Patents

Literature

35results about How to "Reduce processing waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

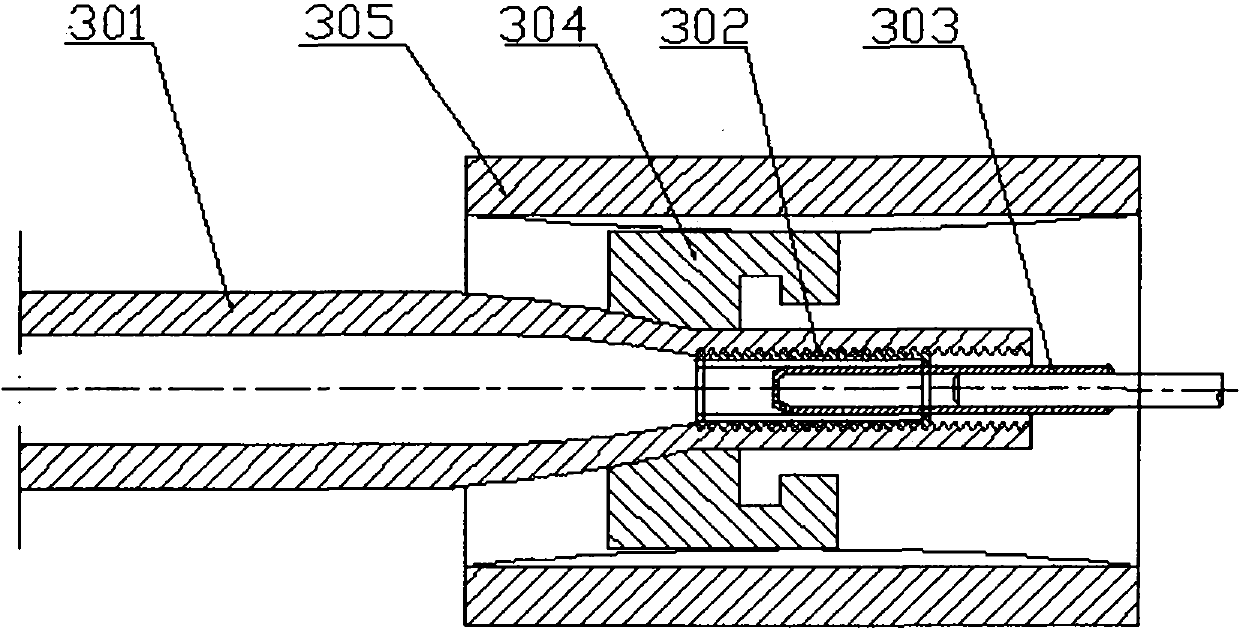

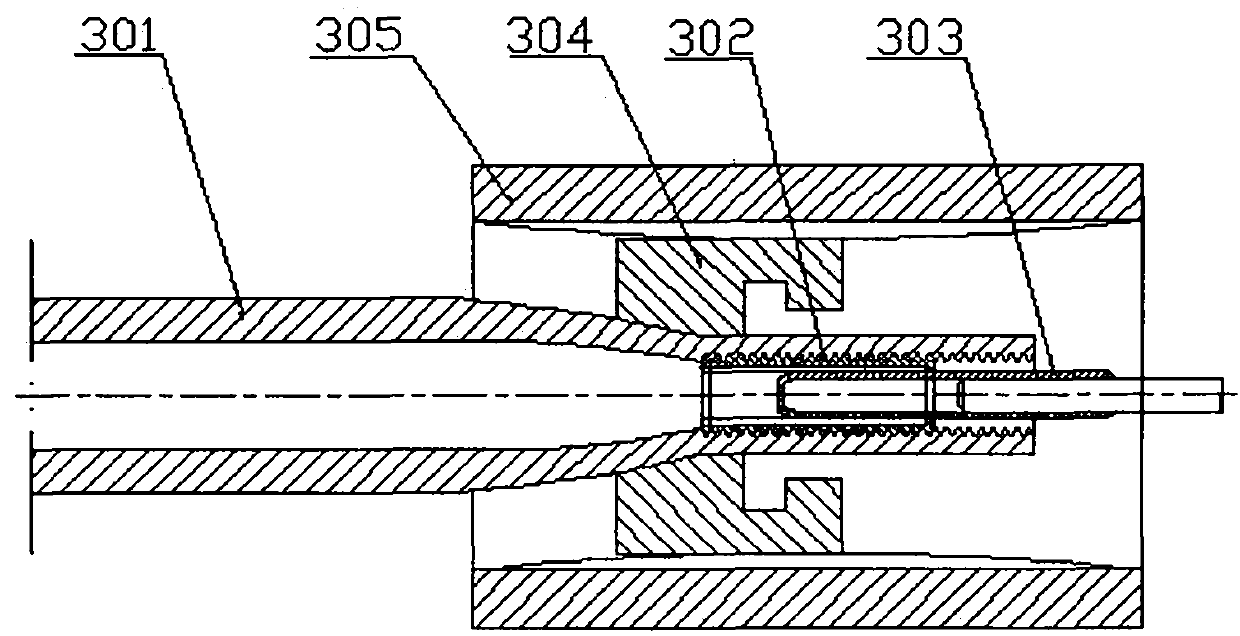

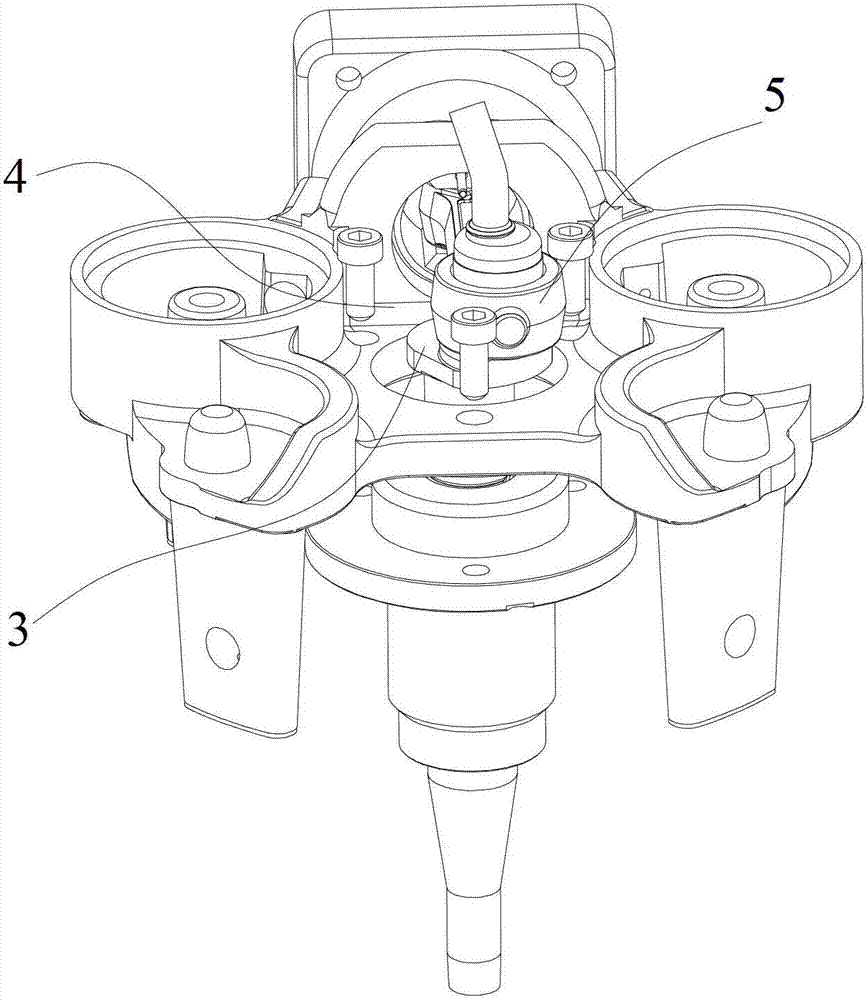

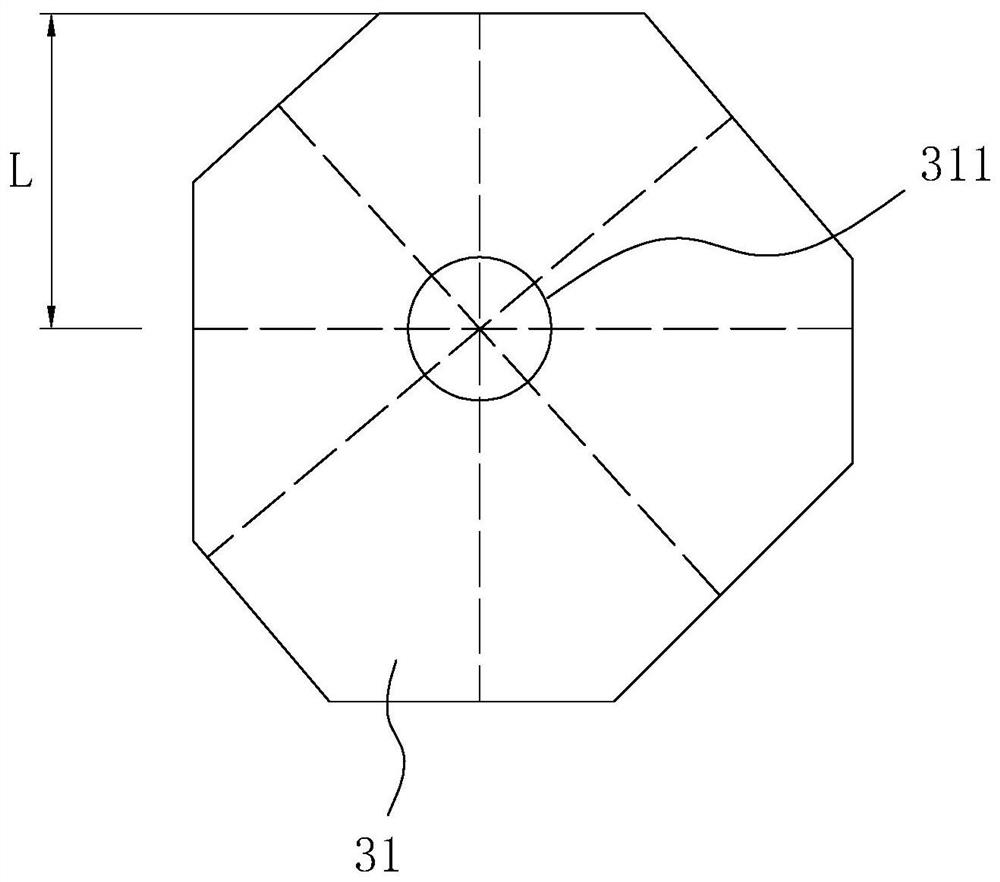

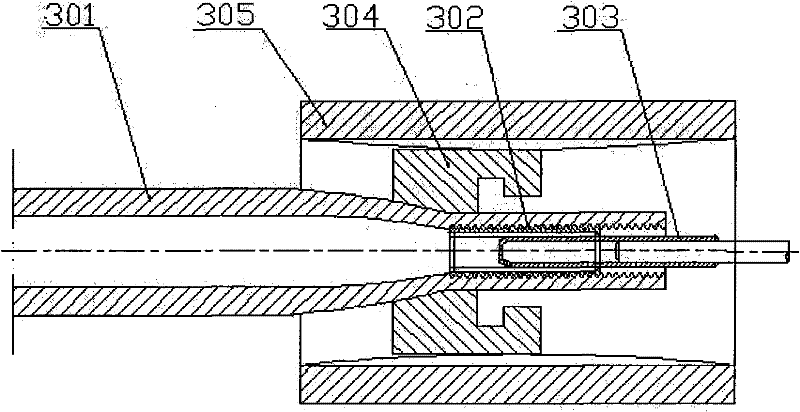

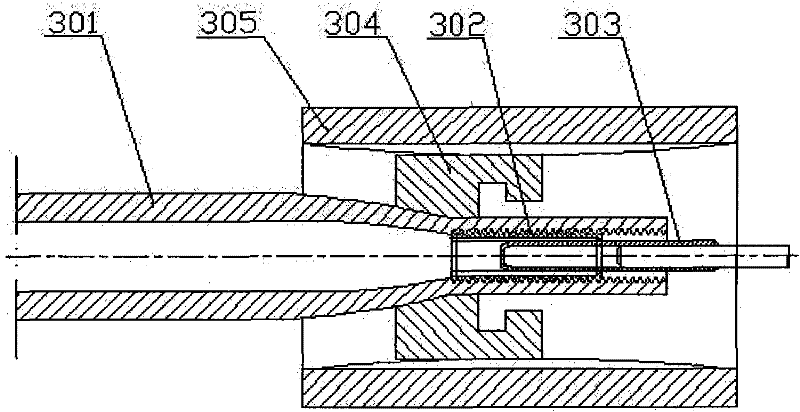

Reducing rotary forging method for internal thread copper pipe

InactiveCN102000755AImproves exterior surface finishIncrease productivityForging/hammering/pressing machinesForging press drivesControl lineFriction force

The invention discloses a reducing rotary forging method for an internal thread copper pipe, in particular a method for machining the internal thread copper pipe by reducing spinning and the extrusion of rotating roller cores. In the machining method, the rotating roller cores with threads are adopted while the reducing spinning is performed, and the inner wall of the cooper pipe is subjected extrusion molding under the action of friction force to ensure that continuous and uniform threads exist on the inner surfaces of copper pipes, and the inner surfaces have the distinct threads, controlled lines and few residues.

Owner:HEFEI GREAT WALL REFRIGERATION TECH

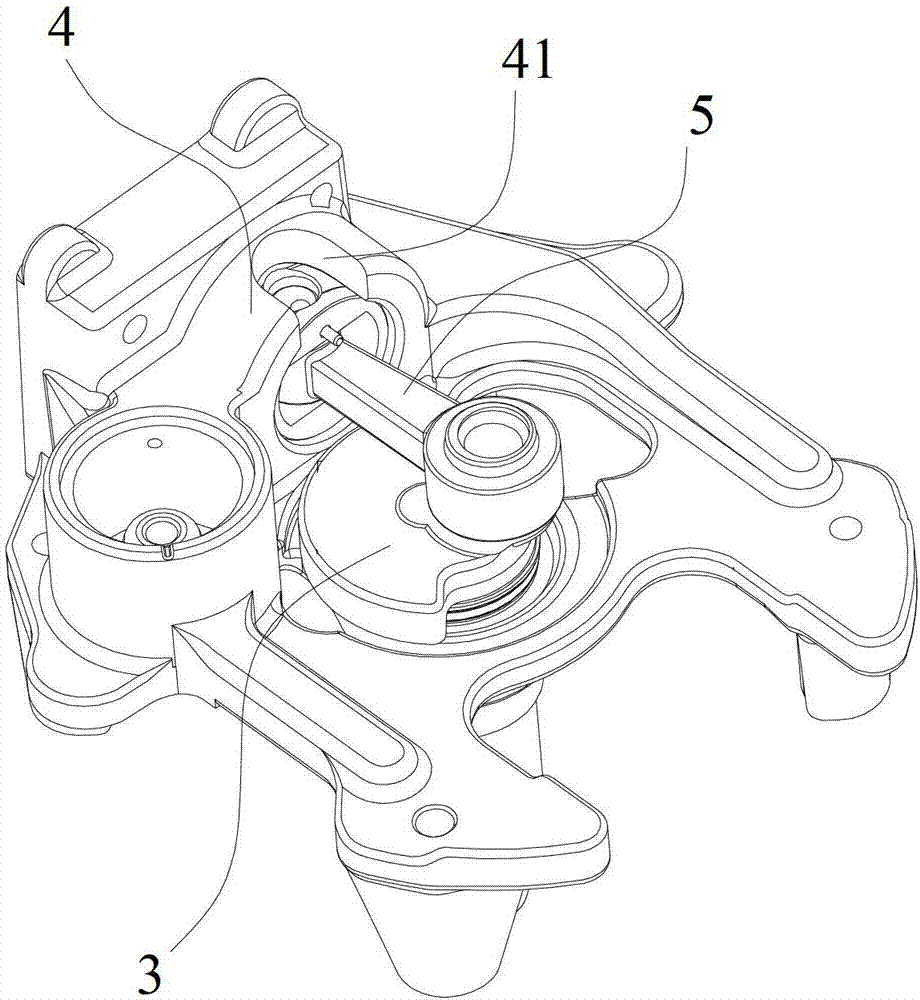

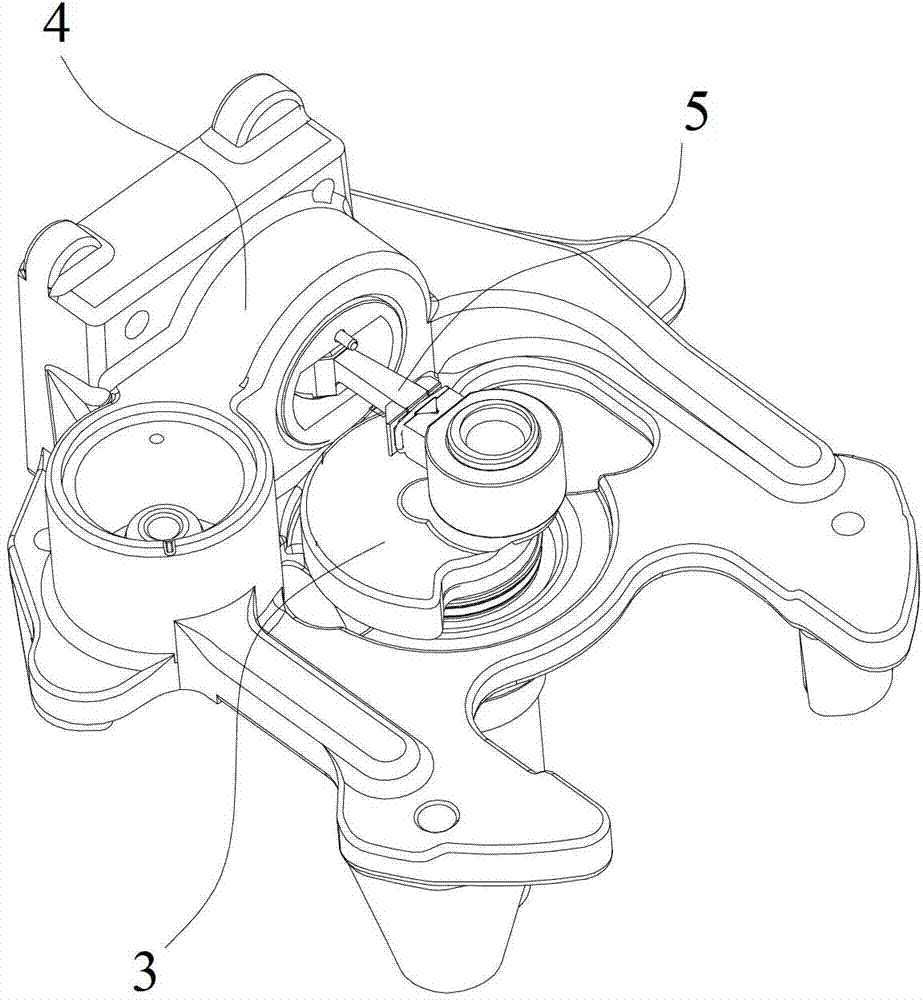

Split crank shaft structure of reciprocating compressor

InactiveCN103244548AMaintain structural integrityReduce processing costsCrankshaftsProduction rateEngineering

The invention discloses a split crank shaft structure of a reciprocating compressor, which is applied to the field of reciprocating compressors. The split crank shaft structure comprises a main shaft part and a crank pin which are separated from each other, wherein one end of the main shaft part is in butt joint with the crank pin in an eccentric manner; and a balance block is arranged on the opposite side of the crank pin. According to the split crank shaft structure, a crank shaft adopts a split structure. When the structure is put into use, two ends of a connecting rod are respectively connected with a piston in a cylinder seat and the crank pin of the crank shaft, and then the crank pin is fixedly connected with the main shaft part. By the structure, the structural integrity of the cylinder seat and the connecting rod is kept, waste of processing of the cylinder seat, the connecting rod and the crank shaft is reduced, the processing cost is saved, and the production rate is improved.

