Patents

Literature

51results about How to "Realize the pressing function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

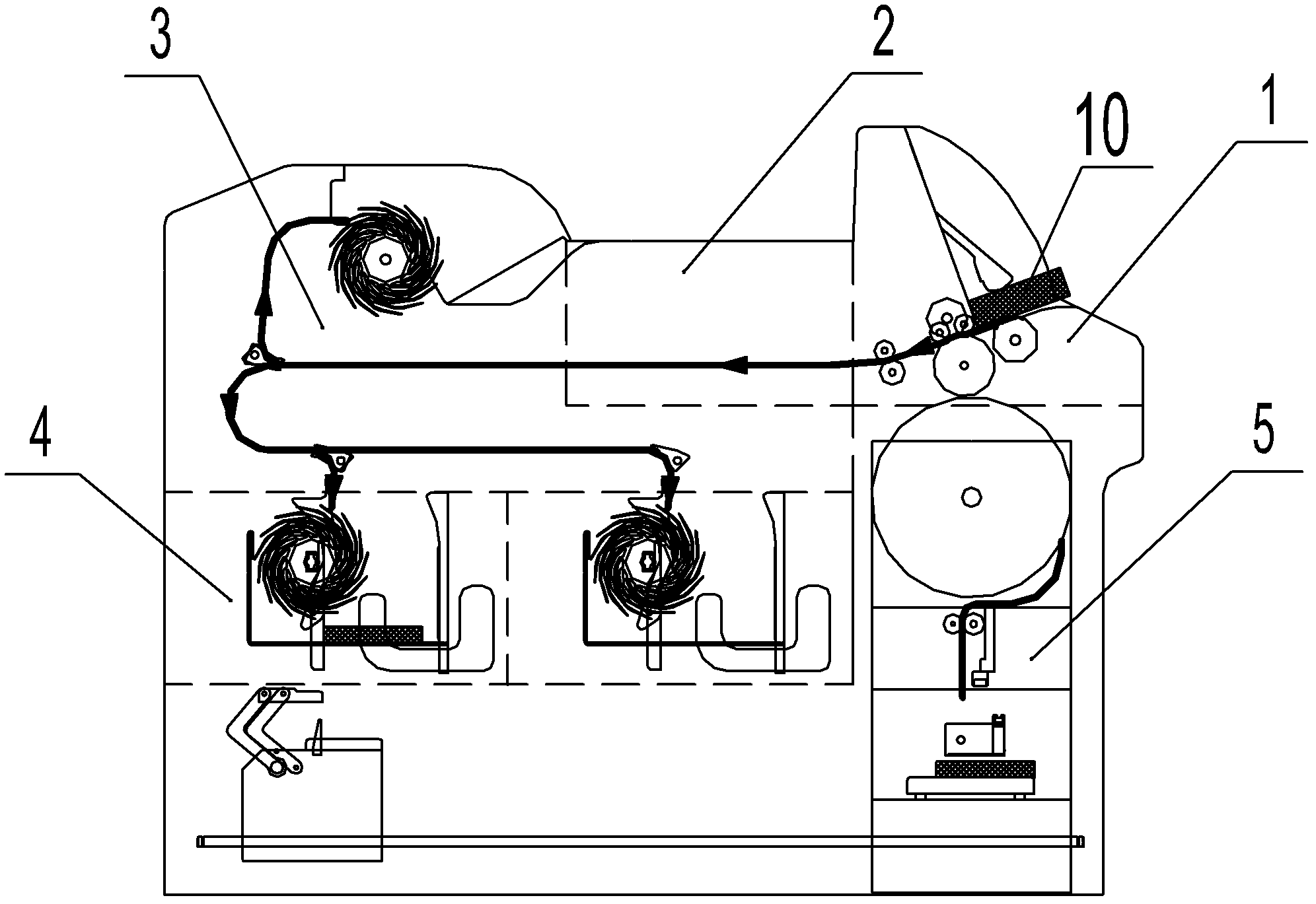

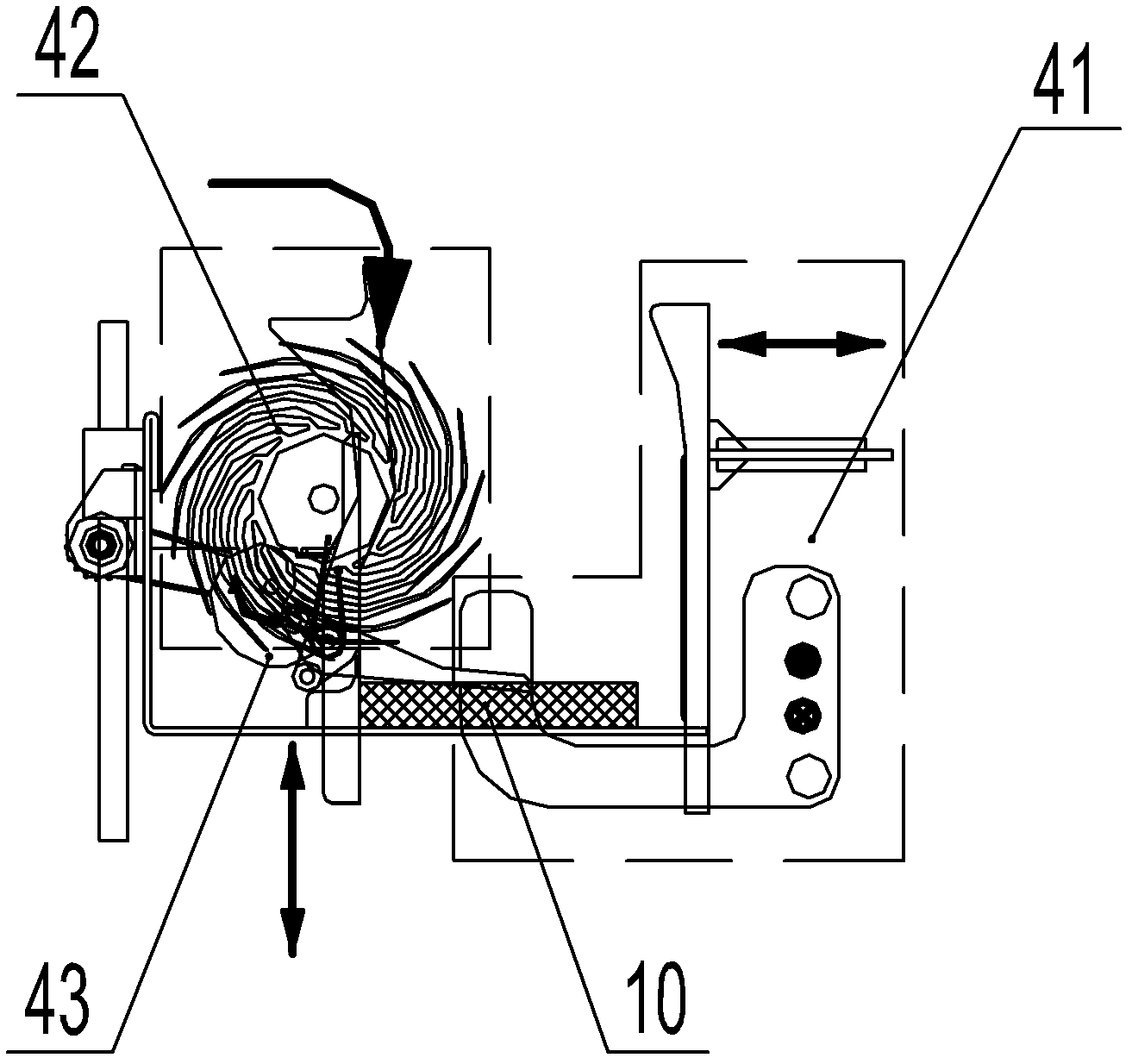

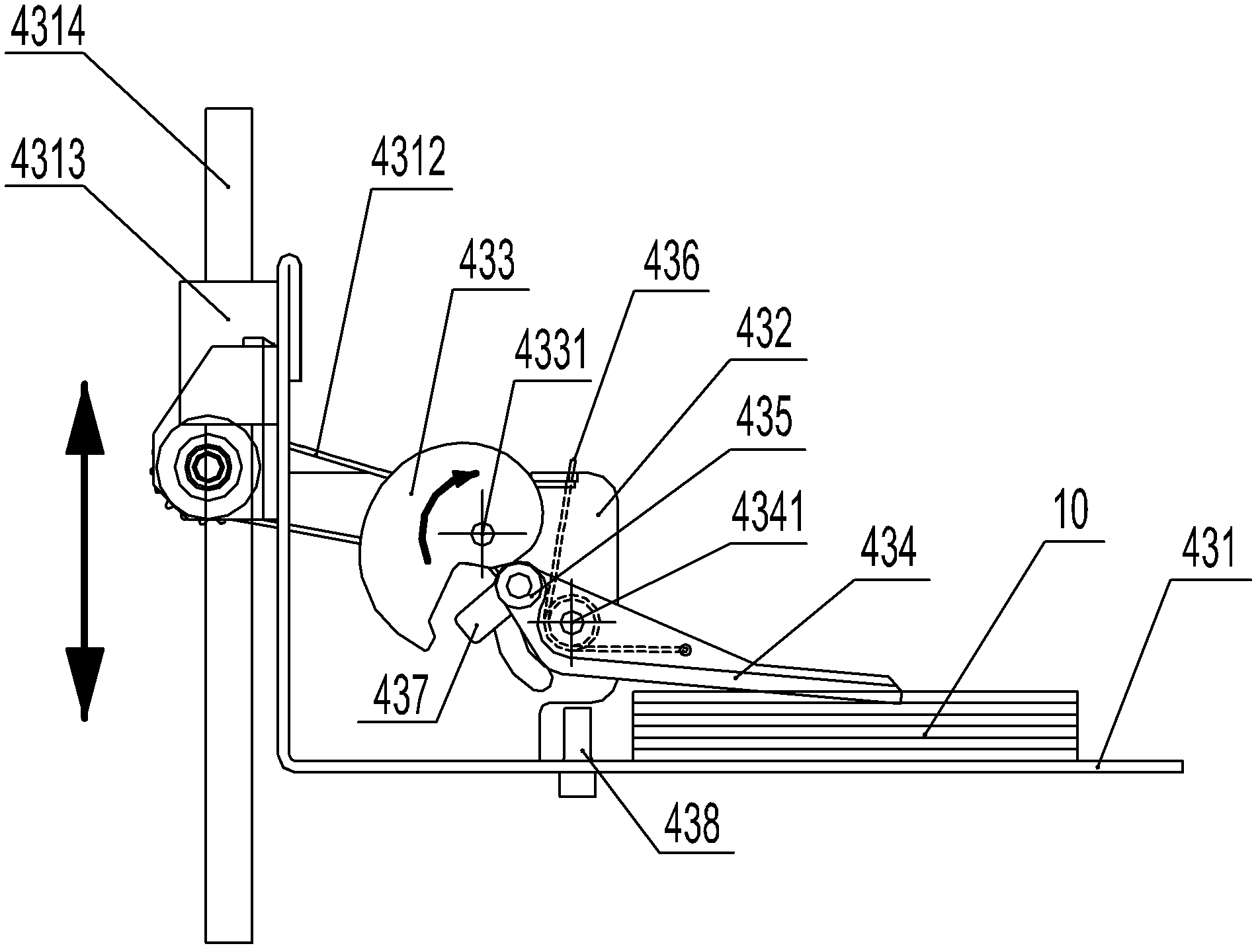

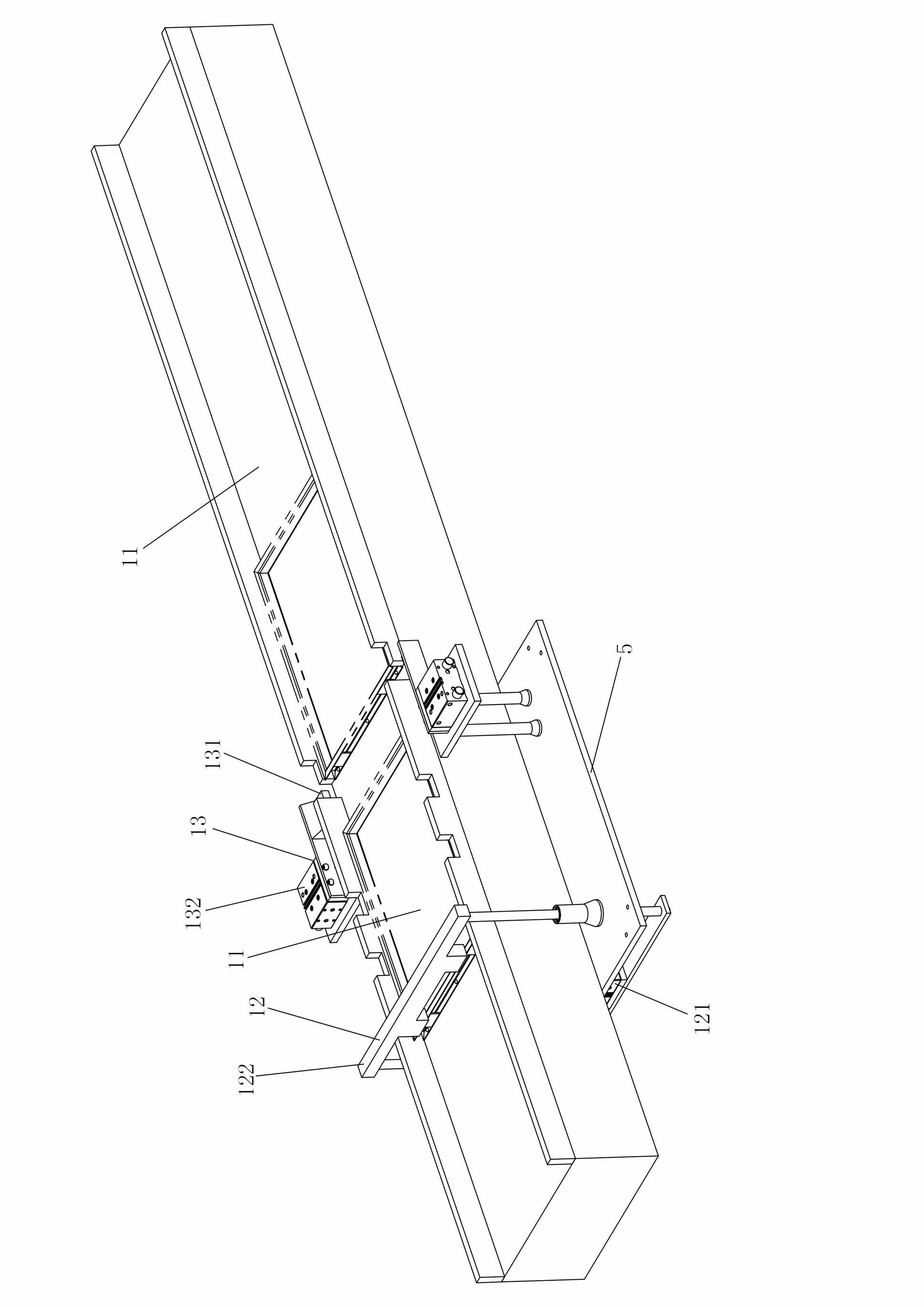

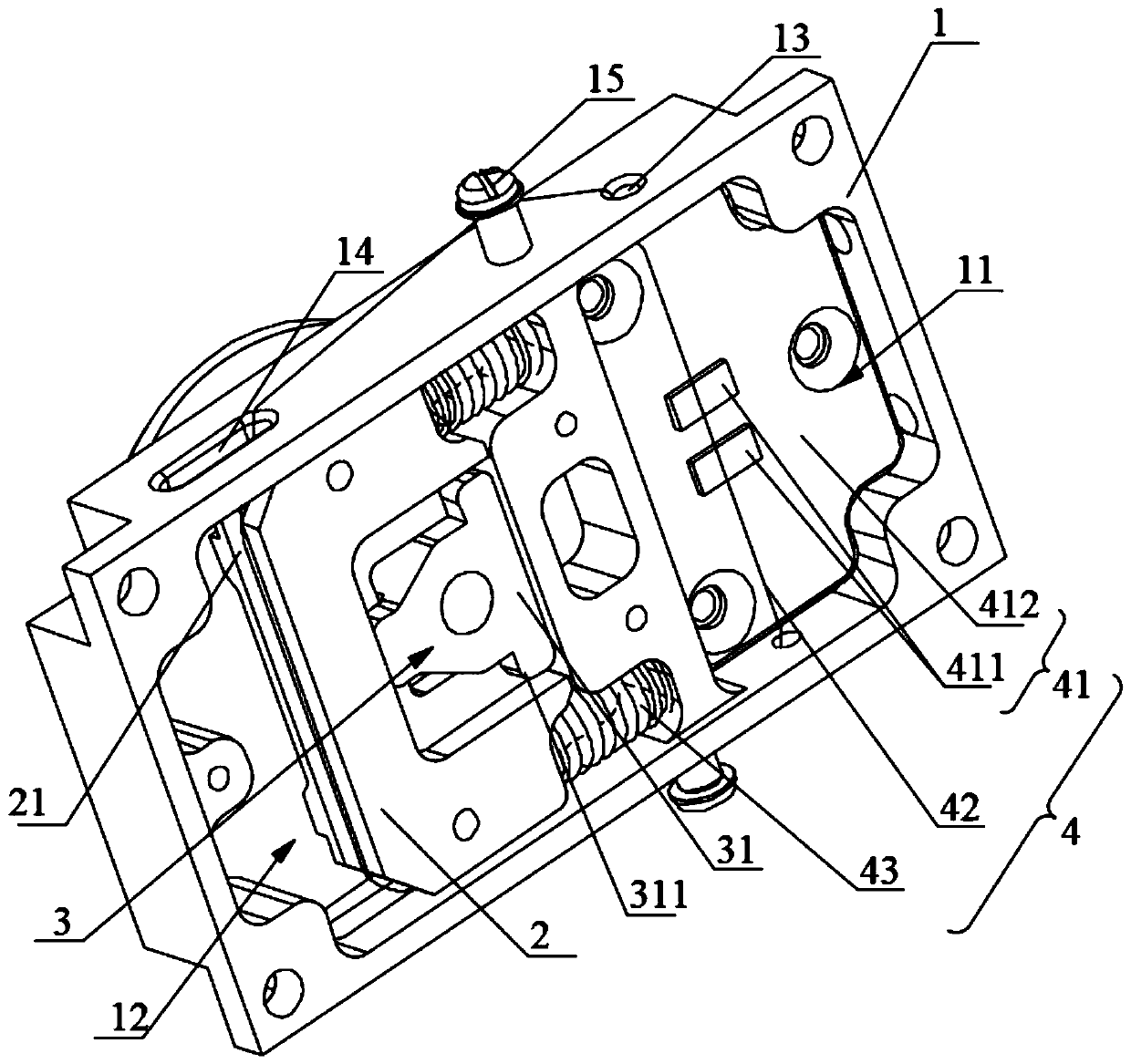

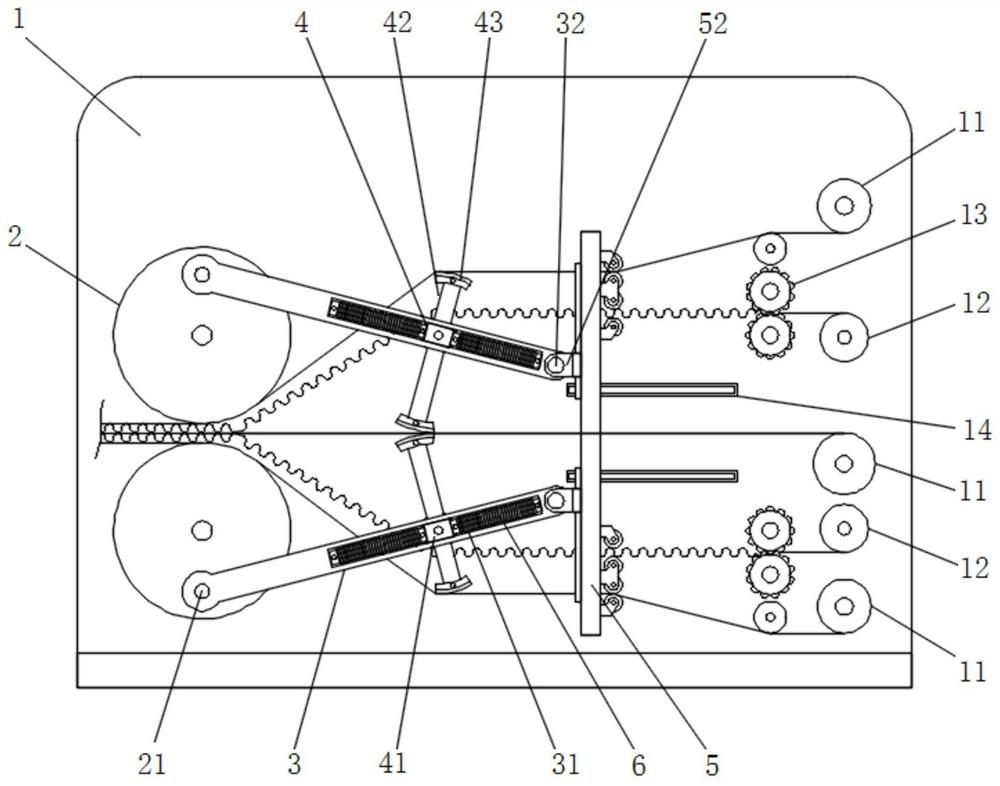

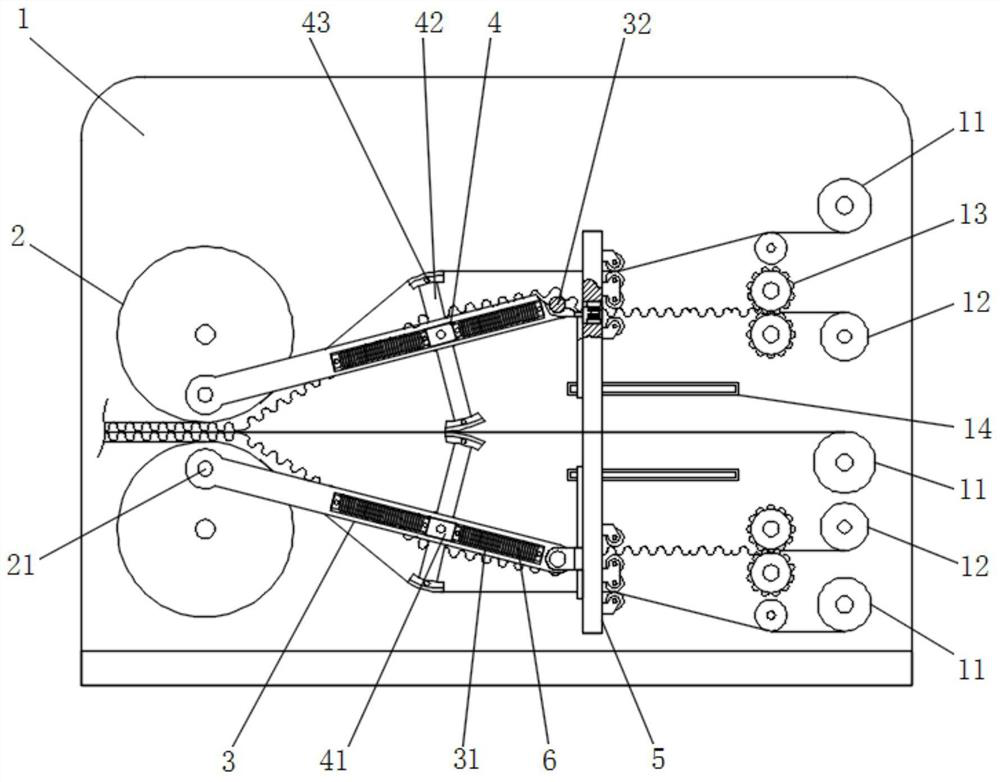

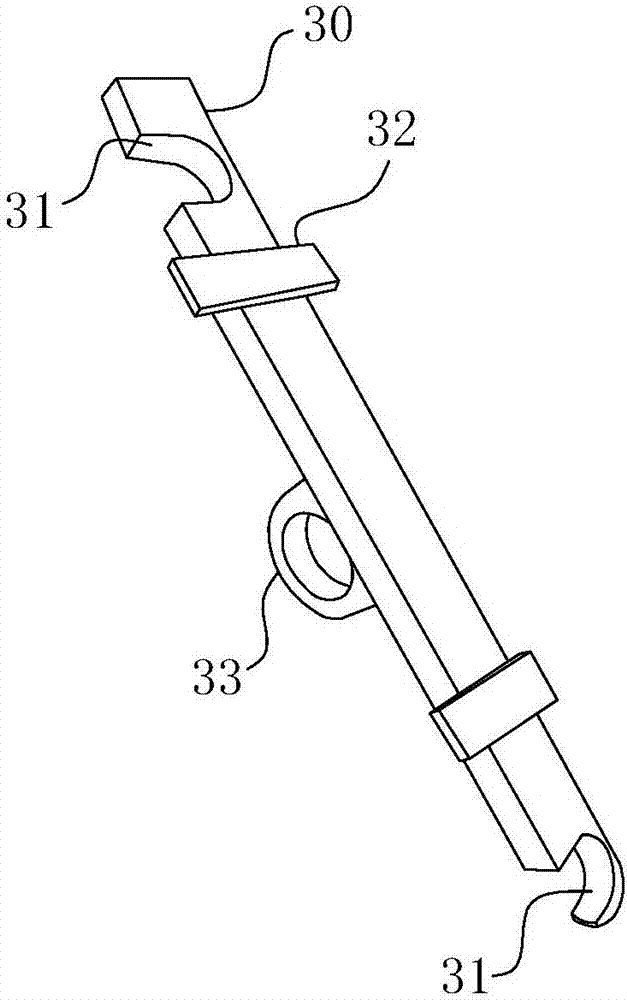

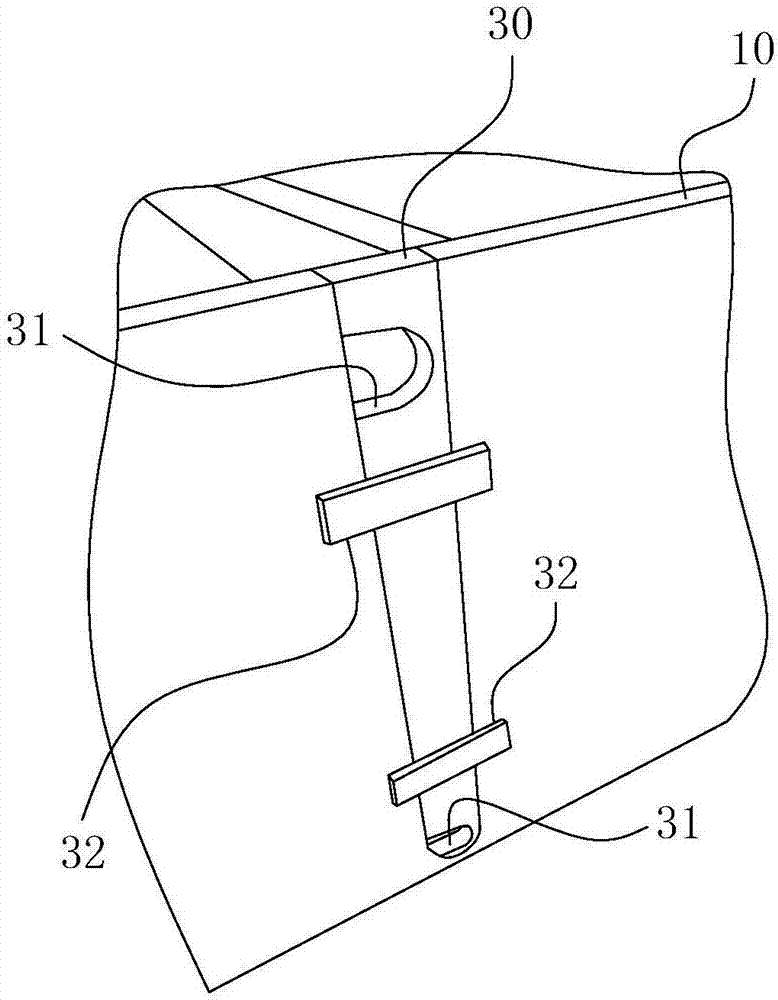

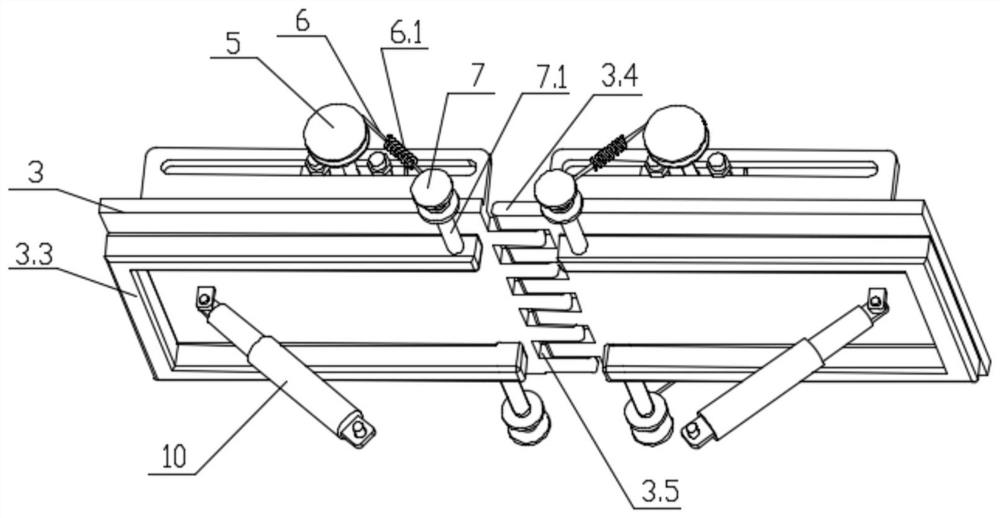

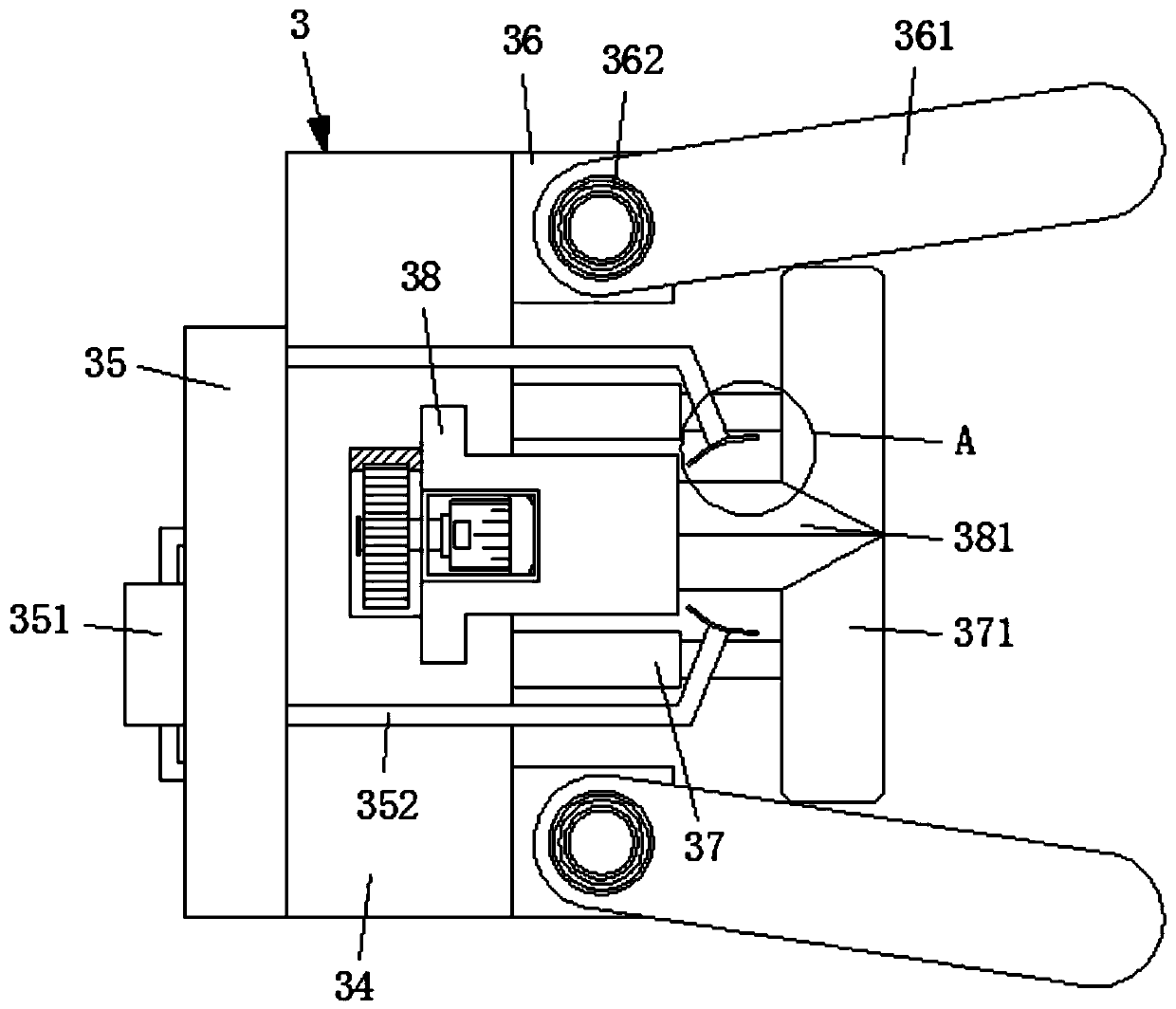

Clearing and binding all-in-one machine and bill stacking and sorting module thereof

ActiveCN102496206ARealize the pressing functionSave spaceCoin/currency accepting devicesBinding material applicationReciprocating motionCam

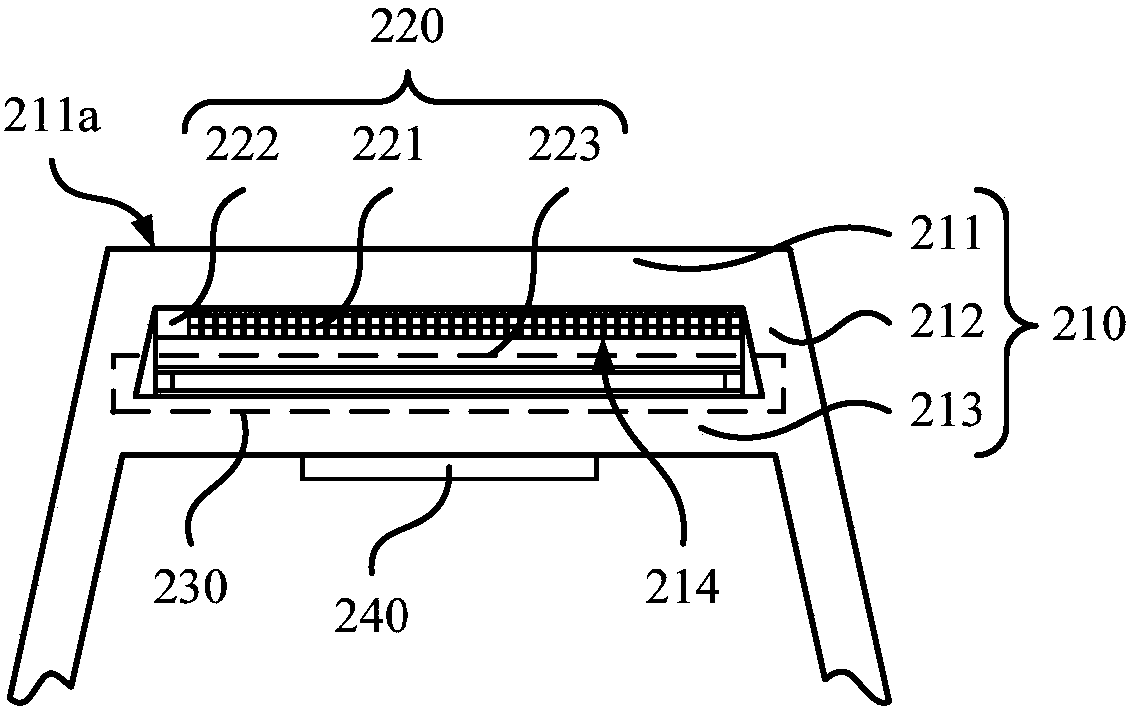

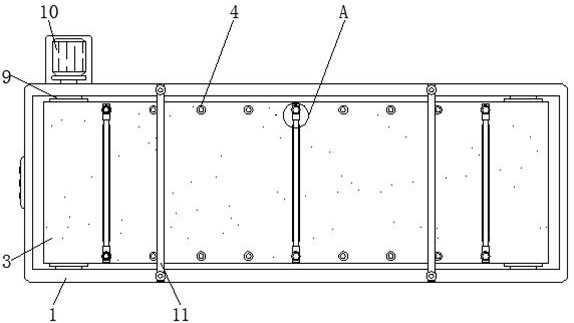

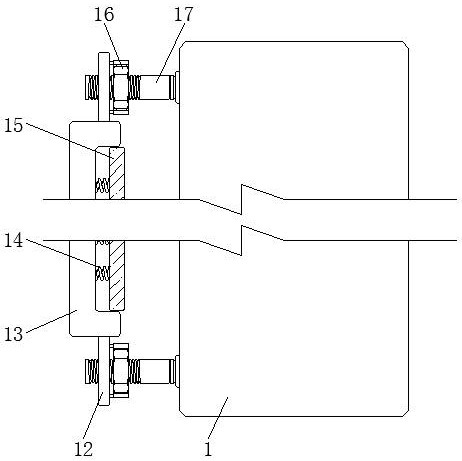

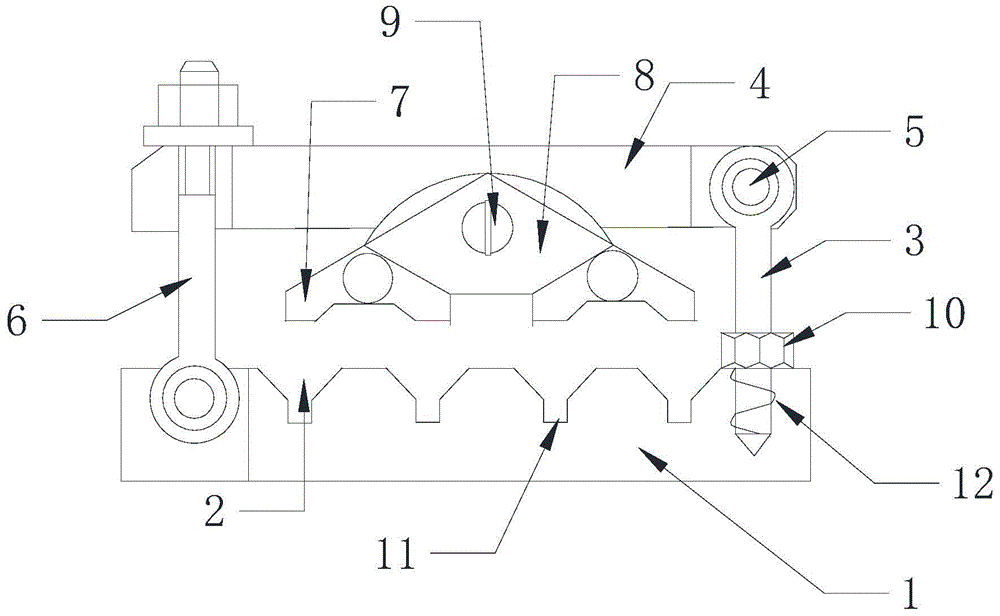

The invention provides a clearing and binding all-on-one machine and a bill stacking and sorting module thereof. The bill stacking and sorting module comprises a bill clamping and conveying sub-module, the bill clamping and conveying sub-module comprises a clamping mechanism and a vertically reciprocating movement mechanism thereof, the clamping mechanism comprises a bearing plate, a support, a cam, a clamping rod and a clamping spring, the support is fixed on the bearing plate, the cam is rotatably arranged on the support through a first rotary shaft, the clamping rod comprises a clamping end, a transmission end and a hinging part, the hinging part is arranged between the clamping end and the transmission end and is hinged on the support through a second rotary shaft, the cam is matched with the transmission end of the clamping rod and can drive the clamping rod to rotate between a releasing position and a clamping position around the second rotary shaft, one end of the clamping spring is fixed on the support, and the other end of the clamping spring is connected with the clamping end of the clamping rod so as to apply an elastic force for clamping bills to the clamping rod.

