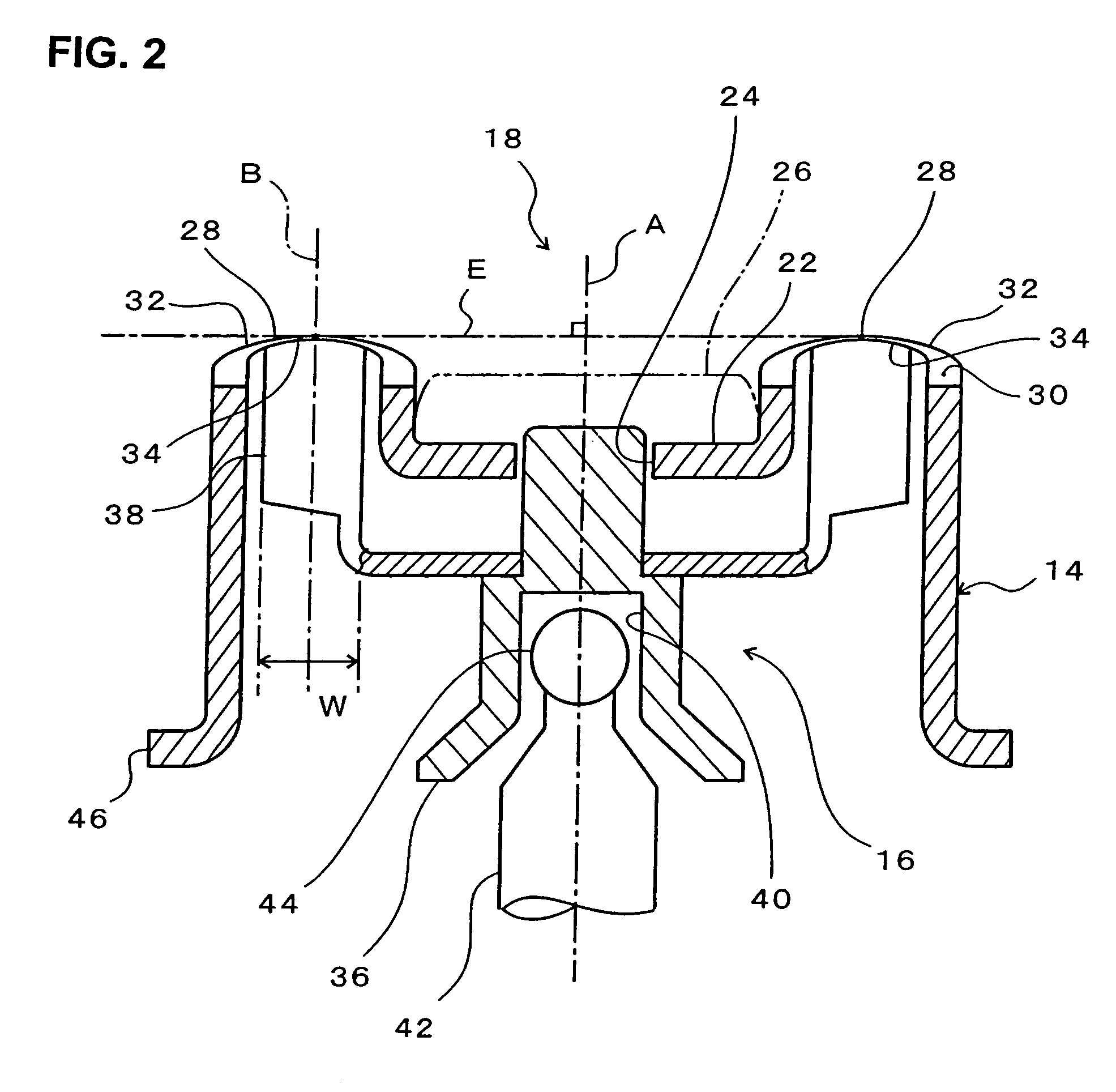

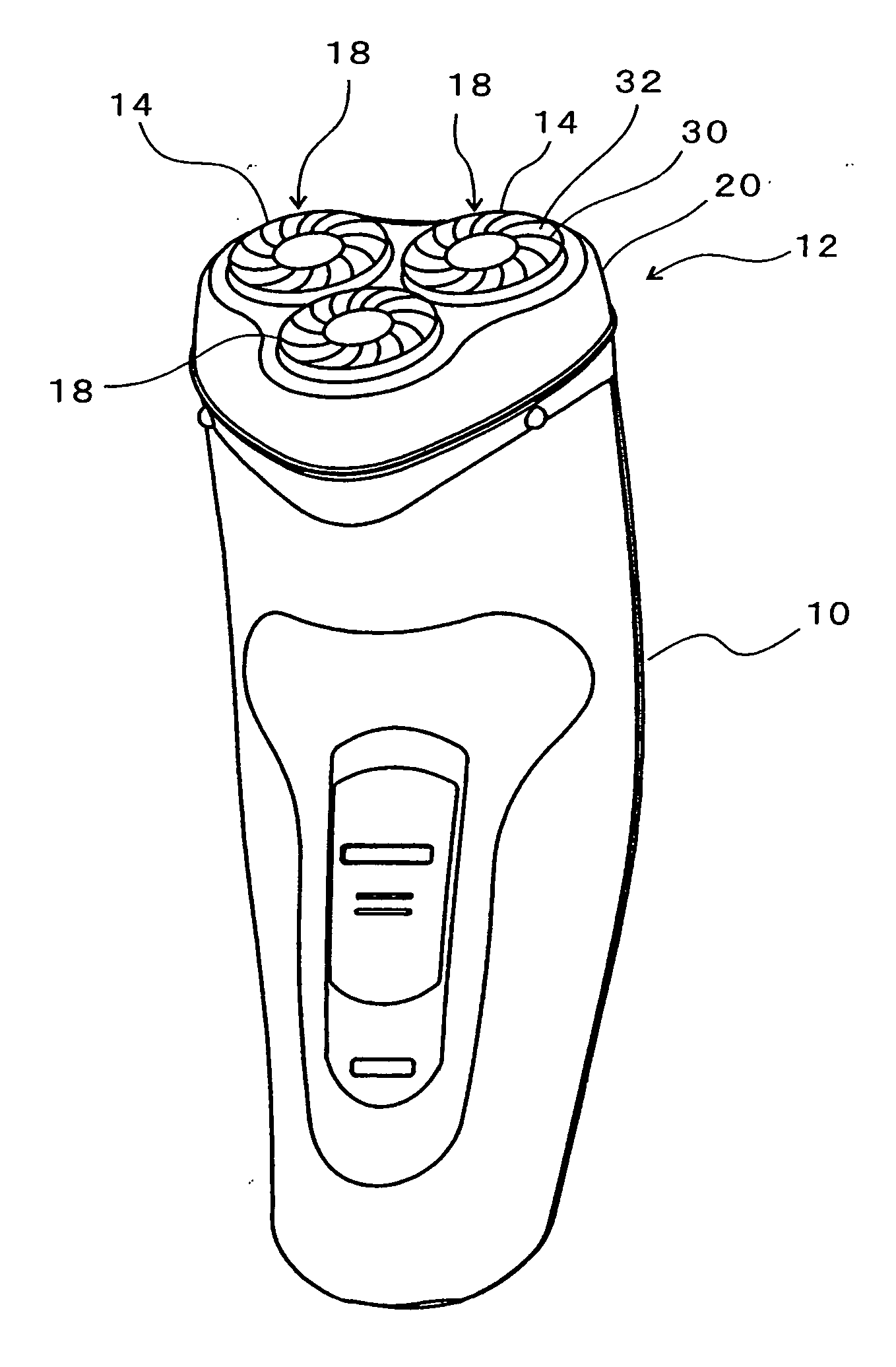

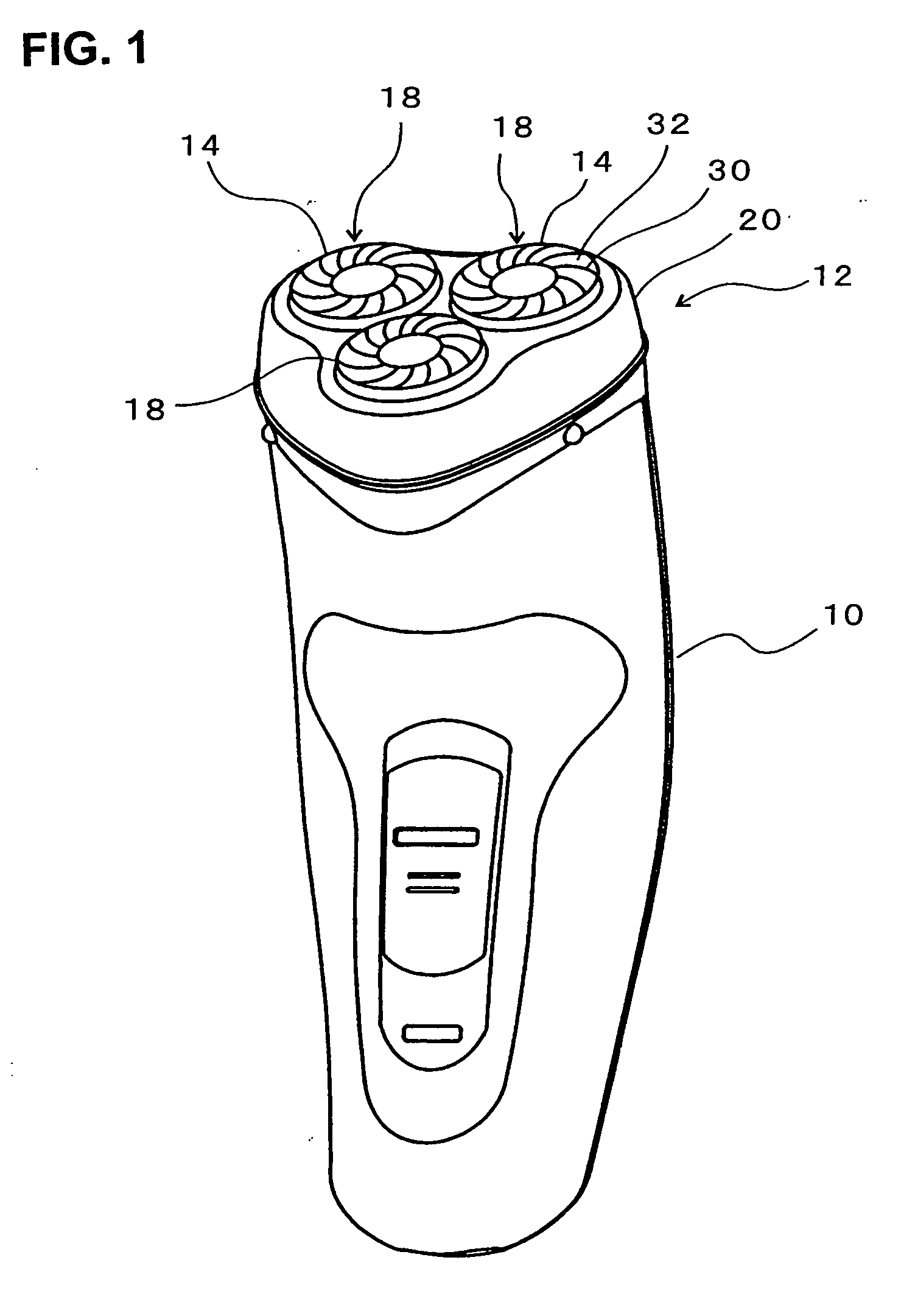

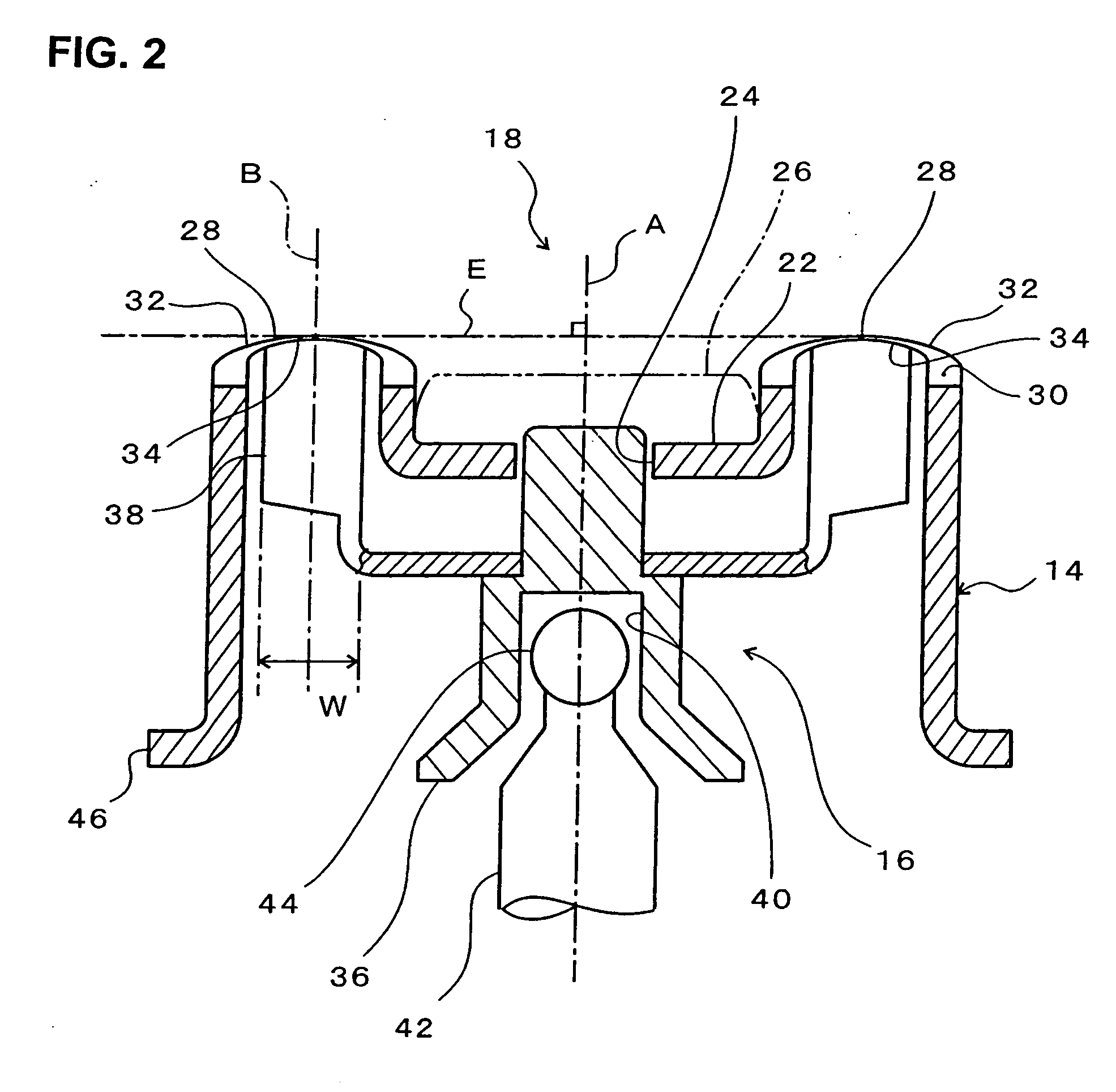

InactiveUS7743507B2Consistent and excellent shavingReduce the amount requiredMetal working apparatusRazor stropCentre of rotation

A rotary type electric shaver with an outer cutter frame provided on a shaver main body. An outer cutter installed in this outer cutter frame and having its shaving surface on the upper surface of a ring-shaped thin layer portion. An inner cutter 16 having a cutter body that rotates and makes sliding contact from below with the lower surface of the outer cutter 14, wherein a thin layer portion 28 is formed in a substantially arc shape that is convex upward in a radial and vertical cross section that includes a center axis line which is the rotational center of the inner cutter. The thickness of the thin layer portion near the apex of the upward convex is smallest at the apex and gradually becomes thicker as distance increases away from the apex.

Owner:IZUMI PROD CO

Rotary type electric shaver

InactiveUS20060179658A1Consistent and excellent shavingReduce the amount requiredMetal working apparatusEngineeringSliding contact

A rotary type electric shaver with an outer cutter frame 20 provided on a shaver main body 10, an outer cutter 14 installed in this outer cutter frame 20 and having its shaving surface on the upper surface of a ring-shaped thin layer portion 28, and an inner cutter 16 having a cutter body 38 that rotates and makes sliding contact from below with the lower surface of the outer cutter 14, wherein a thin layer portion 28 is formed in a substantially arc shape that is convex upward in a radial and vertical cross section that includes a center axis line A which is the rotational center of the inner cutter 16, and the thickness of the thin layer portion near the apex of the upward convex is smallest at the apex and gradually becomes thicker as distance increases away from the apex.