Owner:WANBAO GROUP COMPRESSOR CO LTD

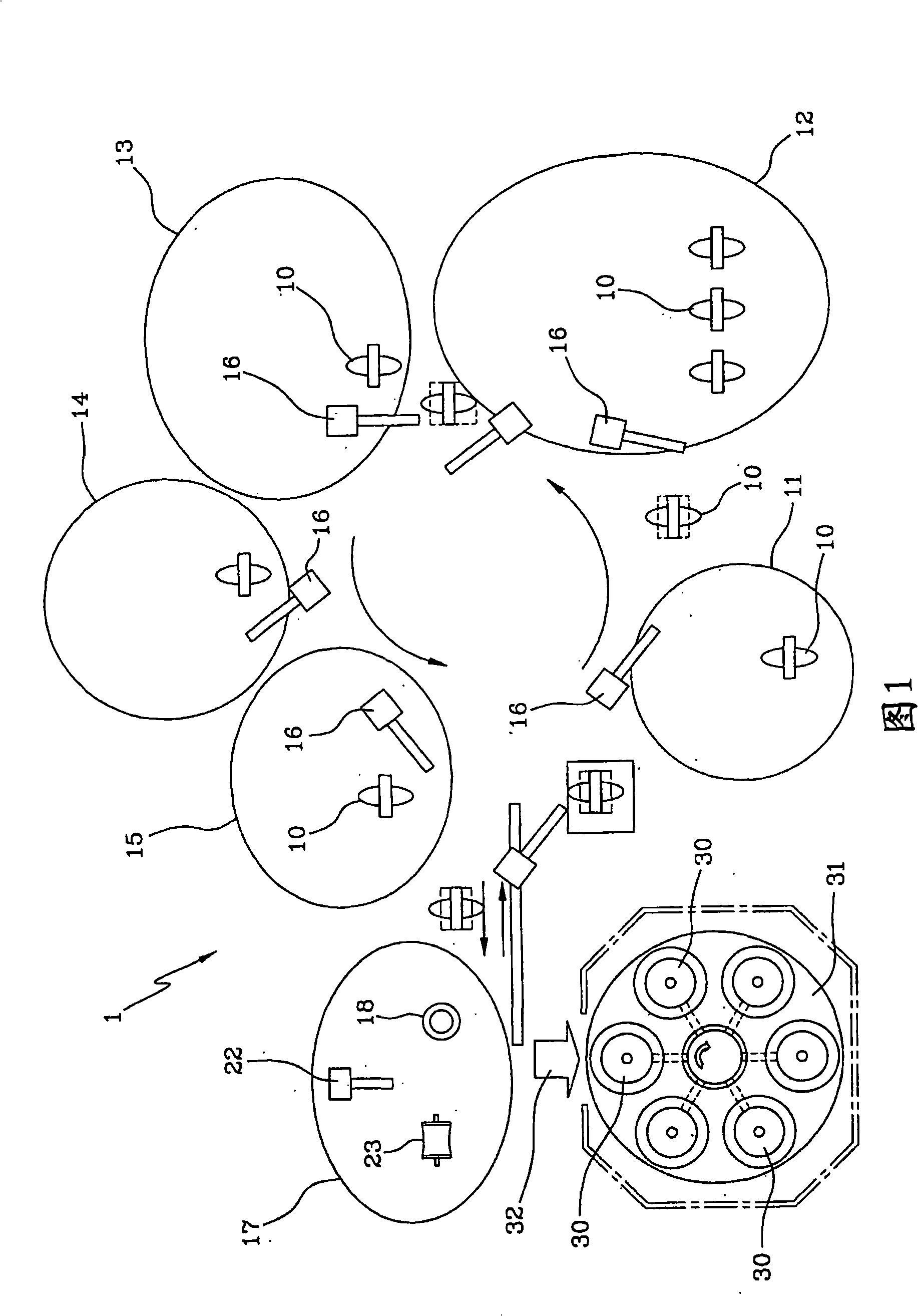

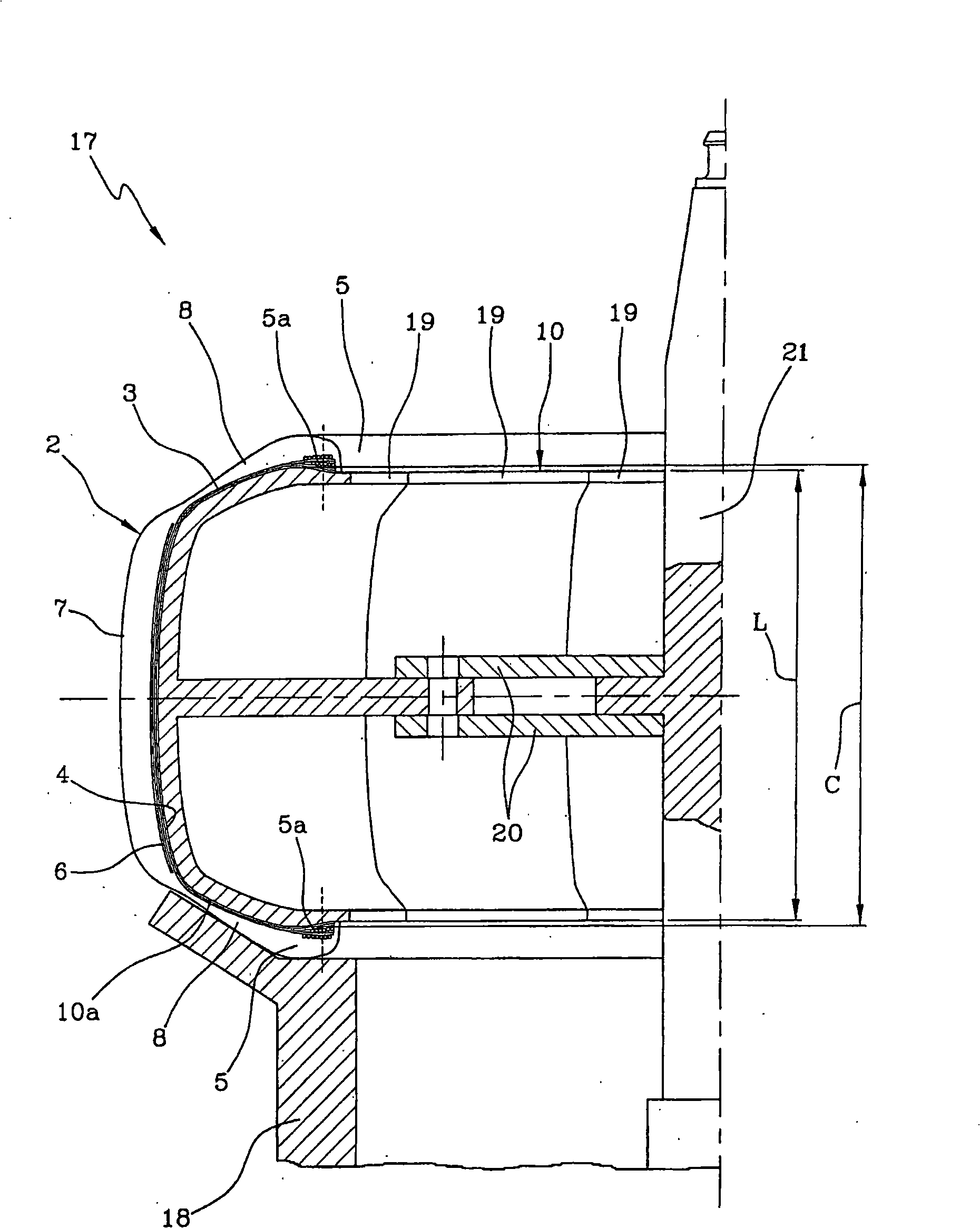

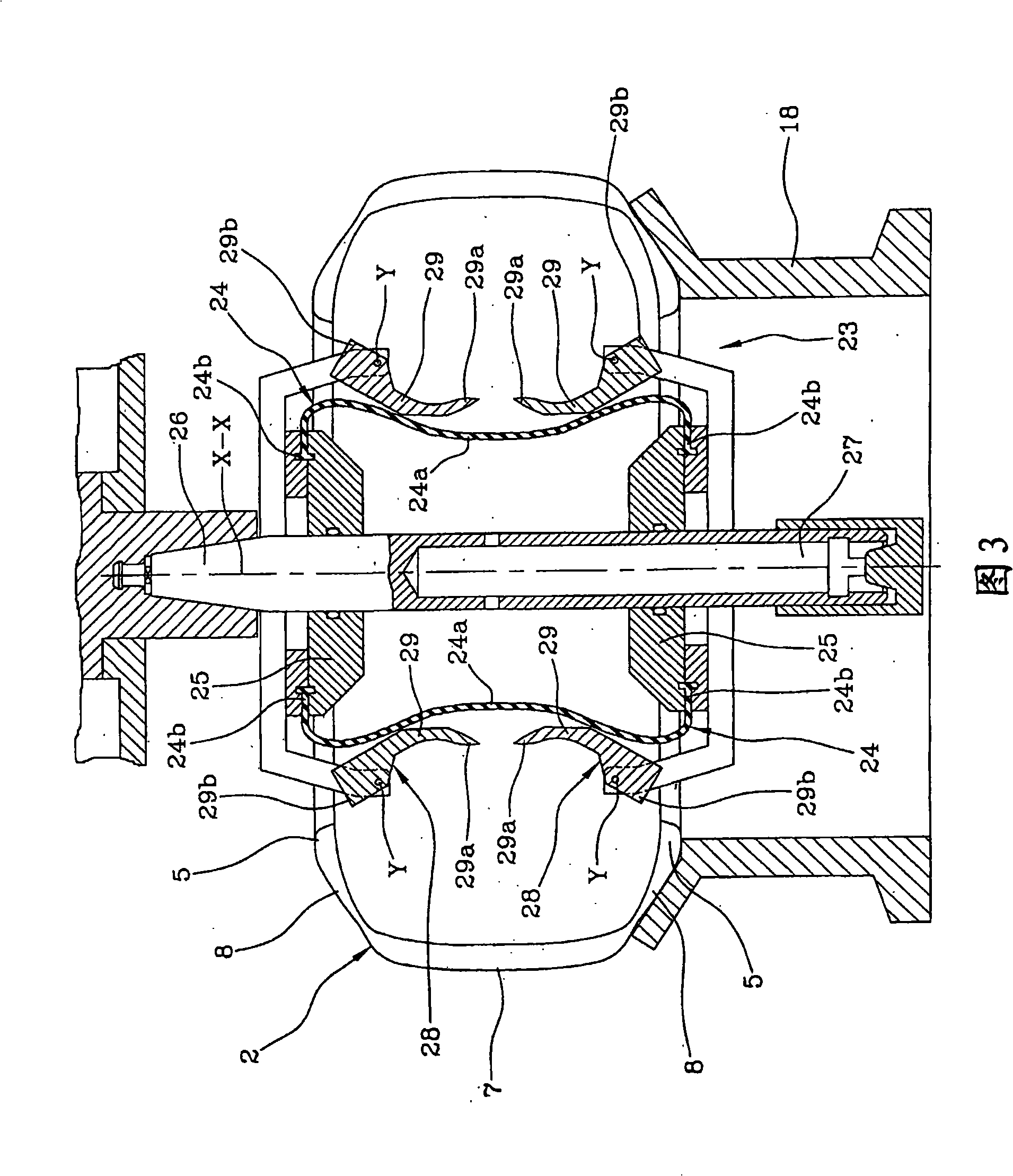

Method and equipment for producing tire

InactiveCN101316697AHigh dimensional accuracyQuality improvementTyresEngineeringBiomedical engineering

Owner:PIRELLI TYRE SPA

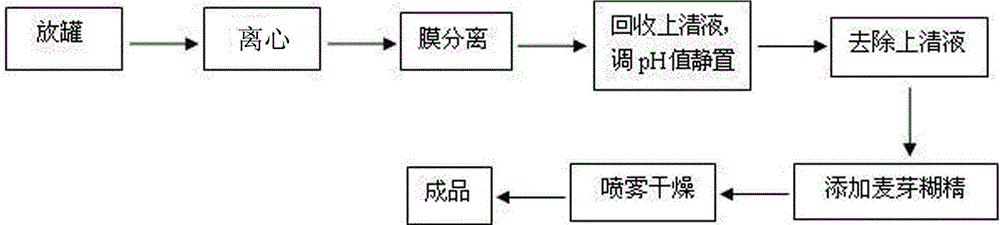

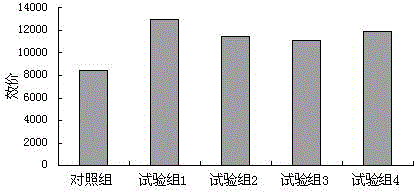

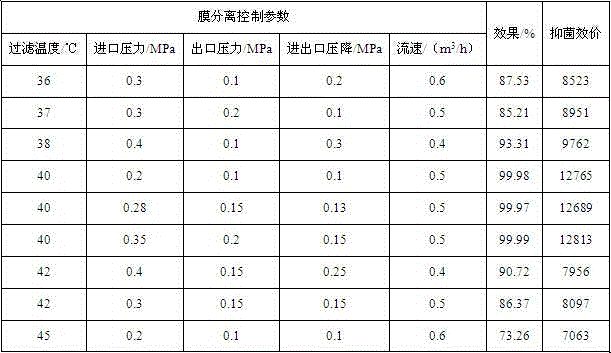

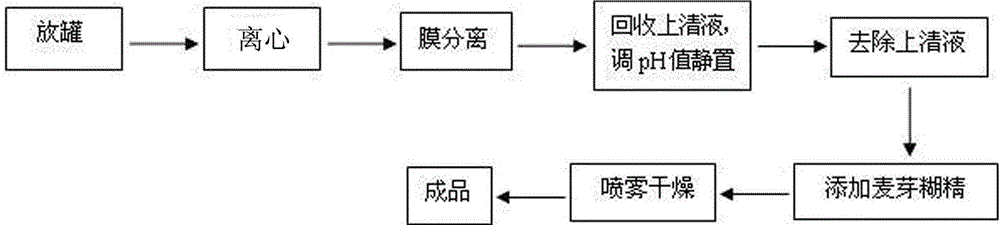

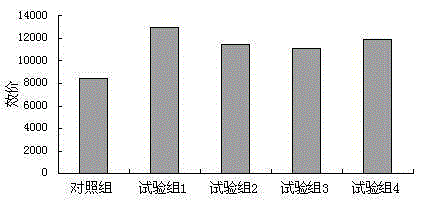

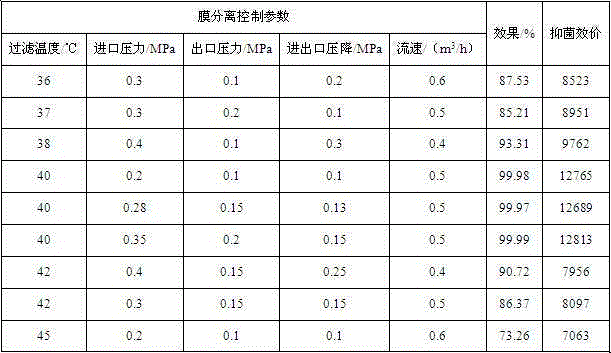

Post-extraction process for producing antibacterial peptide through bacillus subtilis

ActiveCN104130318ADry fastHigh activityDepsipeptidesPeptide preparation methodsSolubilityHybrid protein

The invention relates to a post-extraction process for producing antibacterial peptide through bacillus subtilis and belongs to the technical field of biology. The process comprises the following steps: by taking bacillus subtilis as a production strain, preparing a finished antibacterial peptide product through centrifugation, membrane separation and spray drying treatment of fermentation liquor, centrifuging by adopting two continuous centrifugal machines, performing classification and membrane separation, removing the thallus and hybrid proteins to the greatest degree, thus obtaining the antibacterial peptide with high activity. By utilizing heat resistance of the antibacterial peptide, the antibacterial peptide is rapidly dried through a spray drying technology, the preparation efficiency of the antibacterial peptide is improved, and maltodextrin serving as an auxiliary material has the advantages of high solubility and high stability, is unsuitable for moisture absorption and deterioration and contains rich trace elements and mineral substances. The separated and purified antibacterial peptide is high in activity, low in cost, simple in process and low in post-treatment loss.