Owner:GRG BAKING EQUIP CO LTD

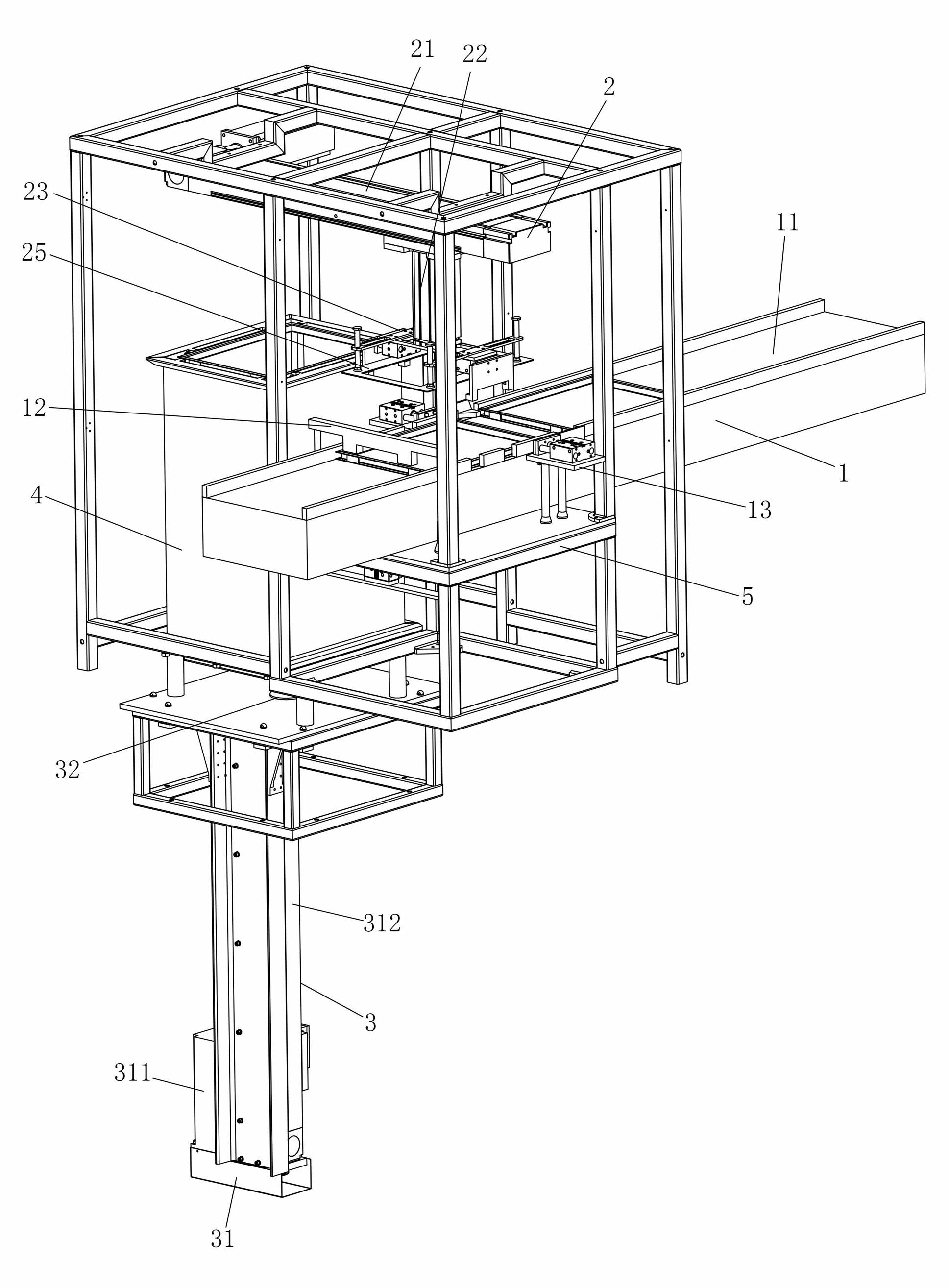

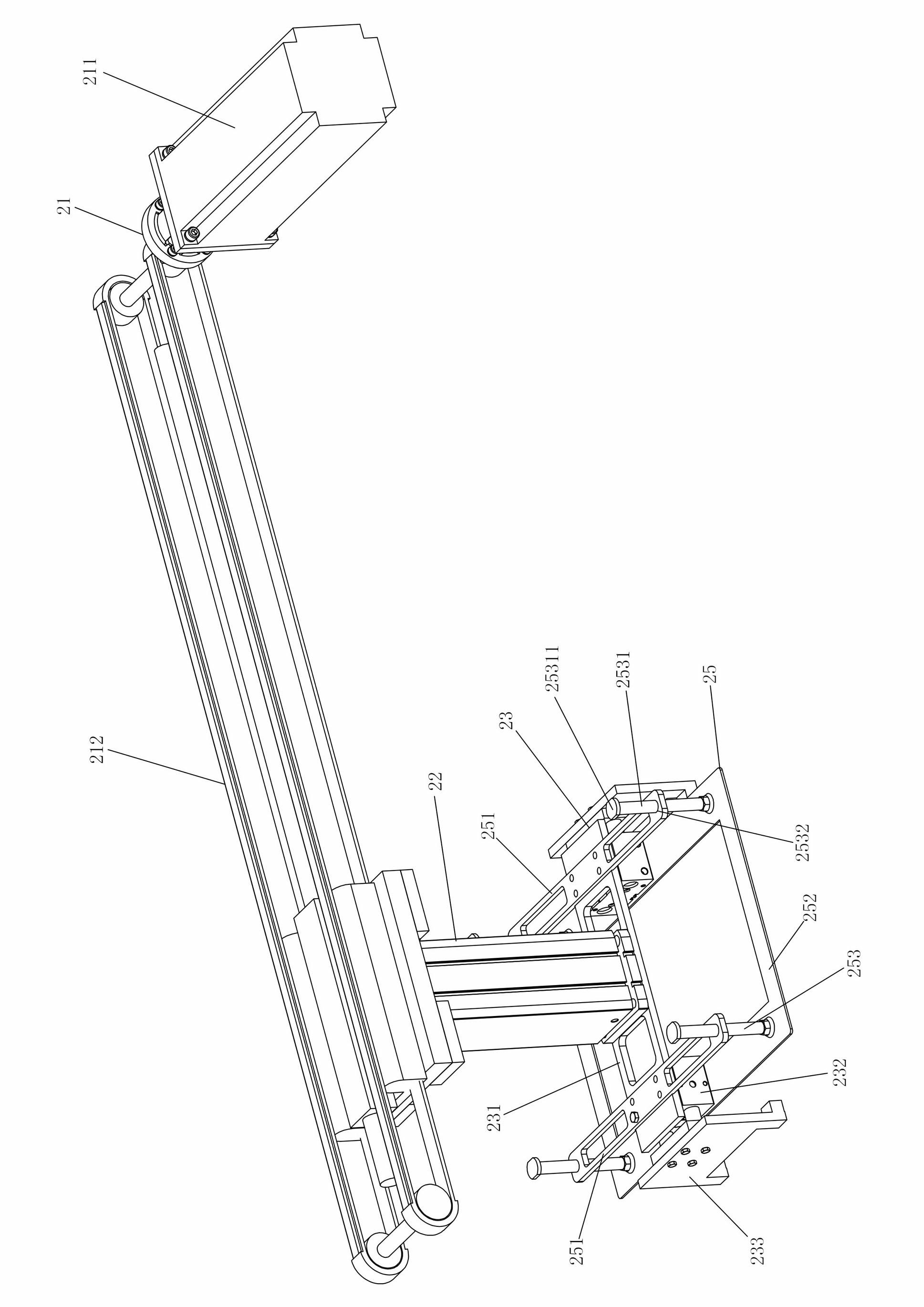

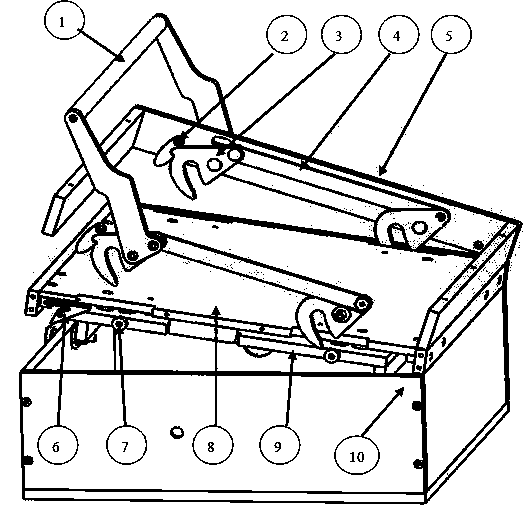

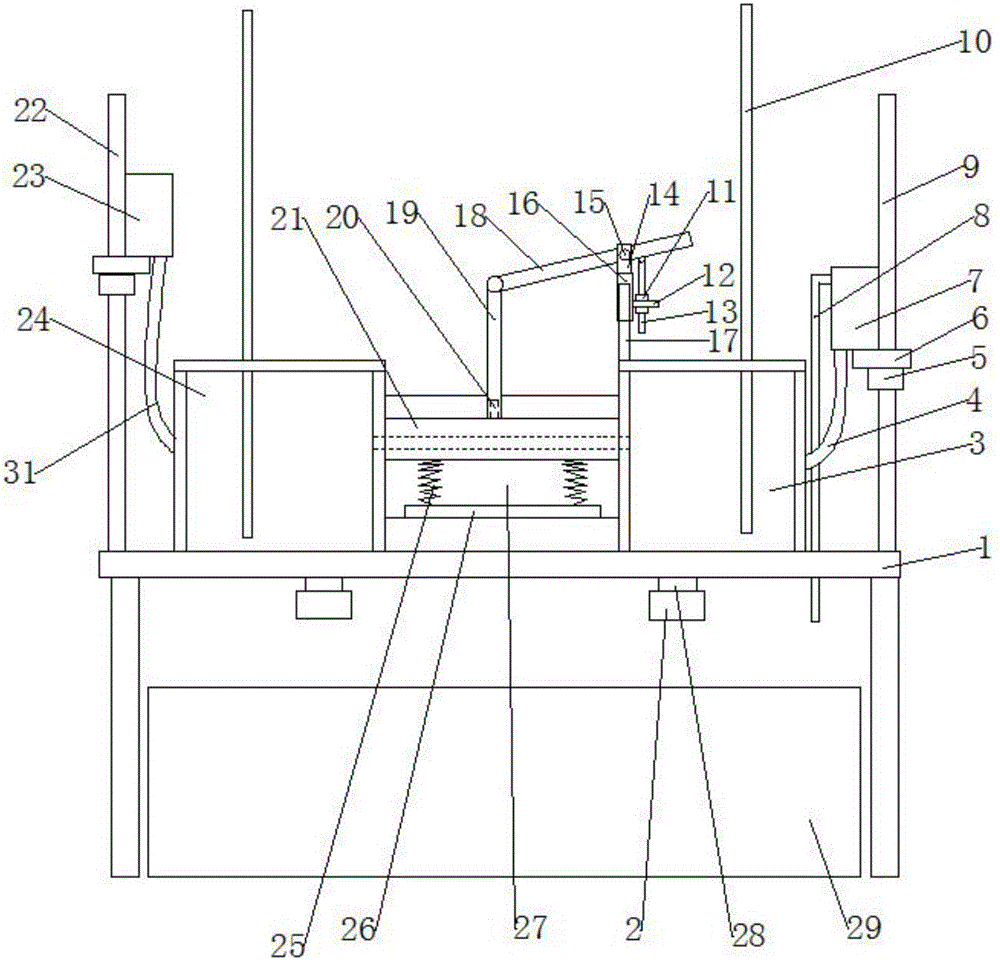

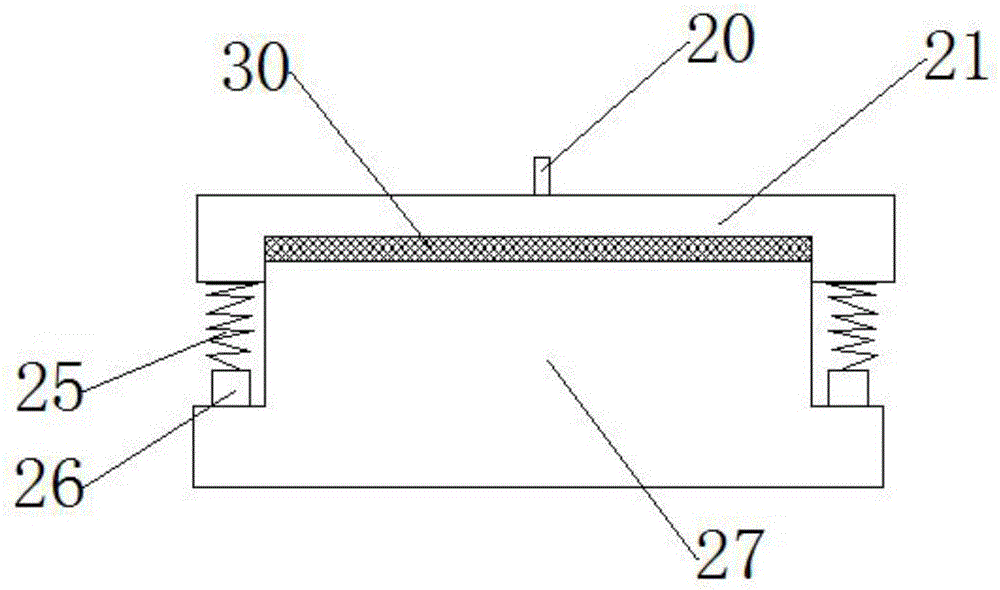

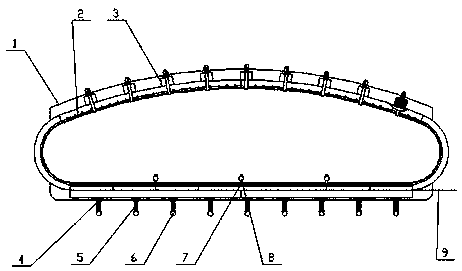

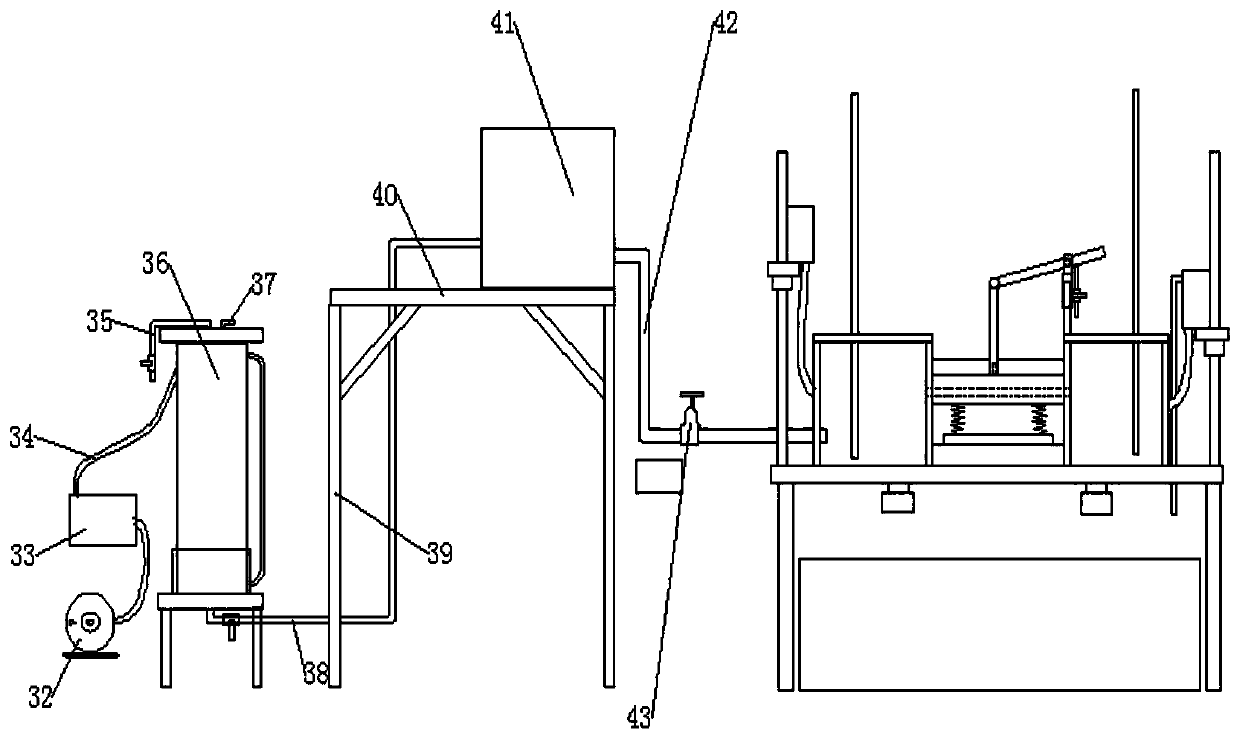

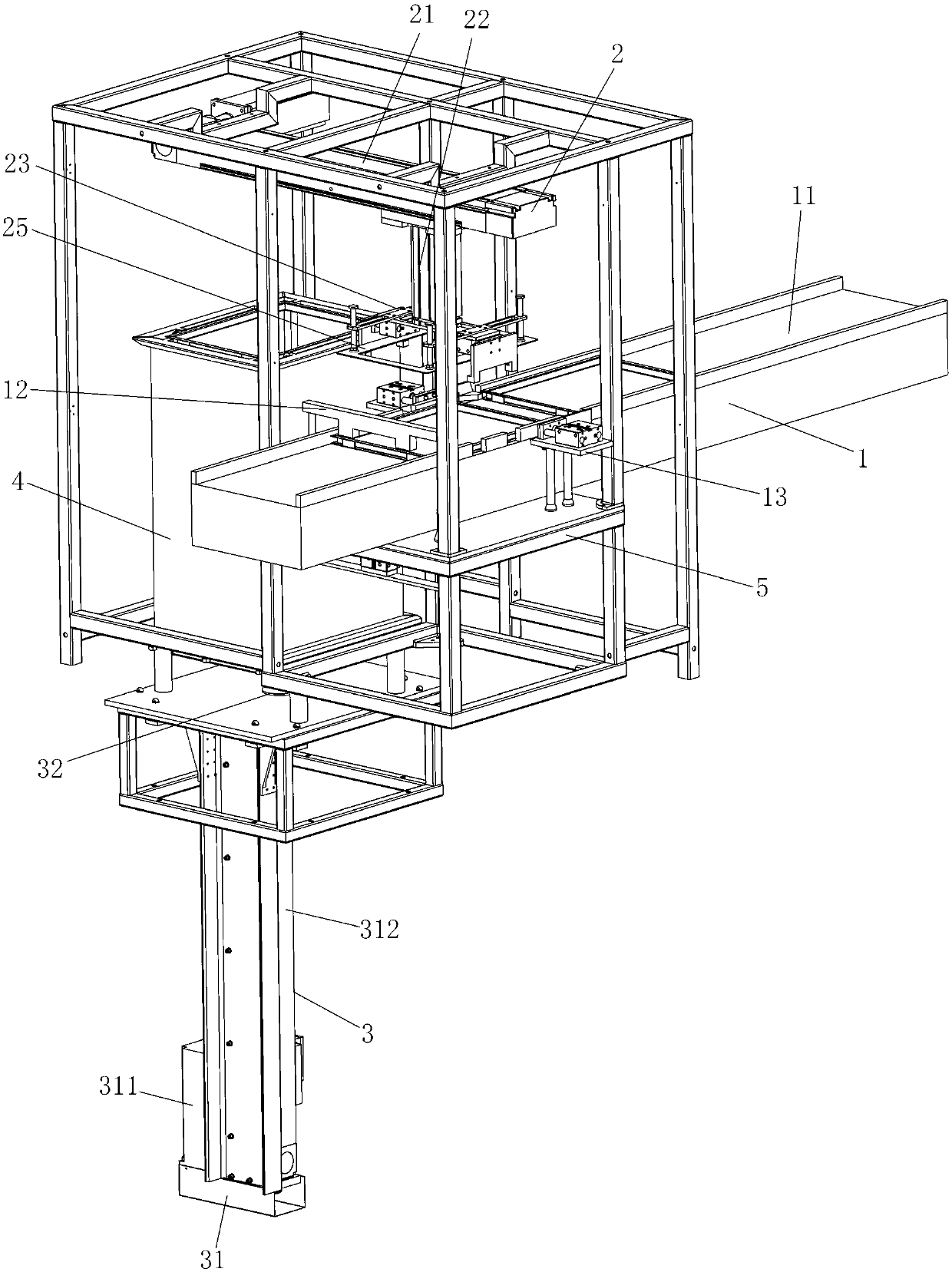

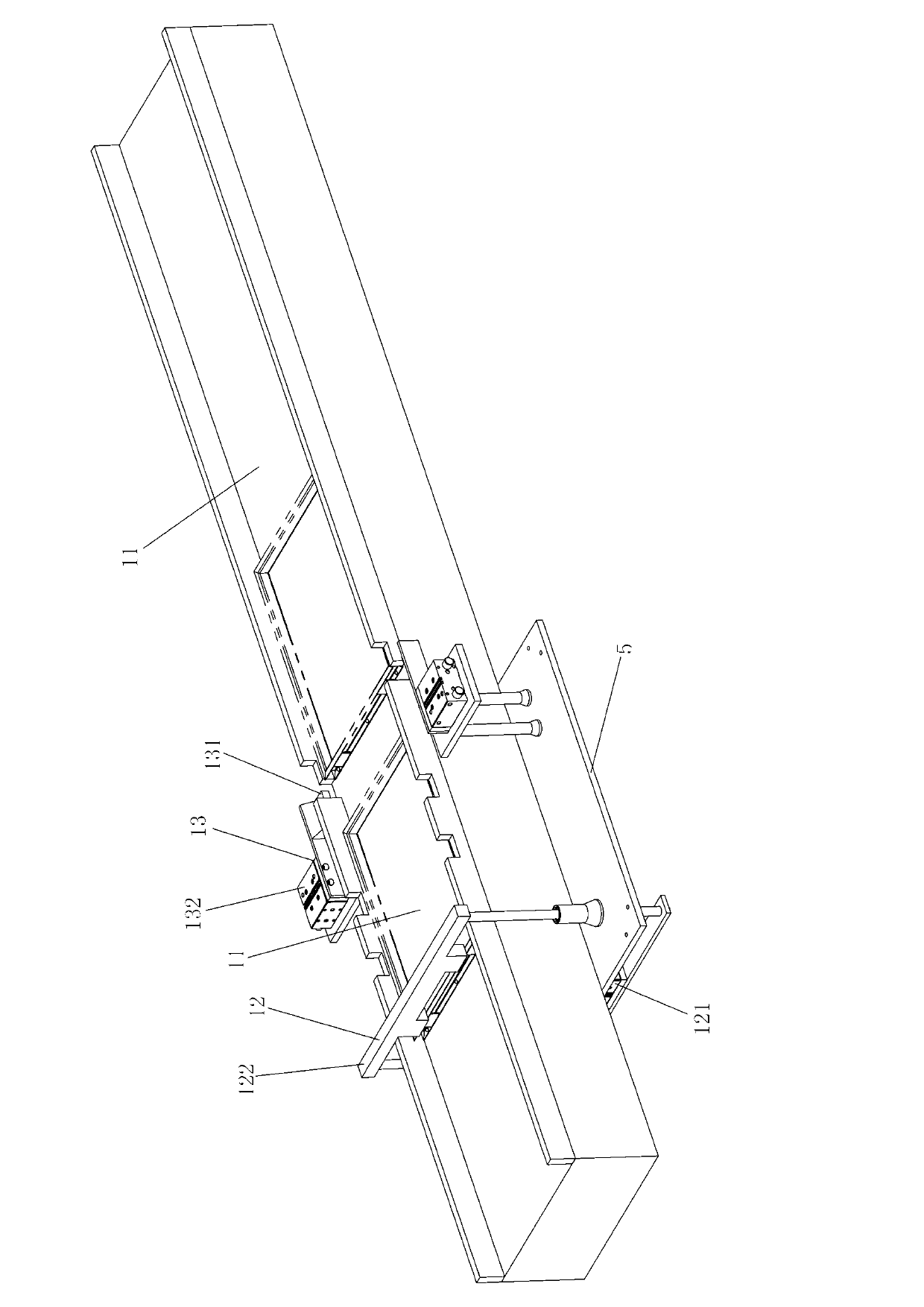

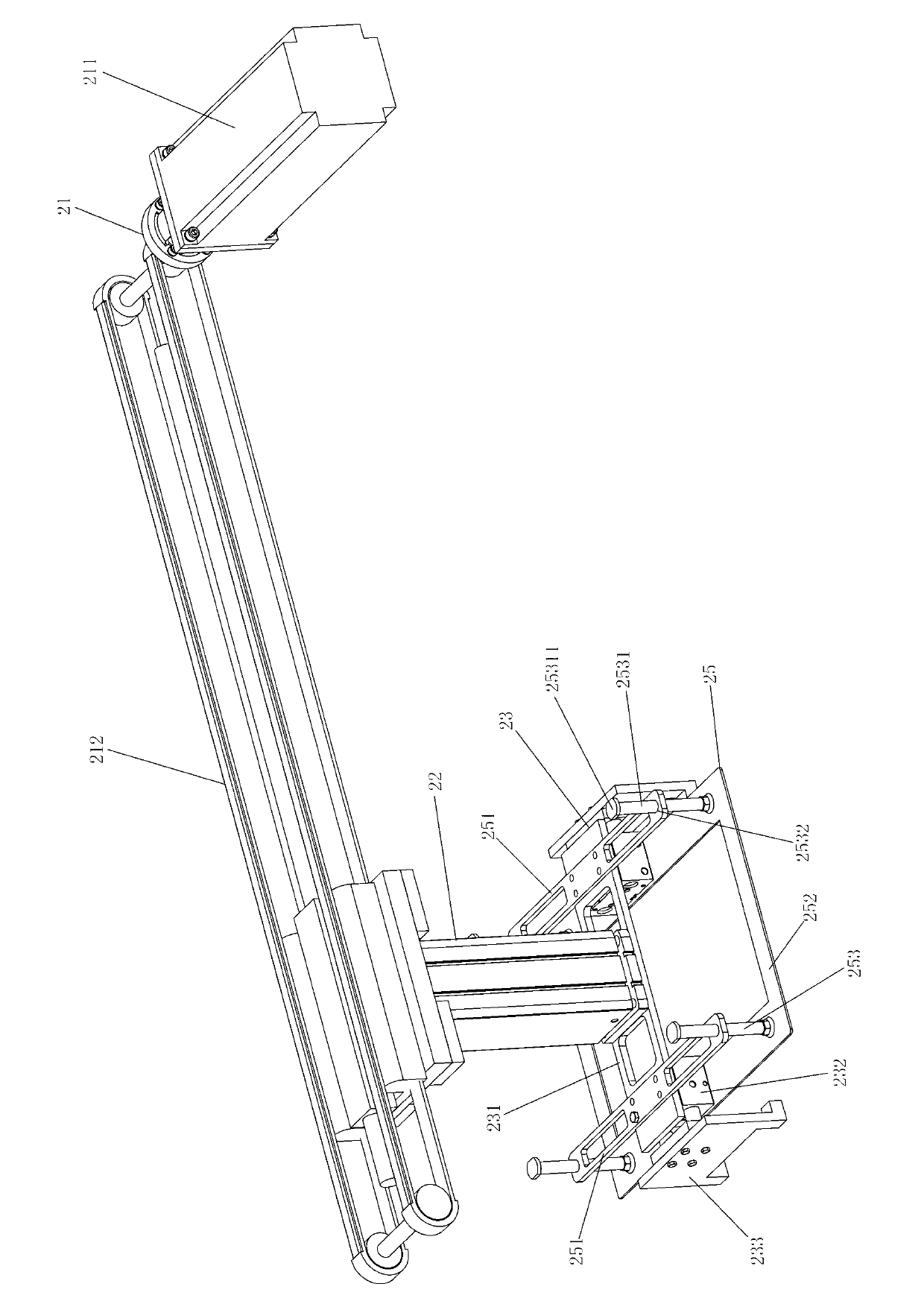

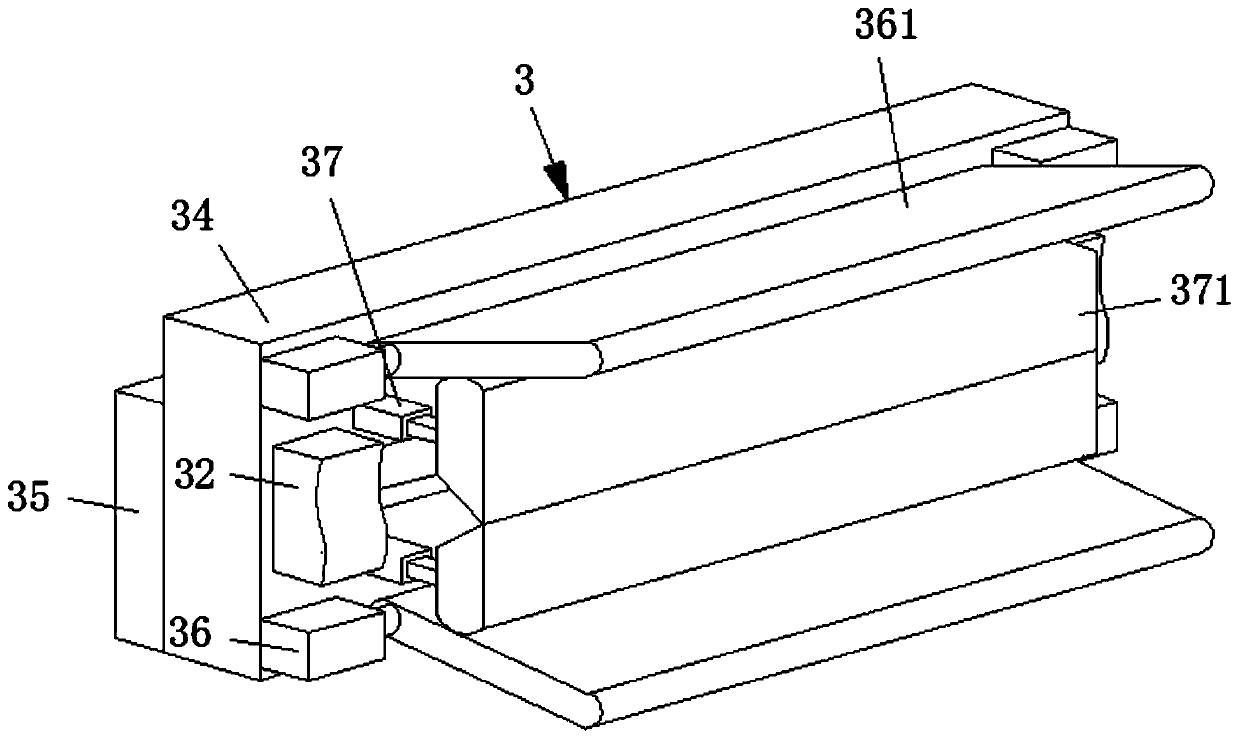

Automatic framing machine for freeze-drying lines

ActiveCN102219122AFully automatedQuality improvementLoading/unloadingConveyor partsFreeze-dryingWorking environment

The invention discloses an automatic framing machine for freeze-drying lines, which comprises a machine frame and a frame delivery mechanism and a frame containing box which are arranged on the machine frame, wherein a frame conveying mechanism for transmitting a bottle collecting frame to the frame containing box from the frame delivery mechanism is arranged above the frame delivery mechanism. The automatic framing machine has the advantages that: a structure is simple and compact; the framing can be performed automatically; the accuracy and efficiency of the framing are high; the sterile work environment of equipment is ensure; and the quality of medicines is improved and the like.