Owner:IZUMI PROD CO

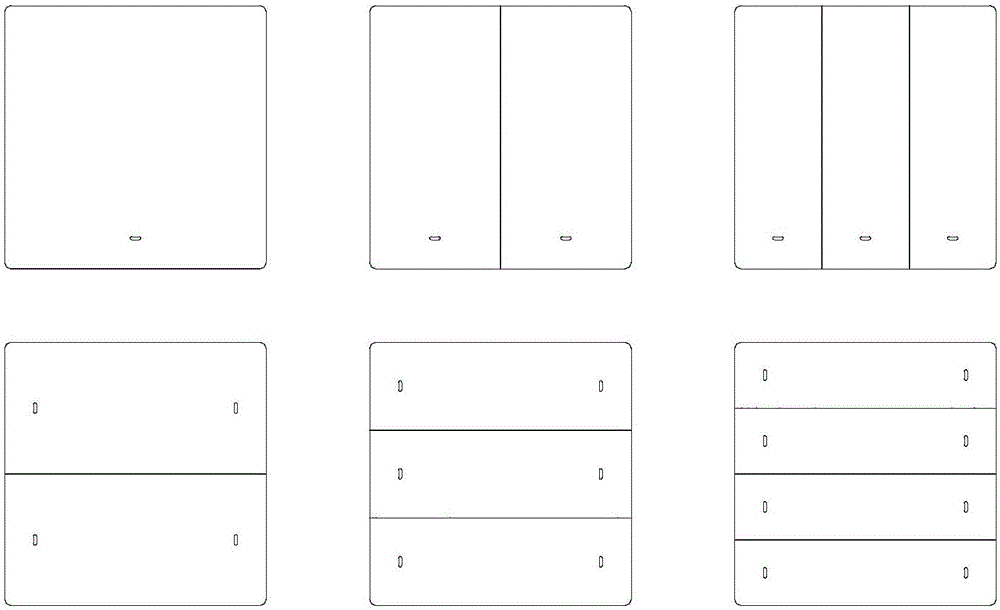

Switch control panel

InactiveCN106847598AEliminate hand feeling errorsConsistent feelElectric switchesTactile feedbackEngineeringElectrical and Electronics engineering

The invention provides a switch control panel. The switch control panel comprises a circuit board and a micro-switch, the micro-switch is fixed on the circuit board, the switch control panel further comprises a support body, the support body is fixed on the circuit board and located at the inner side of the micro-switch, and the height of the upper surface of the end portion of the support body is greater than the height of the micro-switch when the micro-switch is pressed and is smaller than the height of the micro-switch when the micro-switch is lifted, wherein the upper surface of the end portion of the support body faces the micro-switch. The upper surface of the end portion of the support body is located between the lowest position of the micro-switch and the highest position of the micro-switch, the support boy can eliminate feeling difference caused by welding errors of the micro-switch, and therefore the consistency of touch feeling is kept when the switch control panel is in use.

Owner:FUZHOU ONER IND DESIGN CO LTD

Viscose knitted fabric manufacturing method

InactiveCN112011885AReduce consumptionHas antibacterial and deodorizing effectsWeft knittingArtificial filaments from viscosePolyesterYarn

The invention provides a viscose knitted fabric manufacturing method, the manufacturing process is more environmentally friendly, and manufactured fabric is good in bulkiness and softness and quite comfortable. The process comprises the steps of selecting bamboo fibers and wood fibers extracted from wood in a sustainable development forest area, and respectively putting the bamboo fibers and the wood fibers into a digester for cooking and pulping; then sequentially performing washing, performing pulping by a pulping machine, mixing wood dissolving pulp and bamboo dissolving pulp, performing dipping in a dipping barrel filled with alkali liquor, performing squeezing by a squeezer, adding carbon disulfide by a yellowing machine for yellowing, performing grinding, performing filtering, feeding a filtered material into a spinning machine for spinning, performing drafting, refining and desulfurizing, and performing drying to obtain viscose fibers; blending the obtained viscose fibers and regenerated polyester into yarns, wherein the weight ratio of the viscose fibers to the regenerated polyester fibers is 1:(0.6-0.9); and forming a blank by weaving on a circular knitting machine, and performing cylinder matching, end stitching, dyeing and rinsing, dehydration, slitting, high setting, dyeing, dehydration, cloth tidying, baking setting, napping, finished product setting and packaging,so as to obtain the finished fabric.