Owner:山东仙普爱瑞科技股份有限公司

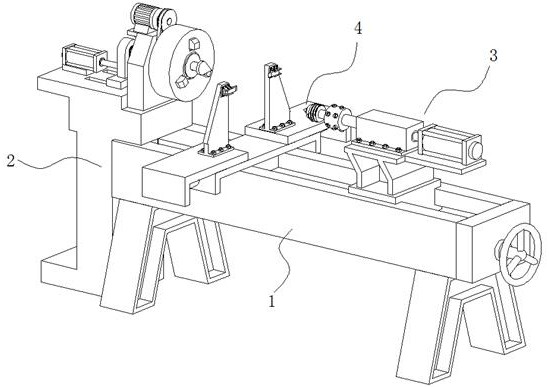

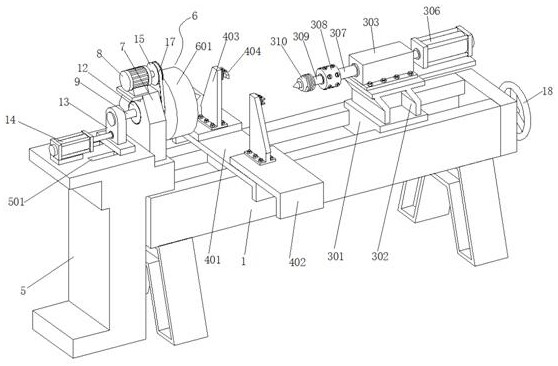

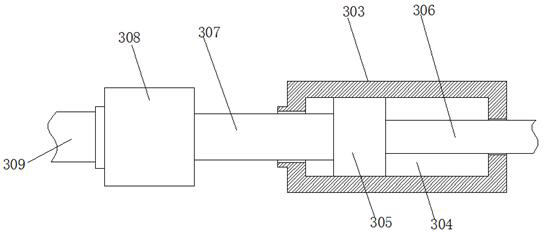

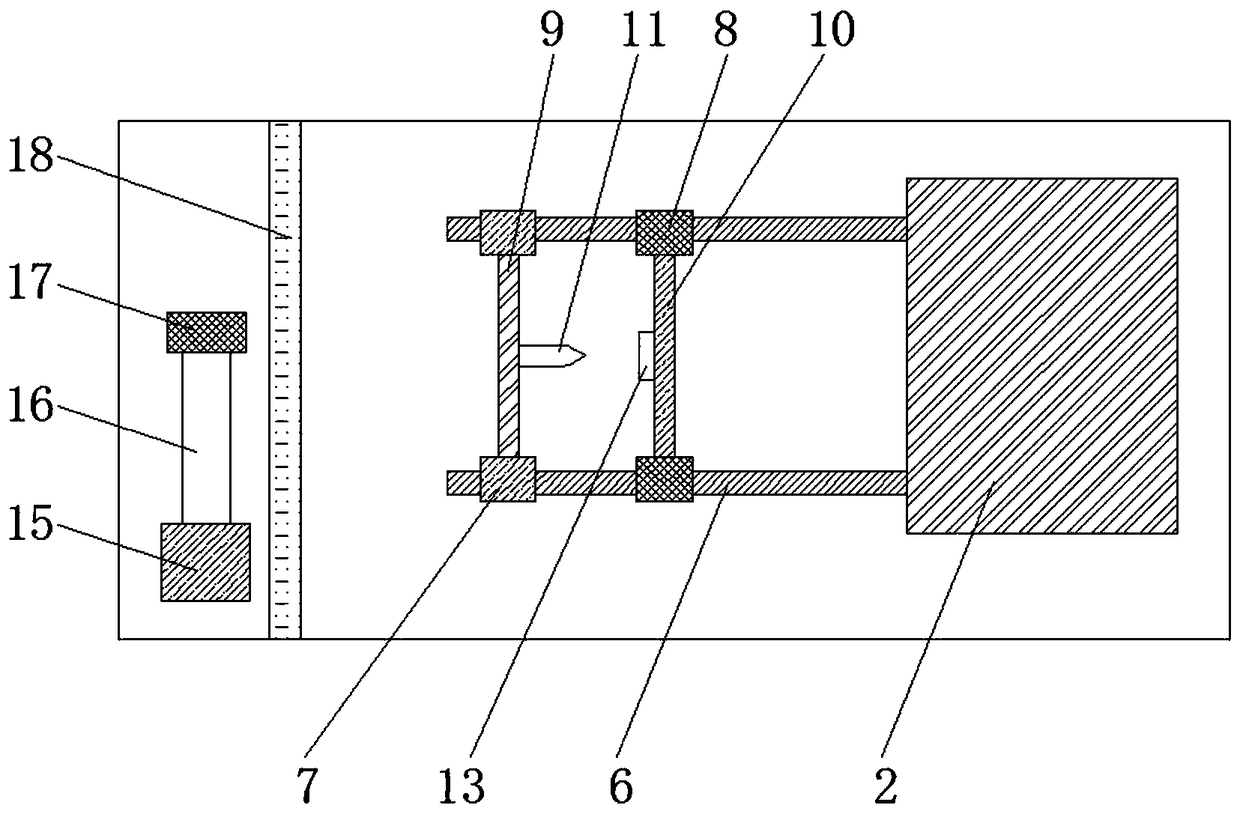

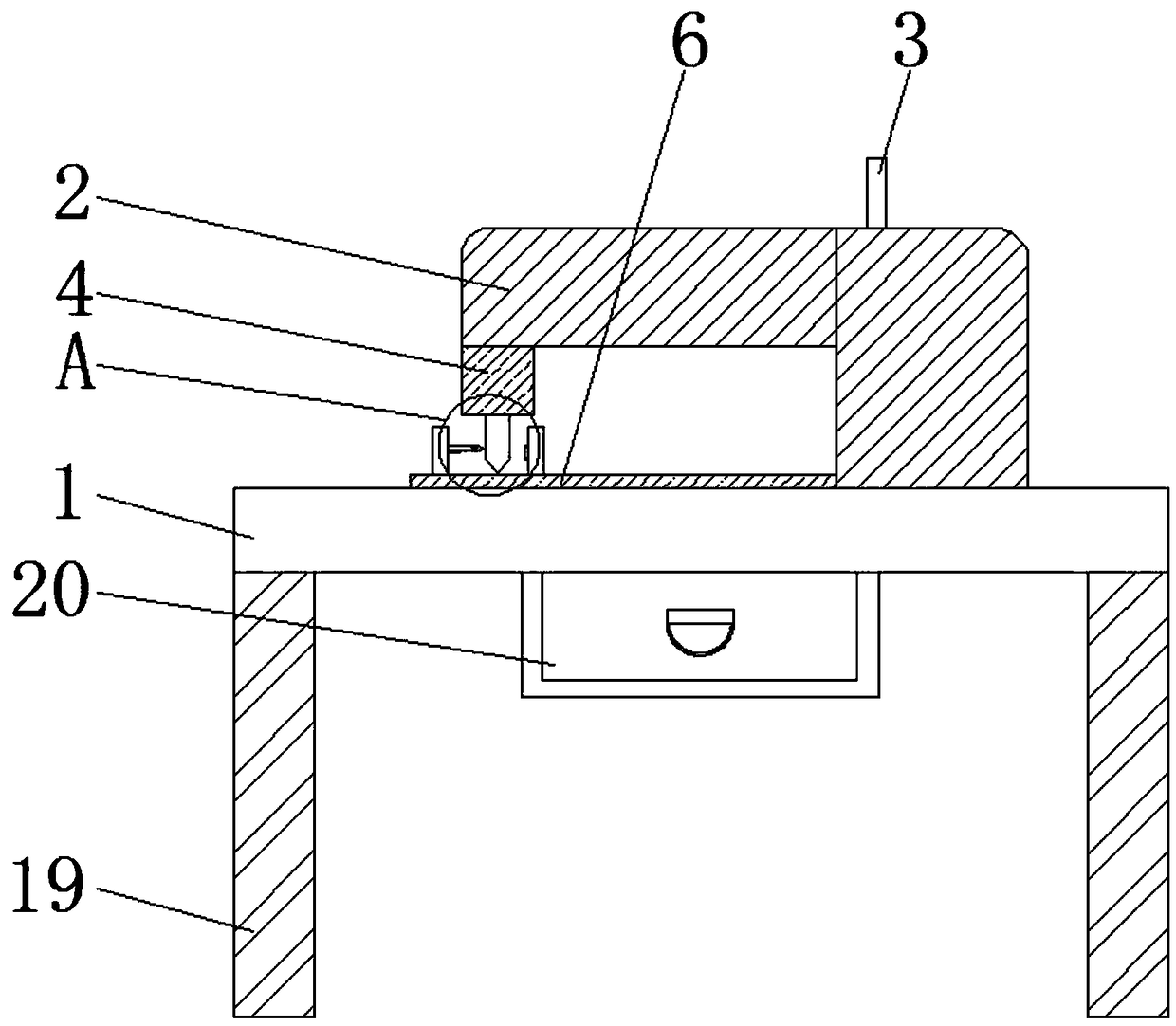

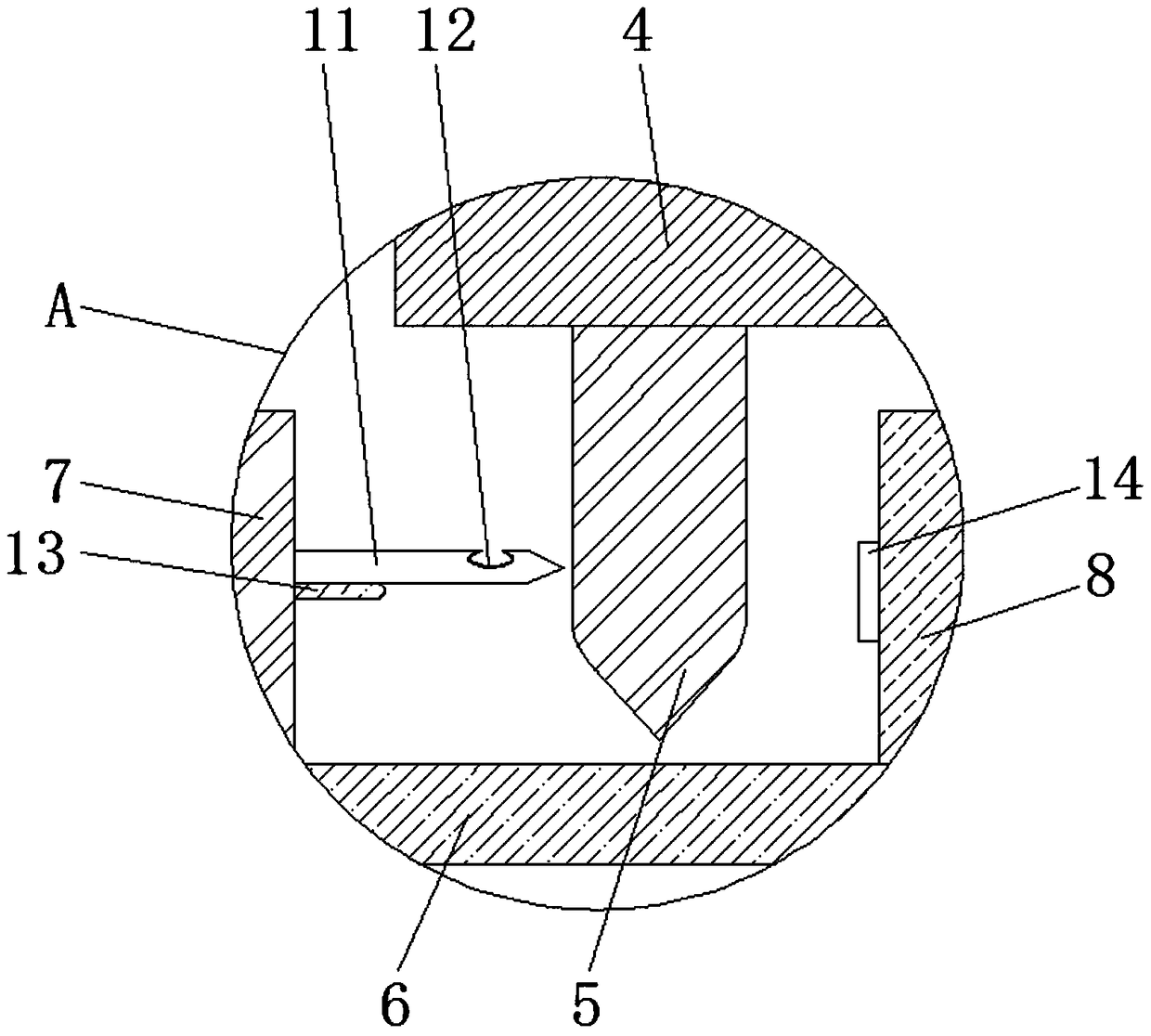

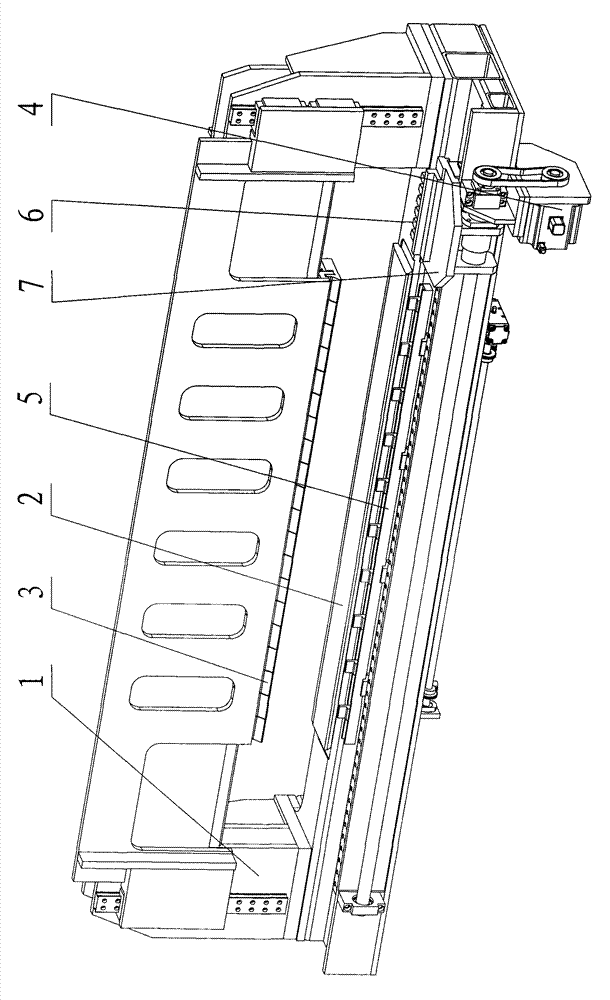

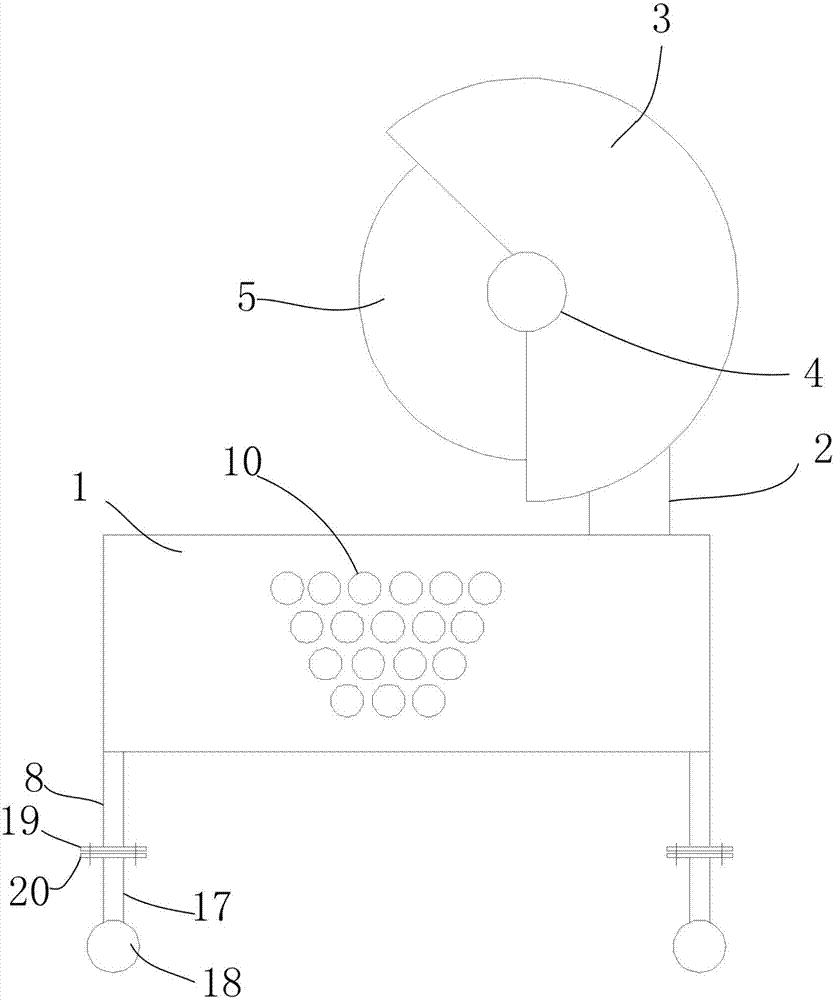

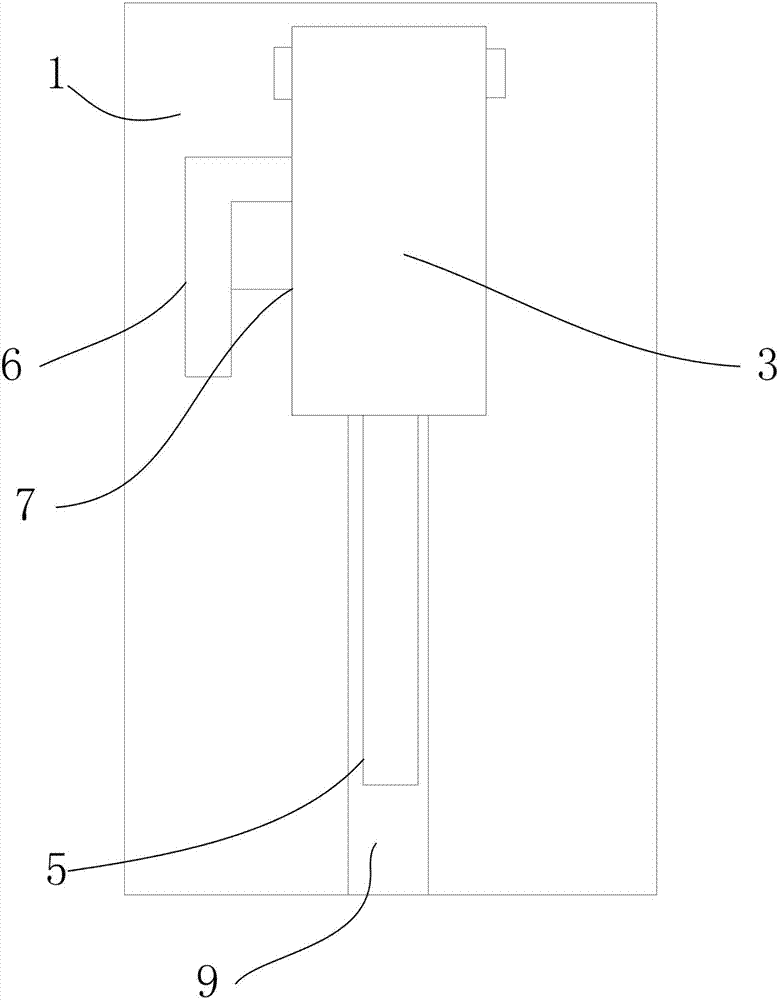

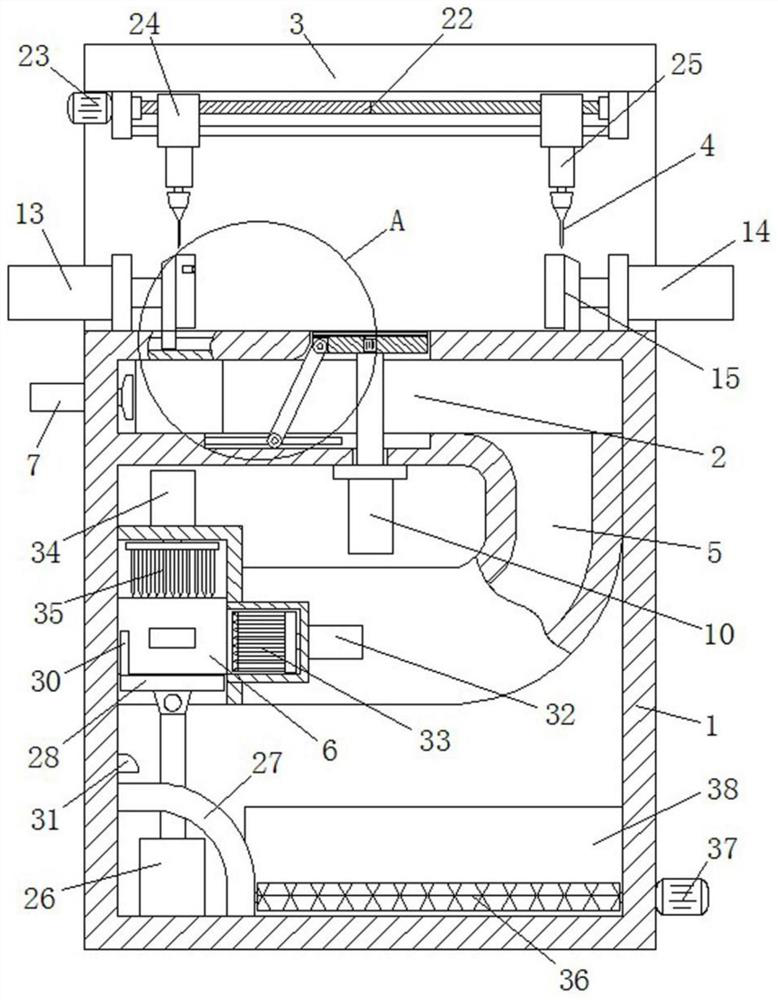

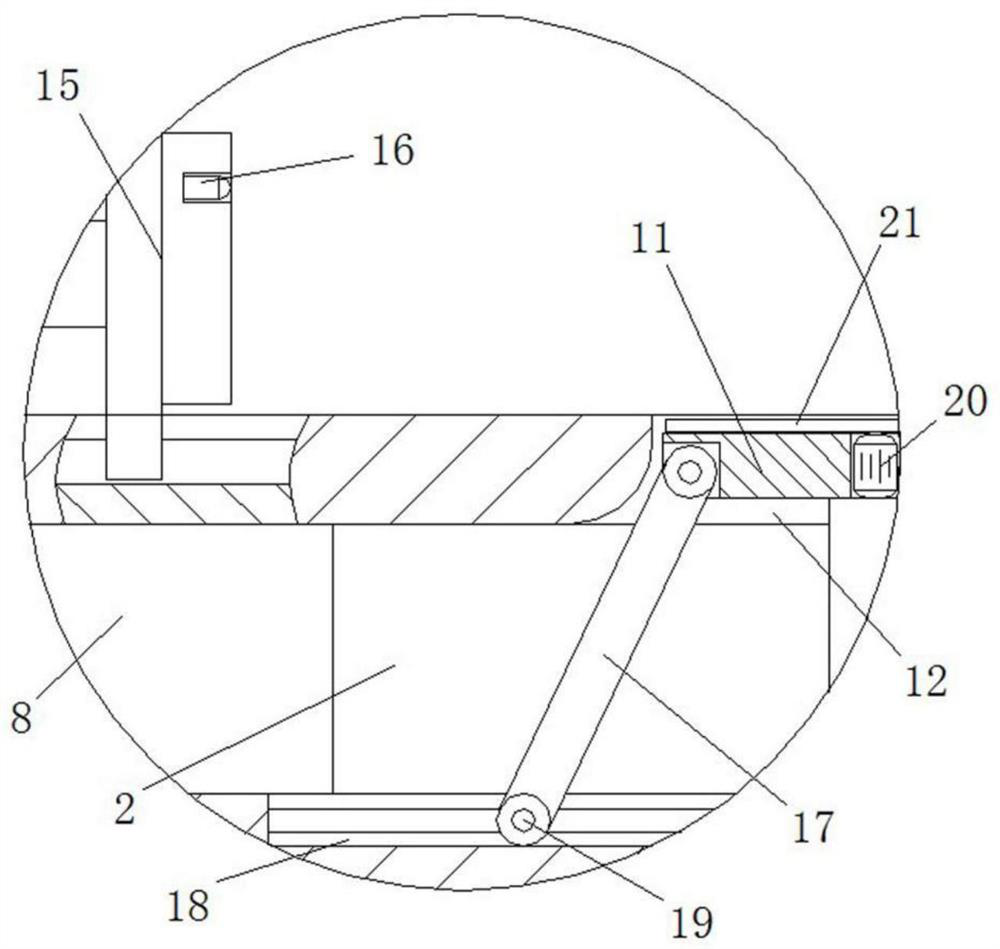

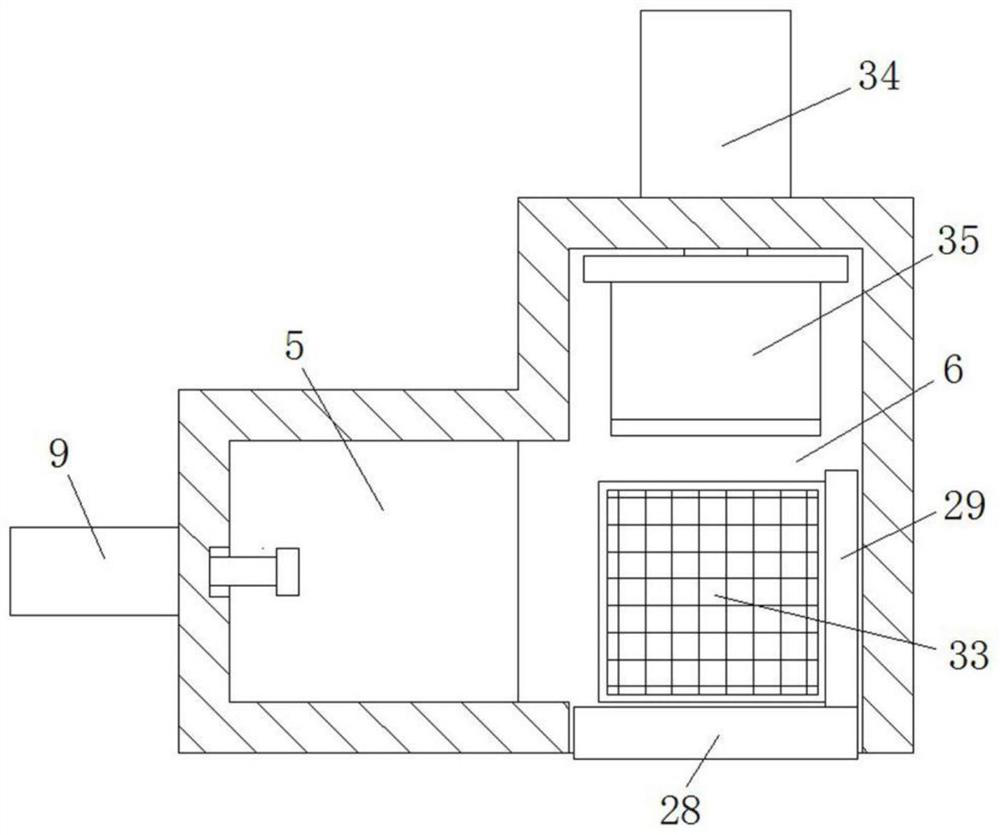

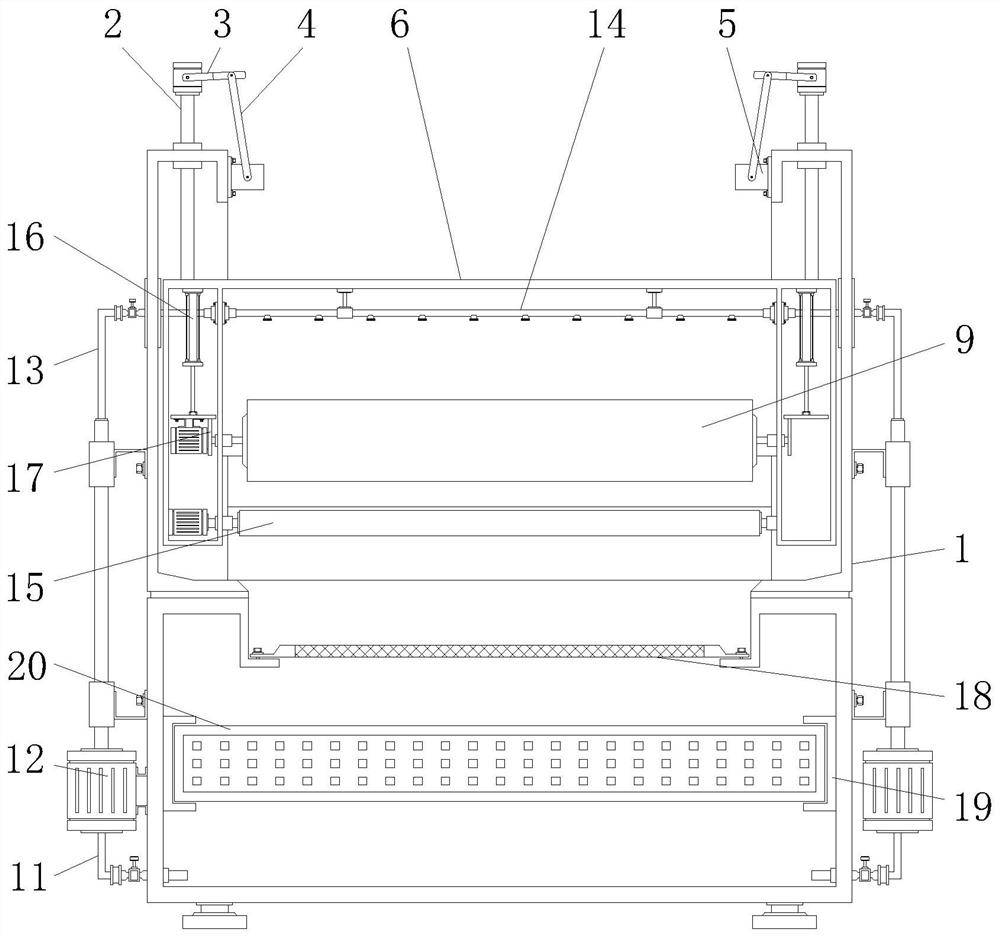

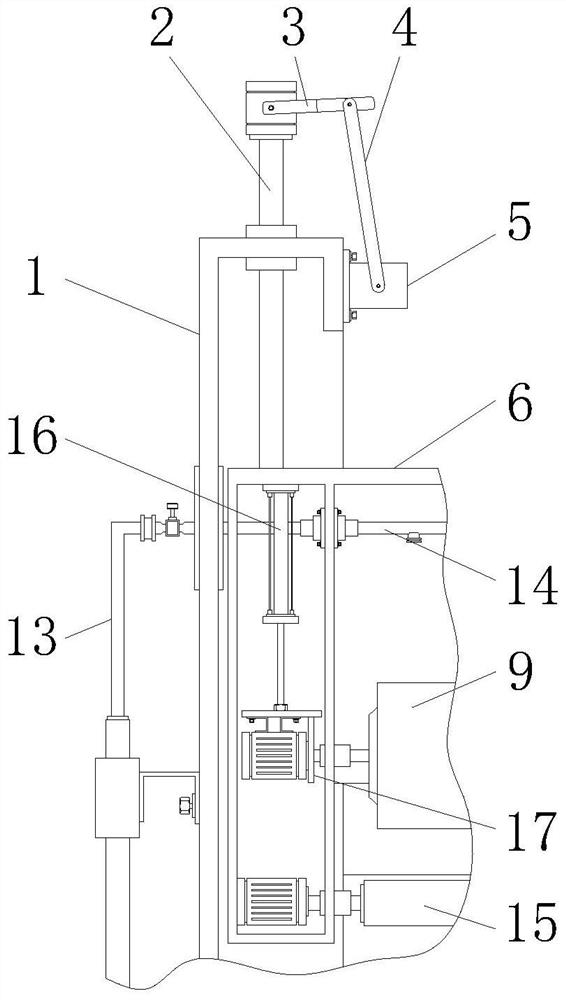

Wood working lathe for wooden vase machining

InactiveCN111844267ASolve the shortcomings that cannot be turnedReduce processing wasteWood-turning machinesElectric machineryStructural engineering

The invention relates to the technical field of artware machining equipment, in particular to a wood working lathe for wooden vase machining. The wood working lathe comprises a lathe bed, a headstockseat, a tailstock and a turning tool mechanism. The tailstock is movably arranged on the upper surface of the other end of the lathe bed. The turning tool mechanism is arranged at the position, between the headstock seat and the tailstock, of the lathe bed. The headstock seat comprises a seat body, a vase end clamped connection mechanism, a rotating frame and a drive motor. The rotating frame is fixedly arranged on the upper surface of the seat body, the vase end clamped connection mechanism is arranged on the right side of the rotating frame, and the drive motor is fixedly arranged on the upper surface of the rotating frame. According to the wood working lathe, the defects that in existing equipment, workers carry out drilling and reaming machining after turned blanks are taken out and then fixed to fixed tools of reaming lathes are effectively overcome, turning and reaming machining of the whole equipment to wood are continuous and integral, operation of the whole process is simple,time waste caused by middle steps is reduced, and the machining efficiency to wooden vases is greatly improved.

