A kind of nano silicon dioxide with controllable particle size and preparation method thereof

A technology of nano-silica and particle size, which is applied in dyeing organosilicon compound treatment, dyeing physical treatment, fibrous filler, etc., can solve the problem of uneven surface roughness of paint, uneven reflectiveness of painted surface, difficulty in particle size, etc. Control and other problems, to achieve the effect of uniform matting effect, consistent hand feeling, and concentrated particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Prepare nano silicon dioxide, complete by the following steps:

[0036] Step (1): Add 10Be (Baumé) natron to the synthesis kettle, start stirring at room temperature, add sulfuric acid with a concentration of 10%, and control the acid flow rate to 0.5m 3 / h, adjust the pH to be 4, react slowly, and wait for the granulation to be uniform to prepare the slurry;

[0037] Step (2): Add a silane coupling agent to the slurry in step (1), stir evenly, raise the temperature to 60°C, and age at a constant temperature for 1 hour, then transfer to the plate frame for washing.

[0038] Step (3): Break up the washed materials in step (2) to make slurry, send the slurry to the drying system for drying, the inlet temperature of the drying system is 400°C, and transfer the slurry to the atomizer after drying. Masterbatch.

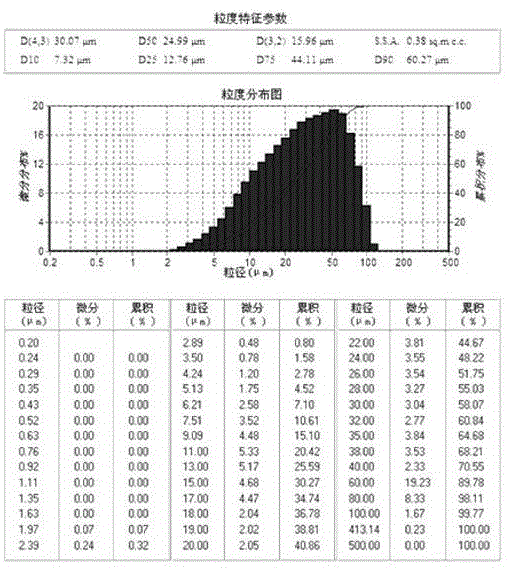

[0039] The particle size of the masterbatch is detected with a laser particle size analyzer, and the results are found in figure 1 .

[0040] Step (4): Put the ...

Embodiment 2

[0043] The preparation of nano silicon dioxide with controllable particle size is completed by the following steps:

[0044] Step (1): Add 30 Be (Baumé) natron to the synthesis kettle, start stirring at room temperature, add sulfuric acid with a concentration of 30%, and control the acid flow rate to 1.75m 3 / h, adjust the pH to 2.5, react slowly, and wait for the granulation to be uniform to prepare the slurry;

[0045] Step (2): Add a surface modifier to the slurry in step (1), stir evenly, raise the temperature to 80°C, and age at a constant temperature for 1 hour, then transfer to the plate frame for washing.

[0046] Step (3): Break up the washed materials in step (2) to make slurry, send the slurry to the drying system for drying, the inlet temperature of the drying system is 450°C, and transfer the slurry to the atomizer after drying. Masterbatch.

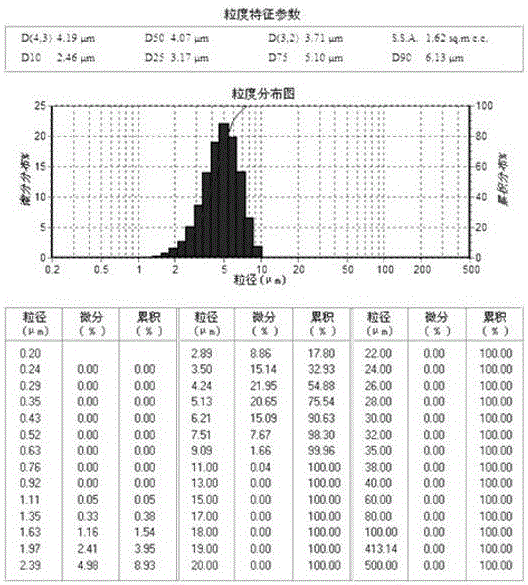

[0047] The particle size of the masterbatch is detected with a laser particle size analyzer, and the results are found i...

Embodiment 3

[0051] The preparation of nano silicon dioxide with controllable particle size is completed by the following steps:

[0052] Step (1): Add 50 Be (Baumé) natron to the synthesis kettle, start stirring at room temperature, add sulfuric acid with a concentration of 50%, and control the acid flow rate to 3.0m 3 / h, adjust the pH to 1, react slowly, wait until the granulation is uniform, and prepare the slurry;

[0053] Step (2): Add a silane coupling agent to the slurry in step (1), stir evenly, raise the temperature to 100°C, and age at a constant temperature for 1 hour, then transfer to the plate frame for washing.

[0054]Step (3): Disperse the washed material in step (2) to make slurry, send the slurry to the drying system for drying, the inlet temperature of the drying system is 500°C, and transfer the slurry to the atomizer after drying. Masterbatch.

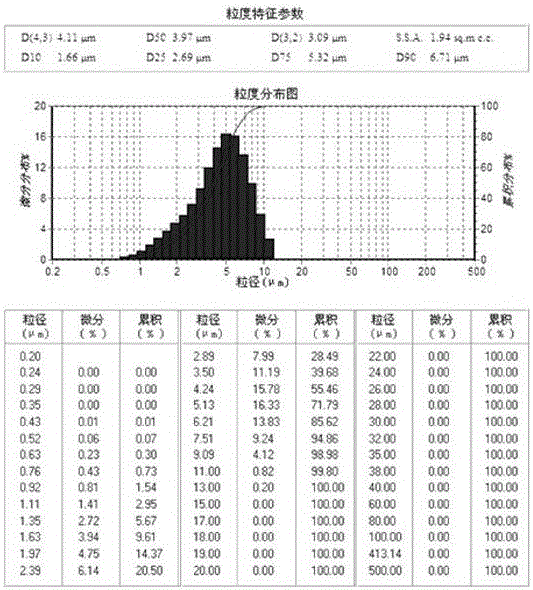

[0055] The particle size of the masterbatch is detected with a laser particle size analyzer, and the results are found in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com