Owner:WUXI HANUO TEXTILE TECH

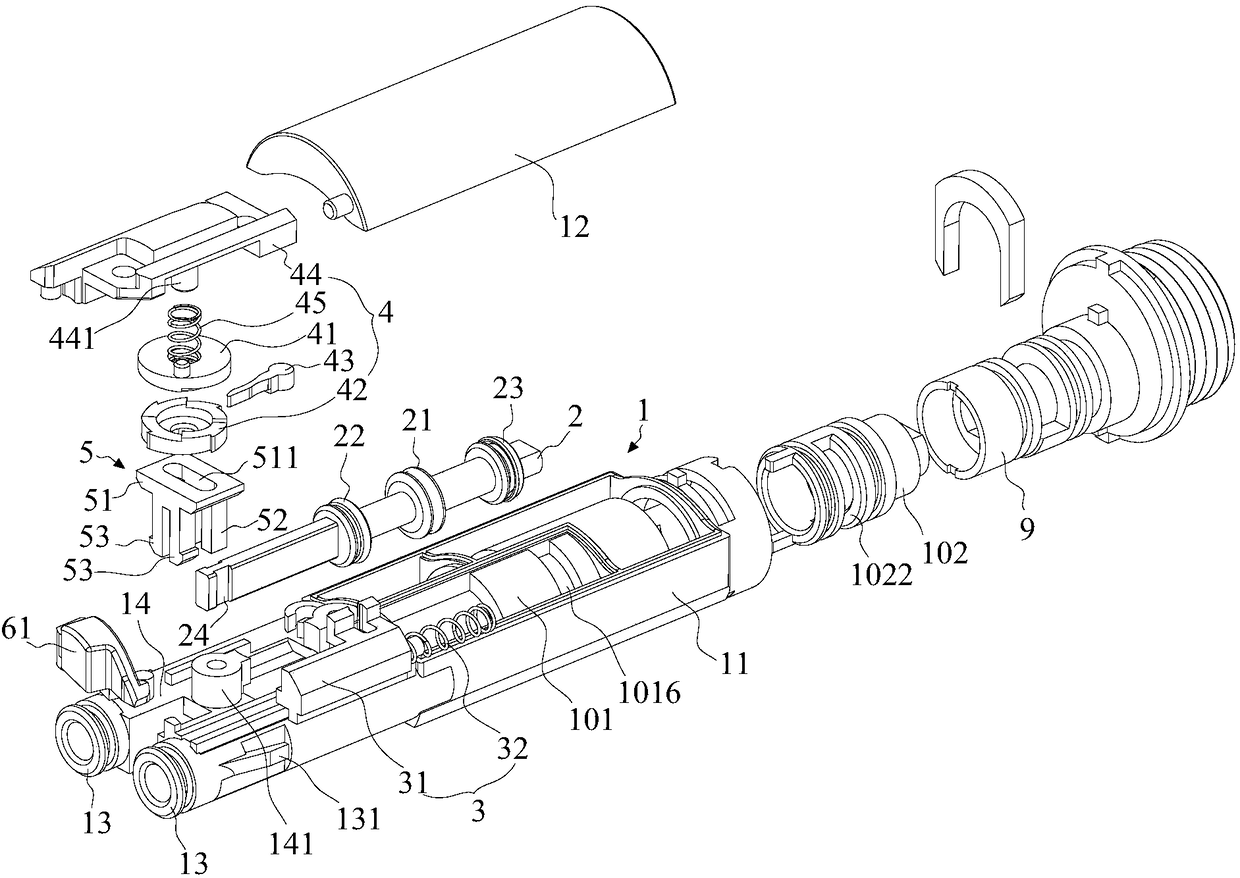

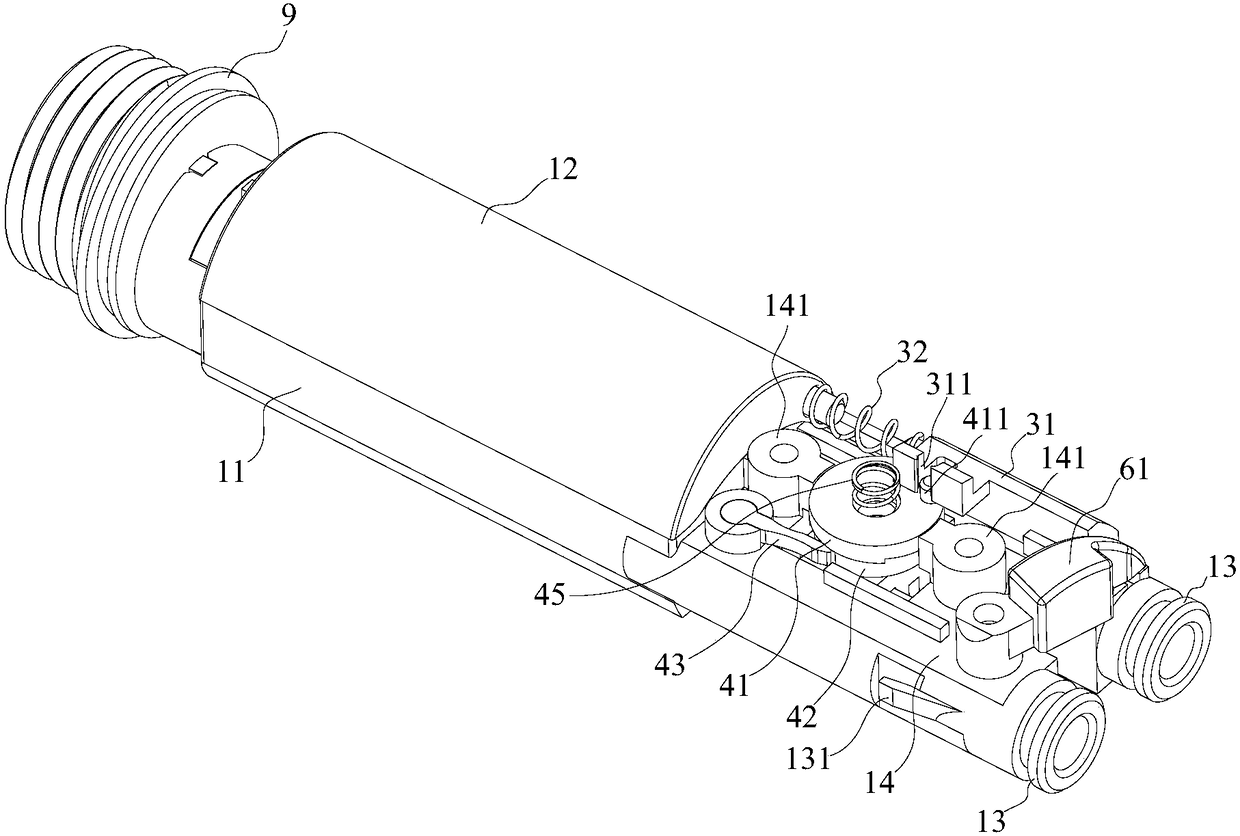

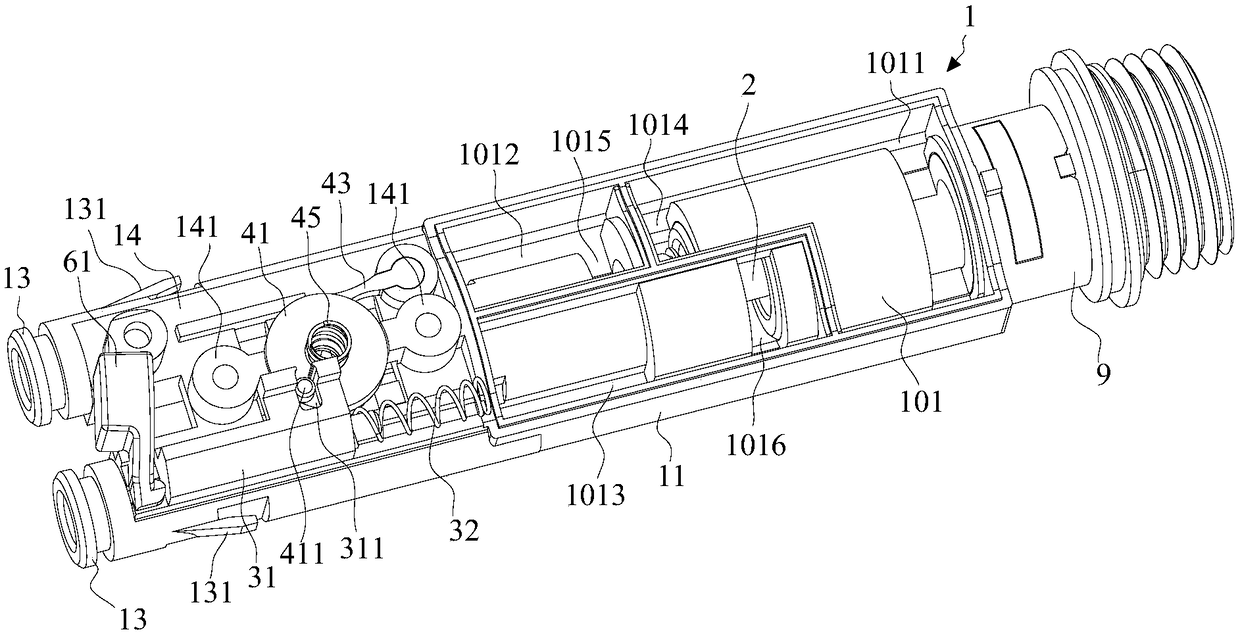

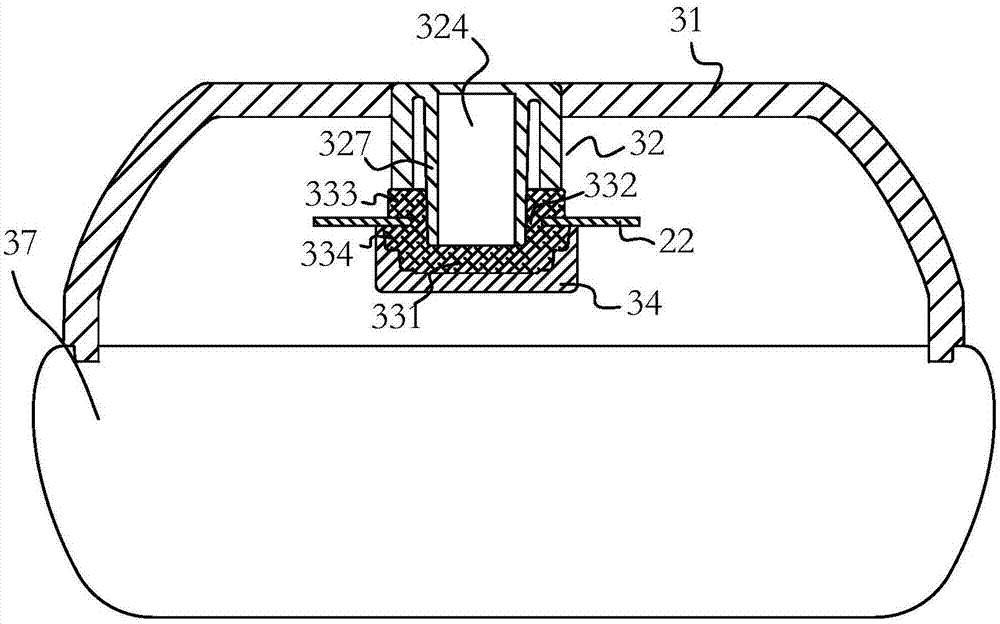

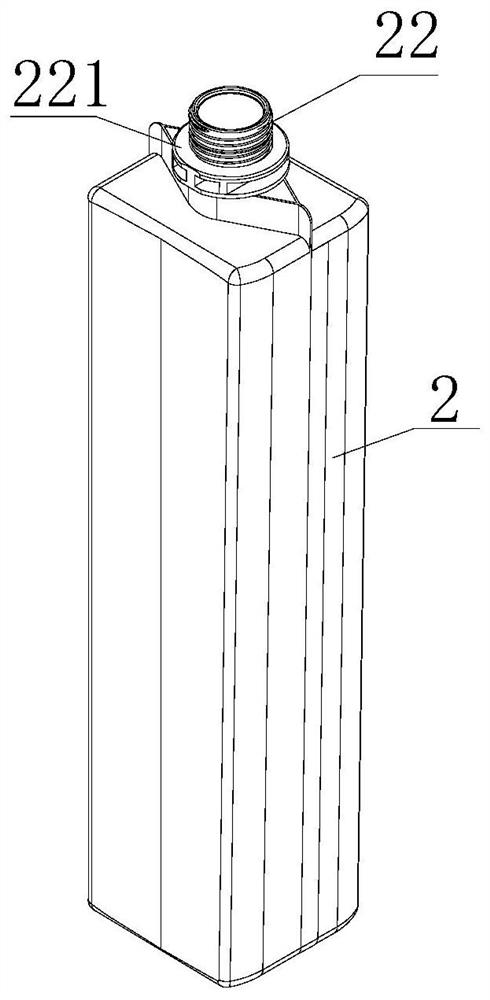

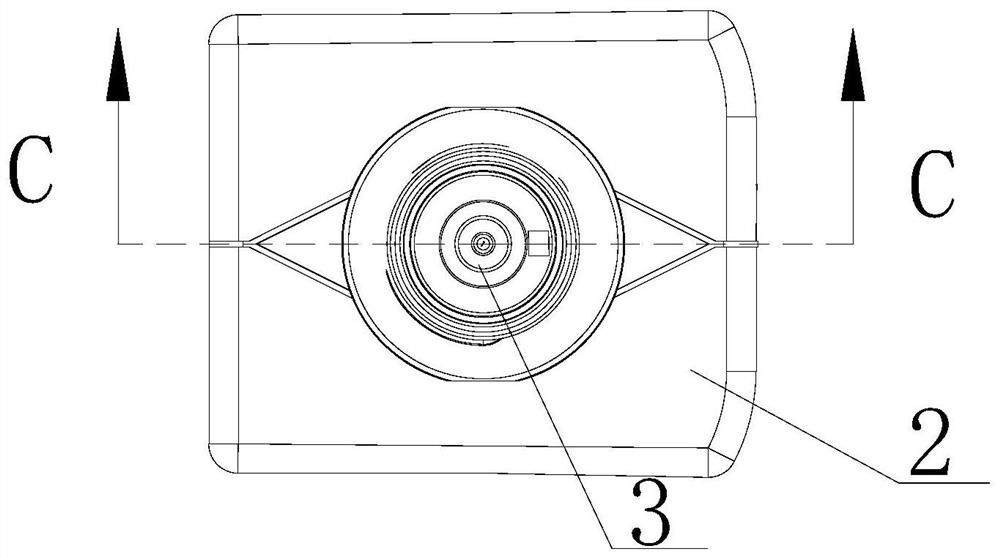

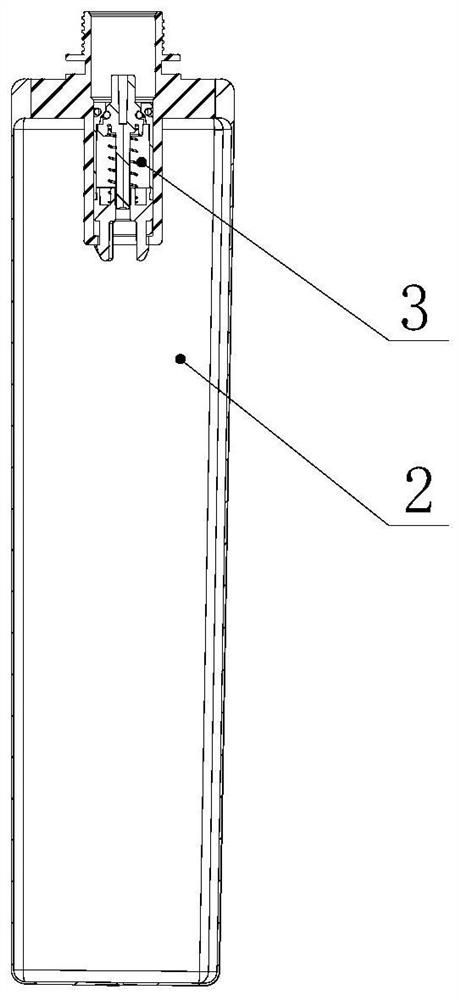

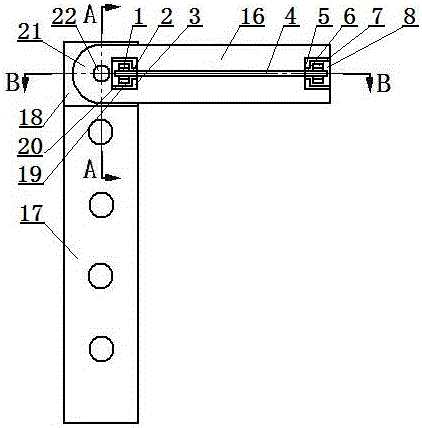

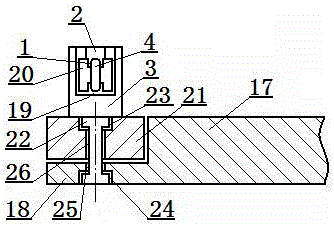

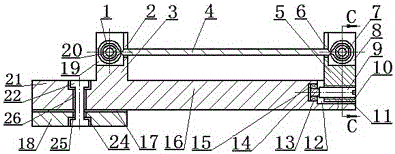

Thin shower and water channel switching device

PendingCN108273679ASmall sizeNo increase in sizeOperating means/releasing devices for valvesSpray nozzlesWater channelReciprocating motion

The invention provides a thin shower and a water channel switching device. The water channel switching device comprises a body, a switching shaft and a driving mechanism. The body is provided with a hollow portion, a water inlet end and a water outlet end. At least two water channels communicating with the hollow portion are arranged at the water outlet end. The switching shaft is arranged in thebody. The switching shaft comprises a water dividing section located in the hollow portion, and a traction section extending out of the water outlet end. The driving mechanism is arranged outside thebody and used for driving the switching shaft to carry out reciprocating motion in the axial direction, so that the switching shaft carries out switching between at least two switching positions, wherein at least one water channel is opened corresponding to each switching position. The driving mechanism comprises a driving part and a one-way rotation device, and the driving part and the switchingshaft are connected through the one-way rotation device.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