Owner:安徽阜南县万家和工艺品有限公司

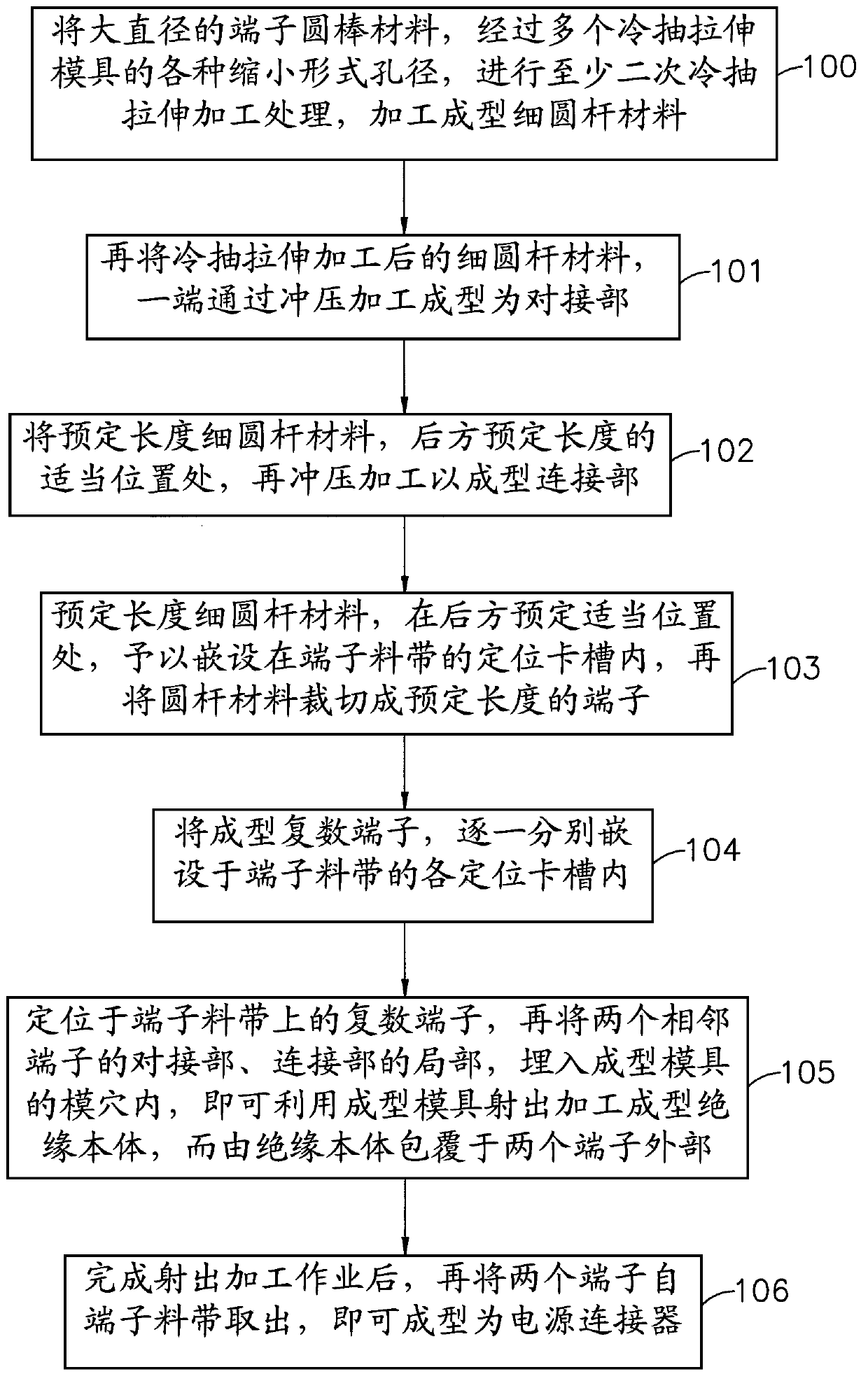

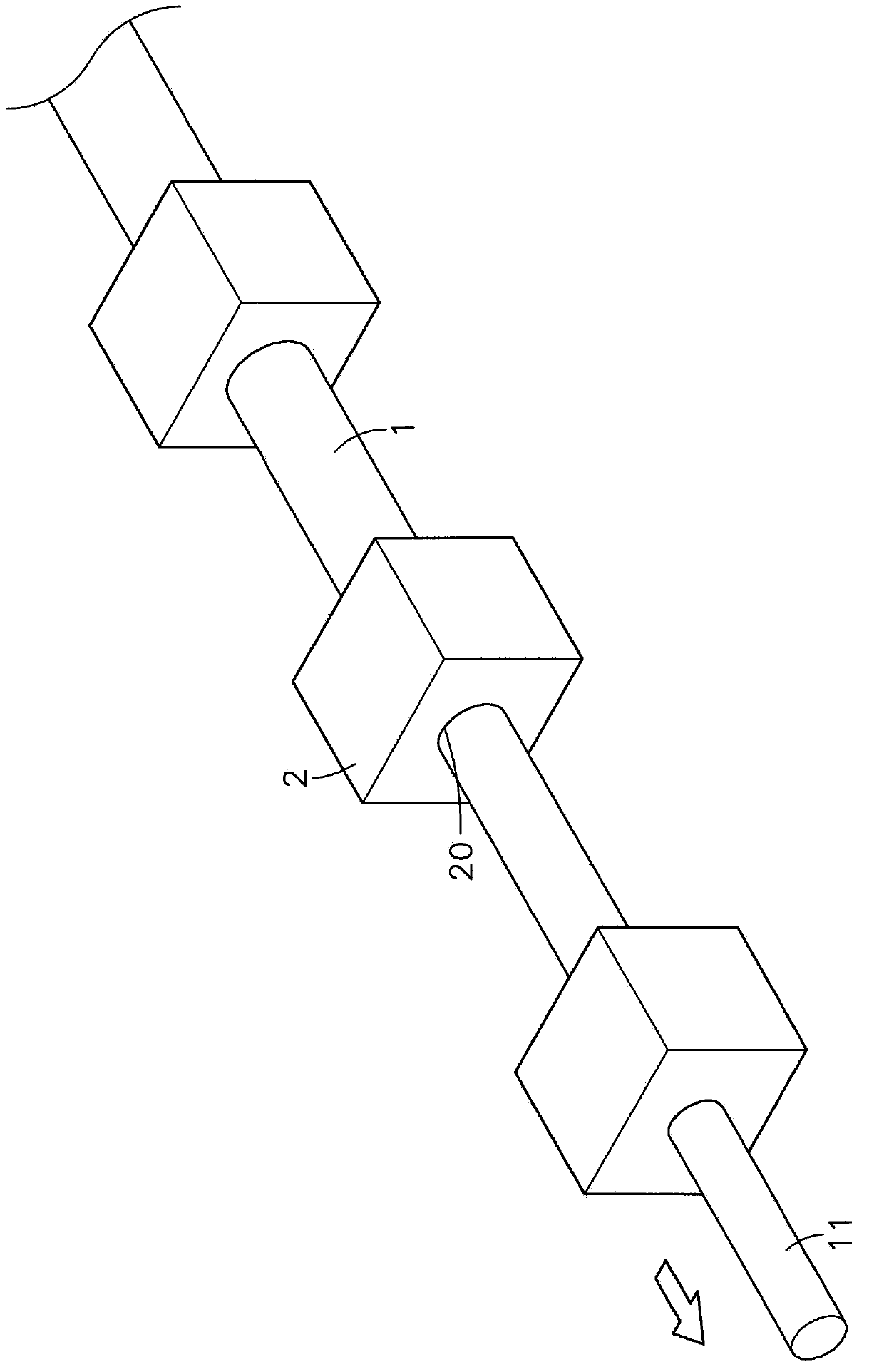

Forming method of power supply connector

InactiveCN103872548AImprove work efficiencyReduce manufacturing costContact member manufacturingContact member assembly/disassemblyManufacturing cost reductionPunching

The invention discloses a forming method of a power supply connector. The forming method comprises the forming steps of processing and forming slender round bar materials by carrying out at least twice cold drawing and stretching processing treatments on terminal round bar materials; punching and forming one ends of the slender round bar materials into terminal butt-joint parts; punching, processing and forming appropriate positions at the rear parts of the slender round bar materials into connecting parts; respectively embedding the slender round bar materials in each locating clamping groove of a terminal material strap one by one, and cutting the slender round bar materials into terminals in preset lengths; respectively locating a plurality of terminals in each locating clamping groove of the terminal material strap after the terminals are formed by repeating the processing mode; embedding the local parts of the butt-joint parts and the connecting parts of two adjacent terminals on the terminal material strap in a die cavity of a forming die, ejecting, processing and forming insulation bodies at the outer parts of the two terminals by utilizing plastics, and separating the two terminals from the terminal material strap; forming the power supply connector after the forming die is removed. According to the forming method disclosed by the invention, the purposes of increasing the working efficiency and reducing the manufacturing cost can be achieved.