Owner:TRUKING TECH LTD

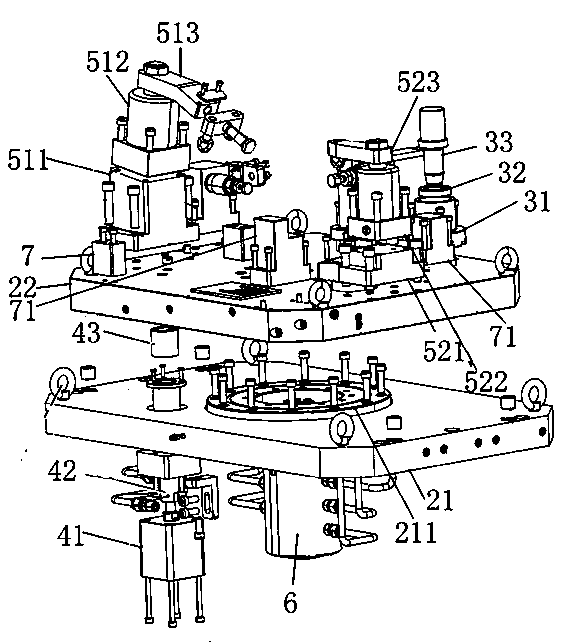

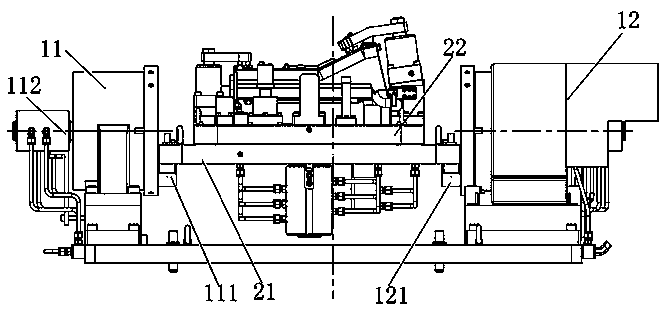

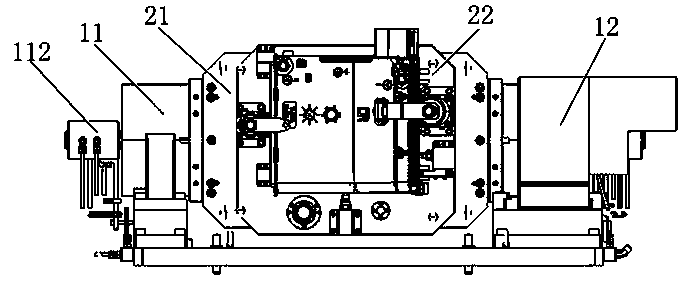

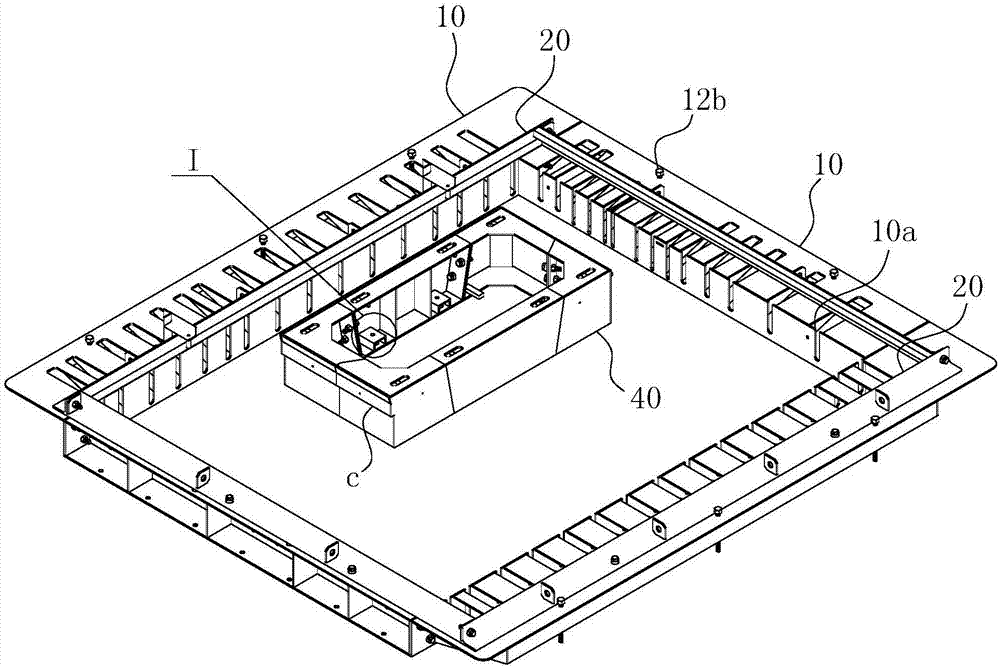

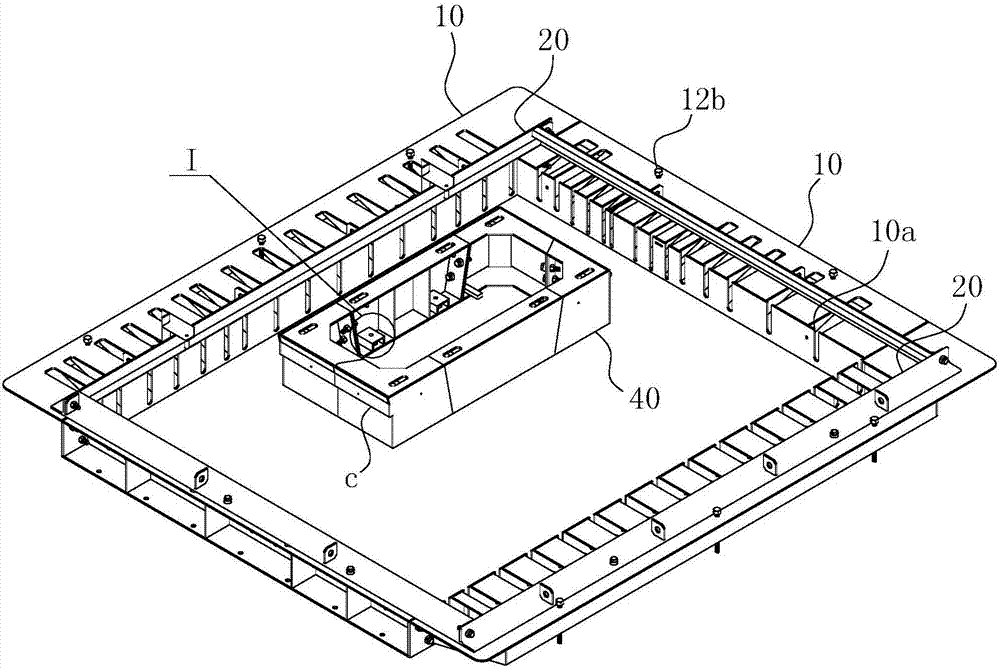

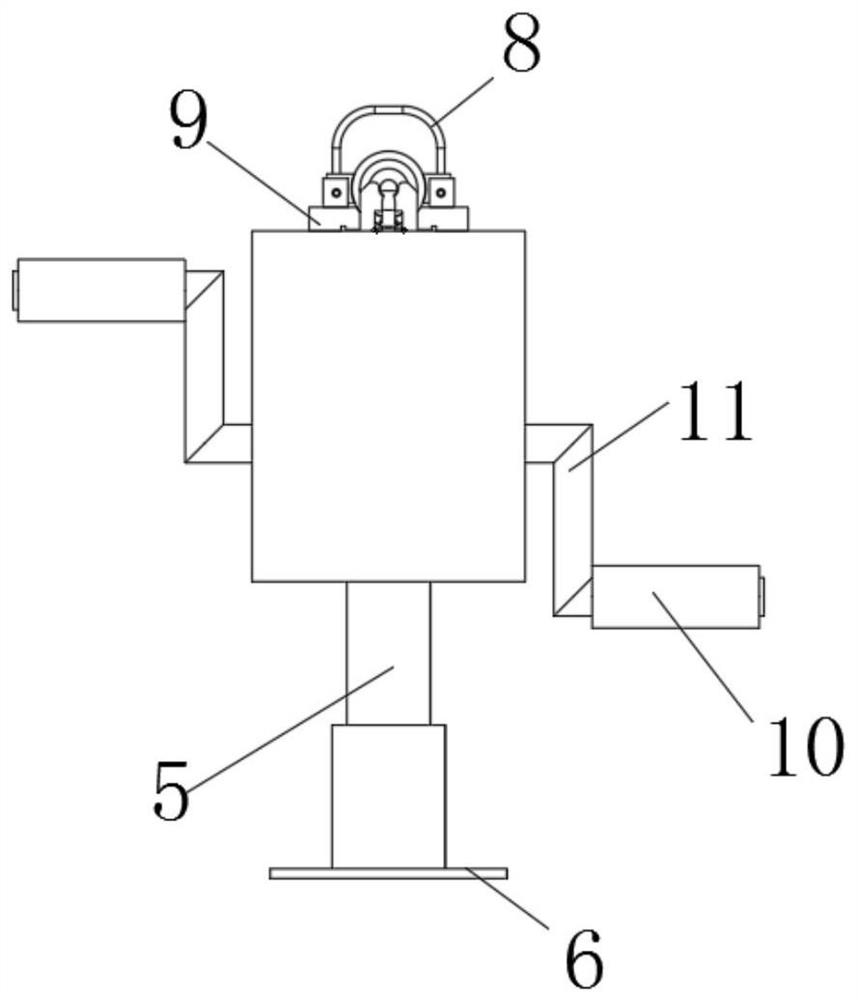

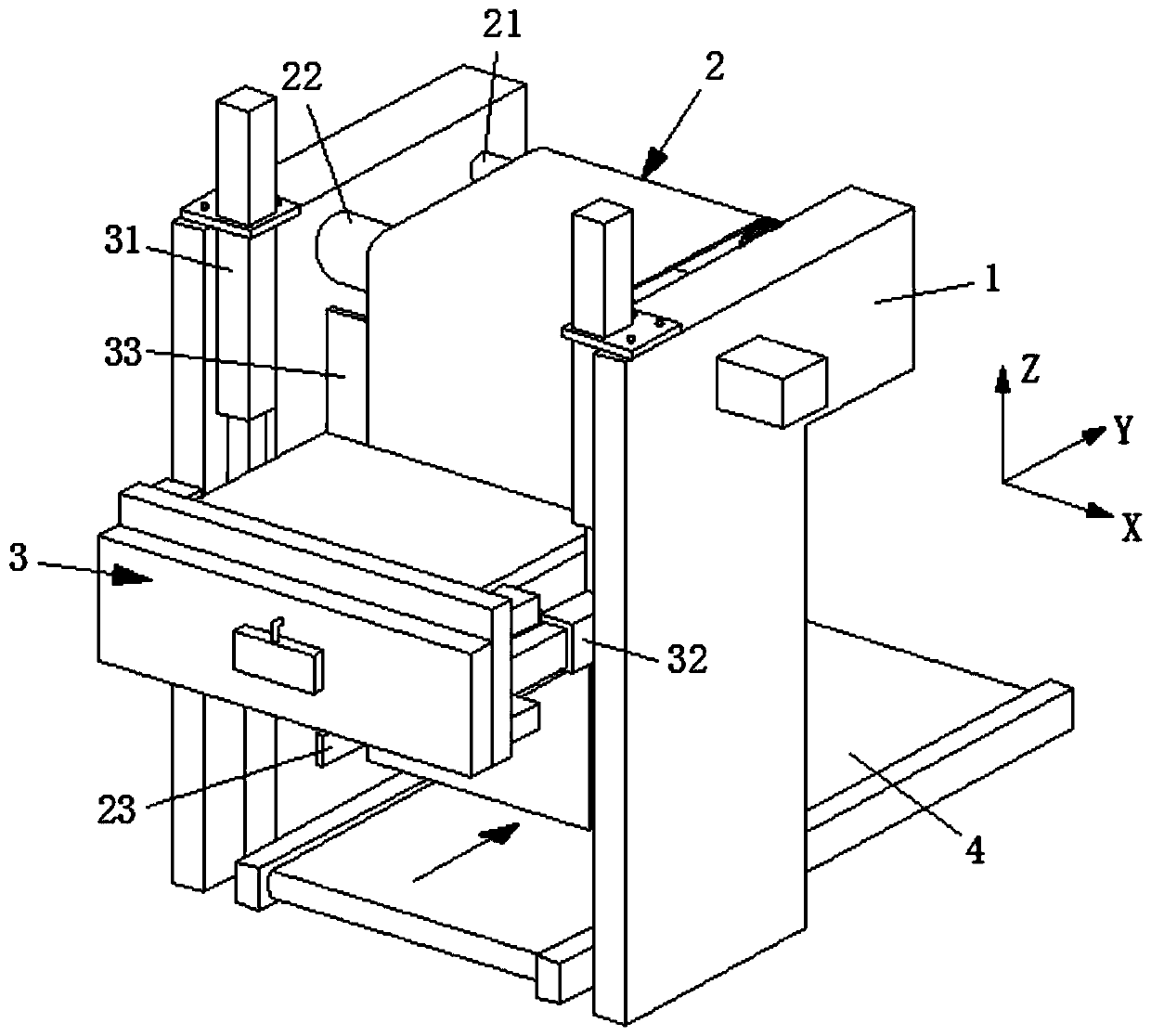

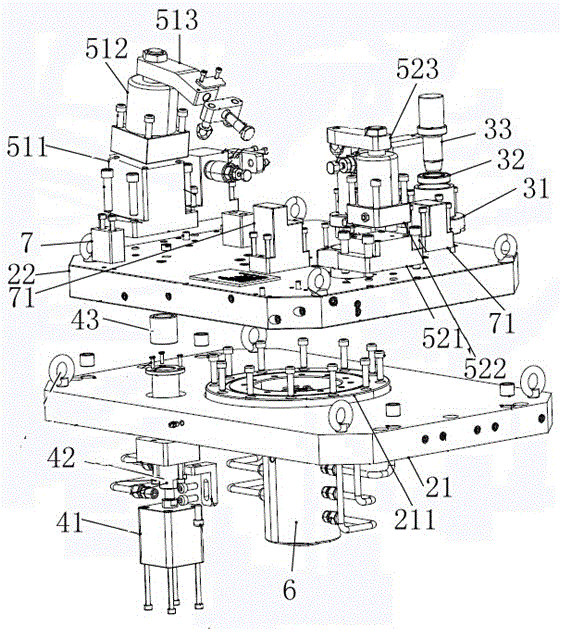

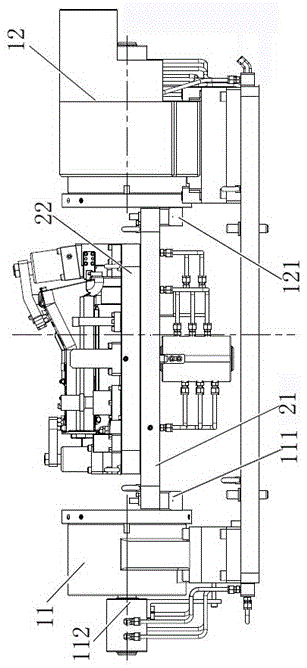

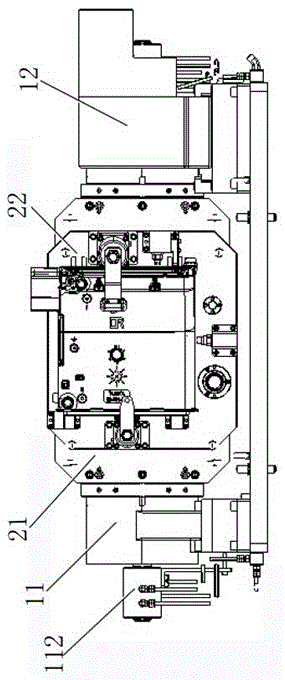

Quasi-five-axis machining centre and machining method thereof

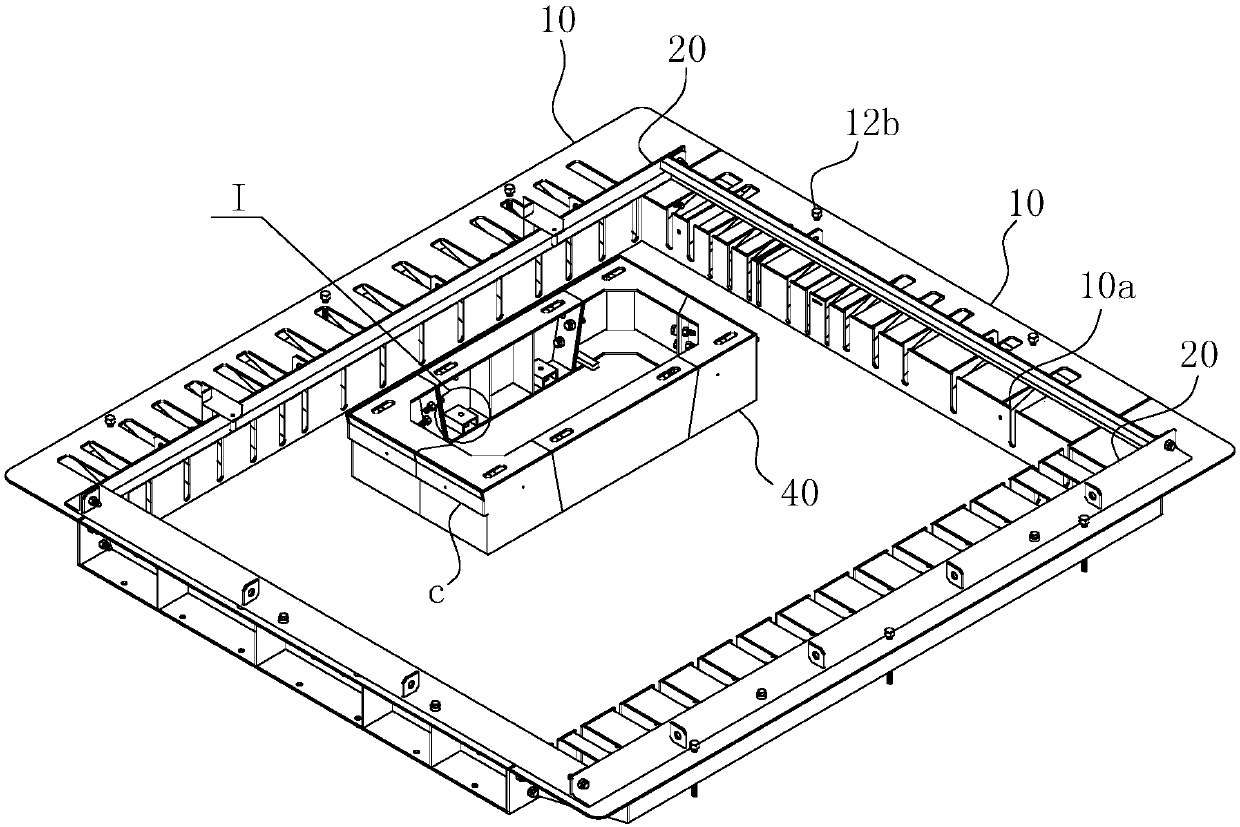

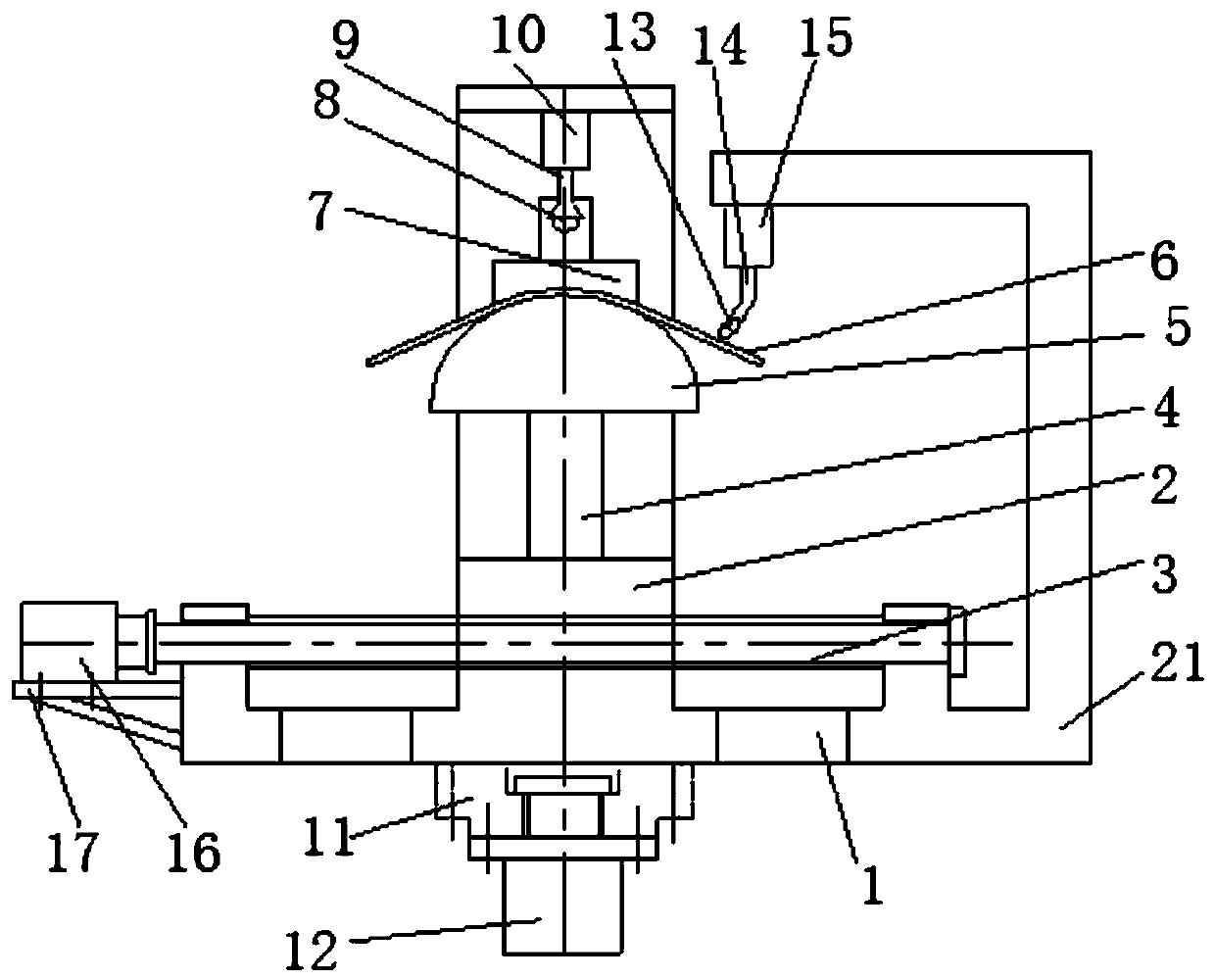

ActiveCN104097072AGuaranteed rotation accuracyGuaranteed rigidityLarge fixed membersPositioning apparatusMachine toolMachining

The invention discloses a quasi-five-axis machining centre and a machining method thereof. The quasi-five-axis machining centre comprises an AC rotary table structure, wherein the AC rotary table structure comprises a C-axis rotary table, the C-axis rotary table comprises a bridge frame plate with one end which is supported and connected to a first support table, and the other end which is supported and connected to a second support table, and a crossing shaft ring capable of freely rotating around a C-axis is further assembled on the bridge frame plate; a rotary plate is arranged by being parallel to the axis direction of an A-axis, and supported and connected to the rotary end surface of the crossing shaft ring, a shaft sleeve is further arranged on the rotary plate, and a rotary bearing capable of freely rotating around the C-axis is arranged in the shaft sleeve; a machining main shaft is detachably connected with a drive pin, and when the rotary bearing moves to be below the drive pin, the drive pin is inserted in the middle hole of the rotary bearing. According to the quasi-five-axis machining centre and the machining method thereof disclosed by the invention, the rotary power source of the C-axis is from the machining main shaft of a common vertical machine, and the existing common vertical XYZ three-axis machine can be utilized, thus furthest reducing the machining cost of polyhedral components; moreover, the machining accuracy is high and the equipment structure is simple.

Owner:SUZHOU MINGZHI TECH

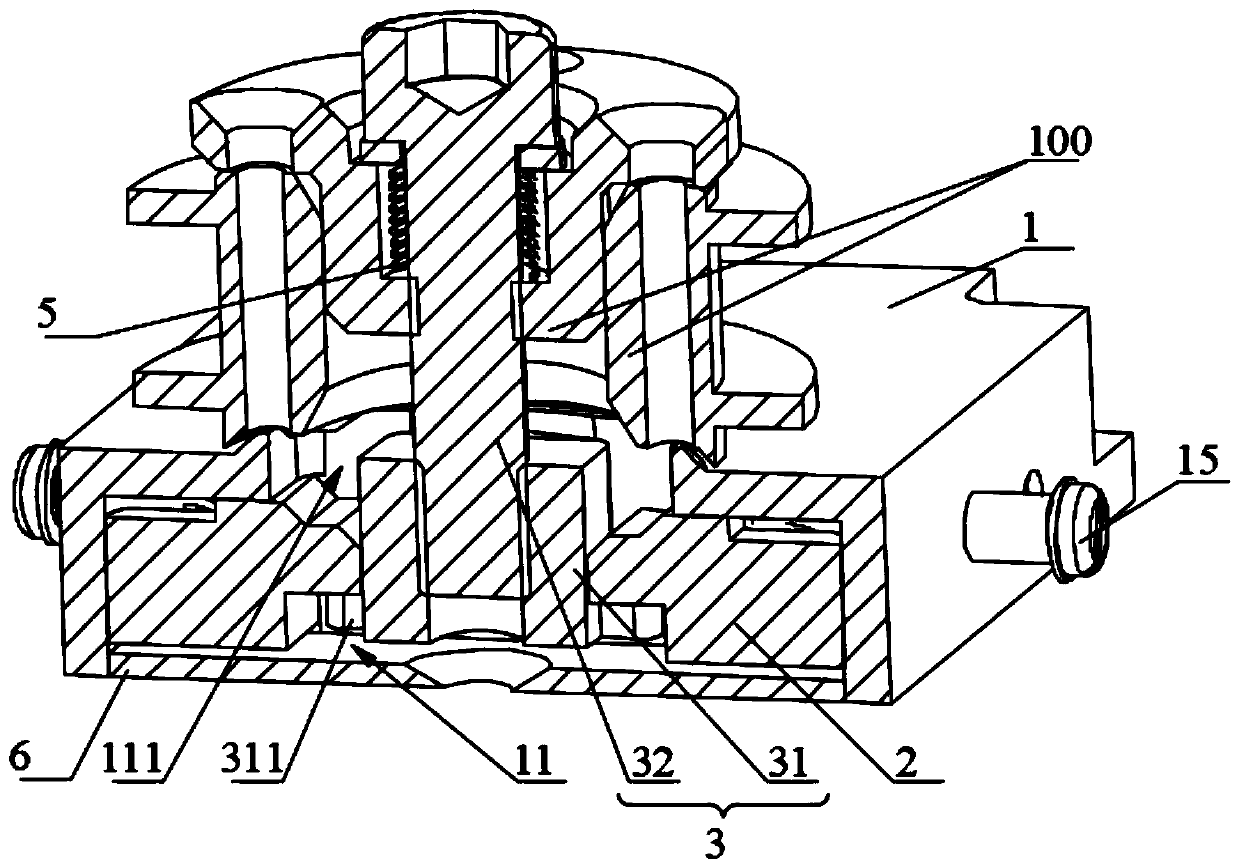

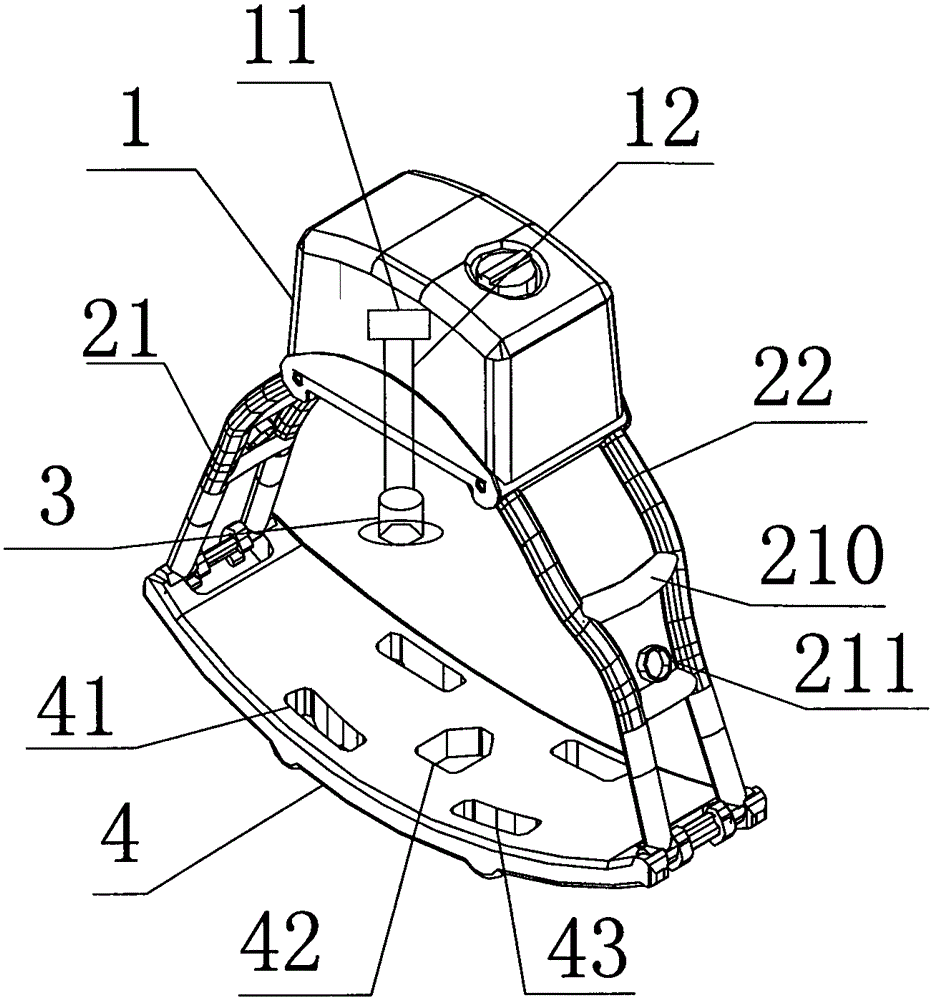

Pressing and releasing mechanism

PendingCN111453003AReduce use costRealize the pressing functionCosmonautic vehiclesCosmonautic component separationSatelliteStructural engineering

