Circulating fluid system for electrostatic adsorption chuck

A technology of electrostatic adsorption and circulating fluid, which is applied in the field of circulating fluid system, can solve the problems affecting the service life of the cooler and the efficiency of the machine, and achieve the effect of avoiding excessive heating power and shortening the heating and cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

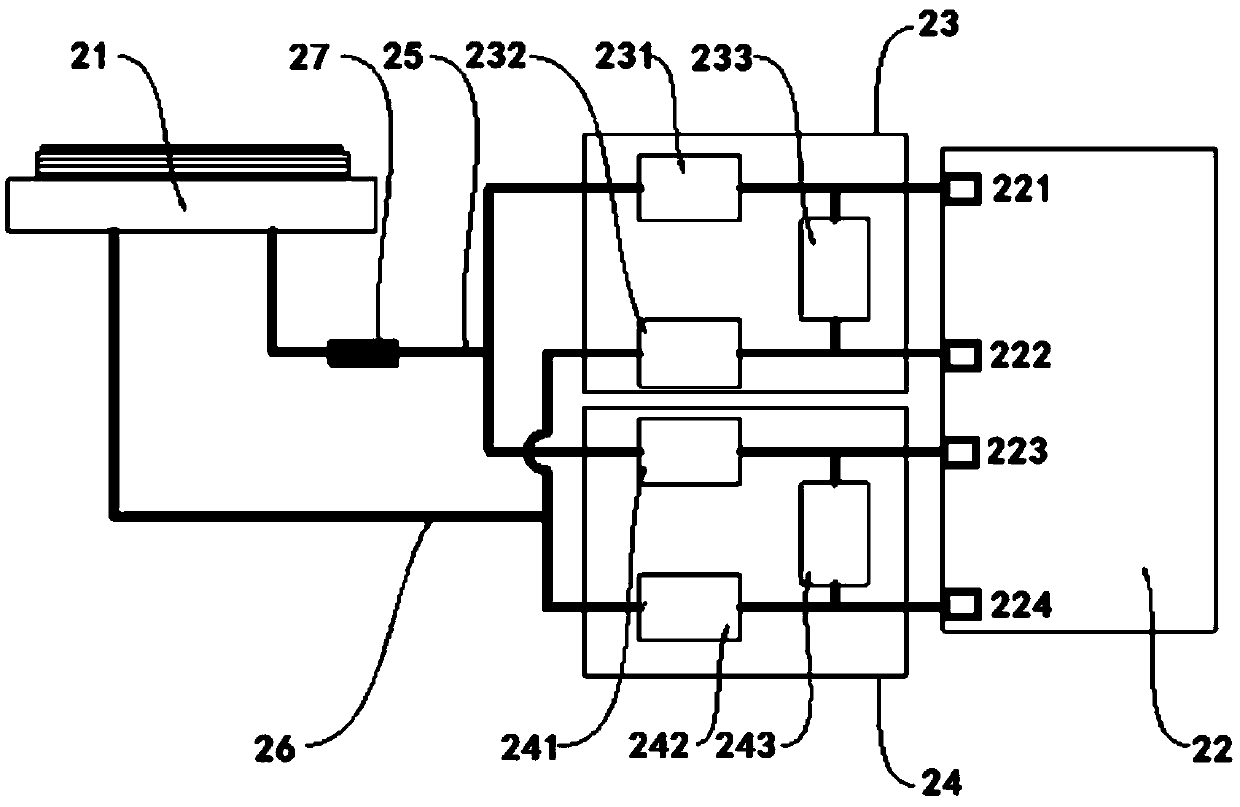

[0034] figure 2 A structural diagram of the circulating fluid system of the electrostatic adsorption chuck according to the first embodiment of the present invention is shown. The base body of the electrostatic adsorption chuck contains a cooling fluid circulation channel (not shown).

[0035] Such as figure 2As shown, the circulating fluid system includes a cooling machine 22 connected to the cooling fluid circulating waterway in the electrostatic adsorption chuck 21 . The cooling machine 22 is configured to be able to pump out the first circulating fluid and the second circulating fluid at different temperatures at the same time, when one circulating fluid circulates through the cooling fluid circulating water circuit, the other circulating fluid is outside the electrostatic adsorption chuck cycle.