Owner:RIIDEA

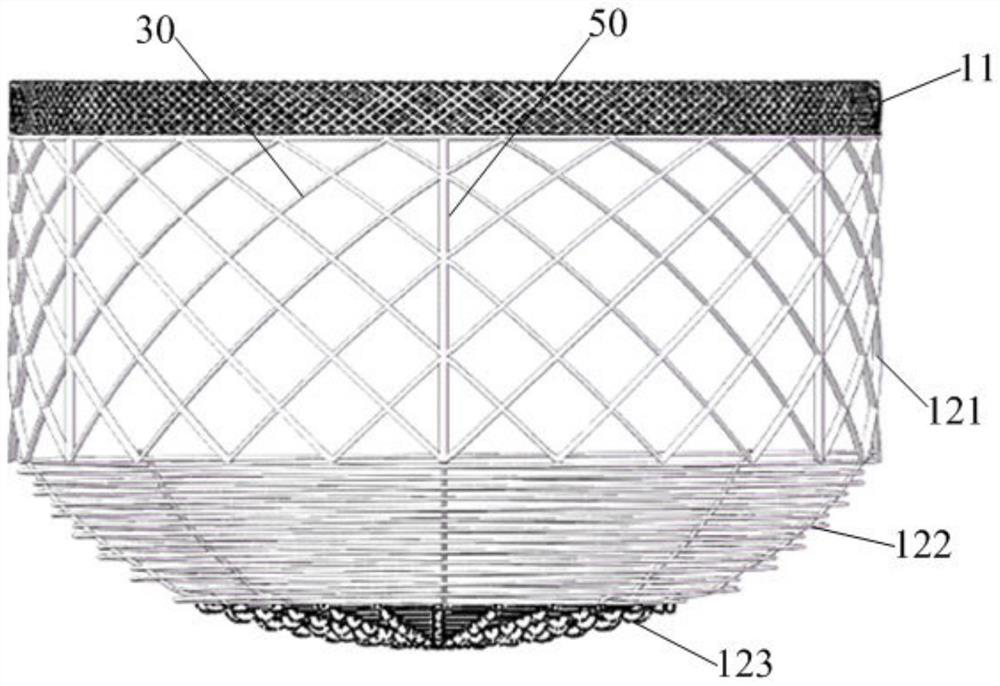

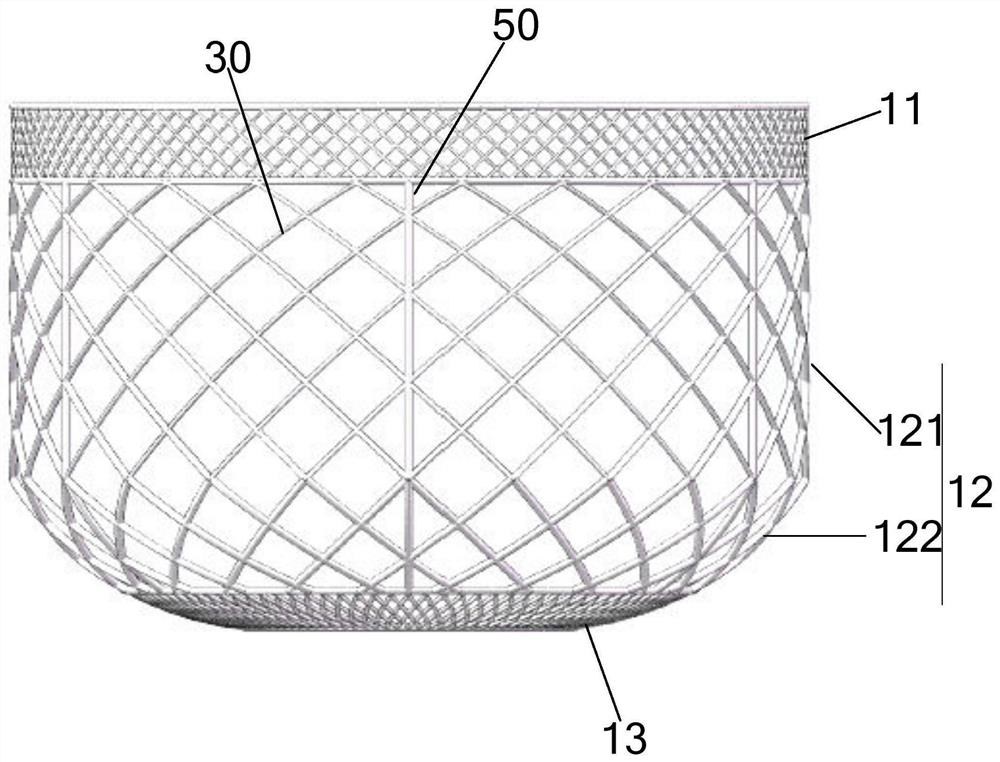

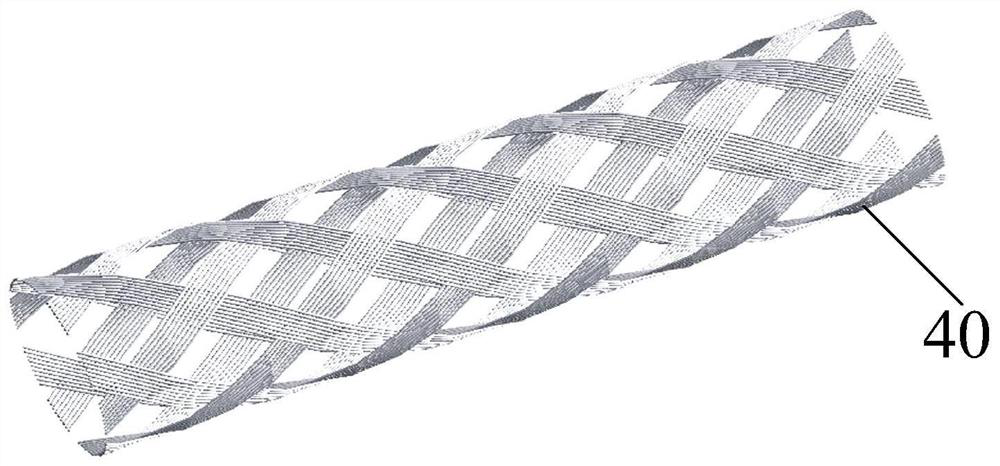

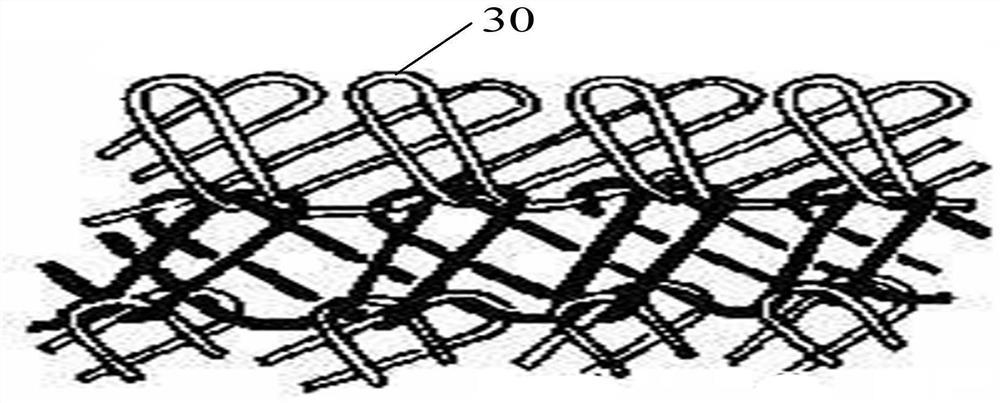

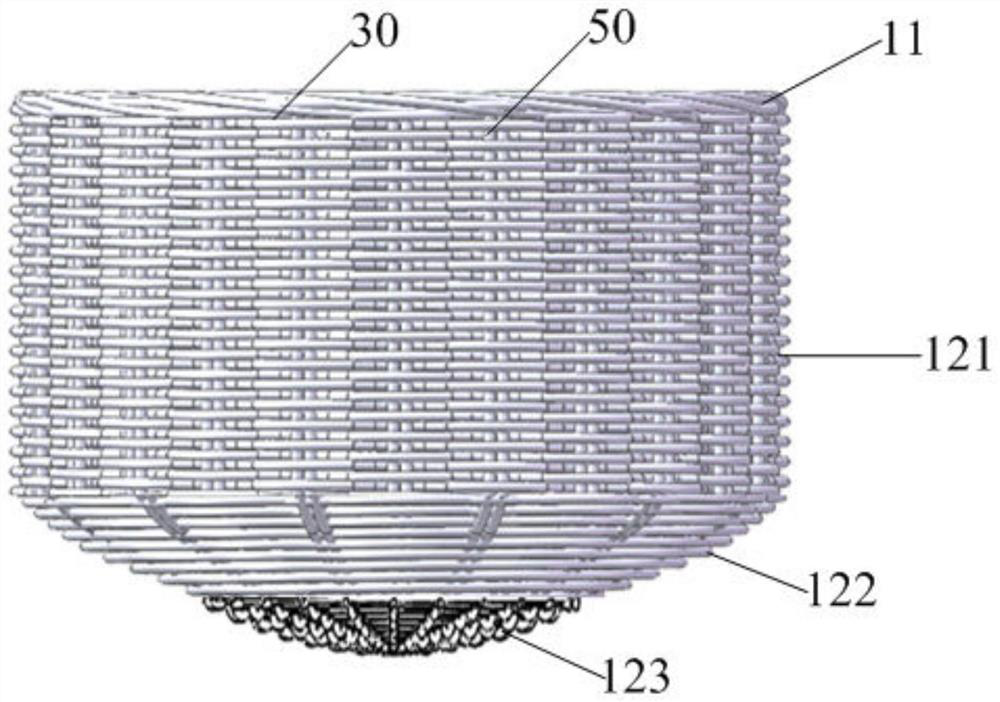

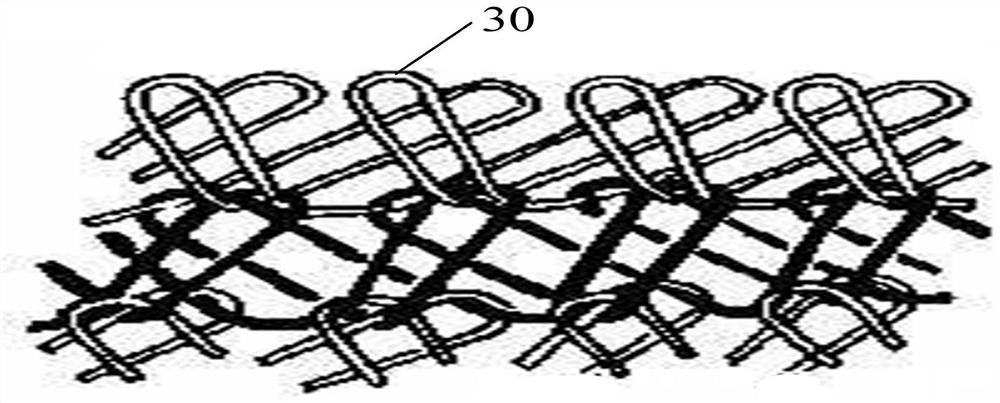

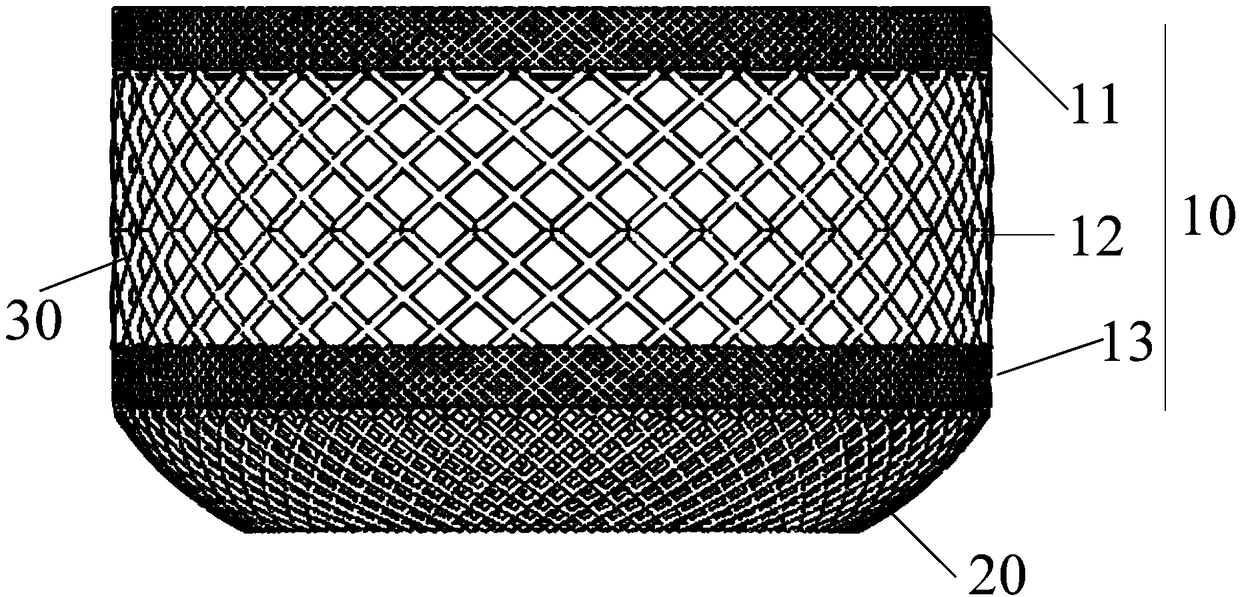

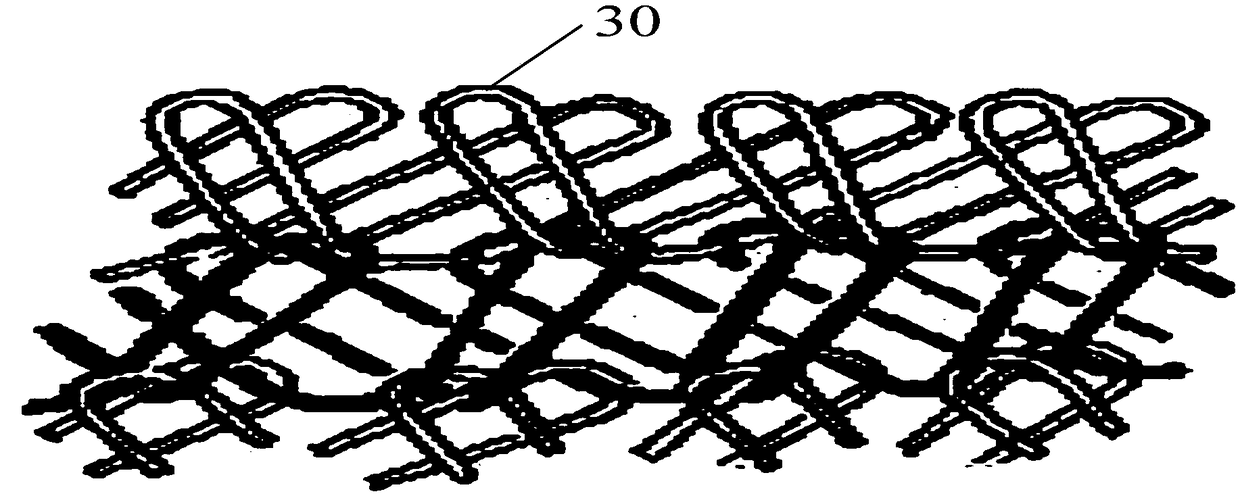

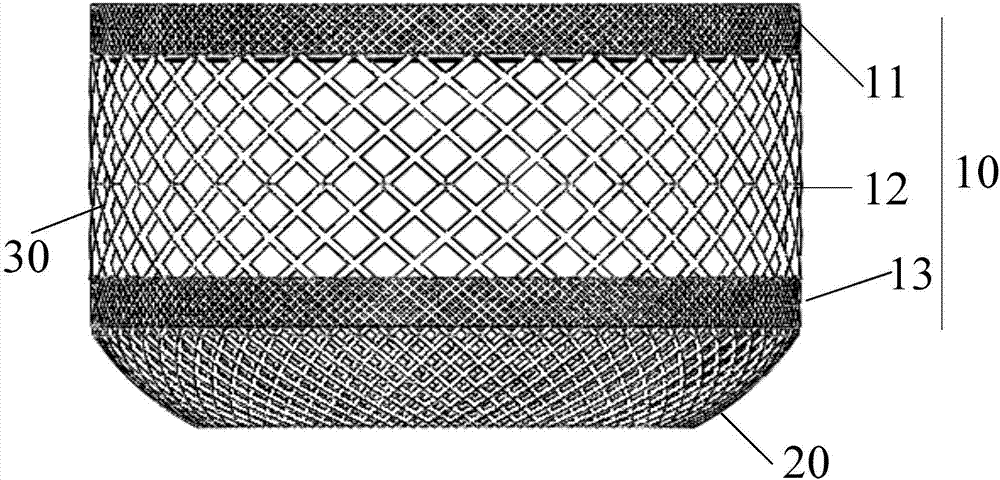

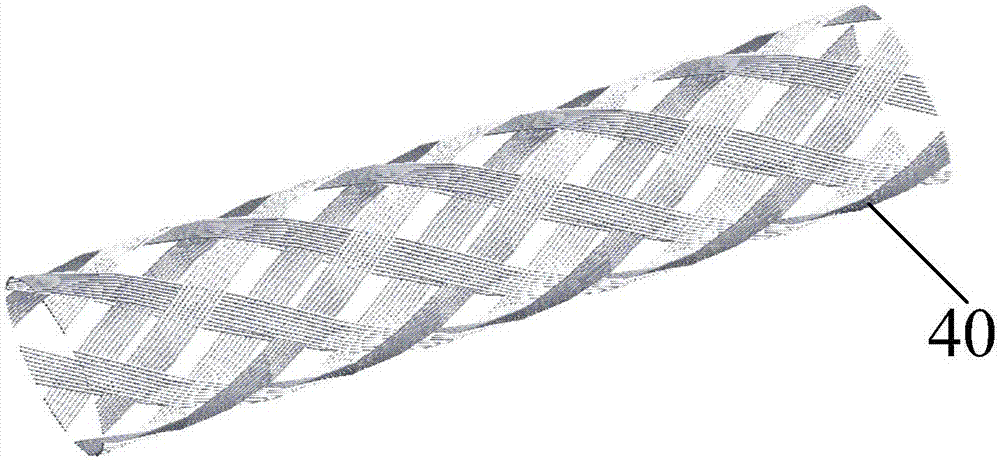

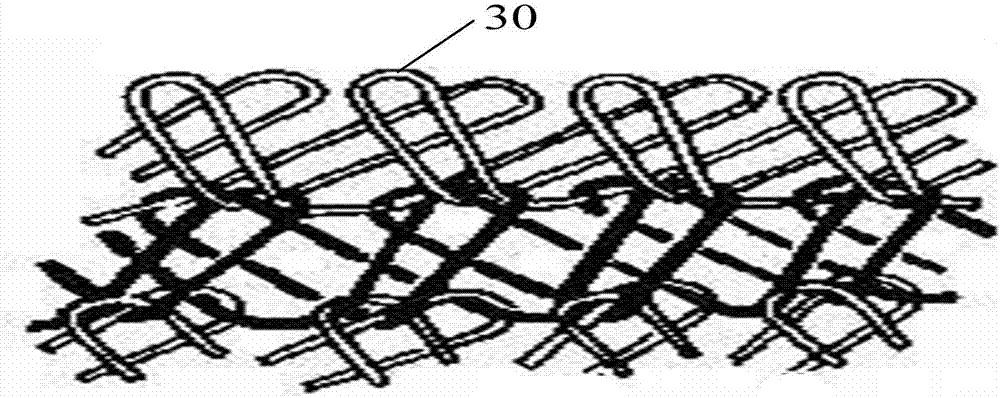

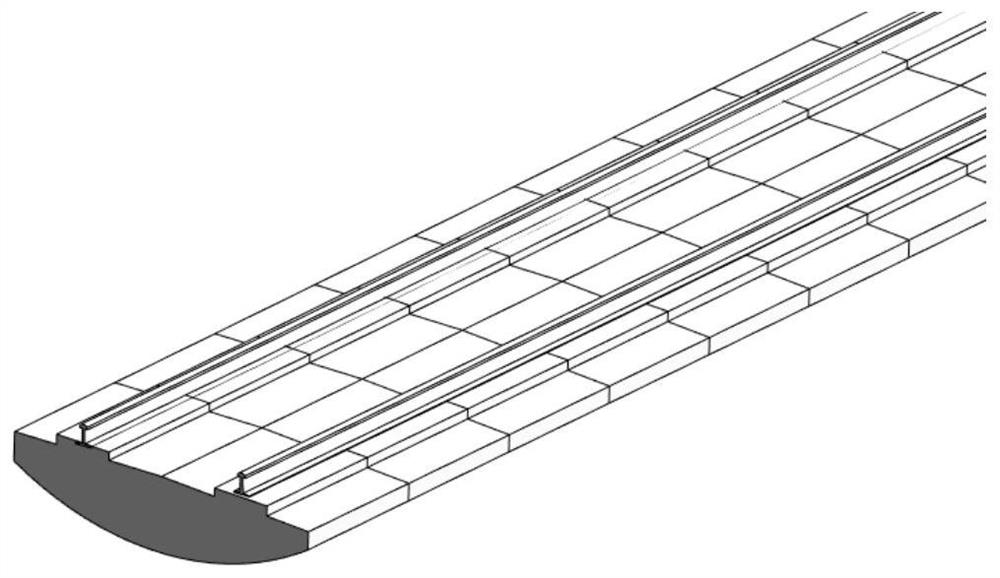

Integrally woven crucible preform and coated crucible prepared from same

PendingCN112176403AReduce processing wasteImprove plasticityPolycrystalline material growthBy pulling from meltFiberCarbon fibers

The invention provides an integrally-woven crucible prefabricated body which is a net-shaped body formed by weaving one or more carbon fiber ropes, and the crucible prefabricated body is formed by densely weaving an opening in the upper end and a compact weaving at the lower end. The crucible is formed by weaving one carbon fiber rope or a plurality of carbon fiber ropes, so that a prefabricated body is unnecessary and working hours are reduced. According to the crucible, straight carbon fiber ropes are adopted for weaving, so that a blank body does not need to be manufactured, the shape plasticity is high, limitation of the blank body is avoided, flexible design and batch production can be achieved, the delivery period is shortened, and material machining waste is little.