The invention relates to the technical field of spaceflight, and discloses a pressing and releasing mechanism which comprises a base, a sliding block, a locking assembly, a pulling releasing assembly,a separating piece; the base is arranged on a satellite body or an aircraft body; an unlocking releasing cavity is arranged in the base; the sliding block is in sliding connection with the internal wall of the unlocking releasing cavity; the locking assembly is pressed by the sliding block after sliding tightening, and one end of the locking assembly is limited and pressed into the unlocking releasing cavity, the other end of the locking assembly is used for pressing a pressing piece onto the satellite body or the aircraft body; the pulling releasing assembly is arranged on the base, and canpress or unlock the abut contact of the sliding block and the locking assembly; and the separating piece is connected between the locking assembly and the pressing piece and is used for enabling the locking assembly to be disengaged from the unlocking releasing cavity. The pressing and releasing mechanism is quick in response during working, small in generated impact, free of pollution and capableof being repeatedly used.

Owner:苏州馥昶空间技术有限公司

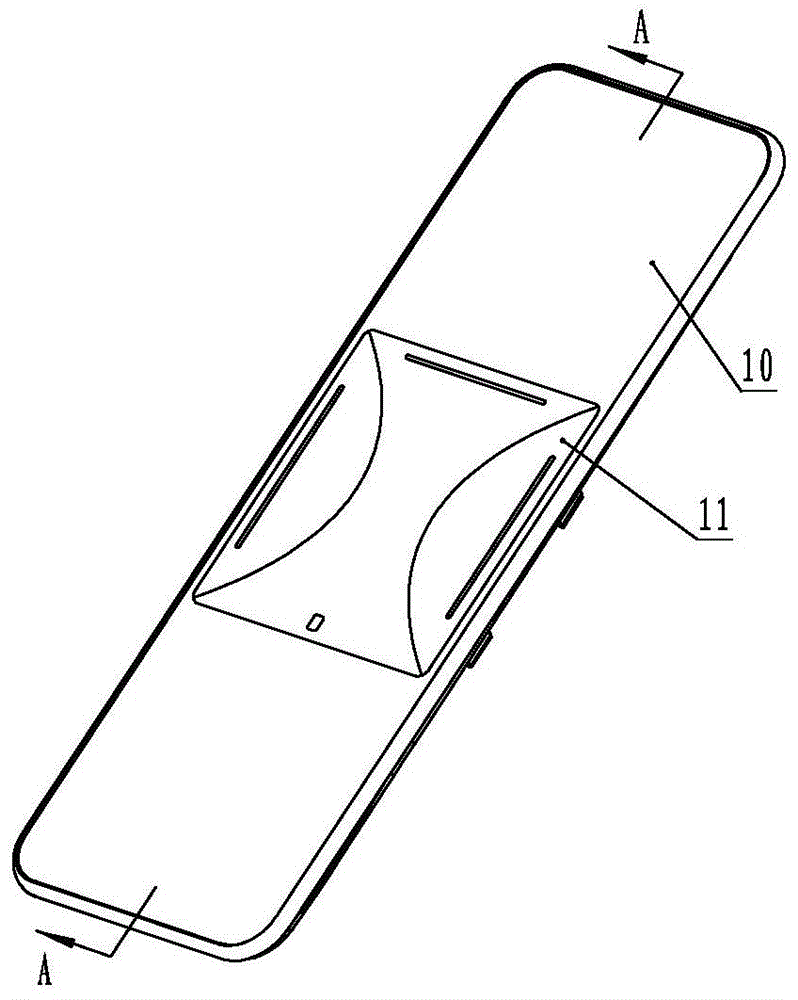

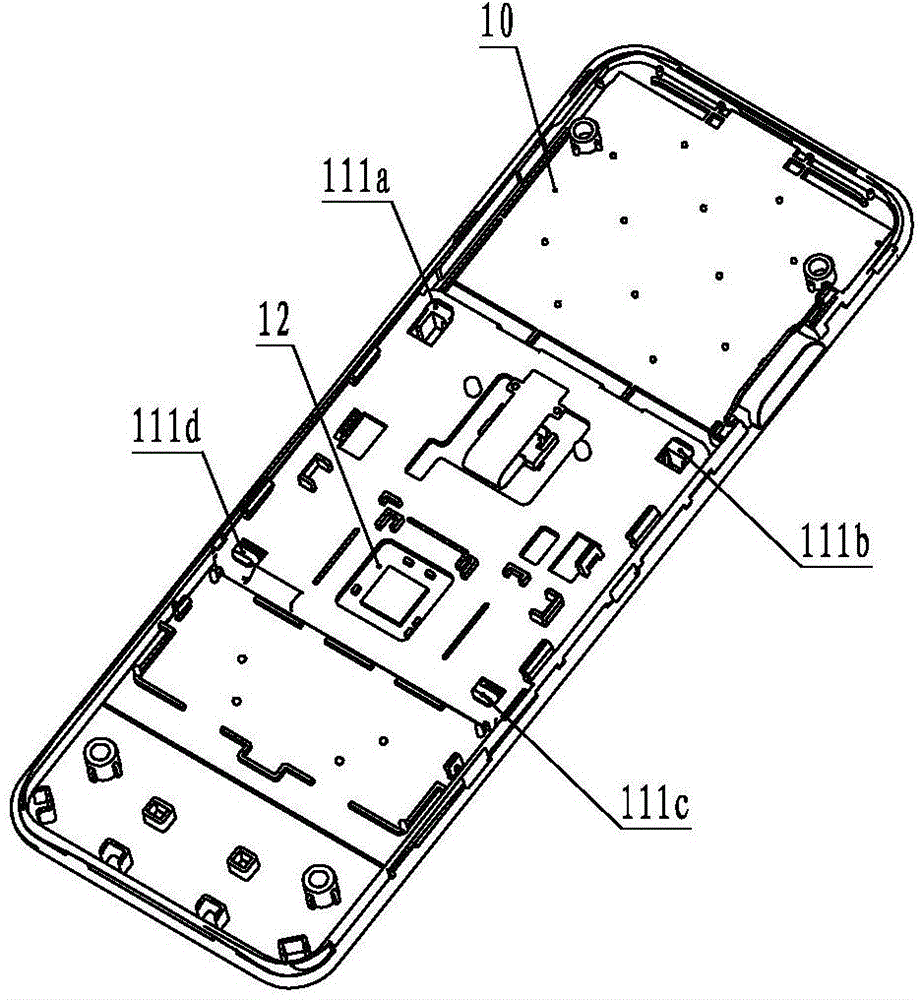

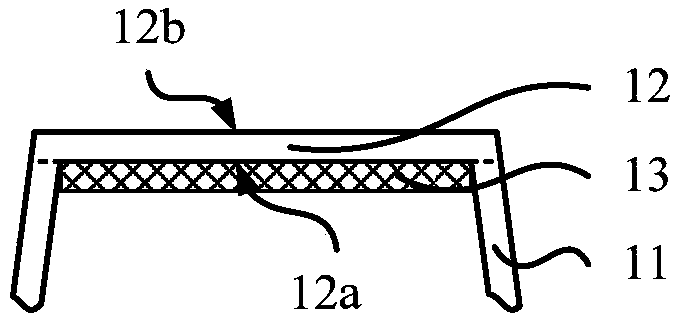

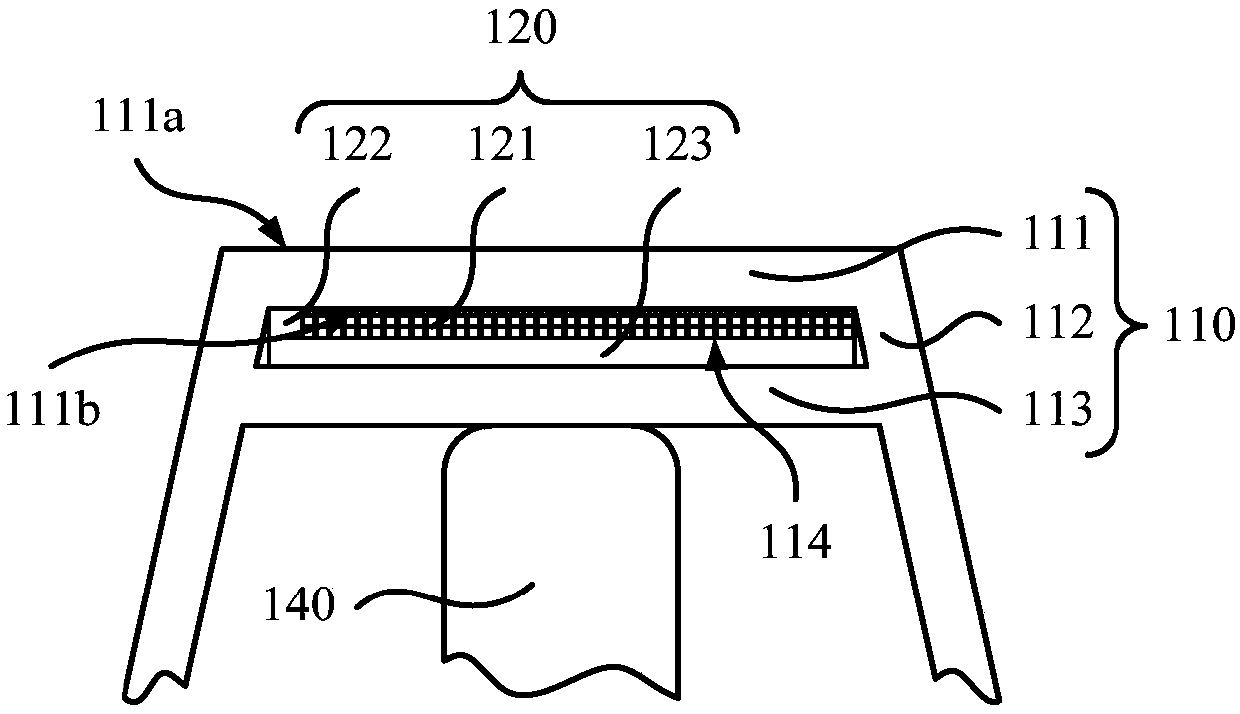

Electronic terminal product touch button structure and remote control

ActiveCN103560034ARealize the pressing functionConsistent feelElectric switchesKey pressingRemote control

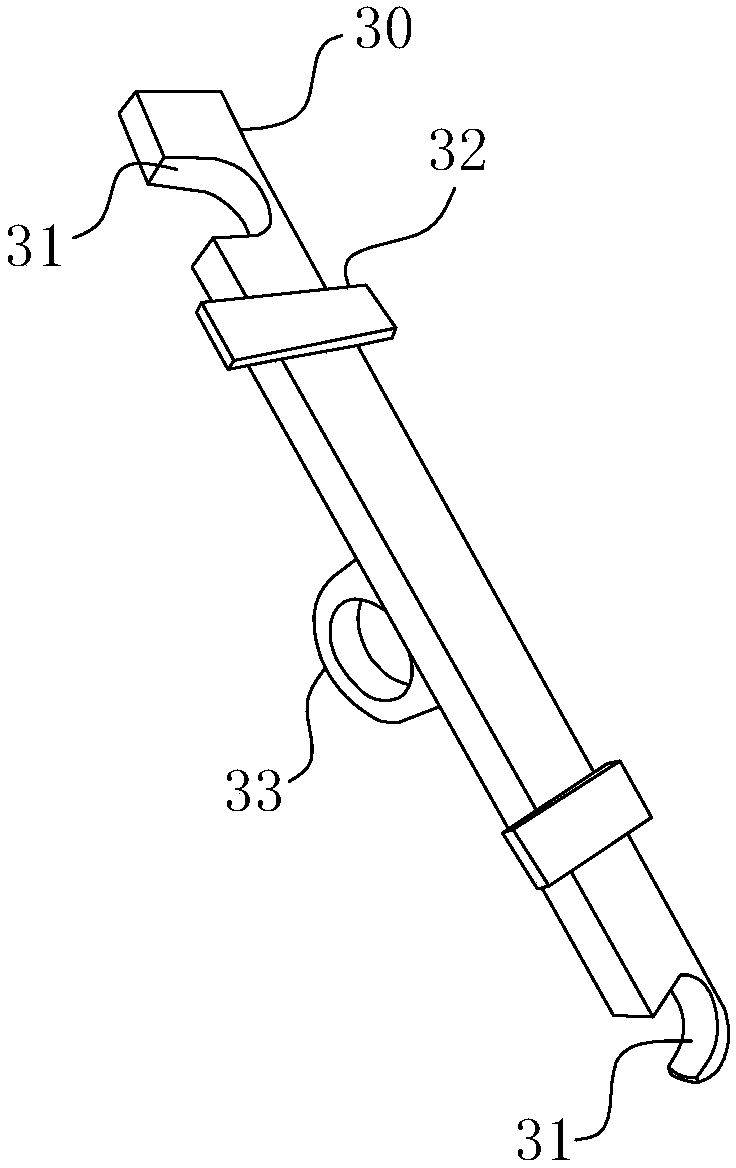

The invention belongs to the technical field of buttons, and particularly relates to an electronic terminal product touch button structure. The electronic terminal product touch button structure comprises a touch panel, a PCBA circuit board and a dome button, wherein the touch panel is arranged at the front face of a front shell of an electronic terminal product, and the edge of the touch panel is tightly connected with the front shell; the PCBA circuit board is arranged between the touch panel and the front shell, and one side face of the PCBA circuit board is firmly connected with the touch panel; the dome button is arranged between the PCBA circuit board and the front shell, and the dome button is arranged at the central position of the other side face of the PCBA circuit board, the dome piece of the dome button is in contact with the PCBA circuit board, and a gap where the touch panel and the PCBA circuit board move perpendicular to the front face of the front shell is arranged between the touch panel and the front shell. Due to the fact that the edge of the touch panel is firmly connected with the front face of the front shell, and the dome button is arranged between the PCBA circuit board and the front shell, the touch panel and the PCBA circuit board have a certain movable space relative to the front face of the front shell, pressing on any area of the touch panel can press down the dome button, so that the electronic terminal product touch button structure can be used as a pressing type button to achieve the pressing function.