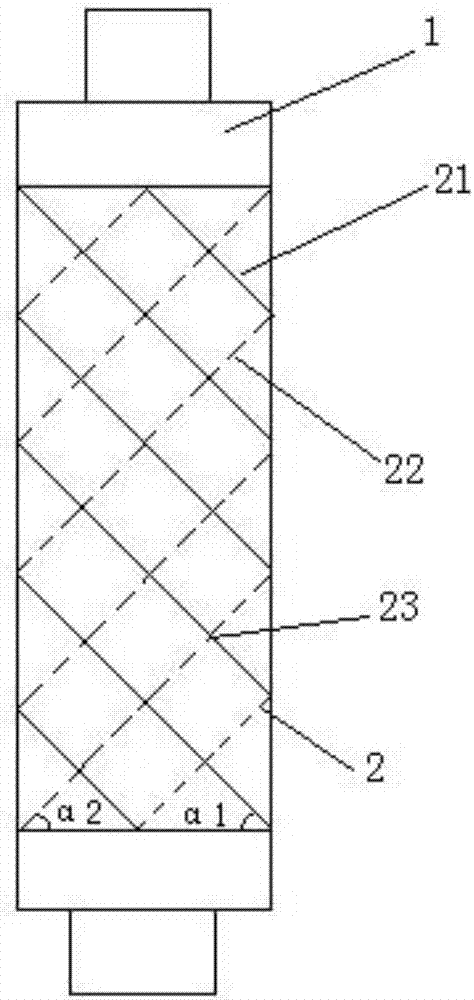

Hot-rolling device for producing three-dimensional roll compacting composite material

The invention discloses a hot-rolling device for producing a three-dimensional roll compacting composite material. The hot-rolling device comprises a hot rolling pressure roller, the surface of the hot rolling pressure roller is covered with a pattern layer, several groups of first helical lines which helically protrude in the anti-clockwise direction and surround the pressure roller and several groups of second helical lines which helically protrude in the clockwise direction and reversely surround the pressure roller intersect with one another to form the pattern layer, the included angle [alpha]1 between each first helical line and the horizontal direction ranges from 0 degree to 90 degrees, the included angle [alpha]2 between each second helical line and the horizontal direction ranges from 0 degree to 90 degrees, intersection points of the first helical lines and the second helical lines are embossing points. On the basis of the existing hot rolling device, the pattern of the pressure roller is changed. Several sets of helical projections which are in inverse surrounding directions intersect with one another to form point pressure. In this way, the rolled non-woven fabric has a three-dimensional effect, the front and back sides have the same smoothness and consistent pattern and hand feeling, and the hot-rolling device can be better applied to the industry demand.