Owner:SHANGHAI QI JIE CARBON MATERIALS

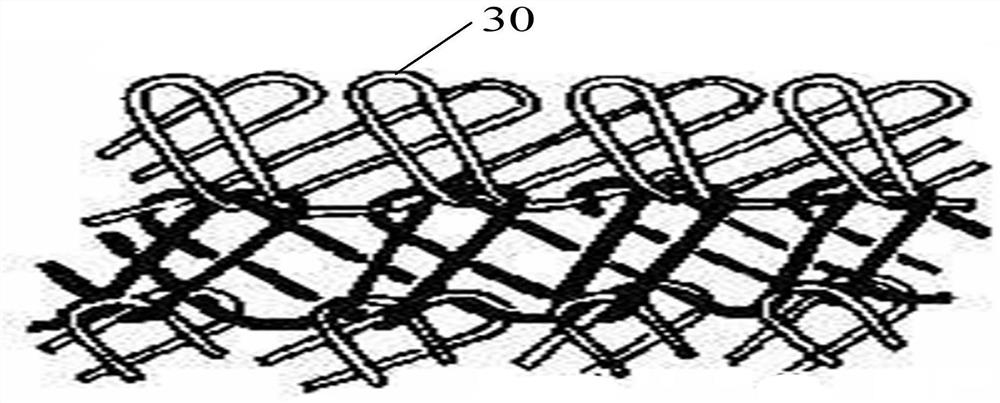

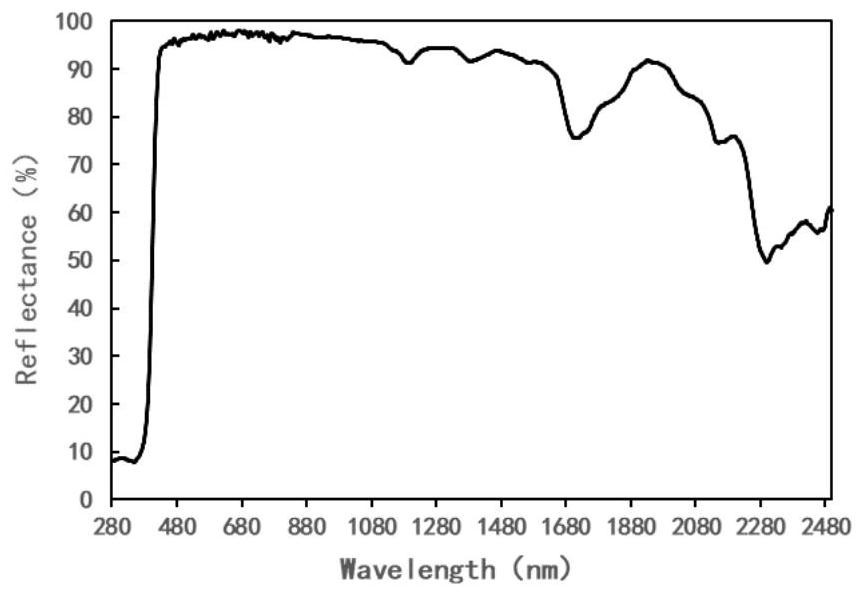

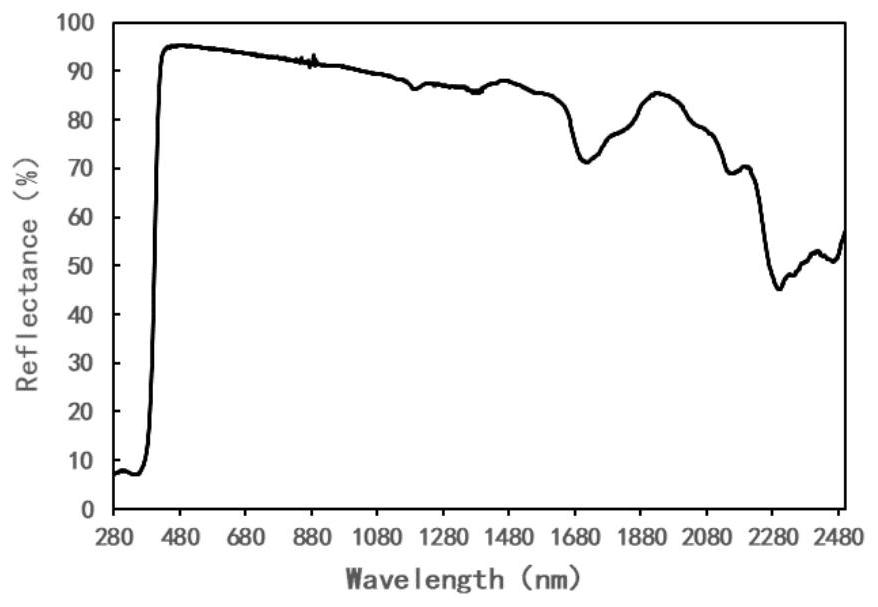

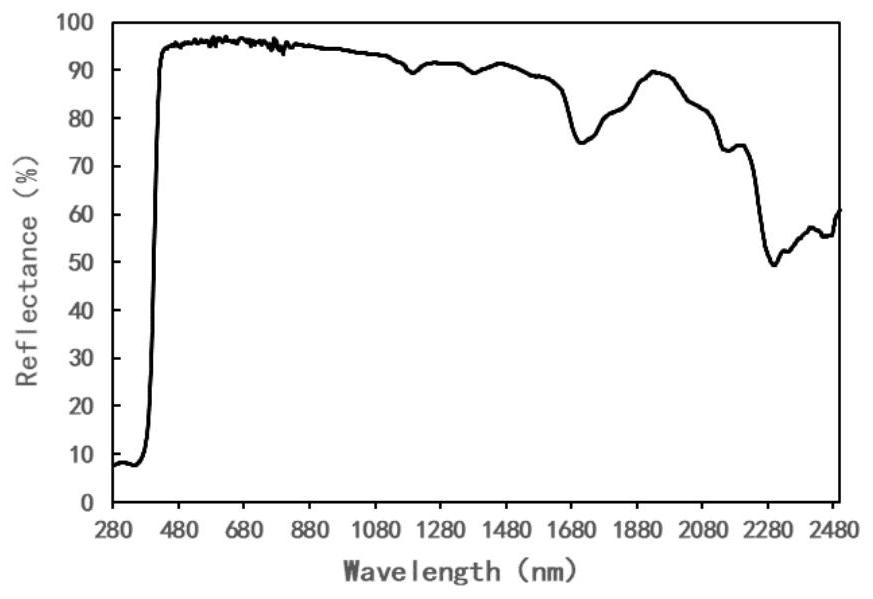

Textile coating with radiation refrigeration function and preparation method thereof

PendingCN114481636AOvercome softnessOvercoming poor folding resistanceTextiles and paperPolymer scienceEmissivity

The invention discloses a textile coating with a radiation refrigeration function and a preparation method of the textile coating, and the textile coating is prepared by coating paint with the radiation refrigeration function. Comprising 20.5%-39.85% of water-based acrylic resin, 30.04%-47.15% of reflective pigment filler, 0.23%-0.43% of a dispersing agent, 0.09%-0.15% of a wetting agent, 0.25%-0.52% of a defoaming agent, 0.27%-0.56% of a thickening agent, 0.37%-0.72% of a coalescing agent and 26.99%-37.99% of water, the elongation at break of the water-based acrylic resin is 400%-850%, the reflective pigment filler comprises first filler and second filler, and the second filler comprises the first filler and the second filler. The particle size of the second filler is larger than that of the first filler, the mass ratio of the first filler to the second filler is 6.5: 1-1: 3, the textile coating adopts a one-step coating method to form a functional layer on the surface of the textile material, the reflectivity of the functional layer in visible light and infrared light is larger than or equal to 85%, and the emissivity of the functional layer in the wave band of 7-14 microns is larger than or equal to 85%. The textile coating disclosed by the invention has good radiation refrigeration function and cooling effect, and also has the advantages of simple preparation method and process, soft surface, folding resistance and the like.

Owner:南京宁智高新材料研究院有限公司

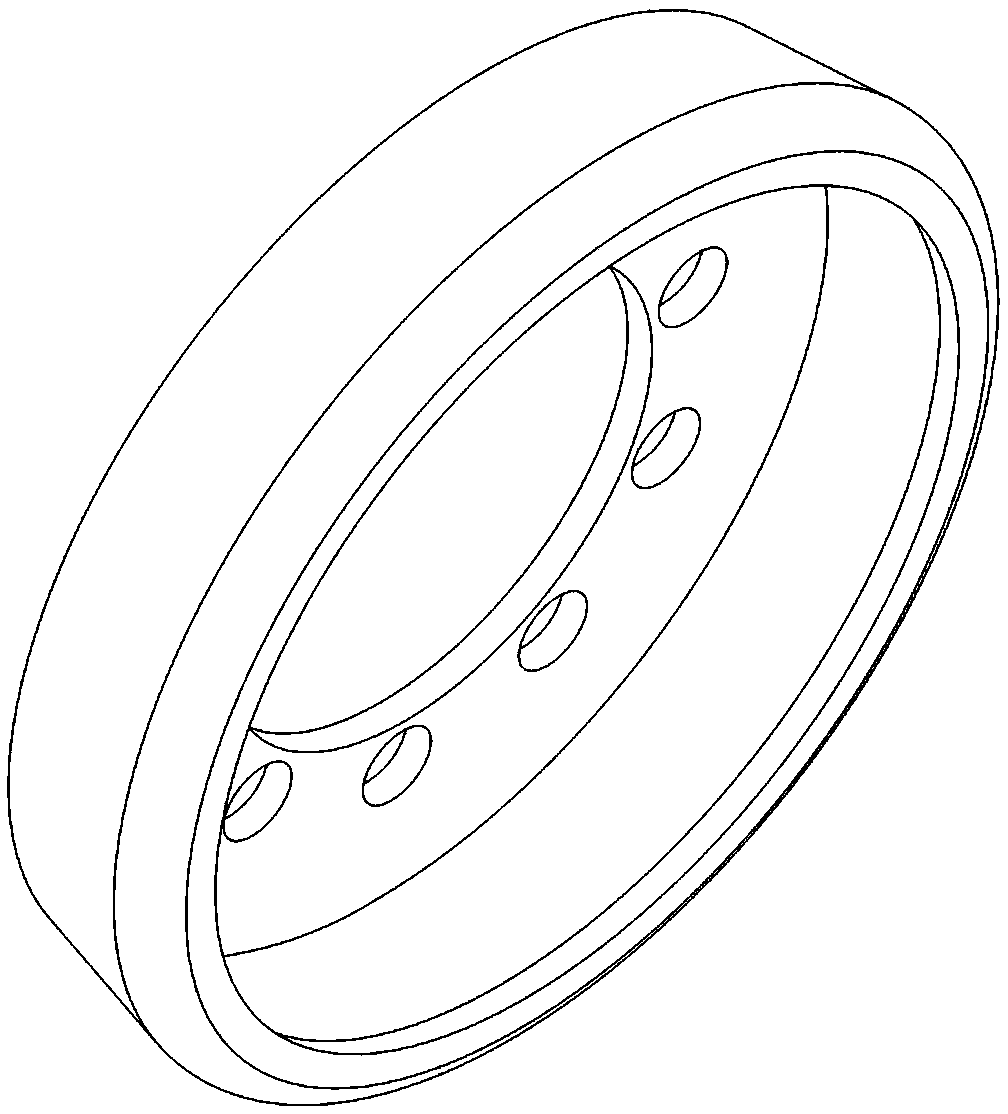

Integrally-woven crucible prefabricated body with bottom holes and coating crucible made of integrally-woven crucible prefabricated body

PendingCN112195508AReduce processing wasteImprove plasticityPolycrystalline material growthBy pulling from meltFiberCarbon fibers

The invention provides an integrally-woven crucible prefabricated body with bottom holes, the crucible prefabricated body is an annular hollow net-shaped body formed by weaving one or more carbon fiber ropes, and the diameter of an opening in the upper end of the crucible prefabricated body is larger than that of an opening in the lower end of the crucible prefabricated body. The crucible prefabricated body is formed by weaving one carbon fiber rope or a plurality of carbon fiber ropes, needling of a prefabricated body is not needed, and working hours are saved; straight carbon fiber ropes areadopted for weaving, a blank body does not need to be manufactured, the shape plasticity is high, limitation of the blank body is avoided, flexible design and batch production can be achieved, the delivery period is shortened, and material machining waste is little.