Owner:QINGDAO GOERTEK

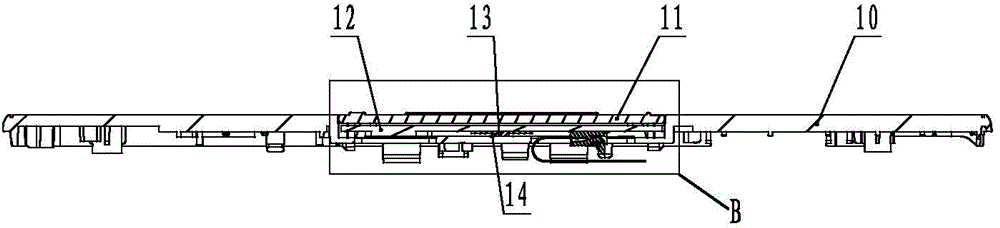

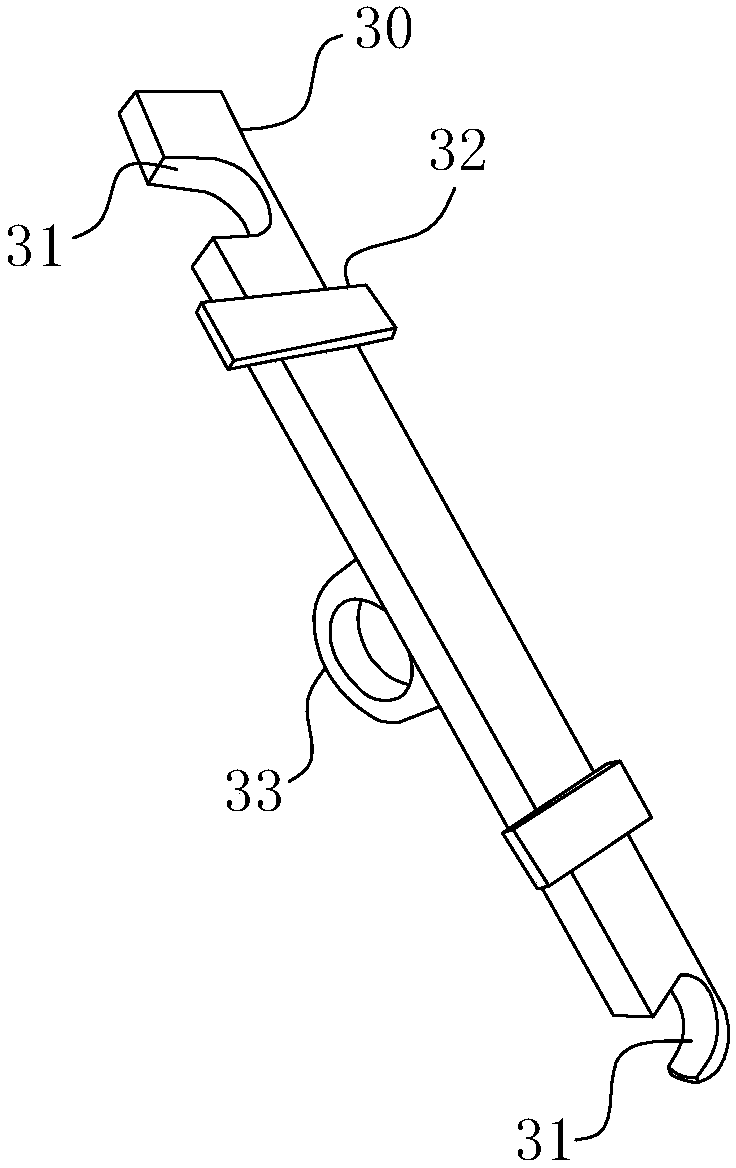

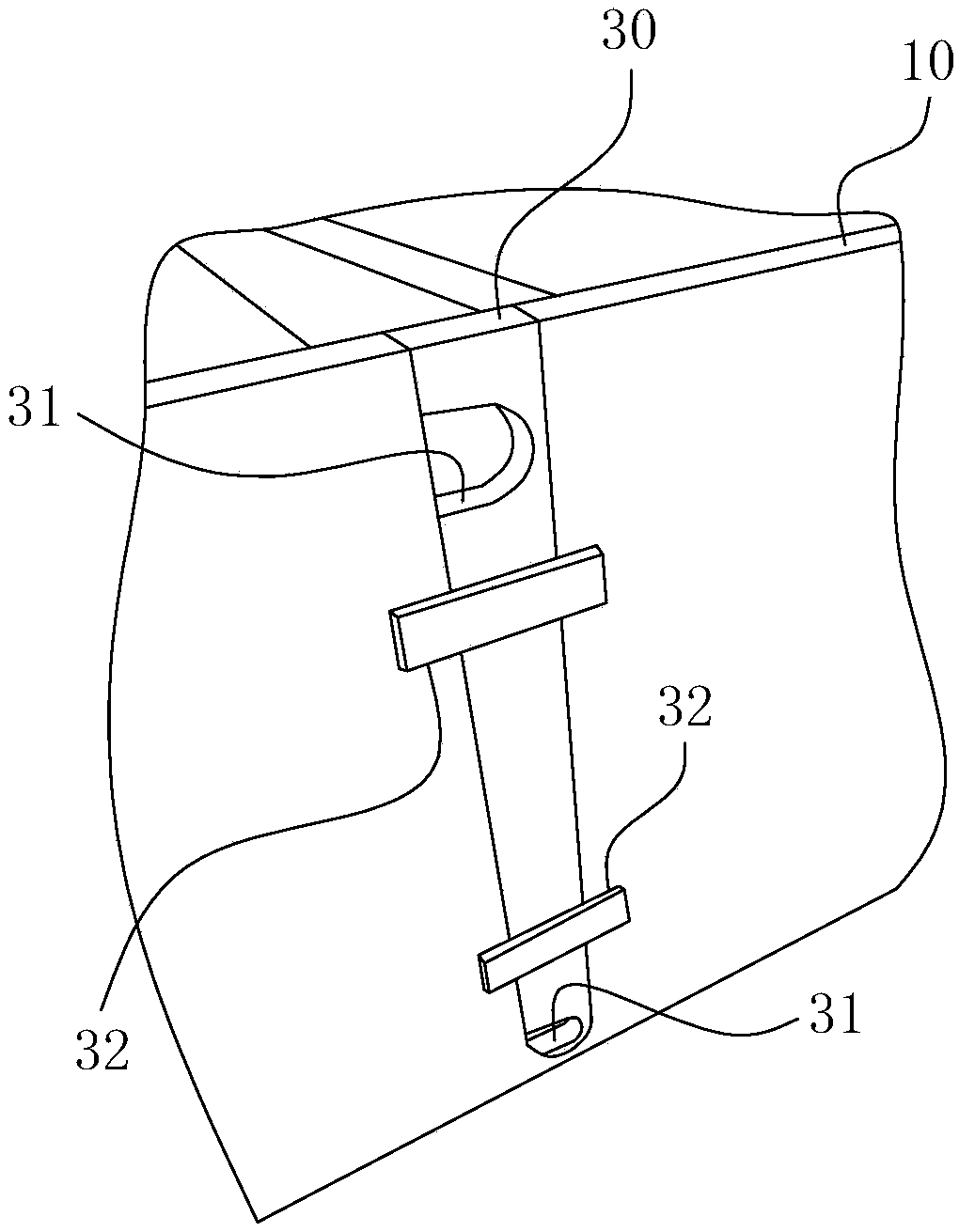

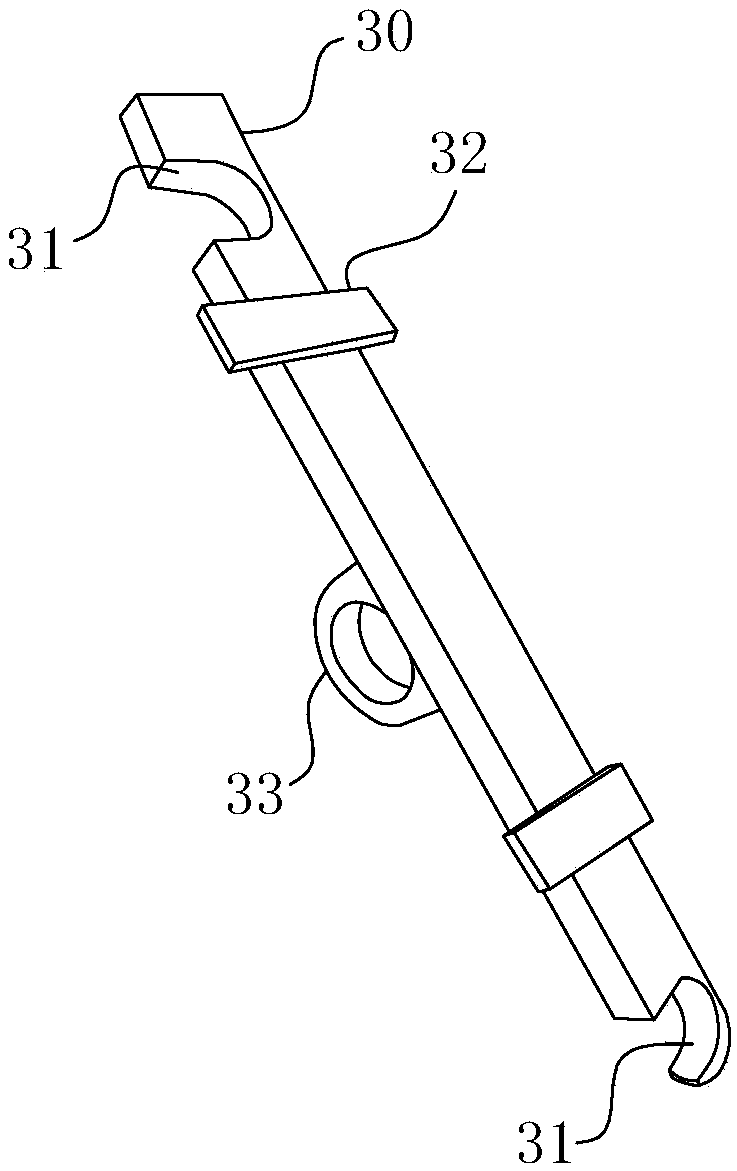

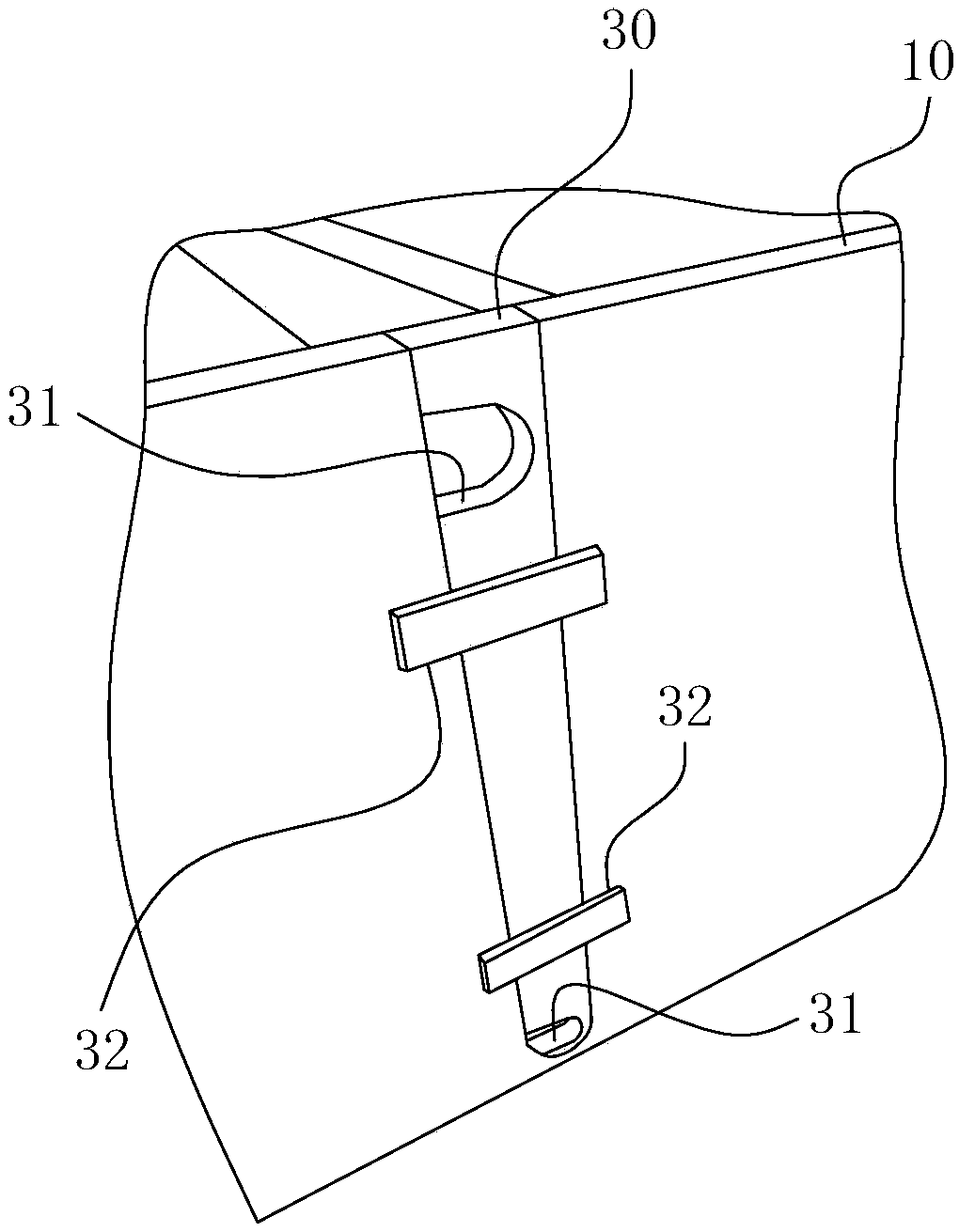

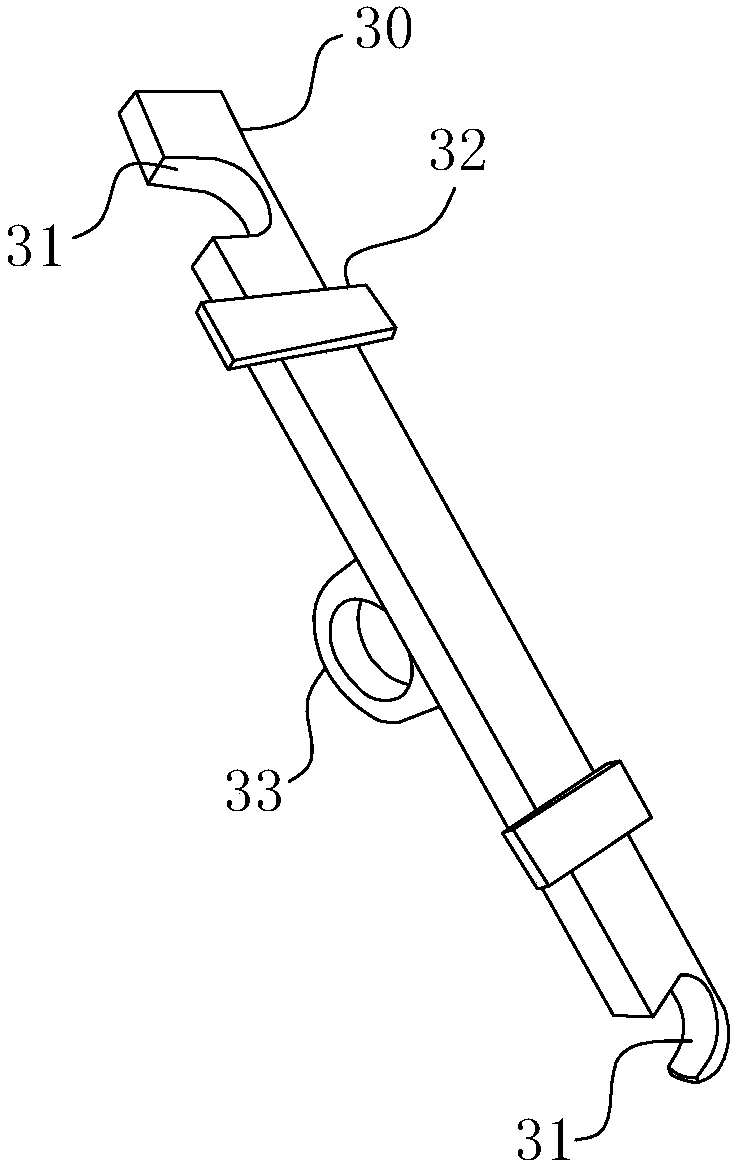

Hook connecting rod pressing-fit mechanism

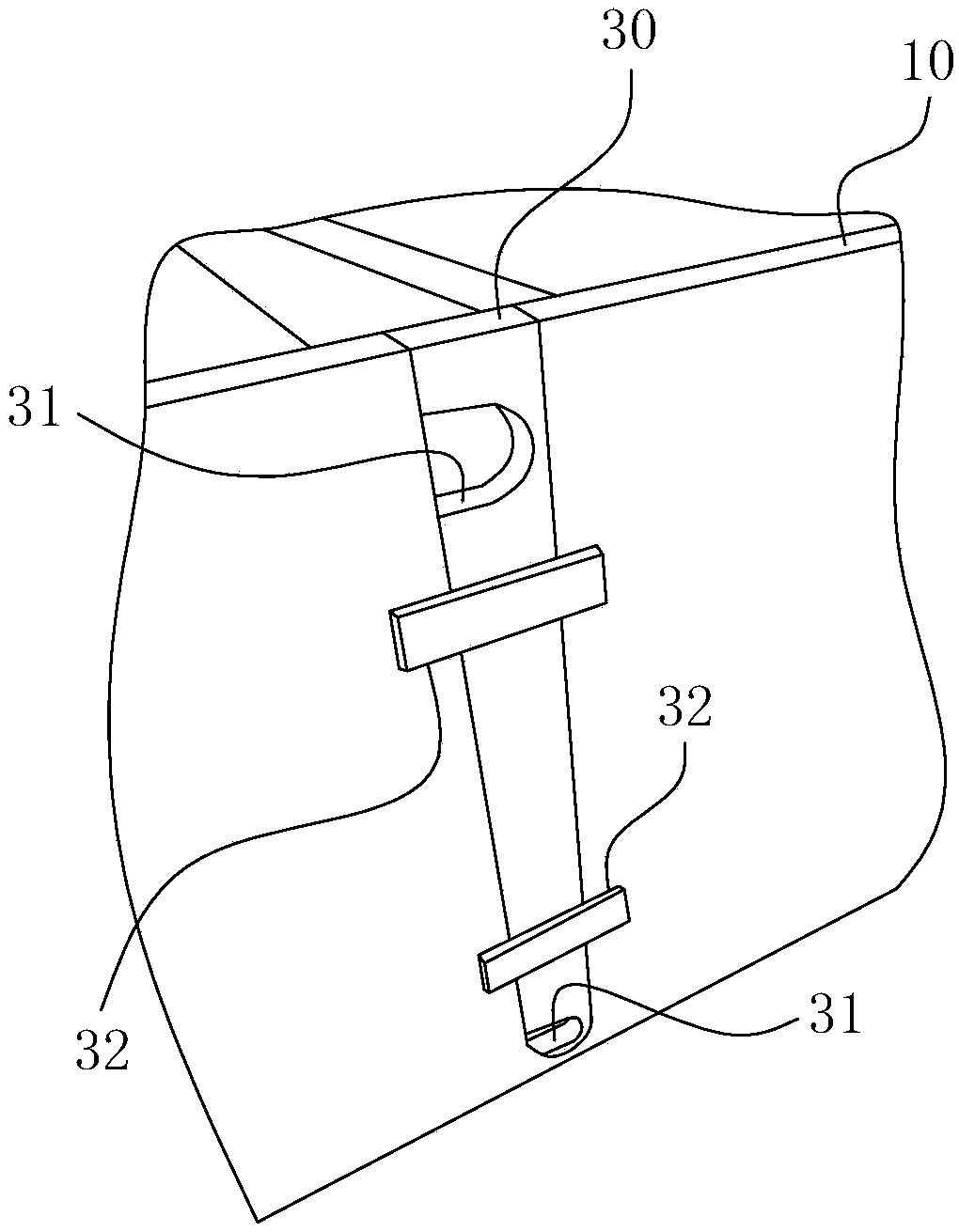

ActiveCN104374959AAvoid dangerGuaranteed tightnessMeasurement instrument housingEngineeringMechanical engineering

The invention relates to a hook connecting rod pressing-fit mechanism. The hook connecting rod pressing-fit mechanism comprises a handle mechanism, a handle positioning block, an inner hook, a synchronous rod, a track plate, an anti-overturn buckle, a roller, an upper pressing plate, a lower pressing plate and a mechanism box. In actual use, an operator fixes a circuit board to be tested between the upper pressing plate and the lower pressing plate, and then the handle mechanism is pressed downwards; in the downward-pressing process, the handle mechanism drives the inner hook to hook the roller, so that the pressing-fit function is achieved; when the handle mechanism is completely pressed downwards, the handle mechanism abuts against the inner hook on the same side as the handle mechanism through the anti-overturn buckle, so that the mechanism sealing performance in the testing process is ensured; when large current or high voltage is tested, the accident occurrence rate is reduced, the risk caused by misoperation of personnel is avoided due to the anti-overturn buckle design, the actions of locking, pressing-fit, locking and the like can be achieved at a time, and a large amount of time is saved.

Owner:SUZHOU SECOTE PRECISION ELECTRONICS CO LTD

Multi-layer corrugated board gluing device

ActiveCN113844104ARealize the pressing functionRealize gluingMechanical working/deformationPaper/cardboardPaper tapeEngineering

The invention discloses a multi-layer corrugated board gluing device, and relates to the technical field of corrugated board processing. The multi-layer corrugated board gluing device comprises a rack, one end of the rack is rotatably provided with three groups of flat paper rolls and two groups of corrugating medium rolls, and the two groups of corrugating medium rolls are located between two adjacent corrugating forming extrusion rollers; and two groups of flattening conveying rollers are rotatably installed at the other end of the rack, two groups of corrugated forming extrusion rollers are arranged at the positions, corresponding to the two corrugated forming extrusion rollers, of the rack, and the number of each group of corrugated forming extrusion rollers is two. The two groups of flattening conveying rollers are rotatably driven, so that the flattening conveying rollers are utilized to realize the pressing function of glued flat paper and corrugated paper, the traction function of all paper tapes is also realized, and meanwhile, the swinging of an arc-shaped glue smearing plate is utilized to realize the functions of gluing and uniformly smearing the bonding surface of the flat paper, thus the gluing and compounding efficiency of the device is improved, and the gluing effect of corrugated board forming and gluing is improved.

