A quasi-five-axis machining center and its machining method

A five-axis machining center, technology to be processed, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of large space occupation, complex structure, and unguaranteed processing accuracy, so as to save investment costs and investment Low cost and the effect of reducing the number of processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

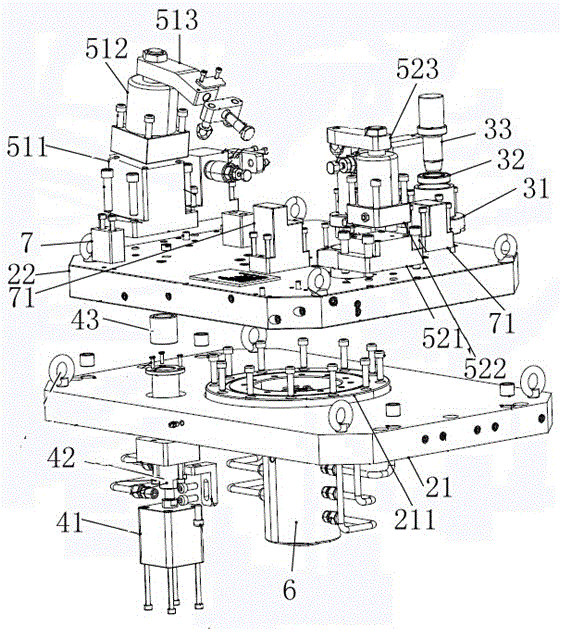

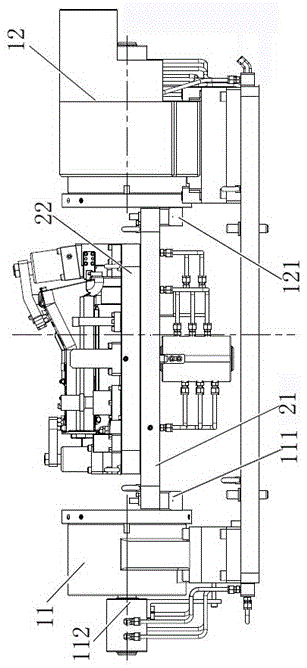

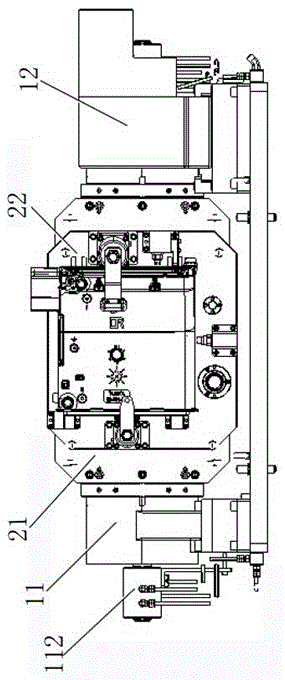

[0048] see Figure 1-Figure 4 , as shown in the legend, a quasi-five-axis machining center includes an XYZ three-axis moving platform (not shown in the figure), a worktable set on the moving platform, a workbench set on the workbench The AC turntable structure and the processing spindle arranged above the AC turntable structure, the above-mentioned AC turntable structure includes an A-axis turntable and a C-axis turntable, and the above-mentioned A-axis turntable includes a headstock 11 and a tailstock 12 arranged on the above-mentioned workbench. The seat 11 is provided with a first support platform 111 and a drive mechanism 112 that can drive the first support platform 111 to rotate around the A axis. The tailstock 12 is provided with a second support platform 121 that can freely rotate around the A axis. The axial direction of the above-mentioned A axis Perpendicular to the aforementioned machining spindle, the aforementioned C-axis turntable includes:

[0049] A bridge pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com