Owner:SHANGHAI QI JIE CARBON MATERIALS

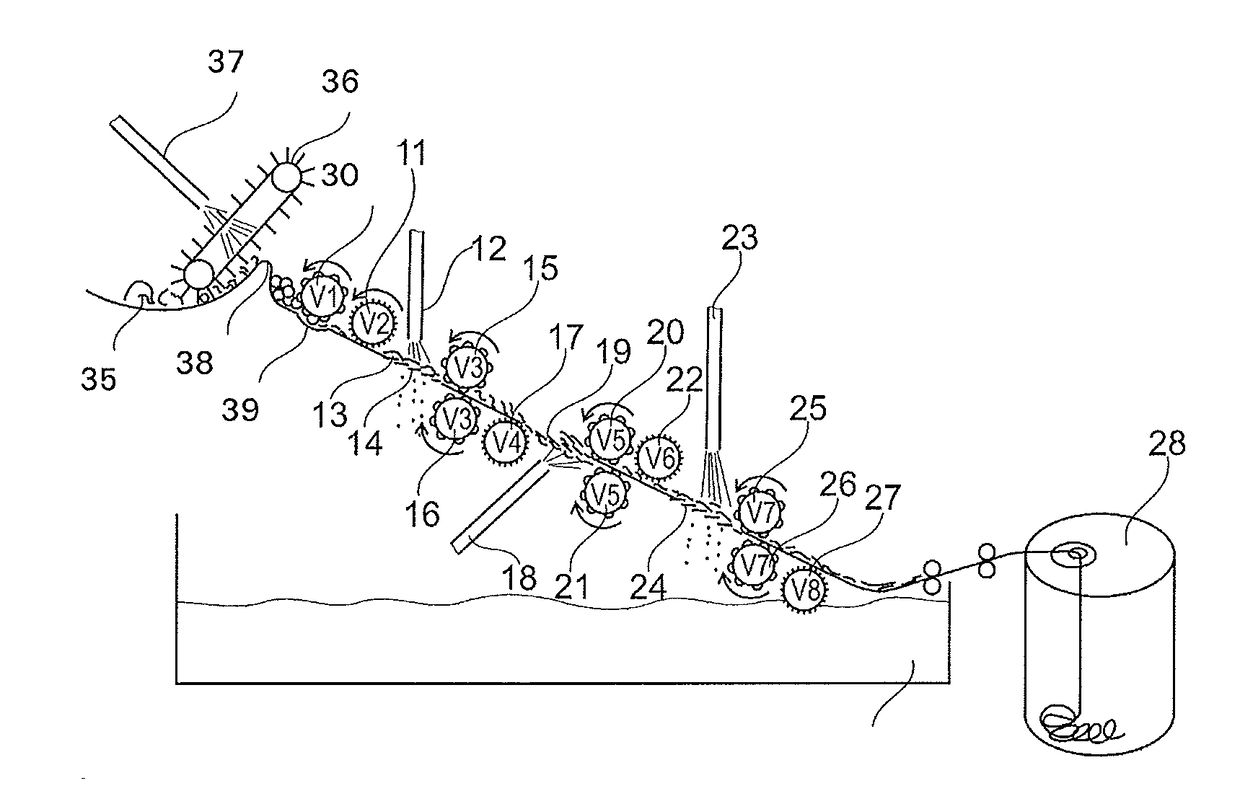

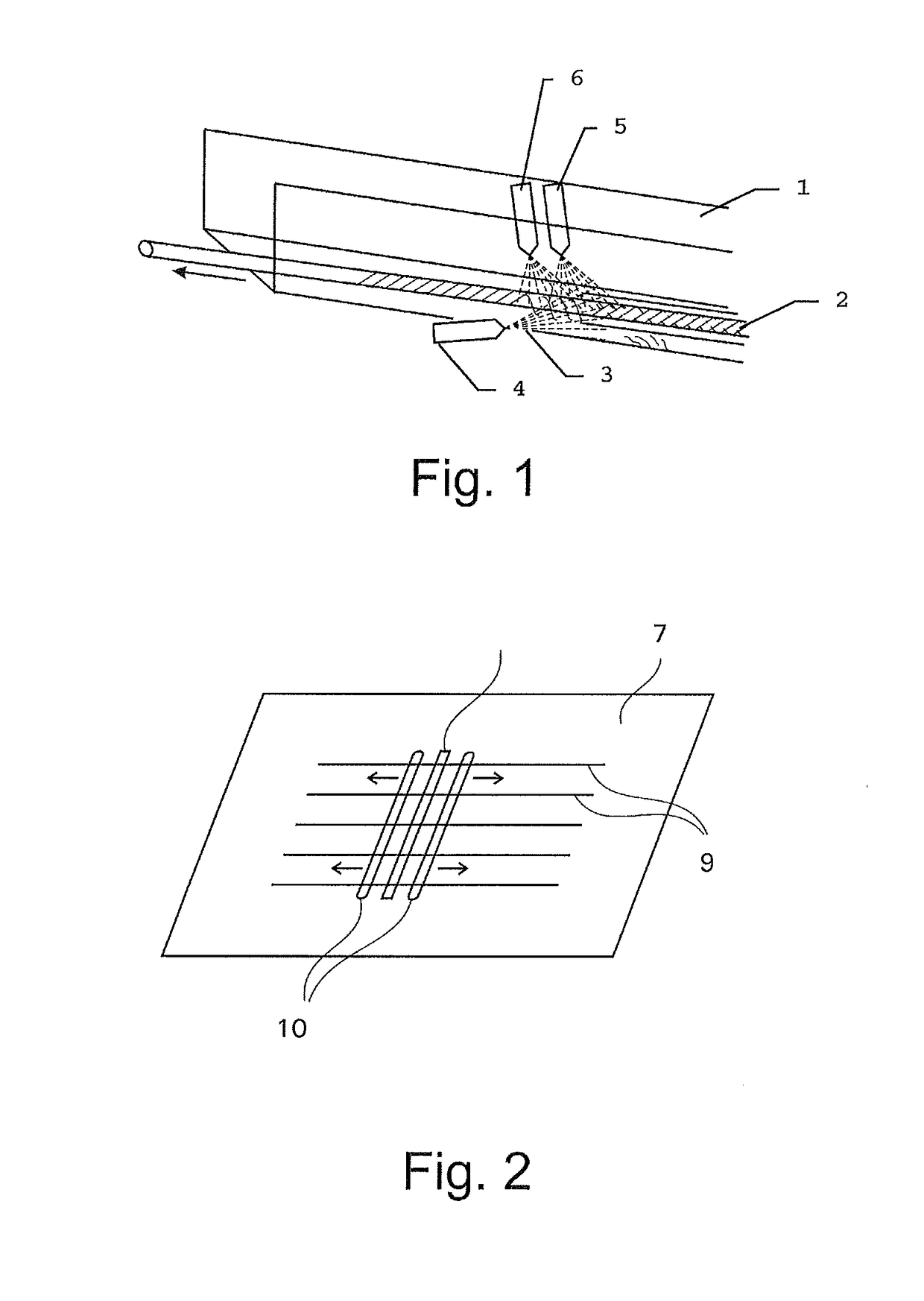

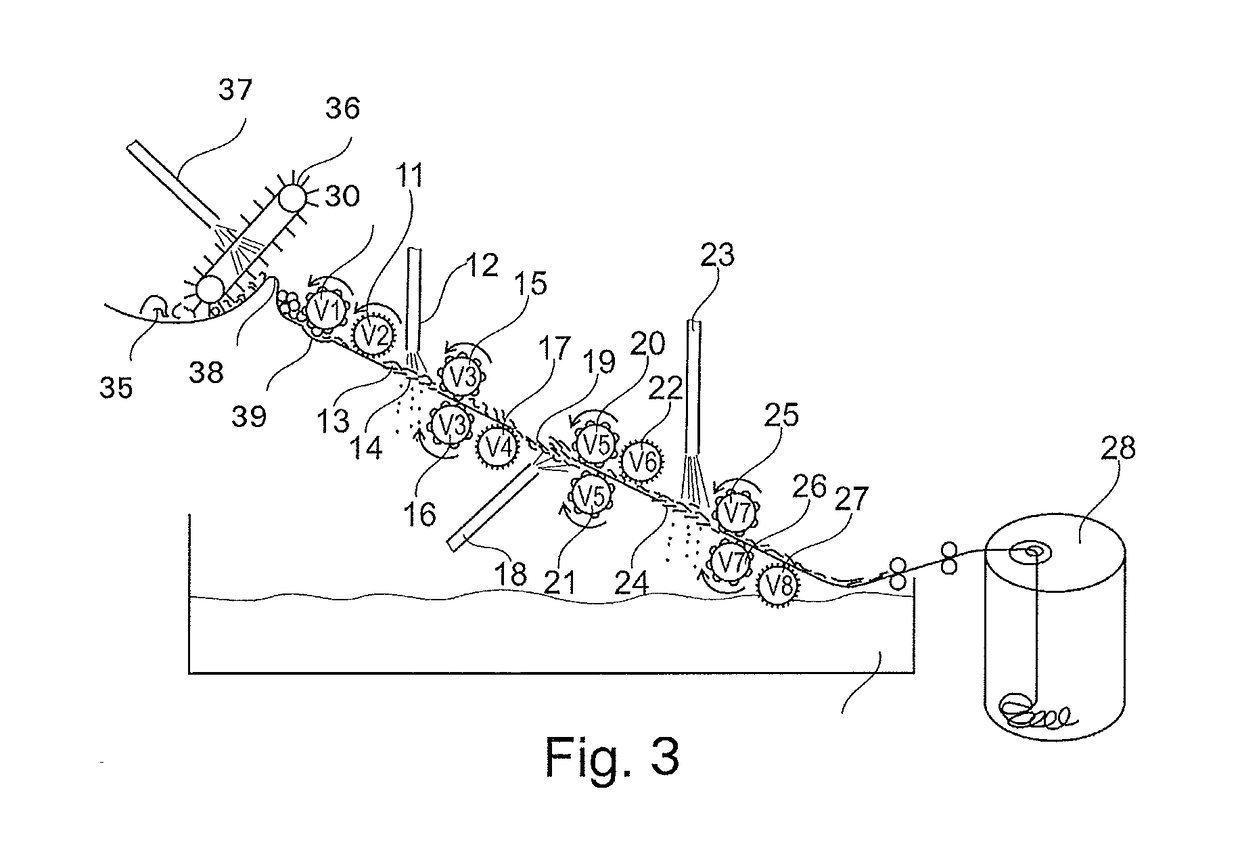

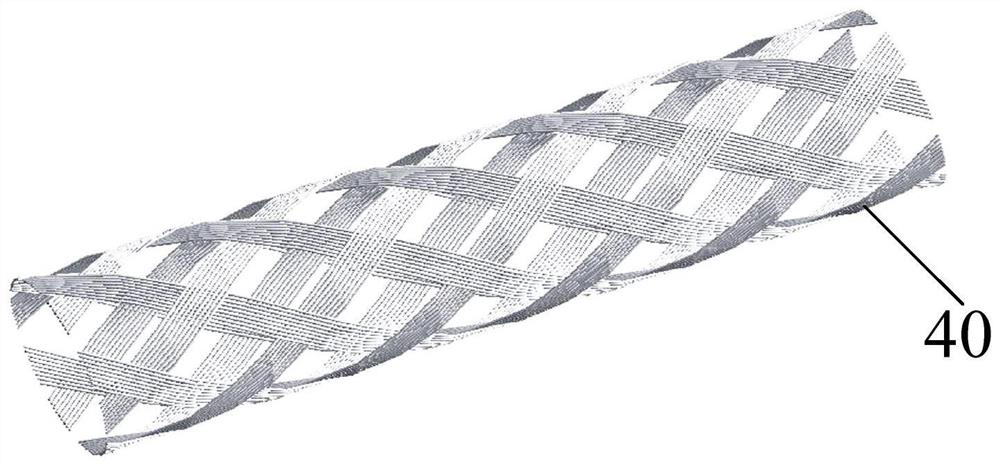

Method for obtaining fibers from at least one plant stem

InactiveUS20170321350A1Less energy inputReduce processing wasteMechanical fibre separationFibre treatment to obtain bast fibreFiberLiquid jet

A method, application and device for obtaining fibres from at least one plant stem or from plant bast is disclosed. The at least one plant stem is treated with at least one high-speed liquid jet or high-speed gas jet. At the start of treatment with the high-speed liquid jet or the high speed gas jet the at least one plant stem has a moisture content of at least 25% and / or vegetable glues, in particular the pectin and hemicelluloses, of the plant stem are in a swollen state.

Owner:MATTES & AMMANN

Integral spiral woven crucible prefabricated body and coated crucible prepared from same

PendingCN112195509AReduce processing wasteImprove plasticityPolycrystalline material growthBy pulling from meltFiberCarbon fibers

The invention provides an integral spiral woven crucible prefabricated body which is a net-shaped body formed by spirally weaving one or more carbon fiber ropes, and a crucible which is woven in a net-shaped hollowed-out mode with the upper end open and the lower end closed. The crucible is formed by weaving one carbon fiber rope or a plurality of carbon fiber ropes, needling of a prefabricated body is not needed, and working hours are saved; straight carbon fiber ropes are adopted for weaving, a blank body does not need to be manufactured, the shape plasticity is high, limitation of the blankbody is avoided, flexible design and batch production can be achieved, the delivery period is shortened, and material machining waste is little.

Owner:SHANGHAI QI JIE CARBON MATERIALS

Production method of coated crucible

InactiveCN108950685ASave man hoursReduce curing processAfter-treatment apparatusPolycrystalline material growthWork timeFragility

The invention provides a production method of a coated crucible. The crucible is an annular hollow net-shaped body formed by braiding one carbon fiber rope or belt; and a production process of the crucible comprises the following step: carrying out a plasma thermal spraying or solid powder solution pre-impregnation and re-sintering step. A crucible top and a crucible bottom of the crucible are prepared by braiding one carbon fiber rope or the plurality of carbon fiber ropes; a needle-punched pre-formed body is not needed and an adhesive is not needed; a processing step of too-long-time vapor phase deposition is not needed, so the working time is saved; the disadvantages that the pre-formed body crucible has poor elasticity and poor fragility are overcome; the thermal deformation stress ofa quartz crucible can be effectively absorbed; meanwhile, the weight of the crucible top of the crucible is greatly reduced and the content of hot melts and impurities of the crucible is reduced; andthe material cost and the application cost are greatly reduced.

Owner:SHANGHAI QI JIE CARBON MATERIALS

Coating crucible with sealing side and manufacture method of coating crucible

PendingCN107964679ASave man hoursReduce curing processPolycrystalline material growthBy pulling from meltMan-hourThermal deformation

The invention provides a coating crucible with a sealing side. The coating crucible comprises a crucible upper with a sealing side and a crucible bottom, one carbon fiber rope or more carbon fiber ropes are woven to form the crucible upper and the crucible bottom, needling performs and binding agents are omitted, vapor-phase deposition processing steps of long time are omitted, working time is saved, the coating crucible overcomes the shortcomings of poor crucible elasticity and high brittleness of the performs, heat deformation stress of a quartz crucible can be effectively absorbed, the weight of the crucible upper is greatly reduced, hot melting and impurity content of the crucible are reduced, and material cost and use cost are greatly reduced.

Owner:SHANGHAI QI JIE CARBON MATERIALS

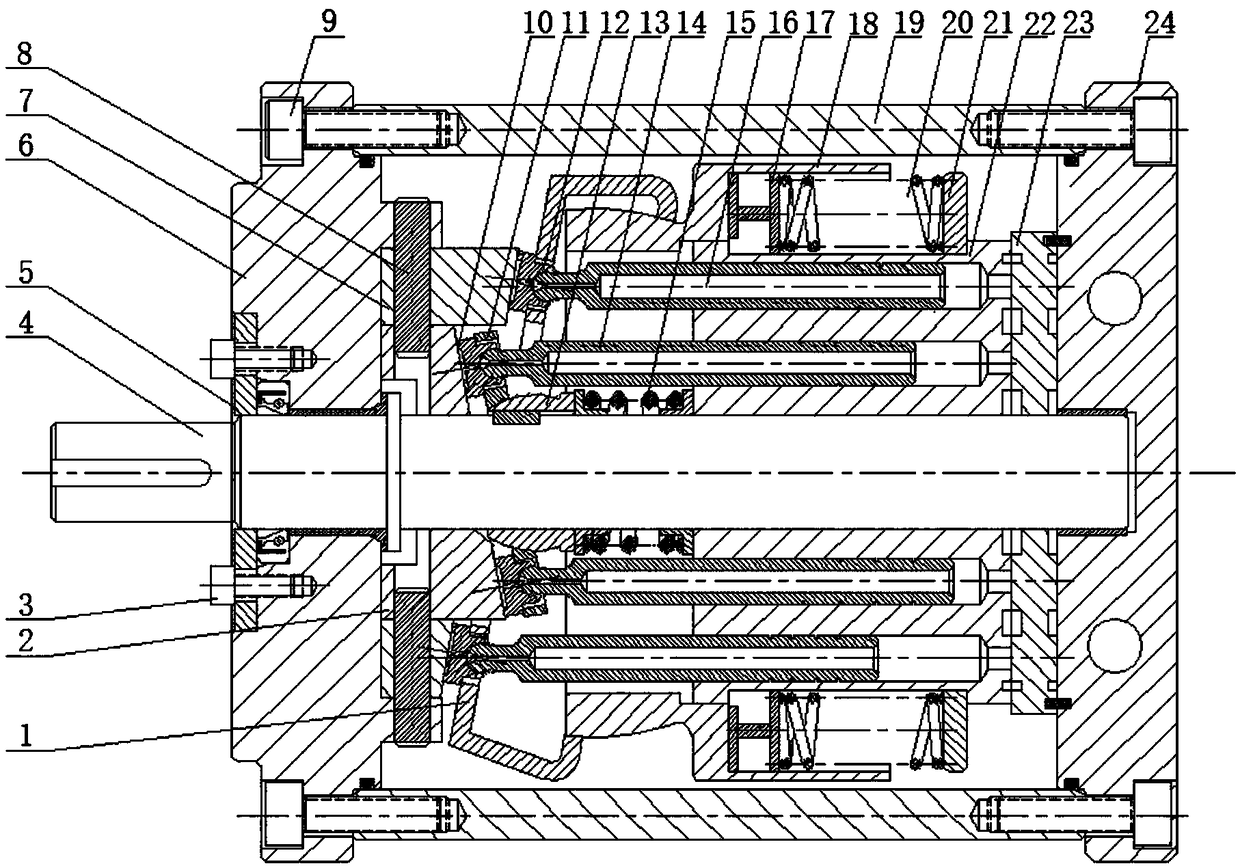

Novel outer row compressed type multi-row axial plunger pump/motor

PendingCN109139404AGood structural symmetryEvenly distributed pressing forcePositive displacement pump componentsReciprocating piston enginesDrive shaftHydraulic machinery

The invention provides a novel outer row compressed type multi-row axial plunger pump / motor, and relates to the field of axial plunger pump / motors of hydraulic machinery. The novel outer row compressed type multi-row axial plunger pump / motor comprises a shell, a cylinder body, a transmission shaft, a thrust plate, an inner swash plate and an outer swash plate; a front gland is connected with a front end cover through hexagonal screws; the front end cover is connected with the shell through hexagonal screws; the shell is connected with a rear pump cover through screws; the transmission shaft drives the cylinder body to rotate through splines, a baffle groove of the cylinder body is internally provided with a baffle, and the outer side of the cylinder body is sleeved with an outer compressedball sleeve; the outer ball surface of the outer compressed ball sleeve is hinged to the inner ball surface of an outer compressed plate, and outer row spring seats and outer row springs are installed in spring holes of the outer compressed ball sleeve; the side, close to the front end cover, of the transmission shaft is provided with the inner swash plate and the outer swash plate; and the innerswash plate and the outer swash plate are connected through swash plate positioning pins. According to the novel outer row compressed type multi-row axial plunger pump / motor, rotating bodies are of afull symmetrical structure, spring force is distributed uniformly, action baffles of the outer row springs are inserted in the cylinder body, cylinder body prepared materials are reduced, the cost isreduced, and the structure is simple and practical.