Owner:嘉兴市荣晟包装材料有限公司

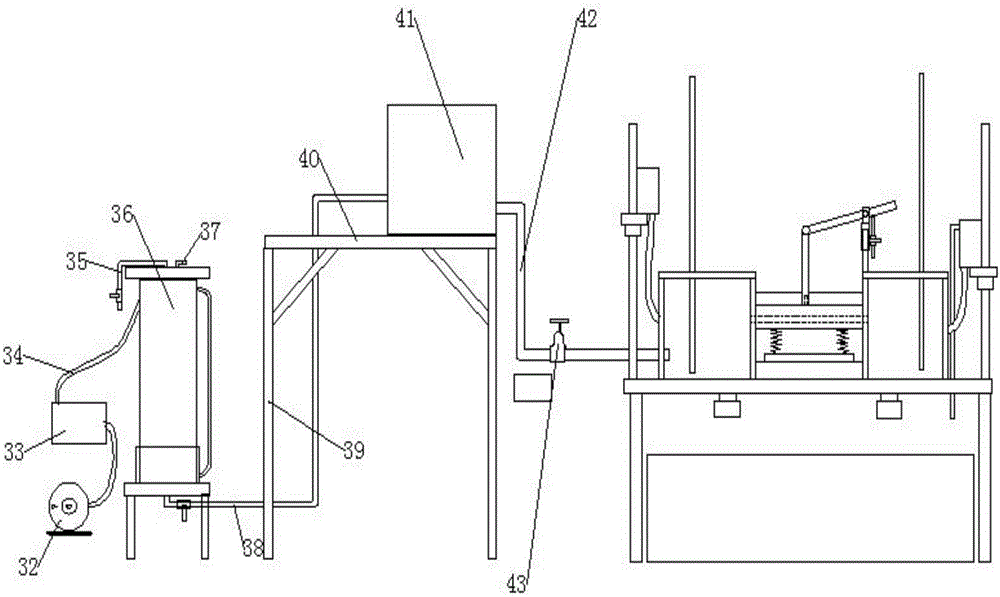

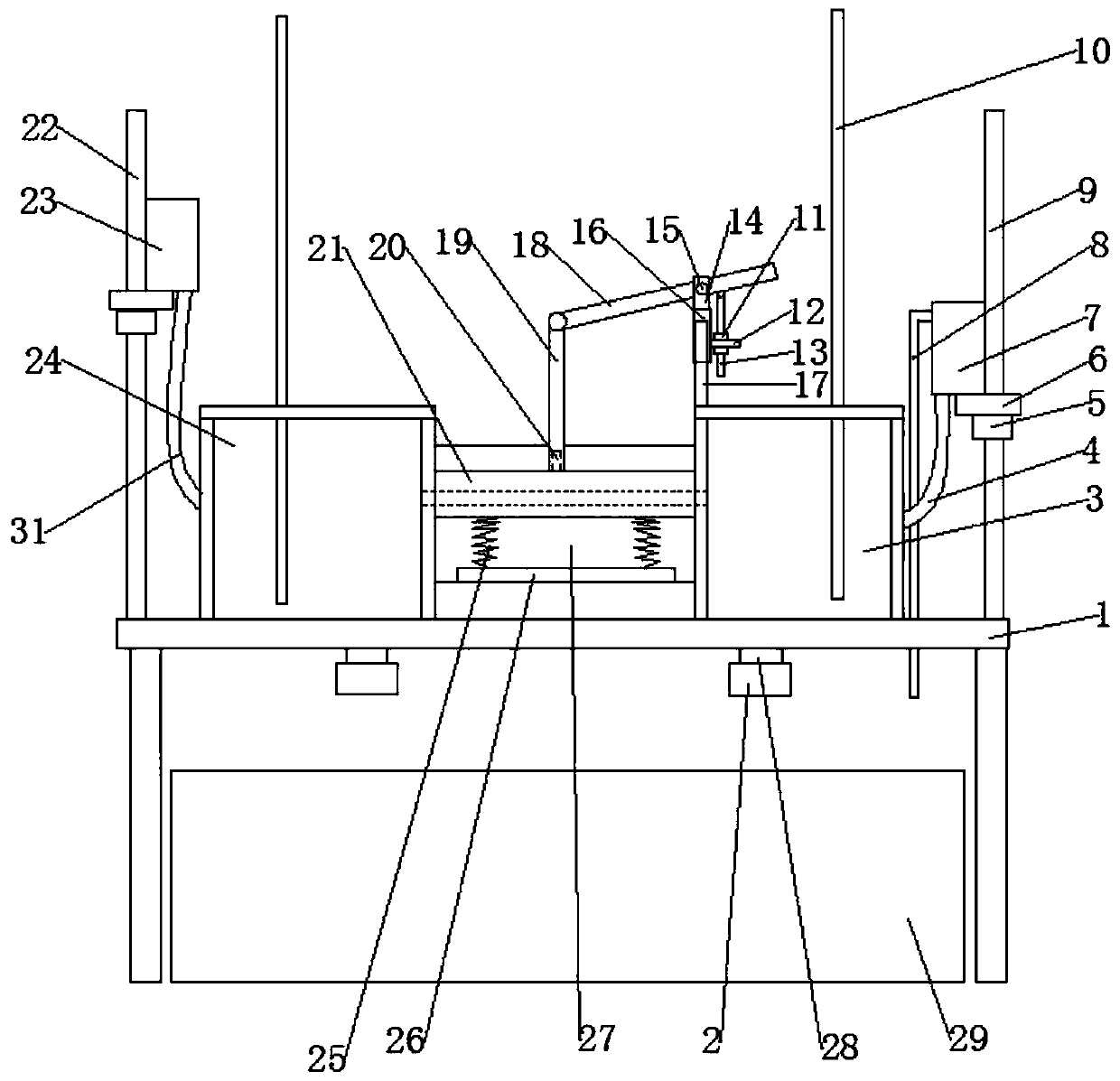

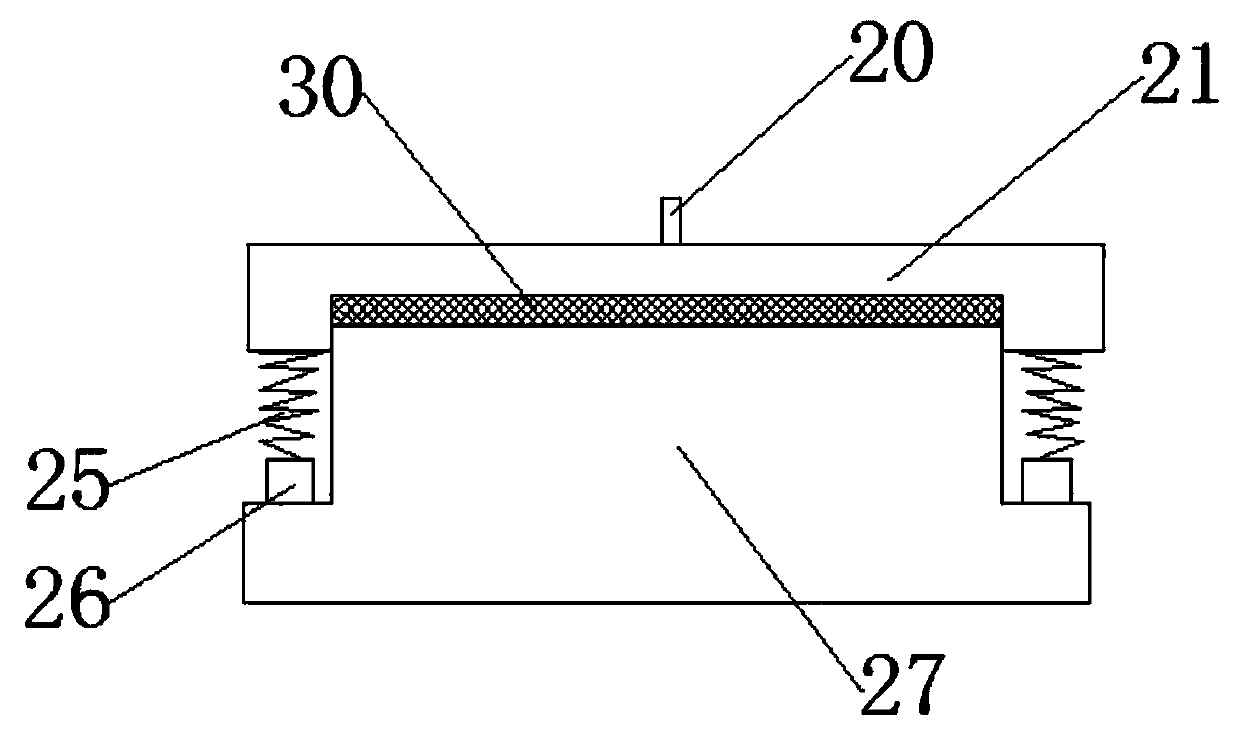

Horizontal permeameter for geotextile

ActiveCN106680179ARealize the pressing functionEasy to replacePermeability/surface area analysisEngineeringPermeameter

The invention belongs to the technical field of geotechnical instruments and particularly relates to a horizontal permeameter for geotextile. The horizontal permeameter comprises a permeation measuring device and a gas and water removing device, wherein the gas and water removing device is arranged on the left side of the permeation measuring device, and the permeation measuring device comprises a first-stage support platform, a permeation chamber, an object table, a press block and a support block; the permeation chamber is arranged at the top of the first-stage support platform, an infiltration water container is arranged on the first-stage support platform on the left side of the permeation chamber, an exudation water container is arranged on the first-stage support platform on the right side of the permeation chamber, the object table is arranged at the bottom in the inside the permeation chamber, the press block is arranged above the object table, and an inverted-U-shaped groove allowing the object table to be inserted in is formed in the bottom of the press block. The horizontal permeameter for the geotextile can test the horizontal permeation performance of the geotextile in a laboratory, obtains more accurate and stable test results and has the advantages of being simple in structure and convenient to operate.

Owner:立方通达(天津)实验仪器有限公司

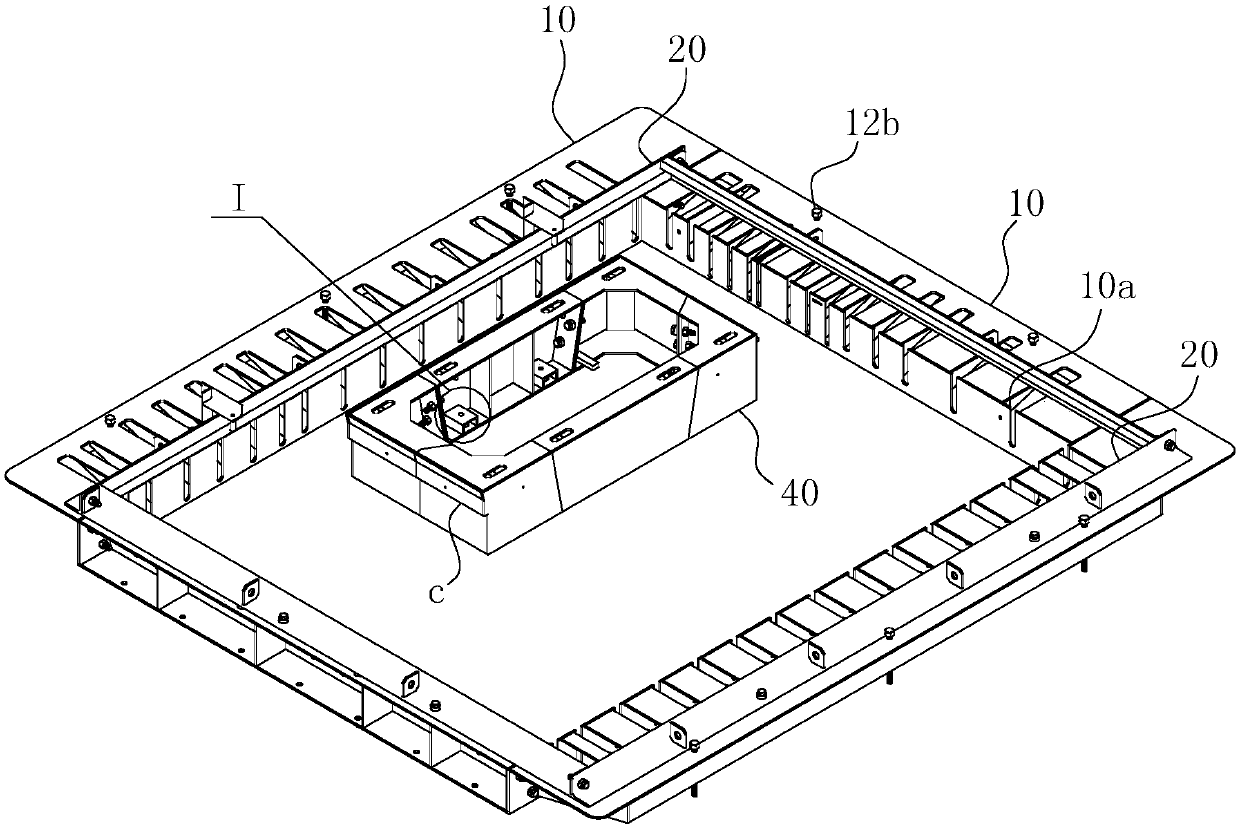

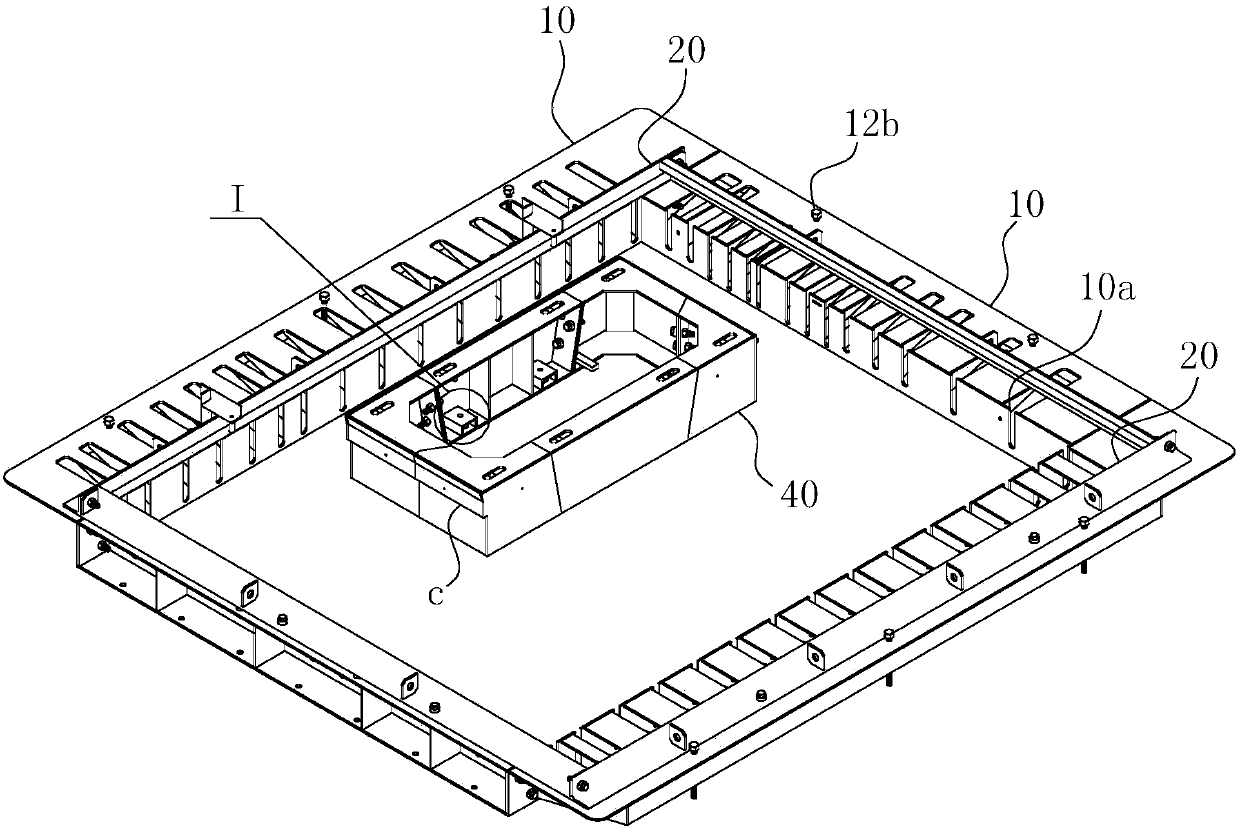

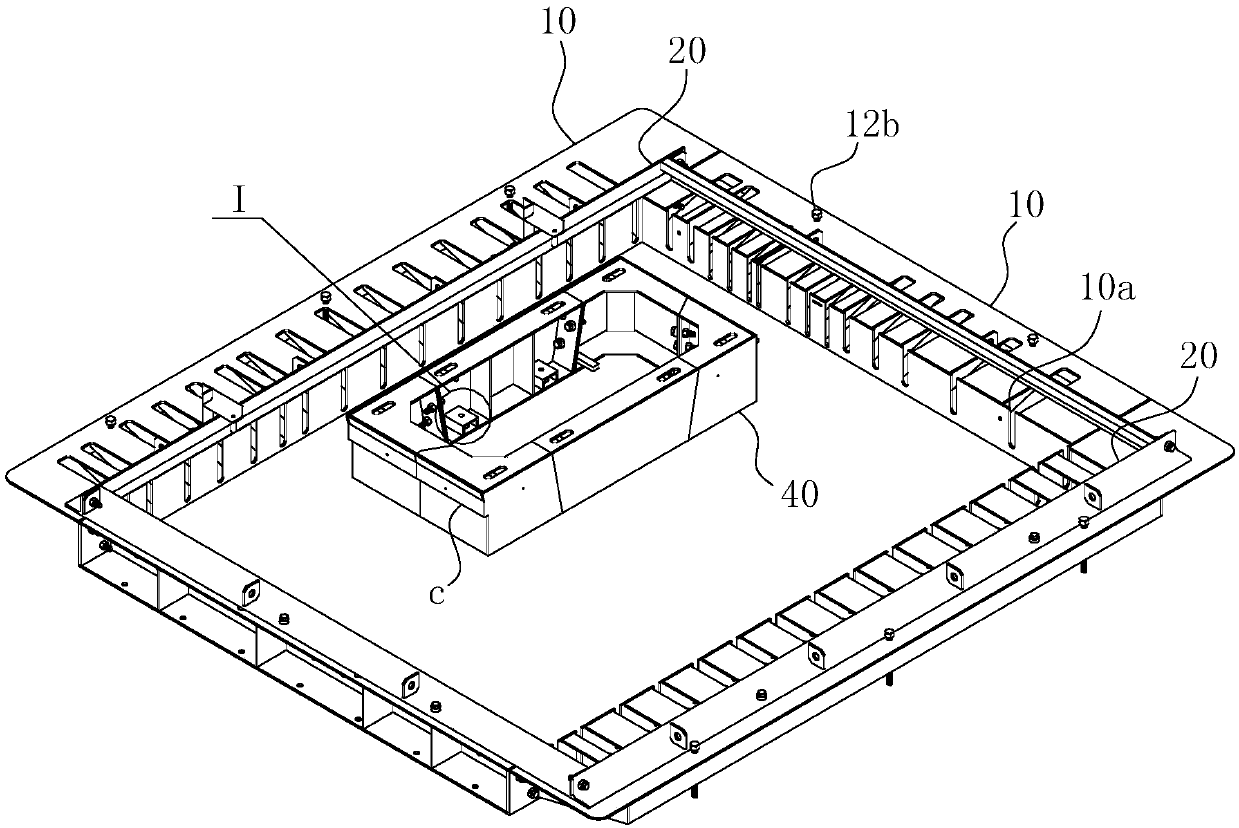

Easy-disassembly type PC wall board mold with window aperture mold set

ActiveCN107127867ARealize the processing effectRealize functionMouldsCeramic shaping mandrelsBuilding productProjection line

The invention belongs to the technical field of building products, and particularly relates to an easy-disassembly type PC wall board mold with a window aperture mold set. The easy-disassembly type PC wall board mold comprises four inner wythe wall side molds and positioning blades; U-shaped positioning grooves are formed in the mold cavity face of the inner wythe wall side molds in a concaved mode; positioning arc grooves are formed in the side position of the longer side of each positioning blade, and the positioning blades are fixed in the U-shaped positioning grooves in an inserted mode; the easy-disassembly type PC wall board mold further comprises the window aperture mold set, the window aperture mold set is divided into four sets of corner end sub-molds and two sets of straight flange sub-molds; on the projection in the perpendicular direction, the projection line formed by vertical truncation surface is parallel to the direction pointed by the top end of one of the truncated corner end sub-molds; and the outline of the cross section of the inner wythe wall board mold is a L shape. The easy-disassembly type PC wall board mold has the advantages of being easy to disassemble, easy and rapid to operate and low in production cost, one-time pouring forming of a window aperture is guaranteed, at the same time, the prefabrication, the integral installation and rapid mold removal operation of steel reinforcement frameworks are achieved, and the production efficiency of prefabricated walls can be improved greatly.

Owner:合肥宝德建筑工业化有限公司

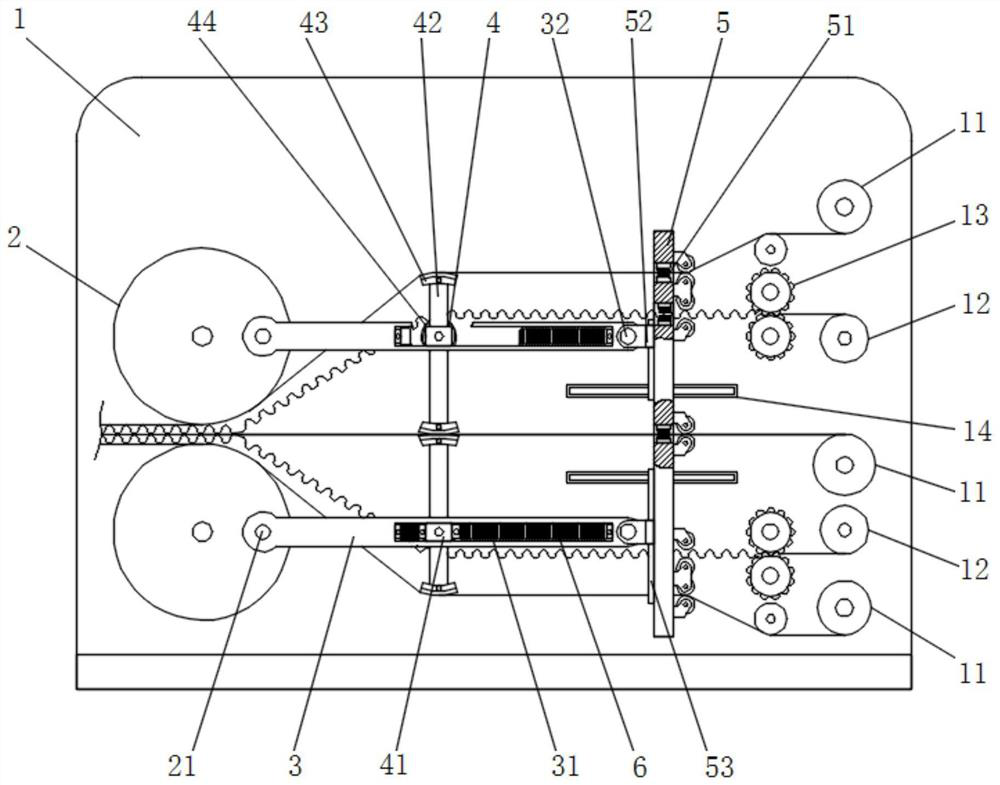

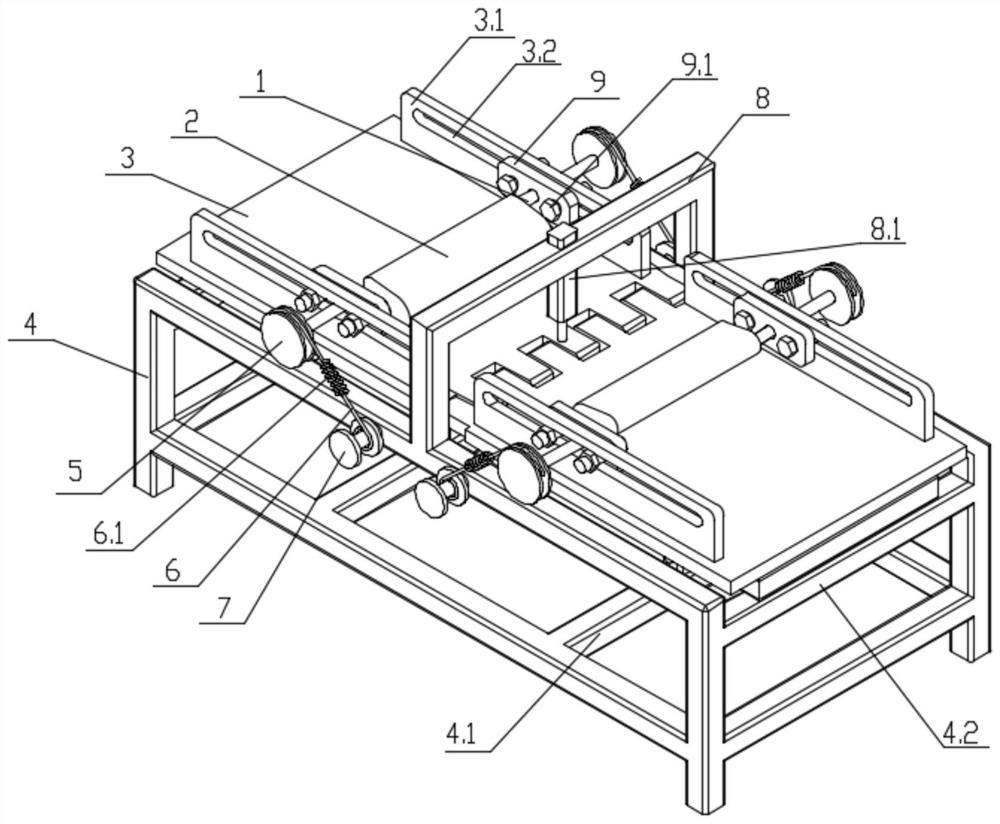

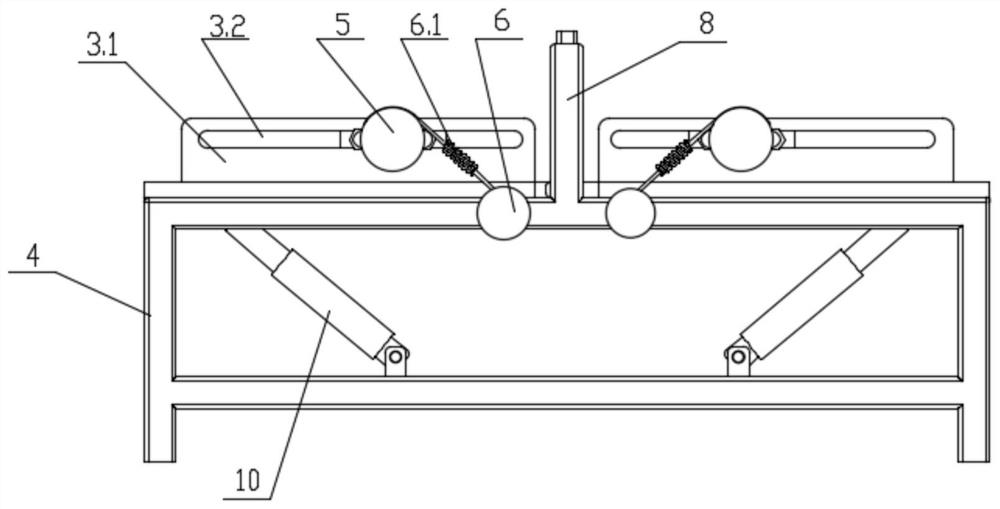

Precise winding device and method for big-diameter two-pole coil

ActiveCN108922771AAchieve precision windingSolve the problem of not being able to arrange the wires preciselyCoils manufactureWinding machineCompression device

The invention relates to a precise winding device and method for a big-diameter two-pole coil. A framework of a two-pole coil is arranged on a winding tooling base; a wire pressing plate is arranged at the outer side of the framework; a compression device fixing seat is arranged along the outer side of the framework; one end of a compression main shaft can slide and rotate on the fixing seat; a stop block is tightly pressed onto the wire pressing plate; the stop block is disengaged from the surface of the wire pressing plate; a spring B has an effect of being attached to the outer side of thewinding tooling base. The method comprises the following winding steps that the framework of the two-pole coil is fixed on the winding tooling base; the winding tooling base is fixed on a vertical wire winding machine to realize the rotation; the wire pression plate tightly presses the wound wire material surface; the compression device fixing seat is arranged at the outer side of the framework; aspring A provides pressing tensioning force; the stop block presses the wire pressing plate; the compression device fixing seat slides to the outer side and rotates to a 90-degree position; the stopblock is disengaged from the surface of the wire pressing plate; the spring B enables the stop block to be tightly attached to the outer edge of the tooling base; jackscrews are fed into a tight jacking plate to provide tension for the wire material straight edge winding; the structure is simple; the operation is convenient; the winding quality and the winding efficiency are high.

Owner:XIAN JUNENG SUPERCONDUCTING MAGNET TECH

PC wallboard mold with window hole module

ActiveCN107116666ARealize the processing effectRealize functionMoulding surfacesMould auxillary partsBuilding productEngineering

The invention belongs to the technical field of building products, and in particular, relates to a PC wallboard mold with a window hole module. The mold comprises four inner wall edge molds and positioning pieces; U-shaped positioning grooves are concavely formed in the mold cavity surfaces of the inner wall edge molds; positioning arm grooves are concavely formed in the long edge sides of the positioning pieces; and the positioning pieces are fixedly inserted in the U-shaped positioning grooves. The mold further comprises the window hole module; the window hole module is divided into four sets of angular end submolds and two sets of straight edge submolds; and the cross sections of the inner wall edge molds are L-shaped. The mold further comprises a positioning circular plate and a pipe sleeve; a pressing plate is placed on the top end surface of the pipe sleeve; and the pressing plate and the pipe sleeve are tightly pressed on the positioning circular plate by fastening screws. The mold has the advantages of simple mold disassembly, convenient and fast operation and low manufacturing cost, can realize prefabrication of a reinforcement skeleton and overall mold insertion operation when guaranteeing once casting formation of window holes, and can greatly improve the manufacturing quality and efficiency of prefabricated walls.