Owner:JIANGSU LIYANG NEW MATERIALS CO LTD

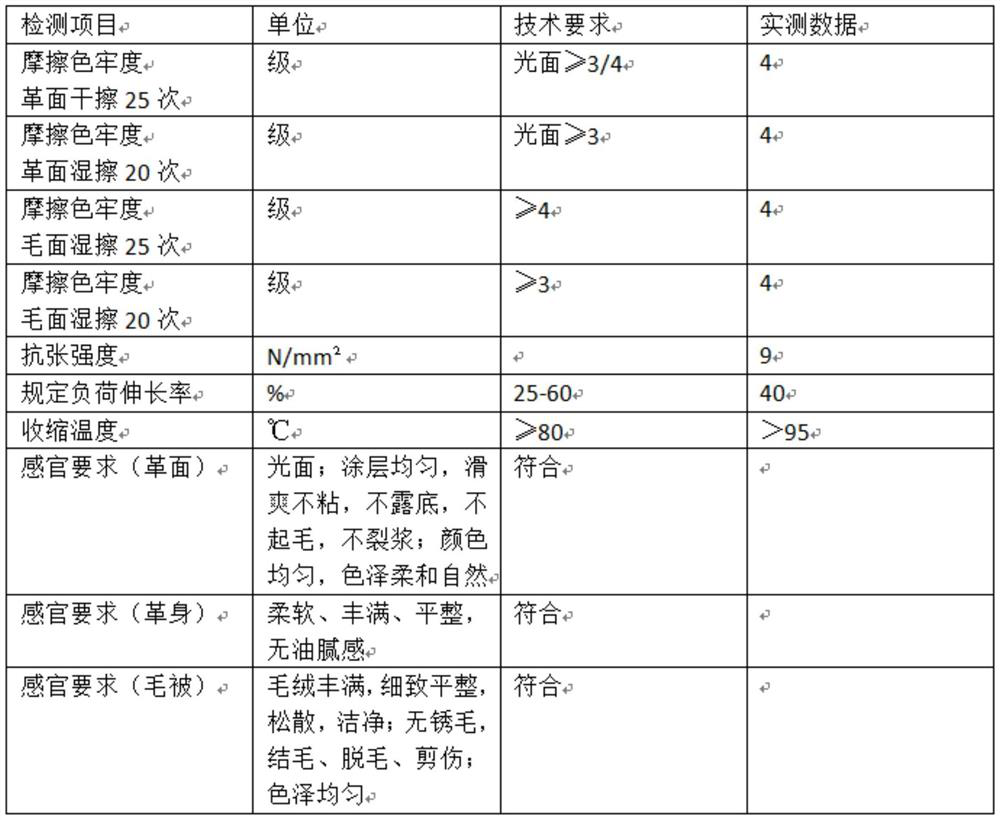

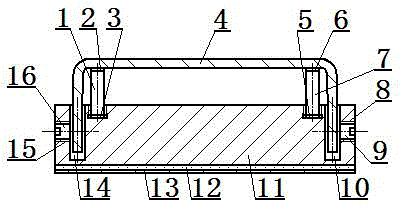

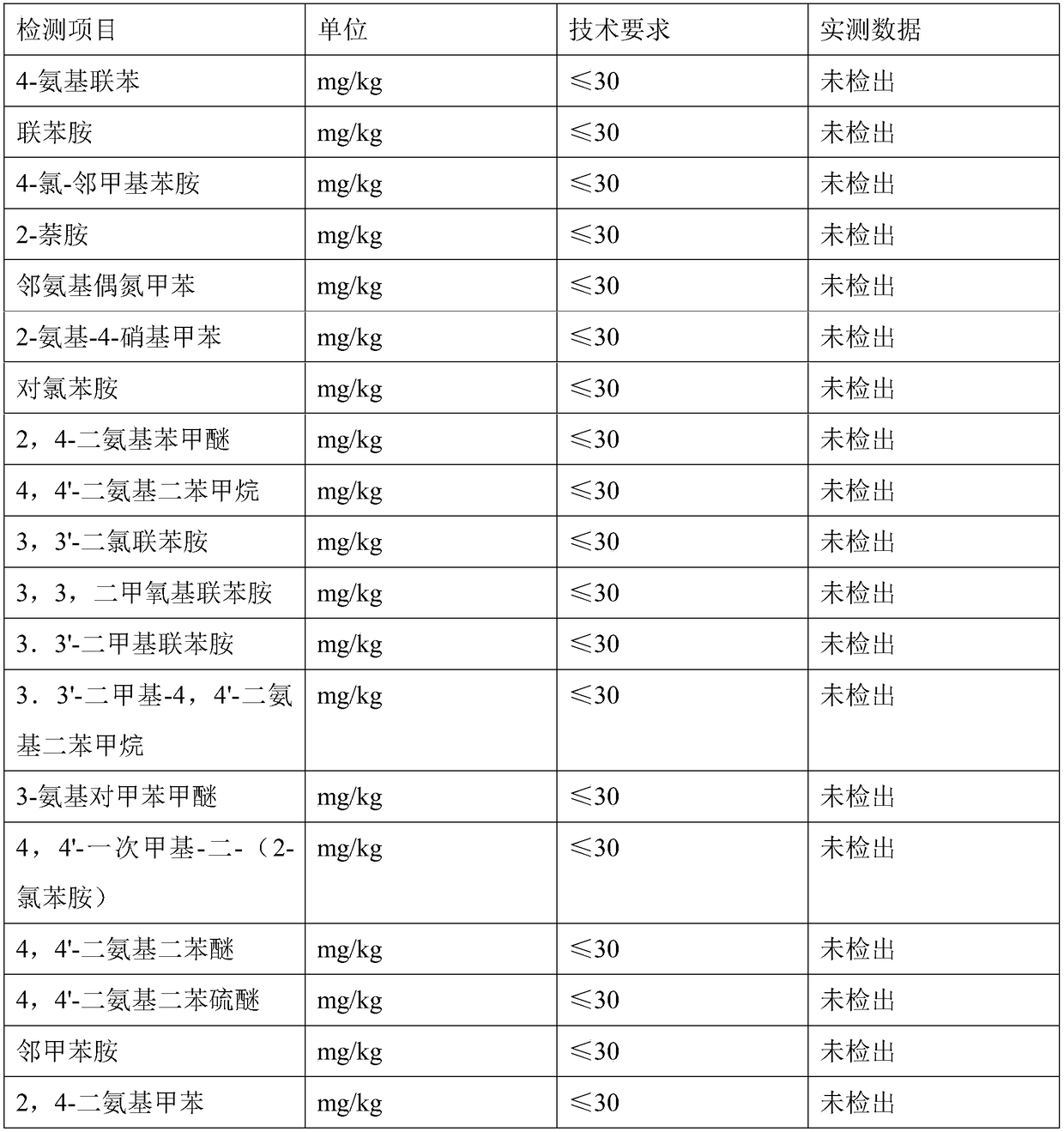

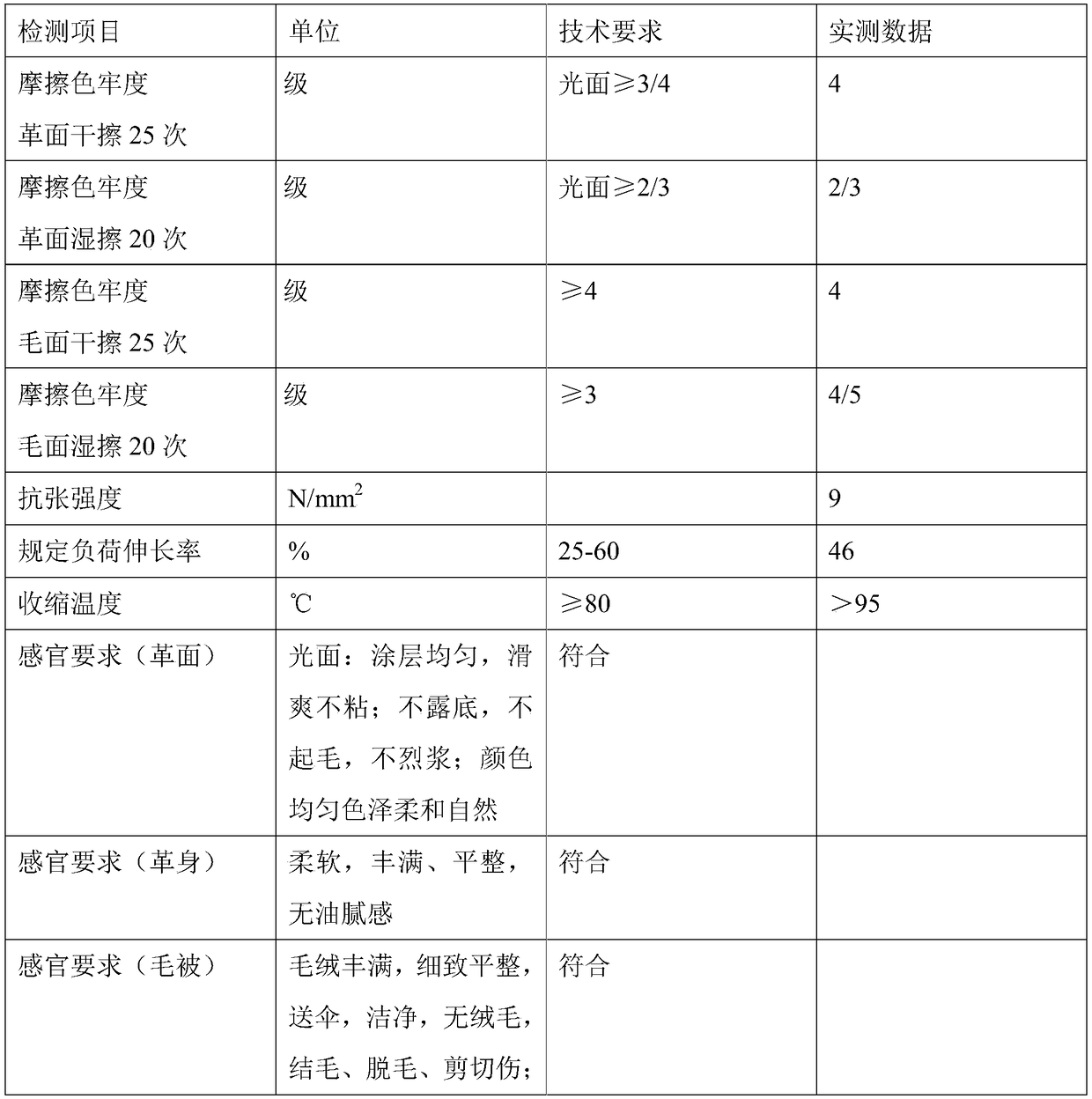

Preparation of high-grade sheep clothing wool leather with chrome-free polymetallic tanning agent

ActiveCN109439810BReduce COD contentEasy to handleTanning treatmentPre-tanning chemical treatmentOrganic acidPolyol

The invention relates to the technical field of wool leather processing, in particular to a process for preparing high-grade sheep clothing wool leather with a chromium-free multi-metal tanning agent. , tanning, wet grinding, retanning, neutralization, fatliquoring, dry finishing, and finished products. Among them, weak organic acids such as polyol acid and polycarboxylic acid are used in softening pickling to carry out pickling and gentle softening at the same time. The invention is a processing technology of white fur leather. The finished product finally has a plump and soft hand feel, white fur and leather board color, short and fine fleece on the board surface, and is resistant to washing and yellowing. It is especially suitable for making high-grade natural and light-colored fur leather products. . This technology does not use chrome tanning agent, can avoid the pollution of three wastes containing chromium, and eliminate the harm of hexavalent chromium; it can effectively reduce COD in wastewater during the tanning process, and at the same time control volatile organic compounds in fur leather.

Owner:浙江中辉裘革科技有限公司

Electric bass finger rest with string

InactiveCN105913833AConsistent feelImprove comfortElectrophonic musical instrumentsAdhesiveEngineering

Owner:罗叶叶

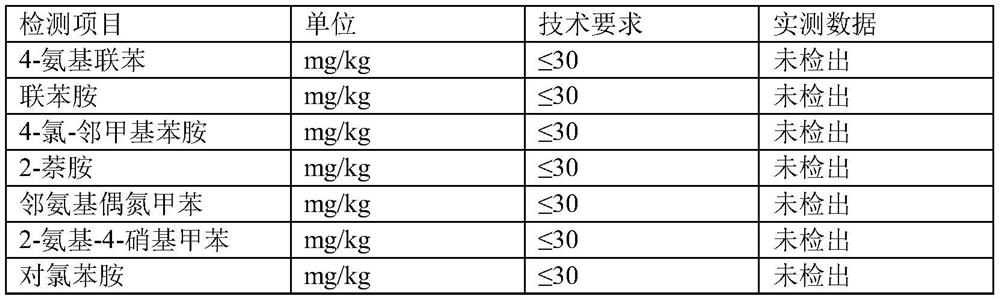

Process for preparing high-end marten coat leather through chromium-free multi-metal tanning agent

