Method for preparing nano-palladium electro-catalyst by ethanol reduction

An electrocatalyst, nano-palladium technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of operator physical injury, complicated steps, high cost, and achieve simple and easy operation. , Good application prospect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1、 Add 20 mL of water and 4 mL of ethanol to the reaction vessel, and stir to obtain a water-ethanol mixed solution system;

[0029] 2. Add PdCl in sequence 2 and SDS powder into the water-ethanol mixed solution system to configure a mixed system, which contains PdCl 2 and SDS concentrations were 7.04×10 -4 mol / L and 7.04×10 -4 mol / L, put the prepared solution on a constant temperature magnetic stirrer at 25°C and stir for 8 minutes, the color of the solution is light yellow;

[0030] 3. Place the evenly stirred reaction solution on a magnetic stirrer to stir and heat. Use N 2 Protection, control the reaction temperature at 70°C, react for 1.5 hours, obtain a black suspension, stop the reaction;

[0031] 4. The black precipitate obtained in the reaction solution was separated by centrifugation, washed with ethanol and acetone, and vacuum-dried at 40° C. for 24 hours to obtain the nano-palladium electrocatalyst.

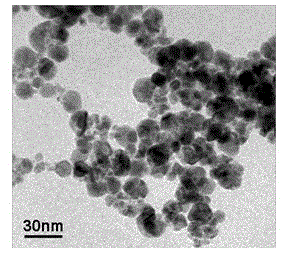

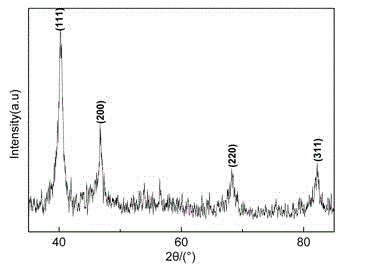

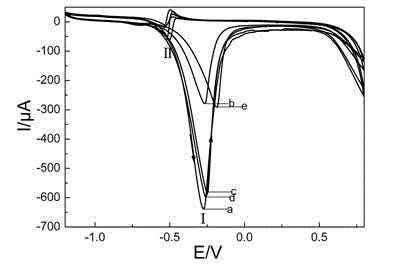

[0032] 5. The transmission electron micrograph (TEM...

Embodiment 2

[0034] 1、 Add 20 mL of water and 4 mL of ethanol to the reaction vessel, and stir to obtain a water-ethanol mixed solution system;

[0035] 2. Add PdCl in sequence 2 and SDS powder into the water-ethanol mixed solution system to configure a mixed system, which contains PdCl 2 and SDS concentrations were 7.04×10-4 mol / L and 3.12×10 -2 mol / L, put the prepared solution on a constant temperature magnetic stirrer at 25°C and stir for 8 minutes, the color of the solution is light yellow;

[0036] 3. Place the evenly stirred reaction solution on a magnetic stirrer to stir and heat. Use N 2 Protection, control the reaction temperature at 70°C, react for 1.5 hours, obtain a black suspension, stop the reaction;

[0037] 4. The black precipitate obtained in the reaction solution was separated by centrifugation, washed with ethanol and acetone, and vacuum-dried at 40° C. for 24 hours to obtain the nano-palladium electrocatalyst.

[0038] 5. The average particle size of the nano-palla...

Embodiment 3

[0040] 1、 Add 20 mL of water and 4 mL of ethanol to the reaction vessel, and stir to obtain a water-ethanol mixed solution system;

[0041] 2. Add PdCl in sequence 2 and SDS powder into the water-ethanol mixed solution system to configure a mixed system, which contains PdCl 2 and SDS concentrations were 7.04×10 -4 mol / L and 7.04×10 -2 mol / L, put the prepared solution on a constant temperature magnetic stirrer at 25°C and stir for 8 minutes, the color of the solution is light yellow;

[0042] 3. Place the evenly stirred reaction solution on a magnetic stirrer to stir and heat. Use N 2 Protection, control the reaction temperature at 70°C, react for 1.5 hours, obtain a black suspension, stop the reaction;

[0043] 4. The black precipitate obtained in the reaction solution was separated by centrifugation, washed with ethanol and acetone, and vacuum-dried at 40° C. for 24 hours to obtain the nano-palladium electrocatalyst.

[0044] 5. The average particle size of the nano-pal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com