Owner:ANHUI BAOYE CONSTR ENG GRP CO LTD

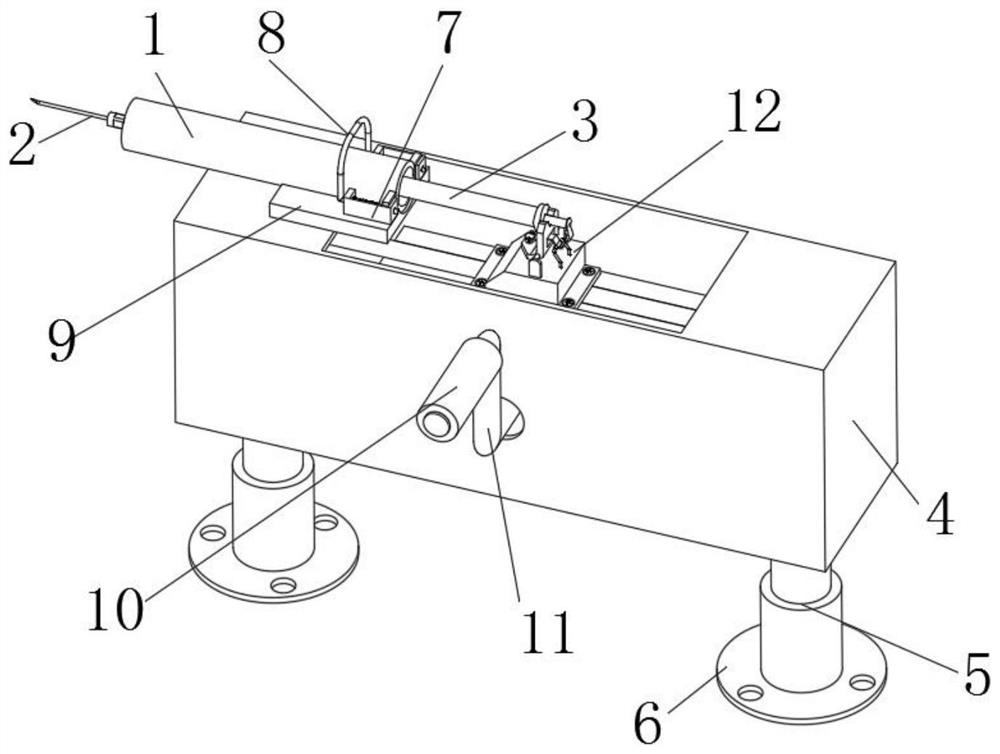

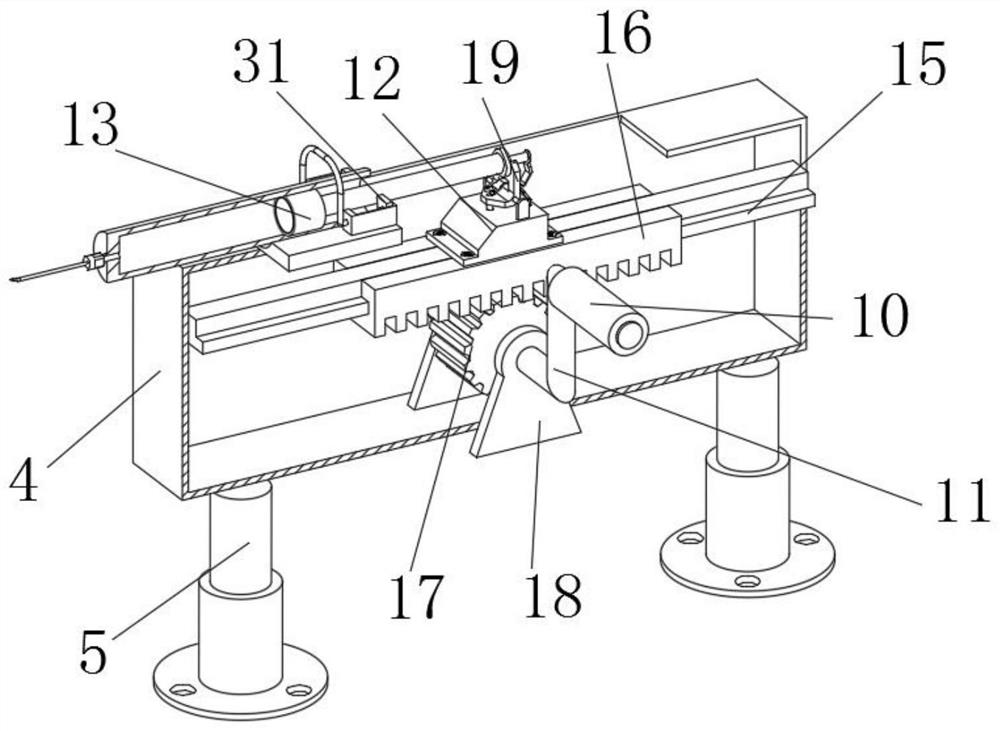

Contrast agent auxiliary injector for intervention department and auxiliary supporting assembly thereof

PendingCN113546251AReasonable structureEasy to operateInfusion syringesIntravenous devicesContrast mediumInjector

The invention discloses acontrast agent auxiliary injector for intervention department and an auxiliary supporting assembly thereof, and relates to the technical field of medical instruments, which comprises an injection mechanism, and an auxiliary injector and an auxiliary supporting assembly which are used for moving the injection mechanism; the injection mechanism comprises an injection pipe, an injection head arranged at one end of the injection pipe, a piston installed in the injection pipe in a matched mode and a push rod fixedly connected to one end of the piston. The auxiliary injector and the auxiliary supporting assembly provided by the invention are reasonable in structure, scale marks are arranged on the injection pipe, the injection pipe is a transparent pipe, the injection amount of a contrast agent is convenient to observe, the contrast agent is convenient to inject by arranging the push rod pushing part, operation is convenient, labor is saved, pushing of the push rod to move is stopped by arranging a push rod thrust unit, the elastic force of a limiting spring, a thrust piston and a thrust rod, so that unnecessary pain of the patient caused by excessive liquid in the biliary tract due to the fact that the blood vessel of the patient is blocked and the contrast agent is injected into the body of the patient through mechanical thrust is avoided.

Owner:AFFILIATED CANCER HOSPITAL OF SHANDONG FIRST MEDICAL UNIV SHANDONG CANCER INST (SHANDONG CANCER HOSPITAL)

pc wall panel mold with window hole module

ActiveCN107116666BRealize the processing effectRealize functionMoulding surfacesMould auxillary partsBuilding productWindow opening

The invention belongs to the technical field of building products, and in particular, relates to a PC wallboard mold with a window hole module. The mold comprises four inner wall edge molds and positioning pieces; U-shaped positioning grooves are concavely formed in the mold cavity surfaces of the inner wall edge molds; positioning arm grooves are concavely formed in the long edge sides of the positioning pieces; and the positioning pieces are fixedly inserted in the U-shaped positioning grooves. The mold further comprises the window hole module; the window hole module is divided into four sets of angular end submolds and two sets of straight edge submolds; and the cross sections of the inner wall edge molds are L-shaped. The mold further comprises a positioning circular plate and a pipe sleeve; a pressing plate is placed on the top end surface of the pipe sleeve; and the pressing plate and the pipe sleeve are tightly pressed on the positioning circular plate by fastening screws. The mold has the advantages of simple mold disassembly, convenient and fast operation and low manufacturing cost, can realize prefabrication of a reinforcement skeleton and overall mold insertion operation when guaranteeing once casting formation of window holes, and can greatly improve the manufacturing quality and efficiency of prefabricated walls.

Owner:ANHUI BAOYE CONSTR ENG GRP CO LTD

A quick-detachable pc wall panel mold with the function of integrally entering the mold of the steel skeleton

ActiveCN107263681BRealize the processing effectRealize functionMoulding surfacesMould auxillary partsBuilding productRebar

The invention belongs to the technical field of building products, and particularly relates to a quick-release-type PC wallboard mold with the integral mold-in function of a steel reinforcement framework. The quick-release-type PC wallboard mold comprises four inner wall side molds and positioning pieces. U-shaped positioning grooves are formed in the mold cavity surfaces of the inner wall side molds in a recessed mode. Positioning arc grooves are formed in the long edge side positions of the positioning pieces in a recessed mode, and the positioning pieces are fixedly inserted into the corresponding U-shaped positioning grooves. Cross sections are made perpendicular to the length direction of the inner wall side molds. The cross sections of the inner wall side molds are in an L shape in appearance. The board surfaces at one sides of plumb plates of the inner wall side molds form inner wall mold cavity surfaces. The quick-release-type PC wallboard mold has the advantages that mold disassembly is simple, operation is easy, convenient and fast, and manufacturing cost is low; forming quality of a prefabrication wall body can be guaranteed while prefabrication and integral mold-in operation of the steel reinforcement framework are achieved; and moreover the manufacturing efficiency of the prefabrication wall body can be greatly improved.

Owner:ANHUI BAOYE CONSTR ENG GRP CO LTD

Detachable pc wall panel mold with window hole module

ActiveCN107127867BRealize the processing effectRealize functionMouldsCeramic shaping mandrelsBuilding productWindow opening

The invention belongs to the technical field of building products, and particularly relates to an easy-disassembly type PC wall board mold with a window aperture mold set. The easy-disassembly type PC wall board mold comprises four inner wythe wall side molds and positioning blades; U-shaped positioning grooves are formed in the mold cavity face of the inner wythe wall side molds in a concaved mode; positioning arc grooves are formed in the side position of the longer side of each positioning blade, and the positioning blades are fixed in the U-shaped positioning grooves in an inserted mode; the easy-disassembly type PC wall board mold further comprises the window aperture mold set, the window aperture mold set is divided into four sets of corner end sub-molds and two sets of straight flange sub-molds; on the projection in the perpendicular direction, the projection line formed by vertical truncation surface is parallel to the direction pointed by the top end of one of the truncated corner end sub-molds; and the outline of the cross section of the inner wythe wall board mold is a L shape. The easy-disassembly type PC wall board mold has the advantages of being easy to disassemble, easy and rapid to operate and low in production cost, one-time pouring forming of a window aperture is guaranteed, at the same time, the prefabrication, the integral installation and rapid mold removal operation of steel reinforcement frameworks are achieved, and the production efficiency of prefabricated walls can be improved greatly.

Owner:合肥宝德建筑工业化有限公司

Key structure and electronic equipment

InactiveCN109817481AIncreasing the thicknessHigh strengthCharacter and pattern recognitionElectric switchesKey pressingEngineering

The invention relates to a key structure and electronic equipment. The key structure comprises a key cap and an optical fingerprint identification module, wherein the key cap is provided with a top plate, and the top plate comprises a pressing surface and a bottom surface which are oppositely arranged; and the optical fingerprint identification module is located on one side of the top plate, the optical fingerprint identification module comprises an image sensor, and the image sensor is attached to the bottom surface of the top plate. Through the adoption of the optical fingerprint identification module, the increase of the thickness of the top plate becomes possible, so that the strength of the key structure can be effectively improved, and the key structure is better compatible with a pressing function and a fingerprint identification function.

Owner:SHANGHAI OXI TECH

PC wallboard mold and its integral molding method

ActiveCN107263684BRealize the processing effectRealize functionMouldsMould fastening meansBuilding productEngineering

The invention belongs to the technical field of building products, and particularly relates to a PC wallboard mold and an integral mold-in method using the same. The PC wallboard mold comprises four inner wall side molds and positioning pieces. U-shaped positioning grooves are formed in the mold cavity surfaces of the inner wall side molds in a recessed mode. Positioning arc grooves are formed in the long edge sides of the positioning pieces in a recessed mode. The positioning pieces are fixedly inserted into the corresponding U-shaped positioning grooves. The PC wallboard mold has the advantages that mold disassembly is simple, operation is easy, convenient and fast, and manufacturing cost is low; and prefabrication and integral mold-in operation of a steel reinforcement framework can be achieved, and the manufacturing efficiency of a prefabrication wall body can be greatly improved. The invention further provides the integral mold-in method which is used for specially implementing the manufacturing process of the prefabrication wall body. The method includes the steps that the steel reinforcement framework matched with an inner wall mold cavity is prefabricated; reinforcing steel bars at the ends of the steel reinforcement framework are correspondingly clamped into the U-shaped positioning grooves; and the positioning arc grooves of all the positioning pieces are clamped into the corresponding reinforcing steel bars at the ends of the steel reinforcement framework one by one, and the positioning pieces are made to enter U-shaped positioning groove cavities.

Owner:ANHUI BAOYE CONSTR ENG GRP CO LTD

A Geotextile Horizontal Permeability Tester

ActiveCN106680179BRealize the pressing functionEasy to replacePermeability/surface area analysisEngineeringPermeameter

The invention belongs to the technical field of geotechnical instruments and particularly relates to a horizontal permeameter for geotextile. The horizontal permeameter comprises a permeation measuring device and a gas and water removing device, wherein the gas and water removing device is arranged on the left side of the permeation measuring device, and the permeation measuring device comprises a first-stage support platform, a permeation chamber, an object table, a press block and a support block; the permeation chamber is arranged at the top of the first-stage support platform, an infiltration water container is arranged on the first-stage support platform on the left side of the permeation chamber, an exudation water container is arranged on the first-stage support platform on the right side of the permeation chamber, the object table is arranged at the bottom in the inside the permeation chamber, the press block is arranged above the object table, and an inverted-U-shaped groove allowing the object table to be inserted in is formed in the bottom of the press block. The horizontal permeameter for the geotextile can test the horizontal permeation performance of the geotextile in a laboratory, obtains more accurate and stable test results and has the advantages of being simple in structure and convenient to operate.

Owner:立方通达(天津)实验仪器有限公司

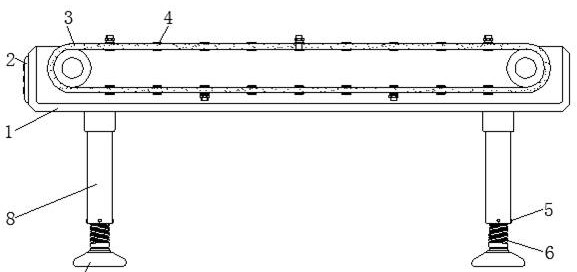

Feeding mechanism for laminate flooring cutting

PendingCN112499120ARealize the height adjustment functionRealize the pressing functionConveyorsLayered productsElectric machineCoupling

The invention relates to the technical field of laminate flooring, in particular to a feeding mechanism for laminate flooring cutting. The feeding mechanism comprises a feeding frame, a feeding belt and supporting legs, and a button switch is installed on the surface of one side of the feeding frame; and a driving motor is installed on the surface of the side, away from the button switch, of the feeding frame; the input end of the driving motor is electrically connected with the output end of the button switch, and a rotating shaft is fixed to the output end of the driving motor through a coupler; second adjusting screws are fixed to the two ends of the surface of the feeding frame, and the surfaces of the second adjusting screws are provided with adjusting nuts in a threaded sleeving mode; connecting blocks are hinged to one sides of the adjusting nuts; and the supporting legs are fixed to the bottom corners of the feeding frame. According to the feeding mechanism, not only are the functions of regulating the height of the feeding frame and tightly pressing floors to be cut through the feeding mechanism achieved, but also the functions of limiting and clamping the floors in different lengths are achieved.

Owner:JIANGSU OUSHENG WOOD

Parallel work-piece pressing device

InactiveCN104400695AAchieve compactionRealize the pressing functionWork holdersEngineeringMechanical engineering

Owner:常州市永联管桩有限公司

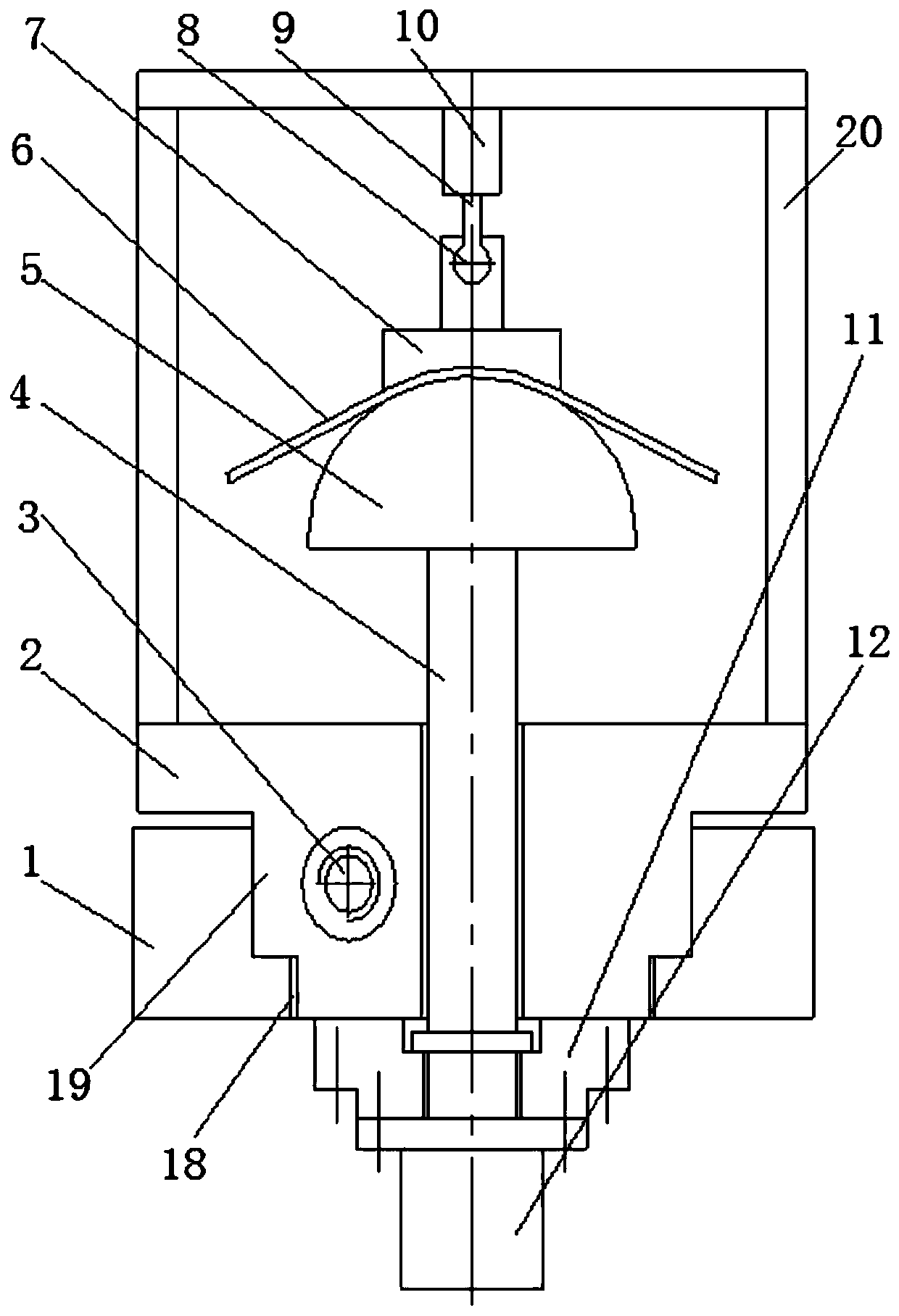

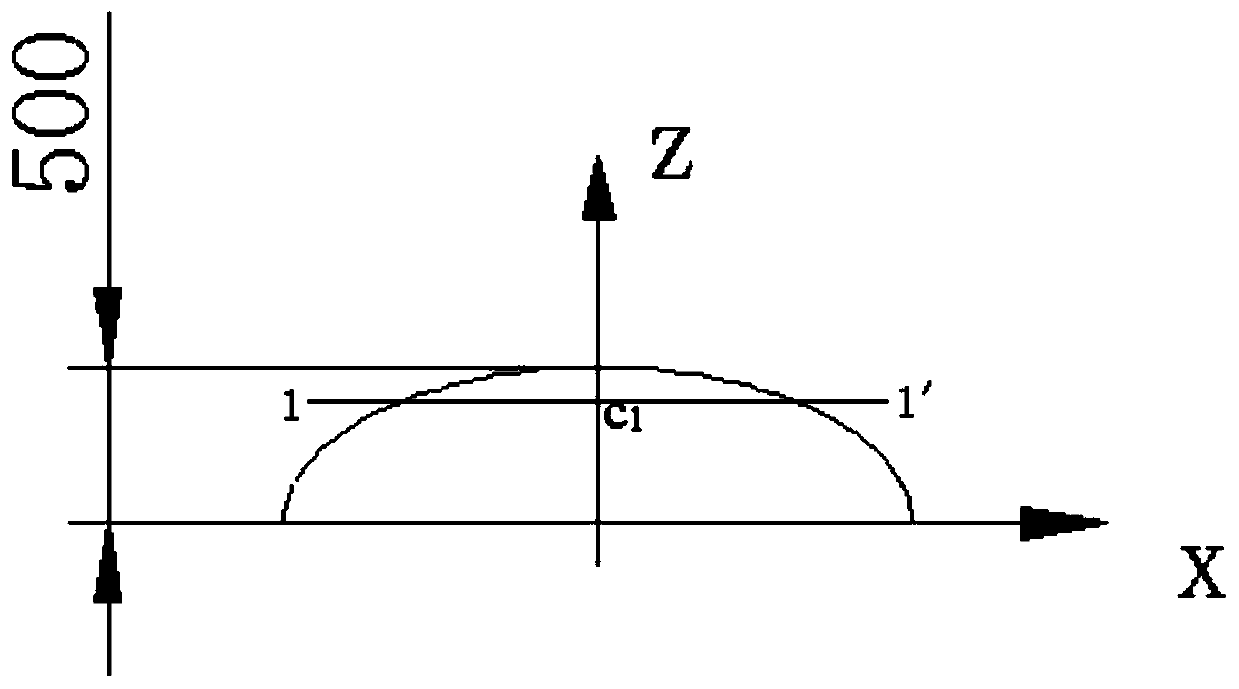

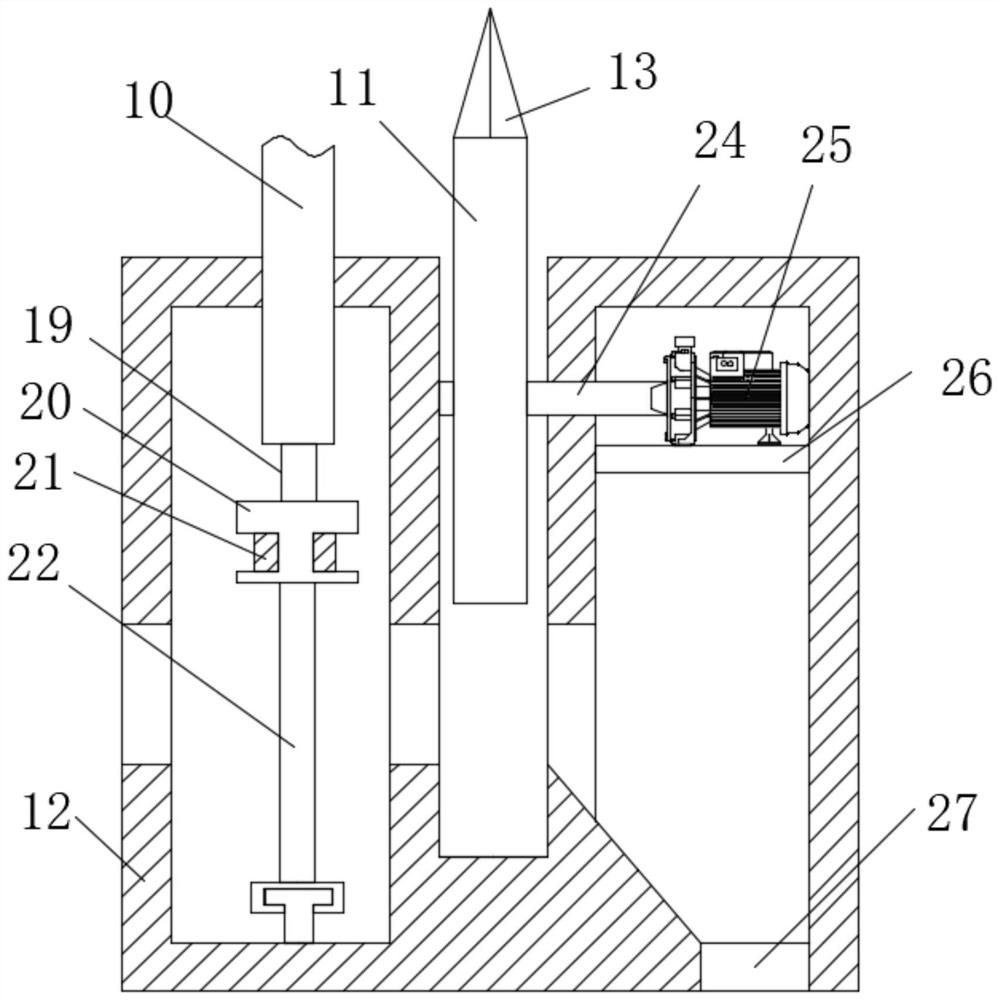

Semi-ellipsoid head-sealing spinning forming device

InactiveCN109794561ARealize the pressing functionAchieving Spinning AccuracyHollow articlesEngineeringMechanical engineering

The invention discloses a semi-ellipsoid head-sealing spinning forming device. The semi-ellipsoid head-sealing spinning forming device comprises a fixing base, the fixing base is provided with a moving beam in a coordinated mode, a horizontal moving mechanism and a spindle rotating mechanism are respectively arranged on the moving beam, the moving beam can move in the horizontal direction with thehorizontal moving mechanism, the spindle rotating mechanism is provided with a semi-ellipsoid head head-sealing inner tube with three unequal sides, a compacting mechanism for compacting blanks is arranged above the semi-ellipsoid head-sealing inner tube with the three unequal sides, and a spinning mechanism for spinning the blanks is arranged one side of the compacting mechanism. The semi-ellipsoid head-sealing spinning forming device solves the problem of difficult spinning forming of a semi-ellipsoid head-sealing with the three unequal sides at present.

