A Simulated Coating Rapid Prototyping Wet Molding Process

A process and coating technology, applied in the direction of coating, can solve the problems of difficulty in meeting the batch size, poor production site environment, long molding cycle, etc., and achieve the effect of good quality of molded products, saving resin consumption, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

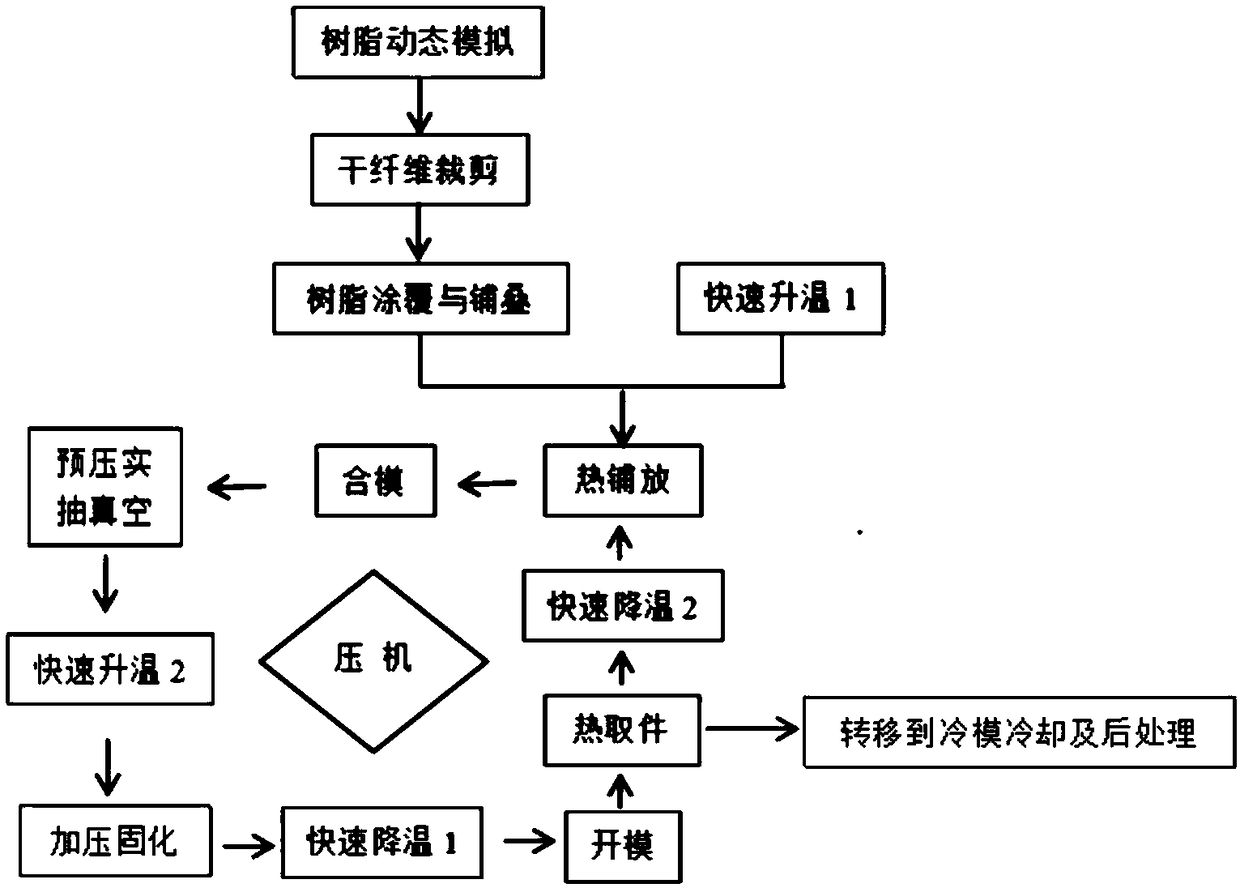

[0024] Please refer to figure 1 , a simulated coated rapid prototyping wet molding process, with dry fiber fabric as reinforcement material, low viscosity, fast curing, high glass transition temperature resin as matrix material, the specific dry fiber fabric is unidirectional carbon fiber cloth, the weight is 250g / m 2 The matrix material is epoxy resin, which can be kept at 120°C for more than 30 minutes without gelling or curing. The curing temperature is 160°C, the curing time is 1 minute, and the glass transition temperature after curing is 145-155°C. The equipment includes: wet method Molding presses, self-cleaning non-stick molds, rapid heating and rapid cooling auxiliary equipment systems, automatic cutting machines, air compressors, coating consoles, spray guns and vacuum pumps; processes mainly include simulated coating processes, rapid mold heating and rapid Cooling process, hot laying process, hot pick-up process and self-cleaning process for self-cleaning non-stick...

Embodiment 2

[0032] Please refer to figure 1, a simulated coating rapid prototyping wet molding process, with dry fiber fabric as reinforcement material, low viscosity, fast curing, glass transition temperature resin as matrix material, the specific dry fiber fabric is unidirectional carbon fiber cloth, the weight is 250g / m 2 ;The base material is vinyl resin, which can be kept at 100°C for more than 30 minutes without gelling or curing. The curing temperature is 130°C, the curing time is 1 minute, and the glass transition temperature after curing is 120-130°C. The equipment includes: wet method Molding presses, self-cleaning non-stick molds, rapid heating and rapid cooling auxiliary equipment systems, automatic cutting machines, air compressors, coating consoles, spray guns and vacuum pumps; processes mainly include simulated coating processes, rapid mold heating and rapid Cooling process, hot laying process, hot pick-up process and self-cleaning process for self-cleaning non-stick mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com