The invention relates to the technical field of marten coat leather processing processes, in particular to a process for preparing a high-end marten coat leather through a chromium-free multi-metal tanning agent. The process comprises the following steps of soaking in water, removing meat, degreasing, picking for softening, tanning, water milling, re-tanning, neutralizing for softening, greasing,dry finishing, and obtaining the finished product. According to the marten coat leather processing process provided by the invention, the finally obtained finished product is full and soft in hand feeling, white in leather board, washable and anti-yellowing, and the process is particularly suitable for manufacturing high-end marten coats in natural color and light color. According to the technology, no conventional aluminum tanning agent is used, the shrinkage temperature after tanning can reach to more than 90 DEG C, and meanwhile, the water resistance of a leather sheet is effectively improved; no aldehyde tanning agent is contained, so that no free formaldehyde is produced; no oil tanning is required, so that the production period is shortened, and meanwhile, the production cost can befurther reduced; and no chromium tanning agent is used, so that the pollution of chromium-containing three wastes can be avoided, and the harm of hexavalent chromium is avoided.

Owner:浙江中辉裘革科技有限公司

Digital paint printing technology

The invention discloses a digital paint printing technology, which is characterized by comprising following steps: (1) pretreatment: subjecting semi-finished cloth to a online counterpoint spray printing pretreatment: spraying a pretreatment liquid on cloth according to the shade of a pattern in a counterpoint spray printing mode; (2) drying: drying the preprocessed cloth; (3) spray printing a paint: spray printing a paint on the surface of dried cloth; (4) post treatment: adopting a wet counterpoint spray printing post treatment liquid, and spray printing the post treatment liquid on the cloth according to the shade of the pattern; (5) drying and baking: baking the cloth for 3 to 5 minutes at a temperature of 150 to 170 DEG C by a drying-baking integrated machine; and (6) moulding and stretching: softly stretching the cloth by a moulding machine.