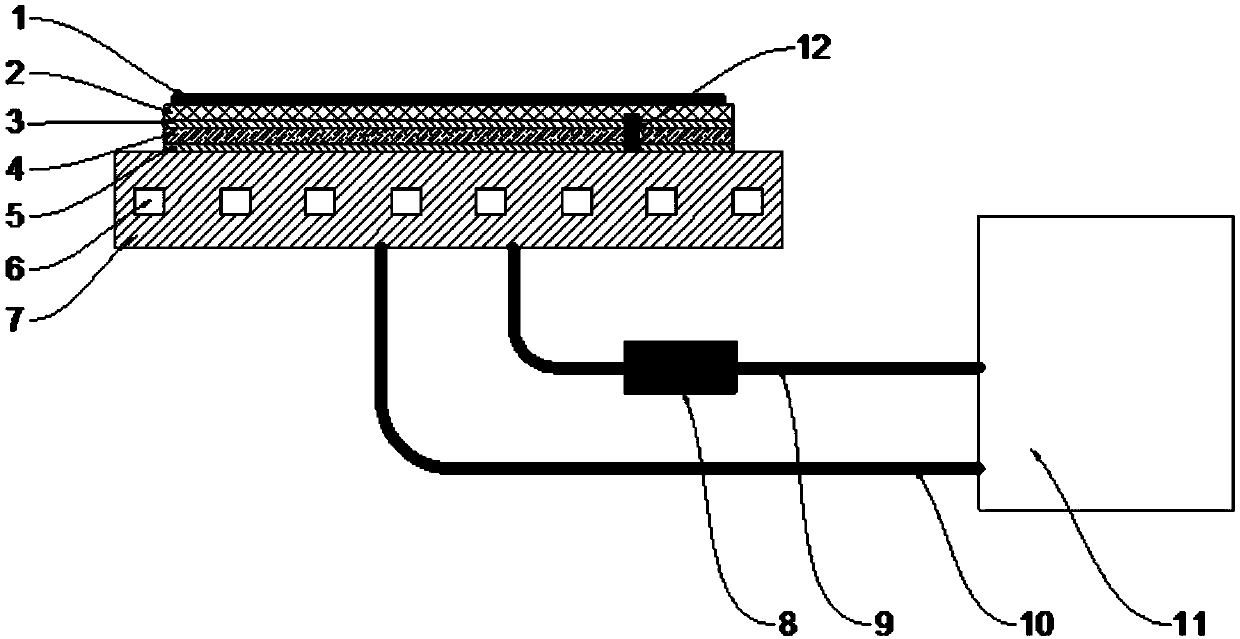

[0036] Electrostatic adsorption chuck 21 can adopt figure 1 structure shown. The temperature of the first circulating liquid and the second circulating liquid can be set a...

no. 2 example

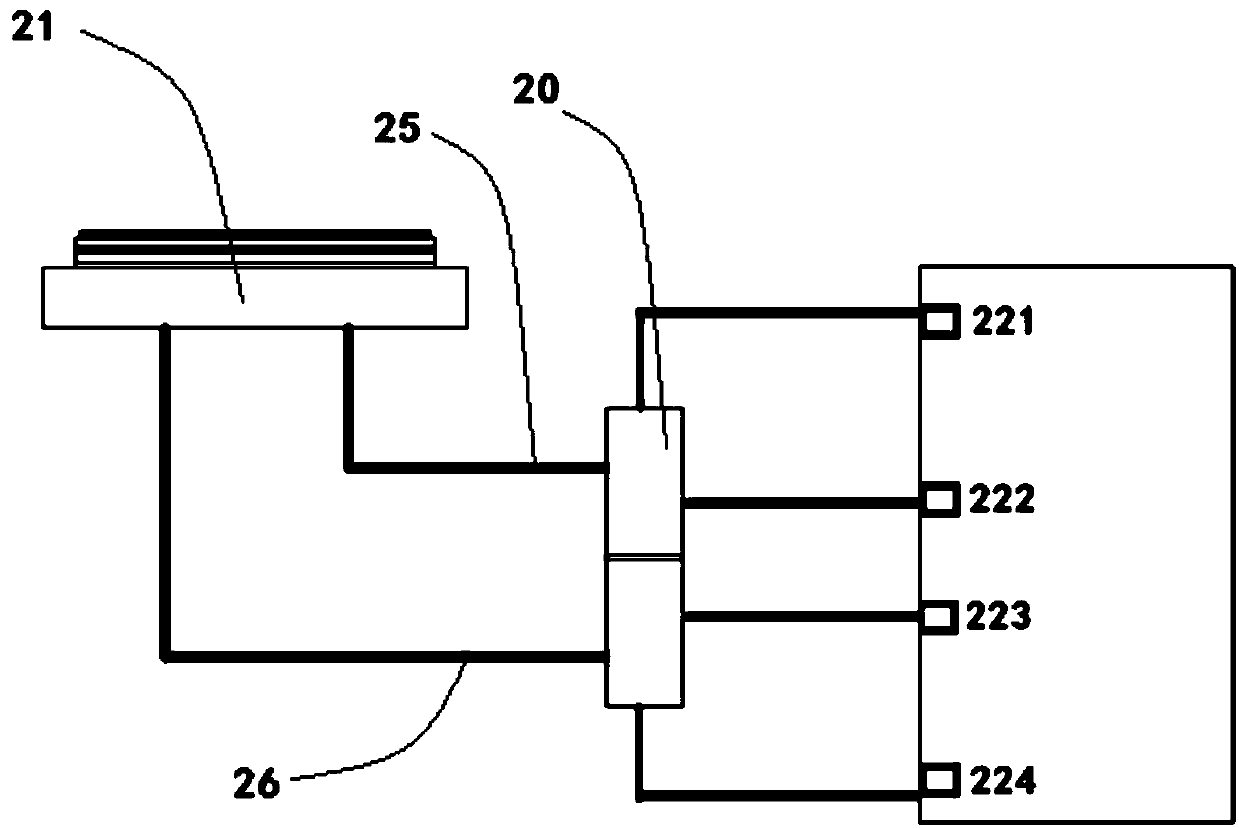

[0056] image 3 A configuration diagram showing a circulating liquid system of an electrostatic adsorption chuck according to a second embodiment of the present invention. In this embodiment, the structures of the electrostatic adsorption chuck 21 and the cooling machine 22 are the same as those in the first embodiment, and the cooling machine 22 is configured to be able to simultaneously pump out the first circulating fluid and the second circulating fluid of different temperatures, one of which When the circulating fluid circulates through the cooling fluid circulation channel in the electrostatic adsorption chuck 21 , another circulating fluid circulates outside the electrostatic adsorption chuck.

[0057] In this embodiment, the circulating fluid system further includes a flow switching device 20 . The first circulating fluid outlet 221, the first circulating fluid inlet 222, the second circulating fluid outlet 223 and the second circulating fluid inlet 224 of the cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com