Hot-rolling device for producing three-dimensional roll compacting composite material

A composite material, three-dimensional technology, used in textiles, papermaking, non-woven fabrics, etc., can solve the problems of different temperatures, smoothness on both sides of the cloth, different hand feel, and different forces on non-woven fabrics, and achieve the same pattern and feel. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

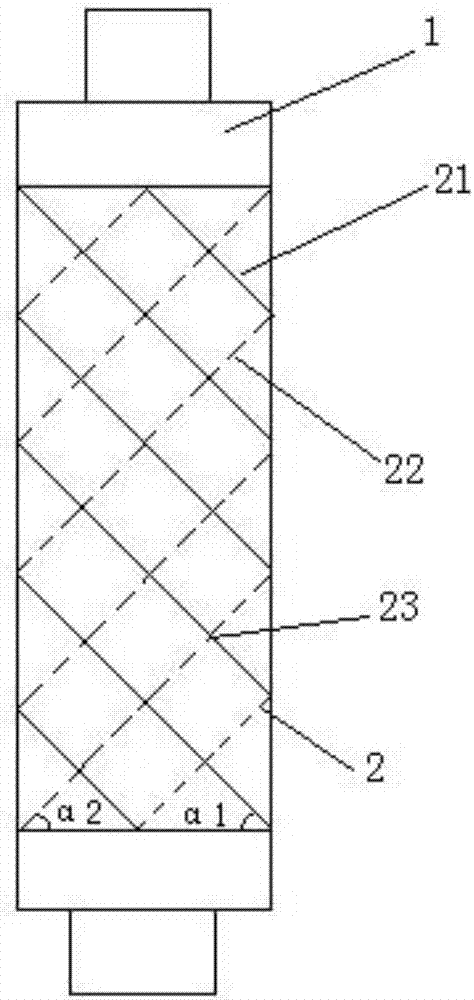

[0011] Such as figure 1 As shown, a hot rolling device for producing three-dimensional three-dimensional rolling composite materials includes a hot rolling roll 1, the outer surface of the hot rolling roll 1 is covered with a pattern layer 2, and the pattern layer 2 is several groups of surrounding pressure rolls The counterclockwise helical convex first helix 21 of the roller is formed at the intersection with several sets of clockwise helical convex second helixes 22 revolving in opposite directions; the first helix 21 and the horizontal direction The angle range of the included angle α1 is 0-90°, the angle range of the included angle α2 between the second helix 22 and the horizontal direction is 0-90°; the first helix 21 protrudes and the second helix The height of the protrusions 22 is selected according to the thickness of the processed nonwoven; the intersection of the first helix 21 and the second helix 22 is an embossing point 23 . The distance between two adjacent li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com