Owner:广东希望高科数字技术有限公司

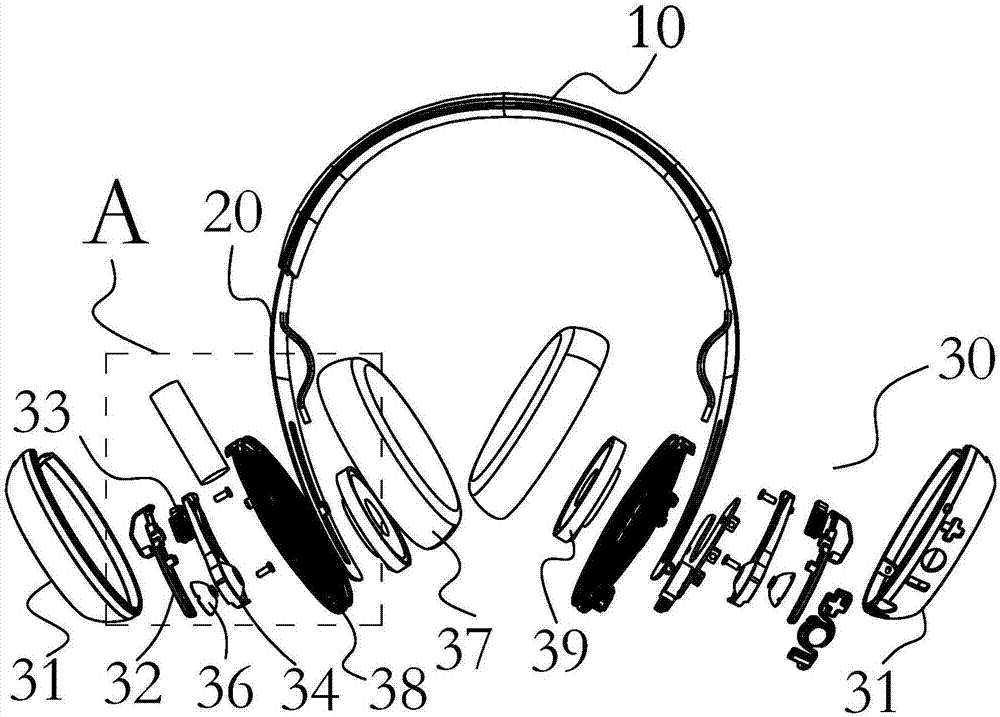

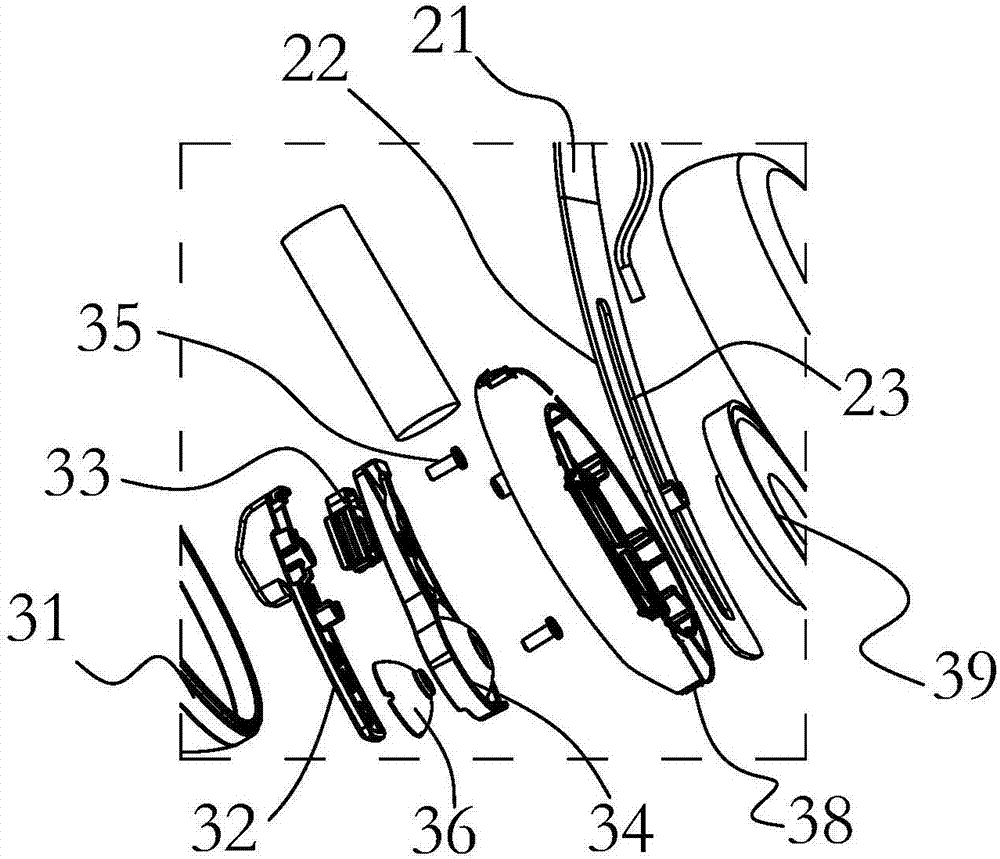

Head-mounted earphone having slide mechanisms

Owner:深圳乐扬电线电器有限公司

Novel soft bag structure

The invention provides a novel soft bag structure. The novel soft bag structure comprises a soft bag and a one-way valve; one end of the soft bag is provided with a liquid outlet end; the one-way valve is arranged in the liquid outlet end; the novel soft bag structure further comprises a shell and a connector; a containing cavity is formed in the shell; one end of the containing cavity is providedwith an opening allowing the soft bag to be placed in; the liquid outlet end of the soft bag is detachably connected with one end of the connector; the connector is detachably connected with the opening end of the shell; and the soft bag is placed in a chamber formed by the shell and the connector. A drawer type soft bag can be directly applied to a washing machine by adopting the soft bag and the one-way valve, is convenient to use and does not occupy external space. As the one-way valve is arranged in the soft bag, no liquid flows out even if the soft bag is inverted after being taken out,and a user does not need to worry about outflow of liquid in a detergent bag. By additionally arranging the shell and the connector, the detergent bag can be kept consistent with a traditional detergent box in appearance, it is guaranteed that a user has a consistent hand feeling of fetching and placing the detergent bag, only the soft bag and the one-way valve are consumables, other components can be recycled, and cost is greatly reduced.

Owner:HANGZHOU KAMBAYASHI ELECTRONICS

A kind of bovine hair fiber for wig and preparation method thereof

ActiveCN111455657BHave physical strengthHigh degree of simulationWigsAnimal fibresBiotechnologyFiber

The invention discloses a method for preparing cow hair fibers for wigs, which includes the steps of oxidizing scales, ammonia hydrolysis, sodium hydroxide hydrolysis and rinsing. The inner cortex of the fibers remained intact. The invention only uses pure natural cow hair as raw material, is non-toxic and non-irritating to the scalp, and meets environmental protection requirements. The thickness, density, color, and feel are consistent with human hair, with good mechanical strength and durability, which is of great significance for improving the quality of wig products and promoting the development and upgrading of the hair product industry.

Owner:邵阳美丽来发制品有限公司

An electronic terminal product touch button structure and remote control

ActiveCN103560034BRealize the pressing functionConsistent feelElectric switchesKey pressingRemote control

The invention belongs to the technical field of buttons, and particularly relates to an electronic terminal product touch button structure. The electronic terminal product touch button structure comprises a touch panel, a PCBA circuit board and a dome button, wherein the touch panel is arranged at the front face of a front shell of an electronic terminal product, and the edge of the touch panel is tightly connected with the front shell; the PCBA circuit board is arranged between the touch panel and the front shell, and one side face of the PCBA circuit board is firmly connected with the touch panel; the dome button is arranged between the PCBA circuit board and the front shell, and the dome button is arranged at the central position of the other side face of the PCBA circuit board, the dome piece of the dome button is in contact with the PCBA circuit board, and a gap where the touch panel and the PCBA circuit board move perpendicular to the front face of the front shell is arranged between the touch panel and the front shell. Due to the fact that the edge of the touch panel is firmly connected with the front face of the front shell, and the dome button is arranged between the PCBA circuit board and the front shell, the touch panel and the PCBA circuit board have a certain movable space relative to the front face of the front shell, pressing on any area of the touch panel can press down the dome button, so that the electronic terminal product touch button structure can be used as a pressing type button to achieve the pressing function.

Owner:QINGDAO GOERTEK

A kind of nano silicon dioxide with controllable particle size and preparation method thereof

ActiveCN103911022BConcentrated particle size distributionThe proportion of large particles is reducedPigment treatment with organosilicon compoundsPigment physical treatmentMasterbatchSodium metasilicate

Owner:FUJIAN SHUNCHANG XINHE NANO SILICON IND

Electric bass pickup provided with finger rest with strings

InactiveCN105957512AAchieve the perfect combinationImprove comfortElectrophonic musical instrumentsTongue and grooveEngineering

The invention discloses an electric bass pickup provided with a finger rest with strings. The pickup set on the pickup is covered on the boss near the end of the bass string; the upper left end of the finger rest is provided with a left protrusion, and the upper right end is provided with a right protrusion; the tenon at the lower end of the right protrusion and the tenon at the upper right end of the finger rest Mortise and tenon joint; there is a threaded hole in the center of the right end of the tenon, and there is a headless hexagon socket bolt in the threaded hole, and a cylinder is provided at the left end of the headless hexagon socket bolt protruding left from the threaded hole; Round concave hole three, the outer diameter of the bearing is in tight contact with the inner diameter of the round concave hole three, and the inner diameter is in tight contact with the outer diameter of the cylinder; The string head and the right string head are fastened respectively in the left square groove and the right square groove. The invention not only realizes the perfect combination of the finger rest and the pickup, but also makes the hand feeling completely consistent when picking the strings, and obviously improves the comfort of the hand feeling when picking the bass strings.

Owner:罗叶叶

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com