Parallel work-piece pressing device

A technology of pressing device and workpiece, applied in workpiece clamping devices, manufacturing tools, etc., can solve the difference of processing position, it is difficult for staff to remember the characteristics of each workpiece uniformly, the difference of each workpiece, the workload of observation is large, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

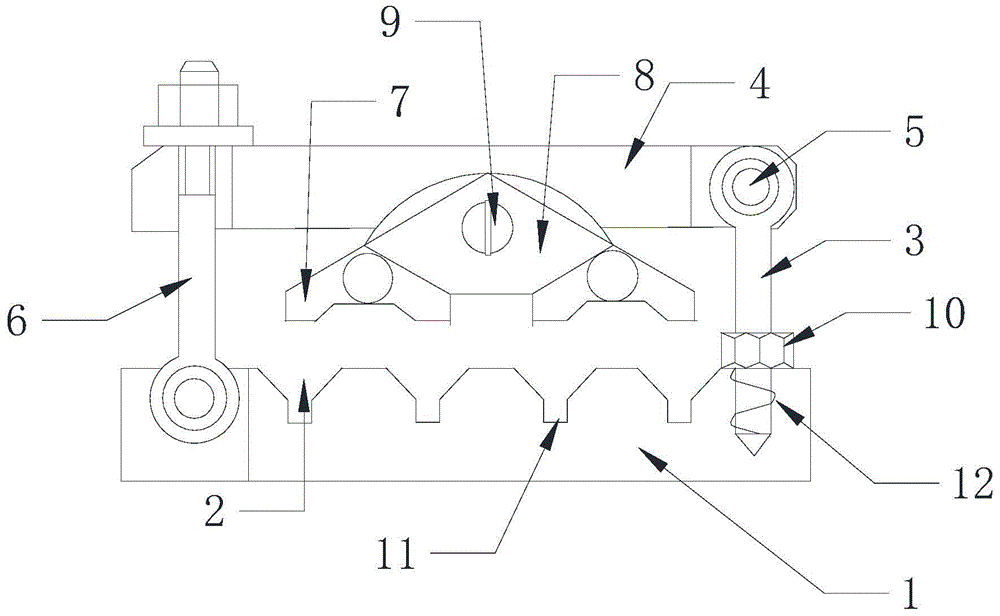

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] The parallel workpiece pressing device includes a workpiece mounting seat 1, the surface of the workpiece mounting seat is provided with at least 4 V-shaped grooves 2, and a support shaft 3 located on one side of the upper surface of the workpiece mounting seat, and the support shaft 3 Can be contracted in the vertical direction, the top of the support shaft 3 is connected to a compression rod 4 parallel to the workpiece mounting seat, one end of the compression rod 4 is connected to the top of the support shaft 3 through a nut 5, and the upper surface of the workpiece mounting seat 1 is The other side is provided with a fastening rod 6, and the movable end of the pressing rod 4 is sleeved on the fastening rod 6;

[0014] It also includes a pressing device located between the pressing rod and the workpiece mounting seat. The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com