Owner:SHAANXI UNIV OF SCI & TECH

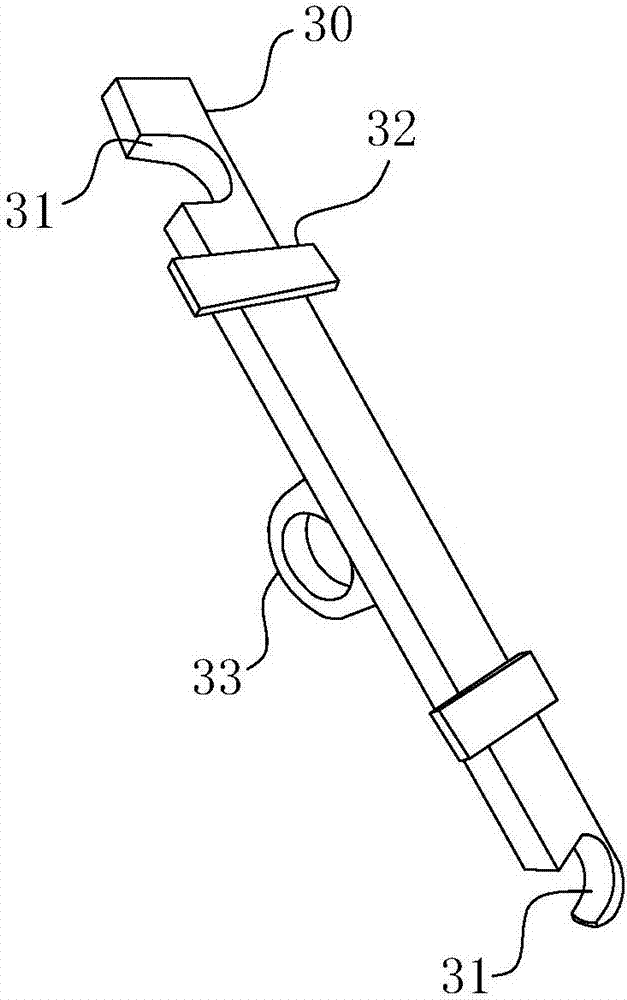

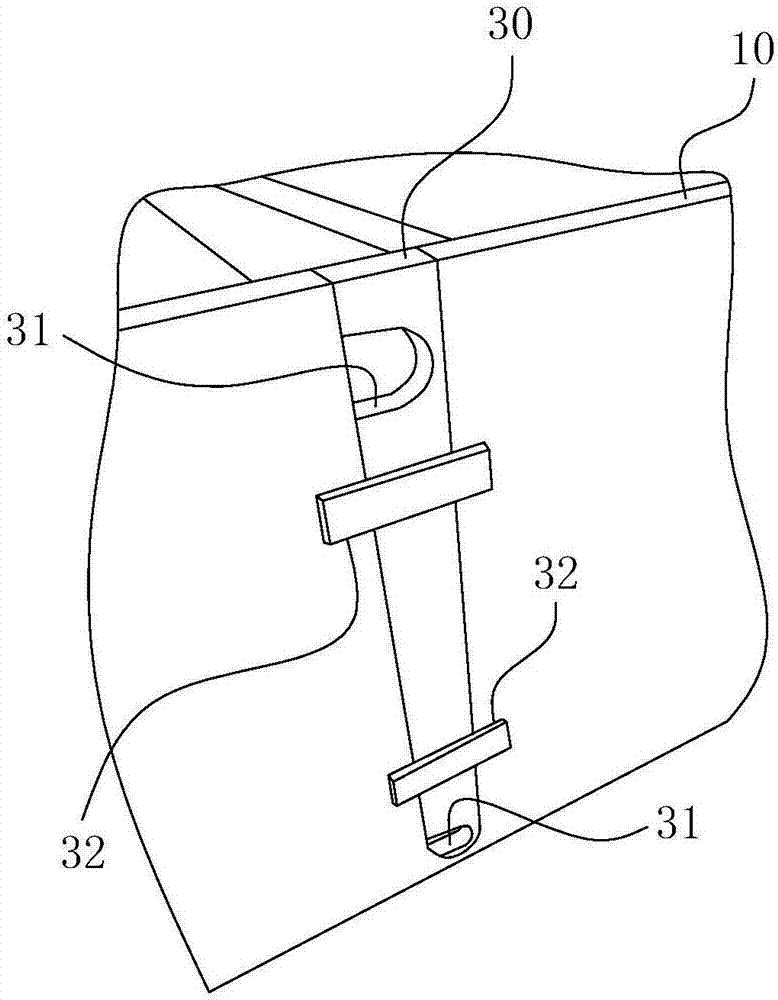

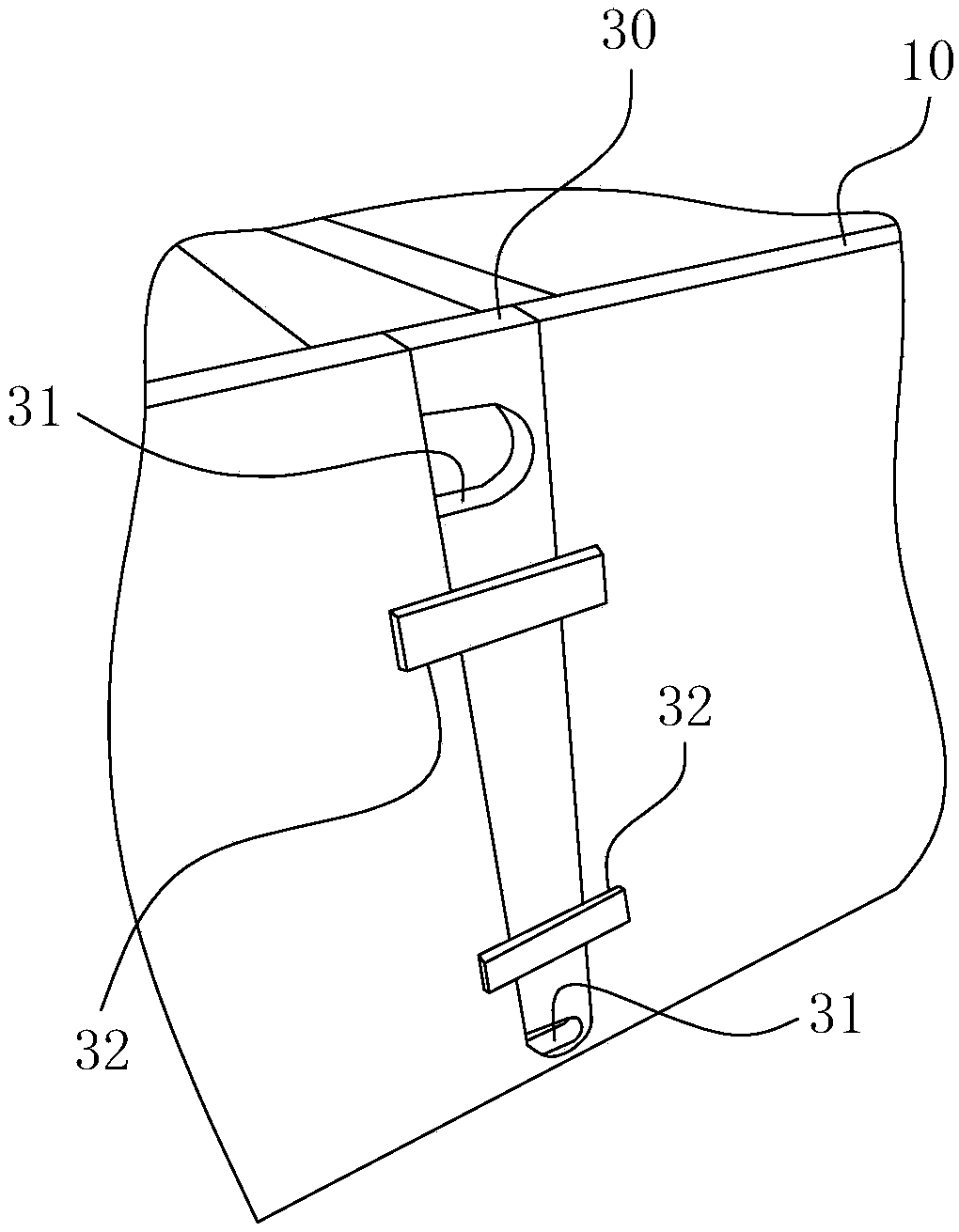

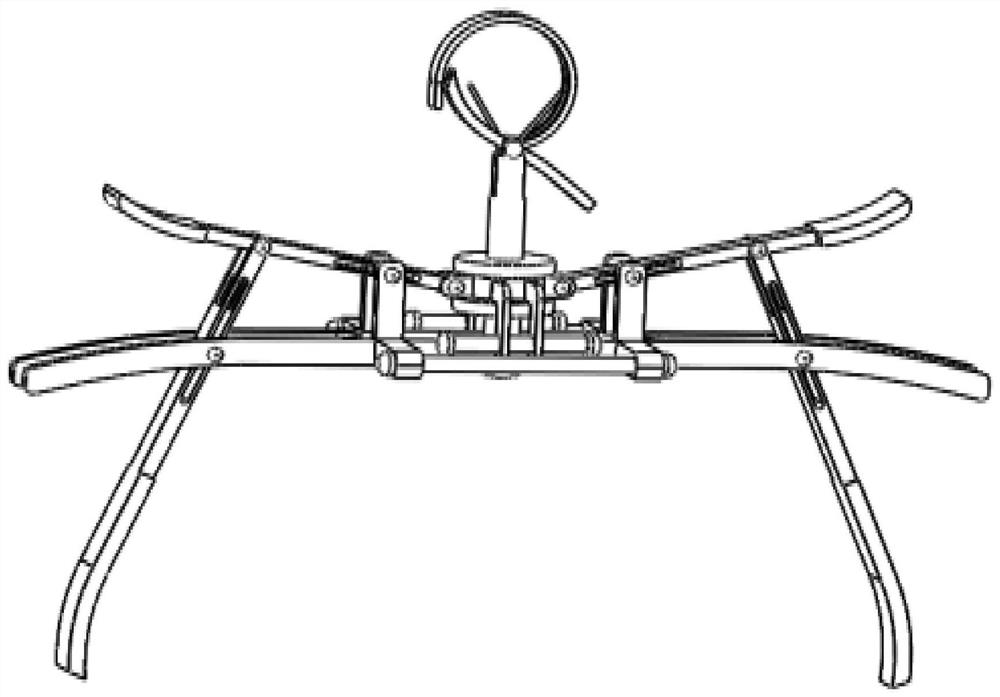

Clothes drying hanger capable of achieving up-and-down clamping and transverse clamping and expanding

ActiveCN111962268ARegulation stabilityRealize the pressing functionApparel holdersOther drying apparatusStructural engineeringMechanical engineering

The invention discloses a clothes drying hanger capable of achieving up-and-down clamping and transverse clamping and expanding. The clothes drying hanger comprises a hanger main framework, a supporting column, a hook portion, lifting portions, press plates, expanding supporting rods and side face clamping plates. The upper end of the supporting column is connected with the hook portion, and the lower end of the supporting column is connected with the hanger main framework. First hinged portions and second hinged portions are connected and arranged on the main framework. The expanding supporting rods and the hanger main framework are hinged on the second hinged portions through first long grooves. The press plates and the lifting portions are hinged on fourth hinged portions. The press plates and the hanger main framework are hinged on the first hinged portions through second long grooves. Third hinged portions are arranged at the positions, on the outer sides of the second long grooves, of the press plates. The expanding supporting rods and the press plates are hinged on the third hinged portions. The side face clamping plates and the side faces of the lifting portions are hingedon sixth hinged portions through fourth long grooves. The corner positions of the side face clamping plates and the side faces of the hanger main framework are hinged on fifth hinged portions. According to the clothes drying hanger, collar up-and-down pressing and transverse clamping and cloth opening can be achieved at the same time only by rotating check rings.

Owner:CHANGZHOU INST OF TECH

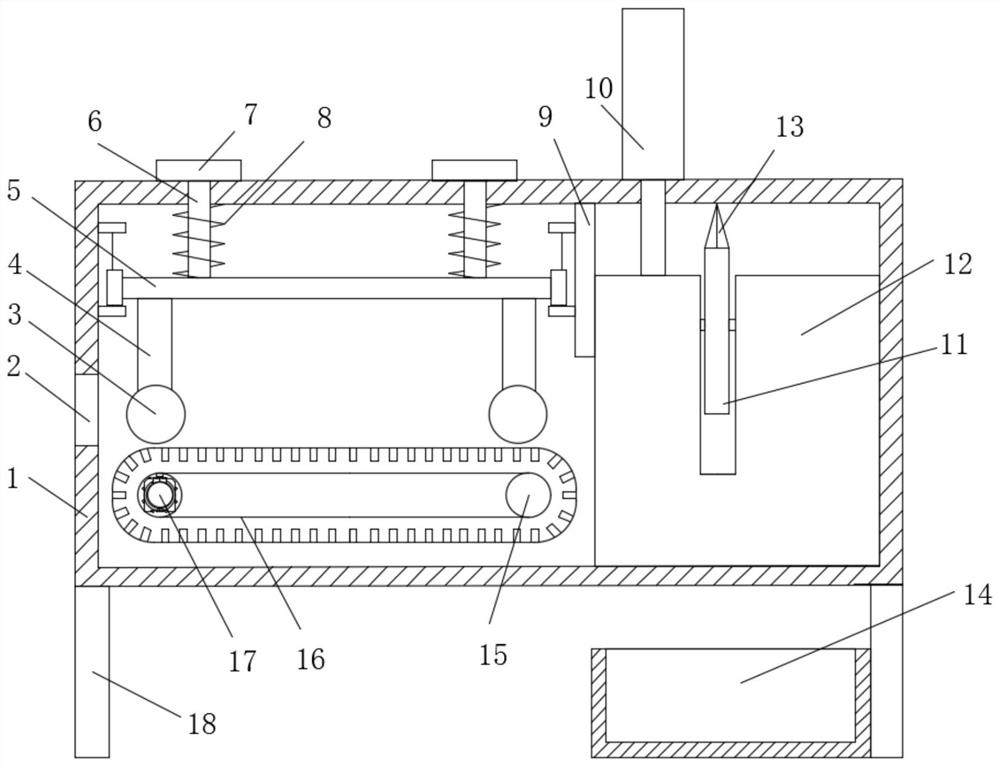

Moxa stick uniform cutting device with automatic feeding function

PendingCN114102708ARealize the transfer functionRealize the pressing functionMetal working apparatusStructural engineeringMechanical engineering

The invention belongs to the technical field of moxa stick processing, particularly relates to a moxa stick uniform cutting device with an automatic feeding function, and aims to solve the problems that existing moxa sticks are cut manually, cutting lengths are different, efficiency is low, automatic feeding cannot be achieved, manual collection is needed, operation is very tedious, and time and labor are consumed. According to the technical scheme, the device comprises a feeding box, a feeding port is formed in one side of the feeding box, a conveying assembly used for conveying moxa sticks is rotationally connected to the inner wall of the feeding box, a fixing plate is fixedly connected to the inner wall of the top of the feeding box, and a pressing assembly used for pressing the moxa sticks is arranged between the inner wall of one side of the feeding box and the fixing plate; according to the moxa stick cutting device, moxa sticks are transversely conveyed through the conveying assembly, the moxa sticks on the conveying belt are pressed through the pressing assembly, the moxa sticks are clamped through the two sliding rods, finally, cutting of the moxa sticks is achieved through the cutting knife, the structure is simple, and operation is convenient.

Owner:湖南汉众农业发展有限公司

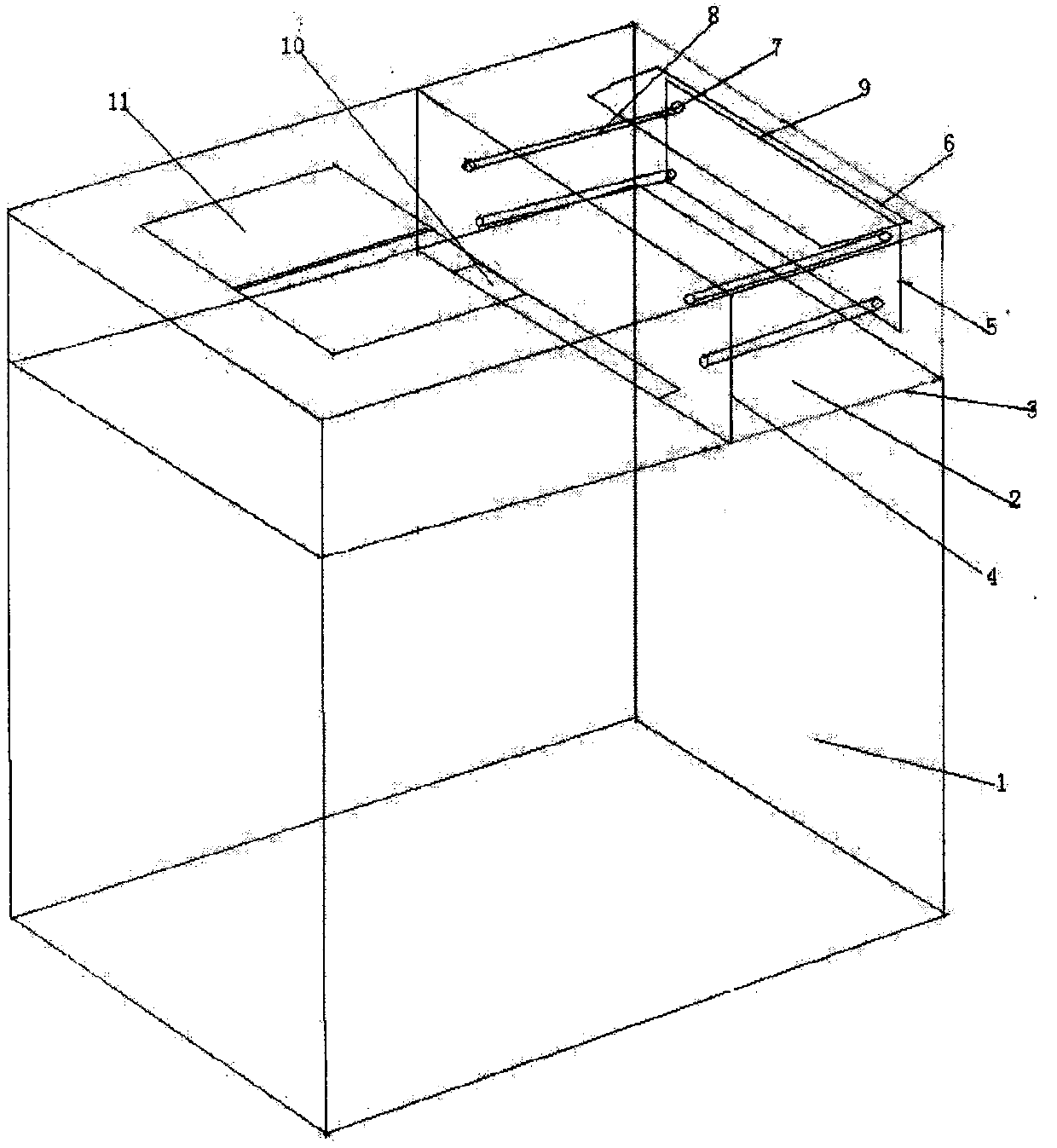

Garbage can capable of pressing objects

The invention discloses a garbage can capable of pressing objects, which belongs to the technical field of articles for daily use. The garbage can capable of pressing the objects is mainly designed tosave the space of the garbage can, the objects are compressed and then thrown into the garbage can, and the utilization rate of a garbage bag is increased. The garbage can is mainly composed of a canbody, a can cover, a bottom plate, a partition plate, a compression plate, a containing groove, protrusions, compression springs, a compression groove, a falling groove and a movable containing plateand is characterized in that the partition plate divides the can cover into two parts; the bottom plate, the partition plate and the can cover are integrated; the bottom of one part is hollow, and the movable containing plate is arranged on the upper end face and used for containing uncompressed garbage; a bottom plate is arranged at the bottom of the other part; the falling groove is formed in the position, close to the partition plate, of the bottom plate; the containing groove is formed in the upper end face of the bottom plate; the compression groove is formed in the outer side face of the bottom plate and used for containing a compression plate; four protrusions are arranged around the inner side of the partition plate and the compression plate; the compression springs are installedon the protrusions; and the compression plate is pressed on the compression spring, and the pressing function can be realized.

Owner:NANJING POLYTECHNIC INSITUTE

Automatic framing machine for freeze-drying lines

ActiveCN102219122BFully automatedQuality improvementLoading/unloadingConveyor partsFreeze-dryingWorking environment

Owner:TRUKING TECH LTD

A precision winding device and method for large-diameter dipole coils

ActiveCN108922771BAchieve precision windingSolve the problem of not being able to arrange the wires preciselyCoils manufactureWinding machineWire rod

The invention relates to a precise winding device and method for a big-diameter two-pole coil. A framework of a two-pole coil is arranged on a winding tooling base; a wire pressing plate is arranged at the outer side of the framework; a compression device fixing seat is arranged along the outer side of the framework; one end of a compression main shaft can slide and rotate on the fixing seat; a stop block is tightly pressed onto the wire pressing plate; the stop block is disengaged from the surface of the wire pressing plate; a spring B has an effect of being attached to the outer side of thewinding tooling base. The method comprises the following winding steps that the framework of the two-pole coil is fixed on the winding tooling base; the winding tooling base is fixed on a vertical wire winding machine to realize the rotation; the wire pression plate tightly presses the wound wire material surface; the compression device fixing seat is arranged at the outer side of the framework; aspring A provides pressing tensioning force; the stop block presses the wire pressing plate; the compression device fixing seat slides to the outer side and rotates to a 90-degree position; the stopblock is disengaged from the surface of the wire pressing plate; the spring B enables the stop block to be tightly attached to the outer edge of the tooling base; jackscrews are fed into a tight jacking plate to provide tension for the wire material straight edge winding; the structure is simple; the operation is convenient; the winding quality and the winding efficiency are high.

Owner:XIAN JUNENG SUPERCONDUCTING MAGNET TECH

A composite steel plate group welding positioning device

ActiveCN112846618BRealize the pressing functionFast assembly welding positioningWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The invention discloses a composite steel plate group welding positioning device, which comprises a bracket. Two working platforms are symmetrically arranged on the inner side of the upper part of the bracket, and two opposite ends of the two working platforms are rotatably connected with the bracket; the inner bottom of the bracket is symmetrically provided with two working platforms. There are two drive mechanisms corresponding to the free ends of the working platforms to turn over; the upper part of each working platform is symmetrically provided with two strip-shaped plates on both sides along its length direction, and the two opposite sides of the two strip-shaped plates are provided with pressing mechanisms , and the pressing mechanism is perpendicular to the strip plate; the invention has the characteristics of simple structure, convenient operation, high versatility, safety and reliability, and time and labor saving. At the same time, it also realizes the pressing function, which can be quickly pressed and positioned, effectively avoiding the problems of welding deformation, warping, position detachment, and lax flashing seams. Angled composite steel plate.

Owner:SHANDONG ZHONGHAO HLDG GRP

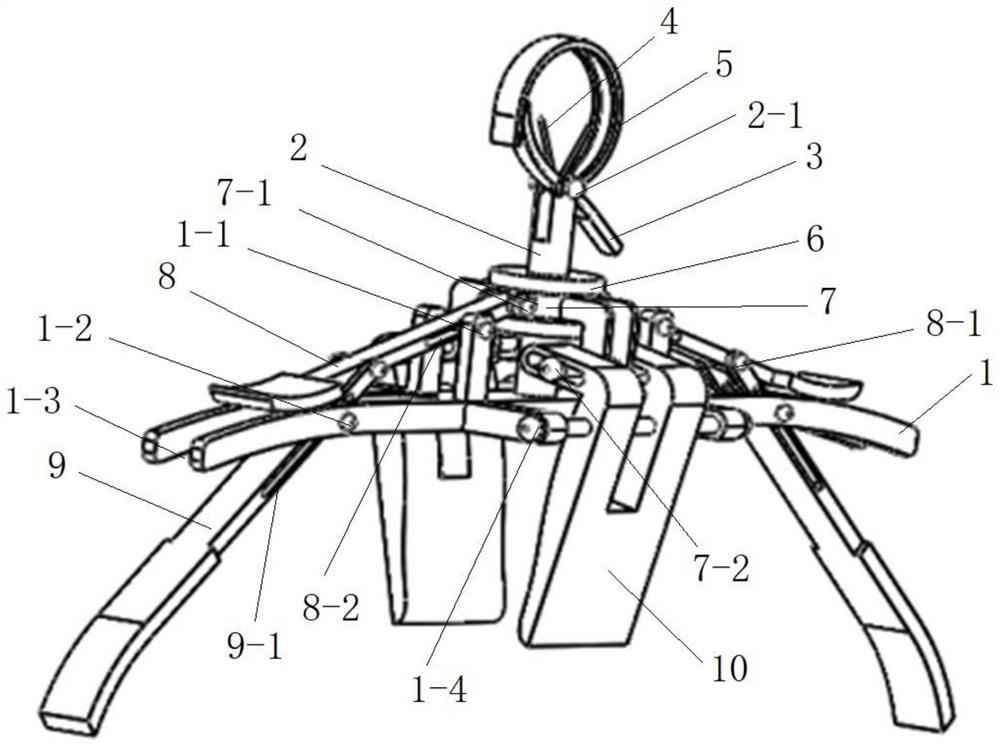

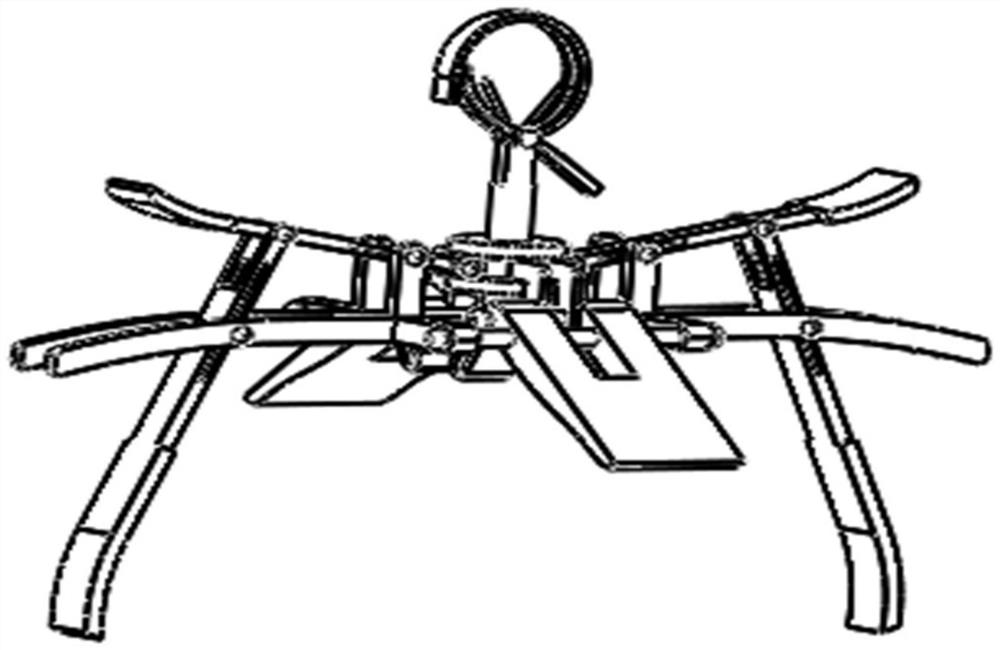

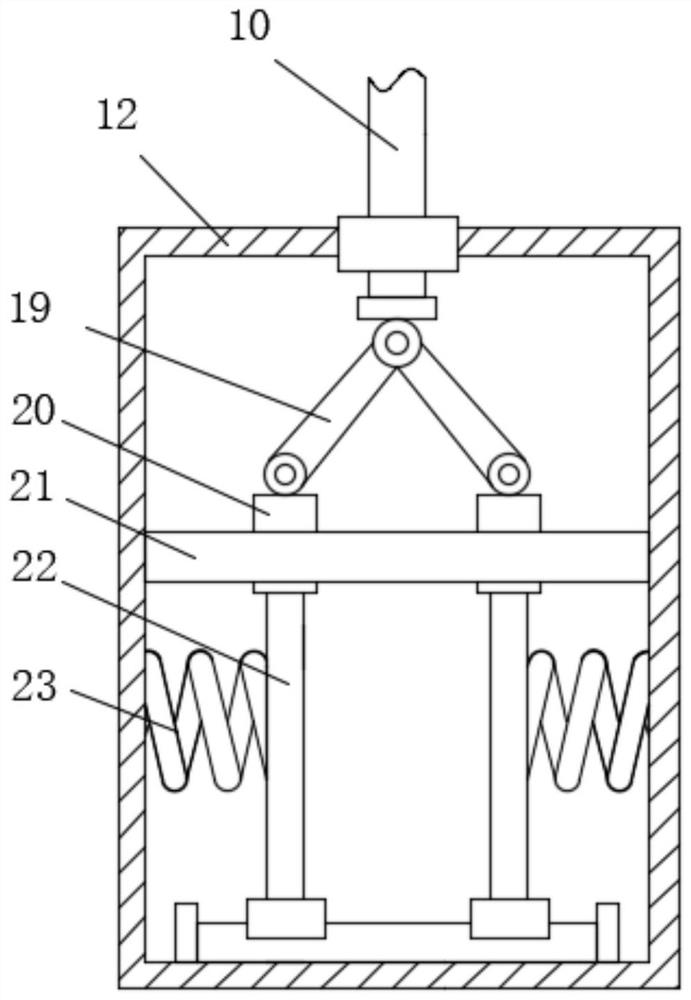

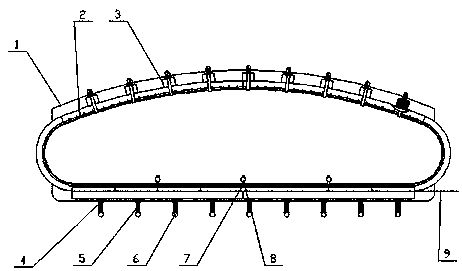

Modular Electric CPR Machine

The invention discloses a modular electric cardiaopulmonary resuscitation apparatus, which comprises a mechanism, two arms and a curved backing plate. The two arms are respectively linked to two sides of the bottom of the mechanism, the curved backing plate is linked with the lower ends of the two arms, and the backing plate is provided with back positioning modules, a head and neck fixing module and transfer modules which can be plugged and unplugged conveniently by joints. A servo motor is arranged in the mechanism, and is connected with a double-travel lead screw through a bearing, the lower end of the double-travel lead screw is connected with a pressure hood, the servo motor drives the double-travel lead screw to drive the pressure hood at the lower end of the double-travel lead screw so that the pressure hood is pushed to press the chest of a patient downwards and cardiaopulmonary resuscitation therapy is achieved. The modular electric cardiaopulmonary resuscitation apparatus is driven by the single motor and accordingly is light, portable and adaptable to various complicated environments, especially adaptable to different first-aid sites. Due to the modular design, the operation steps in the first-aid process can be simplified effectively for first-aid doctors, and the first-aid doctors can gain more rescue time and rescue the patient.

Owner:上海亚迈森医疗科技发展有限公司

A cutting machine with an automatic sharpening mechanism

ActiveCN110370345BSimple structureReduce manufacturing costMetal working apparatusGrinding/polishing safety devicesEngineeringGrinding process

The invention belongs to the technical field of cutting machines and discloses a cutting machine with an automatic knife grinding mechanism. The cutting machine comprises a rack, as well as a discharging mechanism and an automatic cutting mechanism which are sequentially arranged inside a rack from top to bottom, wherein the discharging mechanism is used for releasing materials; the automatic cutting mechanism is used for cutting the materials and comprises a driving component, a cutting component and a knife grinding component; the cutting component comprises a backing plate, a mounting base,a travelling cart and a cutter; and the knife grinding component comprises rotating plate fixing seats, rotating plates, knife grinding bar telescopic fixed rods and knife grinding bars. The cuttingmachine is provided with an elastic knife grinding mechanism, so that automatic knife grinding operation corresponding to the cutting machine is effectively realized; without detaching any component,the operation is simple; and the driving component of the cutter still performs knife grinding drive in the specific knife grinding process, so that installation and use of the knife grinding drivingcomponent are effectively avoided, and further the structure of the whole knife grinding mechanism is simpler.

Owner:桐城市建设投资发展有限责任公司

A quasi-five-axis machining center and its machining method

ActiveCN104097072BGuaranteed rotation accuracyGuaranteed rigidityLarge fixed membersPositioning apparatusEngineeringShaft collar

The invention discloses a quasi-five-axis machining centre and a machining method thereof. The quasi-five-axis machining centre comprises an AC rotary table structure, wherein the AC rotary table structure comprises a C-axis rotary table, the C-axis rotary table comprises a bridge frame plate with one end which is supported and connected to a first support table, and the other end which is supported and connected to a second support table, and a crossing shaft ring capable of freely rotating around a C-axis is further assembled on the bridge frame plate; a rotary plate is arranged by being parallel to the axis direction of an A-axis, and supported and connected to the rotary end surface of the crossing shaft ring, a shaft sleeve is further arranged on the rotary plate, and a rotary bearing capable of freely rotating around the C-axis is arranged in the shaft sleeve; a machining main shaft is detachably connected with a drive pin, and when the rotary bearing moves to be below the drive pin, the drive pin is inserted in the middle hole of the rotary bearing. According to the quasi-five-axis machining centre and the machining method thereof disclosed by the invention, the rotary power source of the C-axis is from the machining main shaft of a common vertical machine, and the existing common vertical XYZ three-axis machine can be utilized, thus furthest reducing the machining cost of polyhedral components; moreover, the machining accuracy is high and the equipment structure is simple.

Owner:SUZHOU MINGZHI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com