Garbage can capable of pressing objects

A technology for trash cans and objects, which can be used in trash cans, garbage collection, household appliances, etc., and can solve problems such as space occupation, garbage bags being squeezed and damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

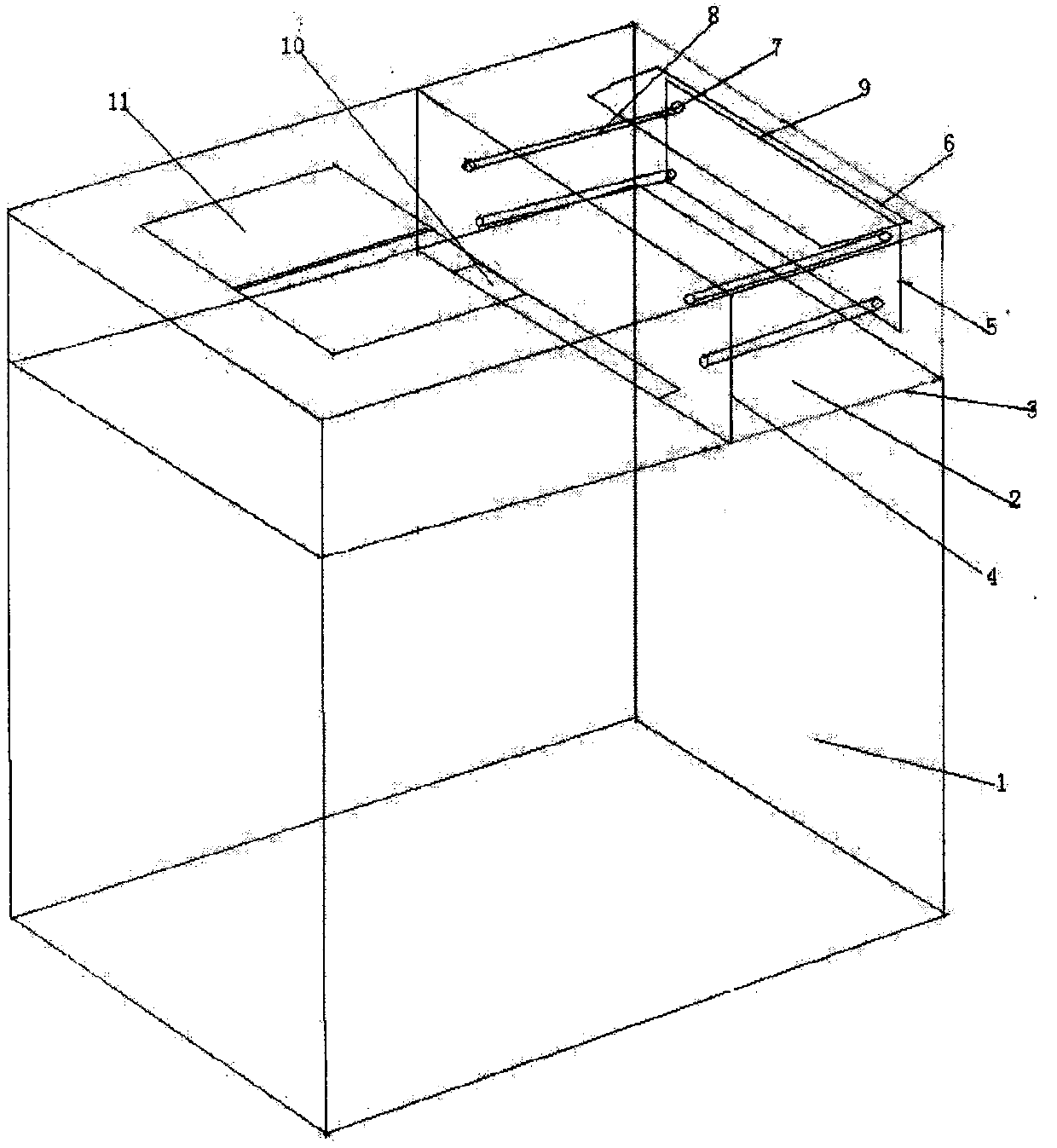

[0012] Below in conjunction with accompanying drawing, the technical scheme that a kind of garbage can that can press object technical problem of the present invention is taken is described further: its structure is as shown in accompanying drawing, mainly consists of cylinder body 1, cylinder cover 2, bottom plate 3, partition Plate 4, compression plate 5, placement groove 6, protrusion 7, compression spring 8, compression groove 9, drop groove 10, movable placement 11 boards, is characterized in that: partition 4 divides cylinder cover 2 into two parts, bottom plate 3. The clapboard 4 and the cylinder cover 2 are integrated, a part of the bottom is hollow, and the upper end surface is provided with a movable placement plate 11, which is used to place garbage that does not need to be compressed; the bottom of the other part has a bottom plate 3, which is close to the clapboard Drop slots 10 are provided at 4 places, placement slots 6 are provided on the upper end surface, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com