Owner:ANHUI UNIV OF SCI & TECH

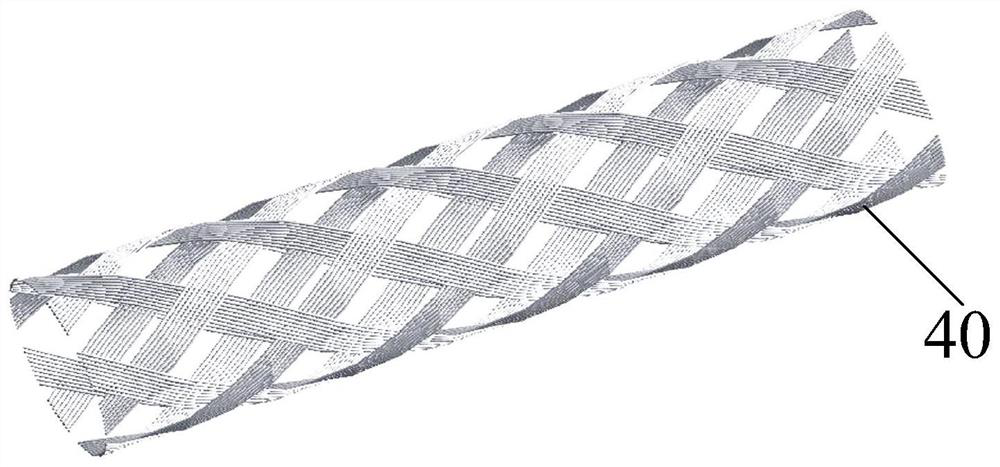

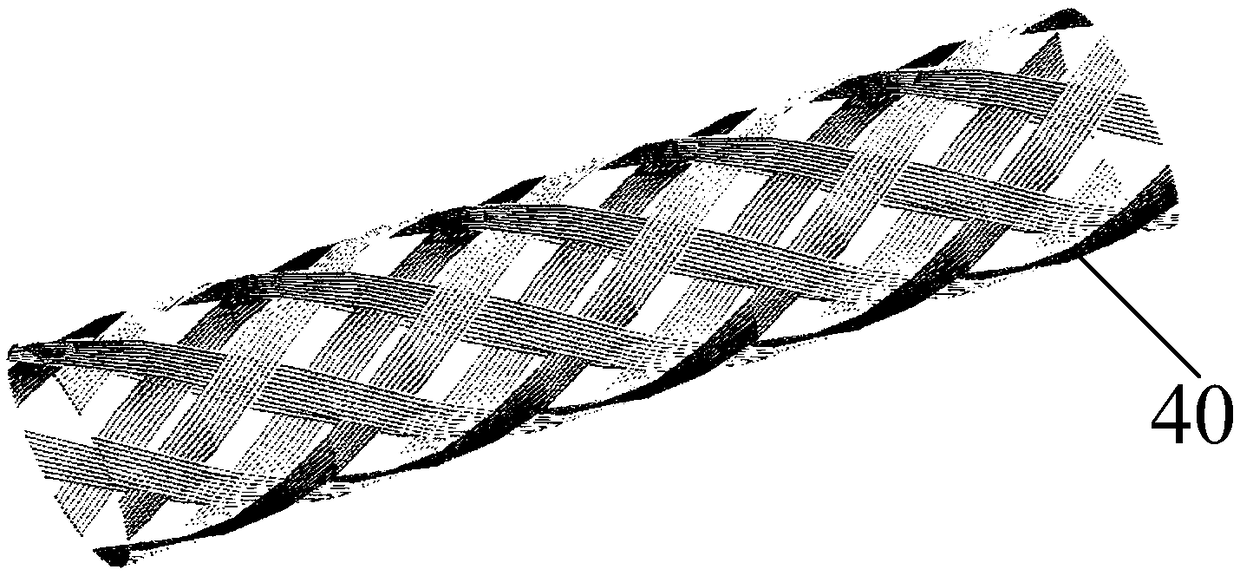

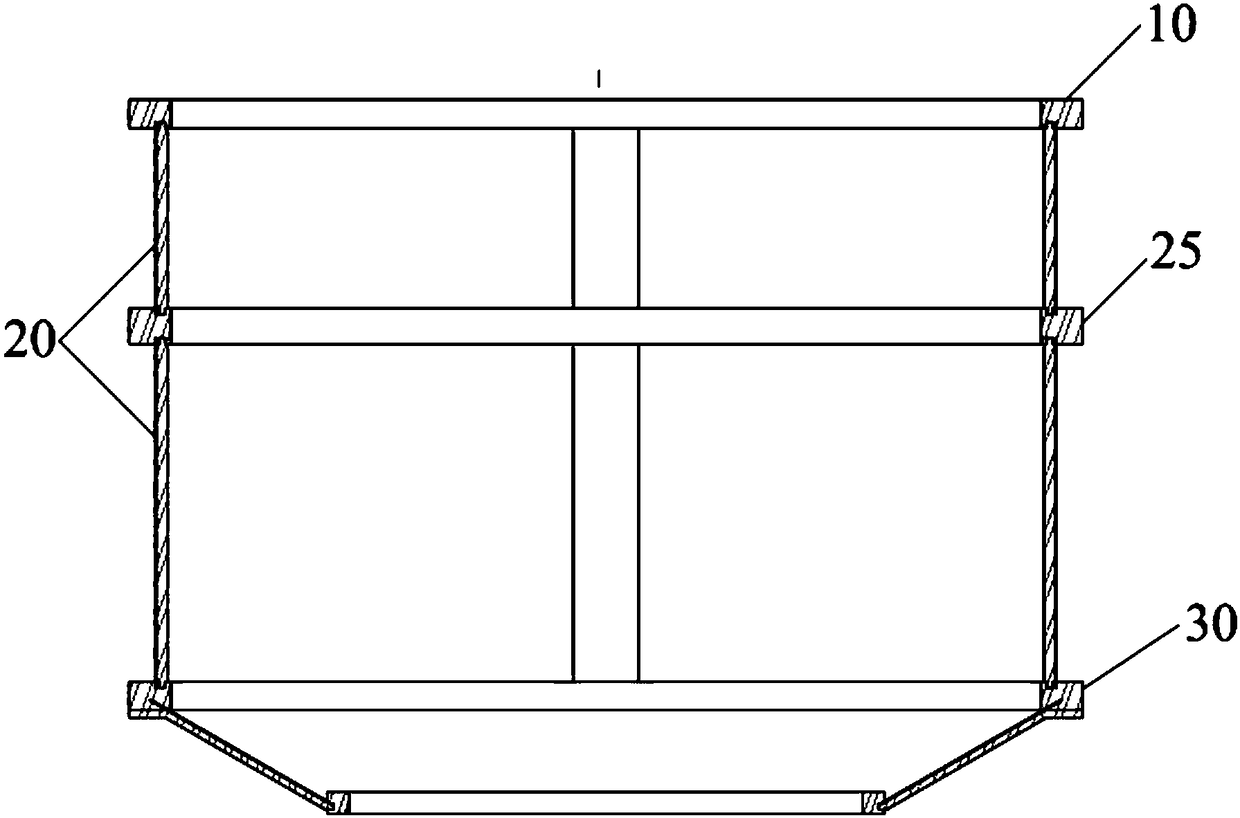

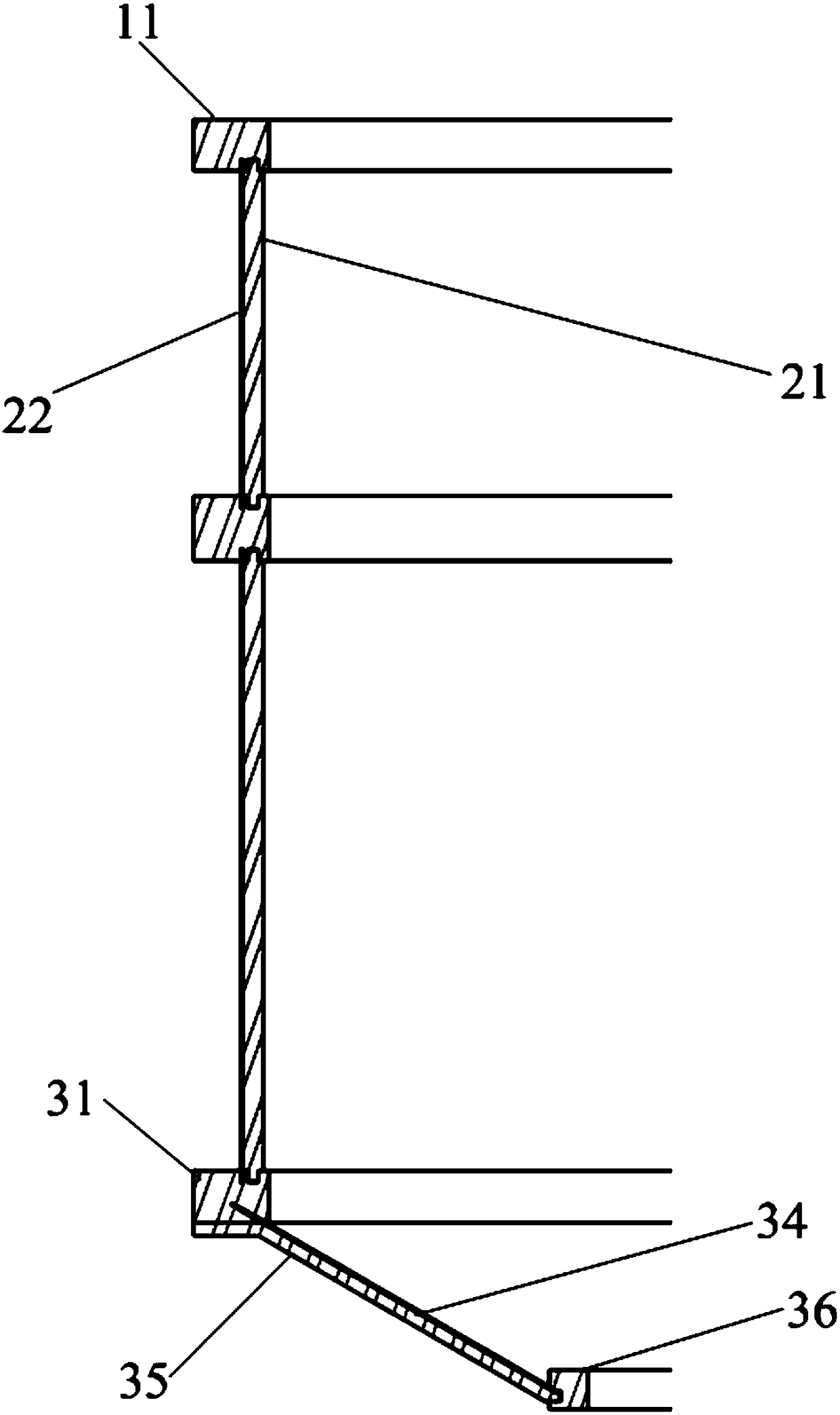

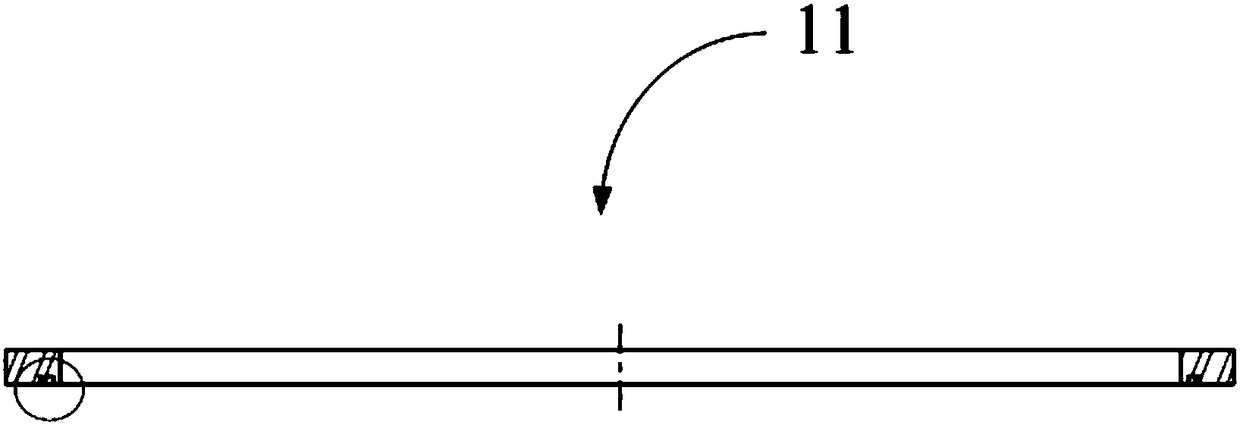

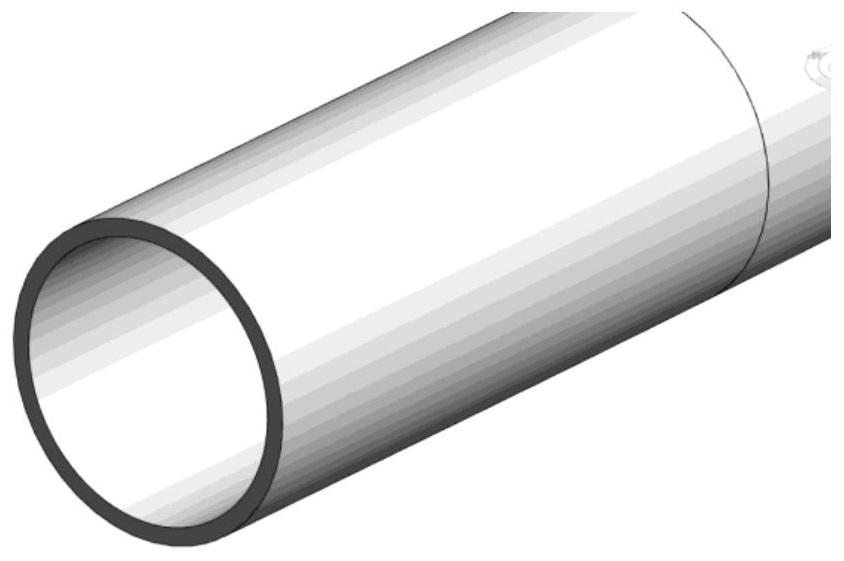

Draft tube as well as making method and material thereof

PendingCN108103567AReduce thicknessReduce weightPolycrystalline material growthBy pulling from meltEngineeringMaterials processing

The invention provides a draft tube. The draft tube is applied to a heat field and comprises an upper ring part, a cylinder part, N middle ring hoops, a lower ring part and at least one cylinder rib plate, wherein N is an integer larger than or equal to 0; the cylinder part is made of a flexible and bendable material. The draft tube is light in weight, high in strength, non-stripping and high in safety. A blank is not needed to be made, batch production is realized, and accordingly, the delivery period is shortened, and few materials are wasted in processing.

Owner:SHANGHAI QI JIE CARBON MATERIALS

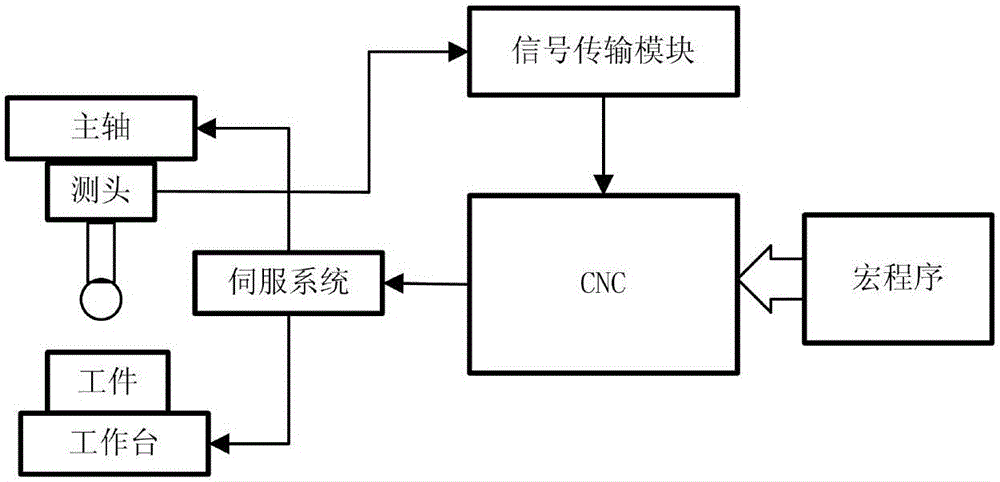

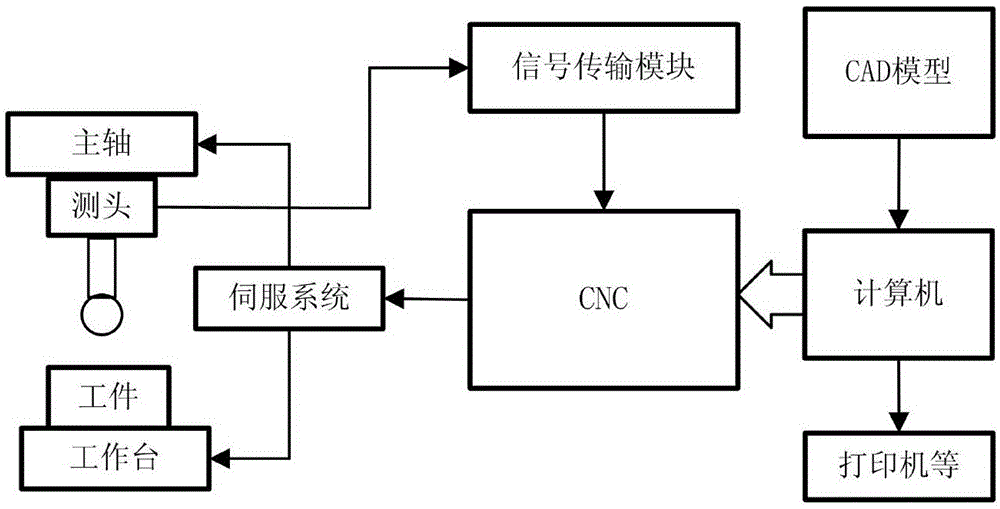

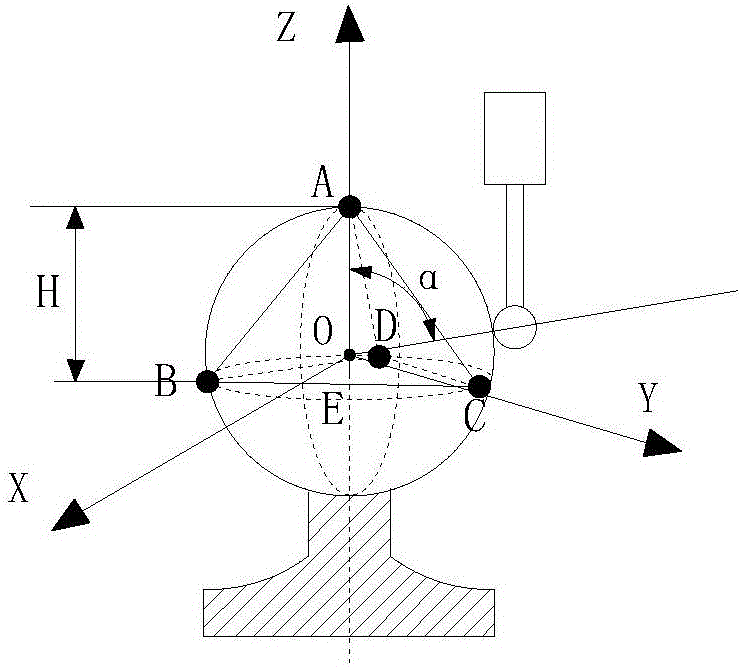

Online inclined hole measuring method through numerical-control machine tool

InactiveCN106826395AAvoid secondary card transfer errorsReduce labor costsMeasurement/indication equipmentsEngineeringMachining process

The invention provides a key online inclined hole measuring method through a numerical-control machine tool, and machining and measuring are conducted on the same equipment. By the adoption of the method, secondary swivel-clamp errors can be effectively avoided, a machine tool measuring head is added and installed in a tool magazine system of a numerical-control system, in the workpiece machining process, a measurement macroprogram is edited in advance, measurement of a machined workpiece can be conducted at any time according to technological requirements, and the effect that machining and measuring are conducted at the same time is achieved indeed. Discarded products can be found as early as possible, labor cost is reduced, productivity is liberated, and machining waste is reduced.

Owner:GUANGDONG UNIV OF TECH

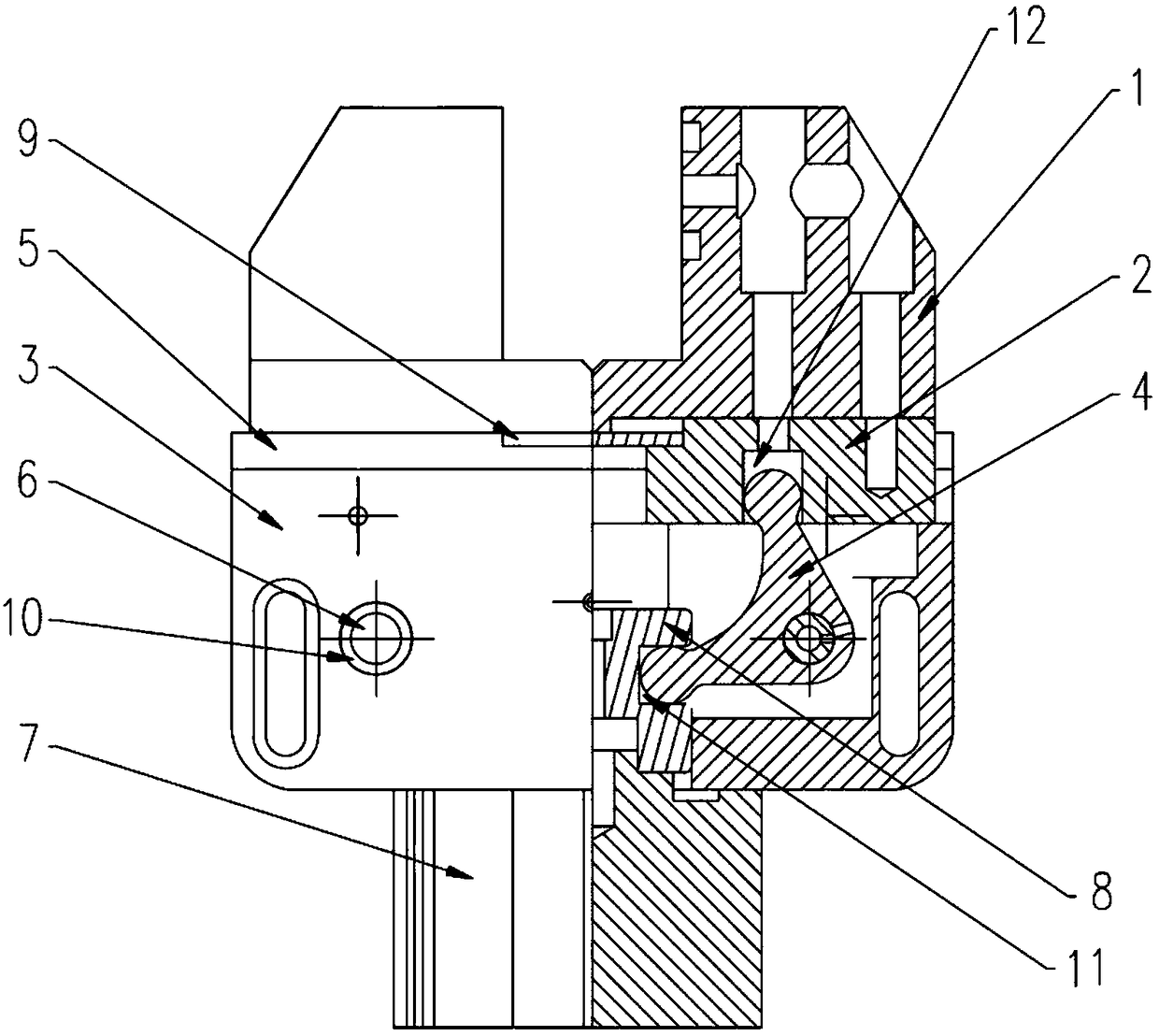

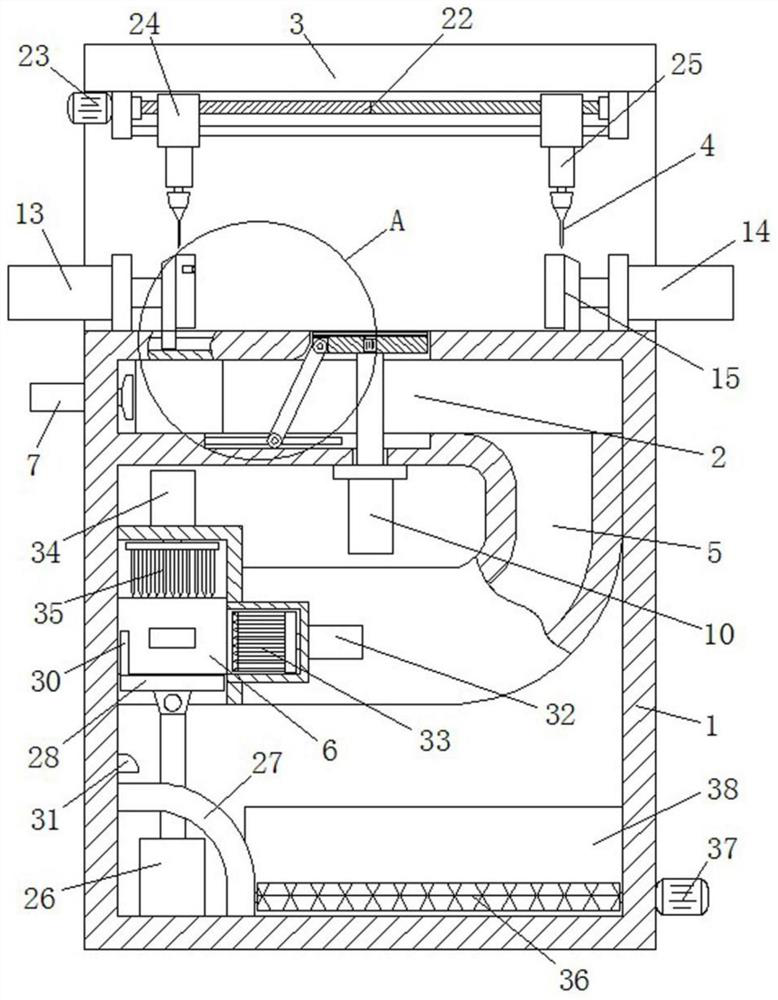

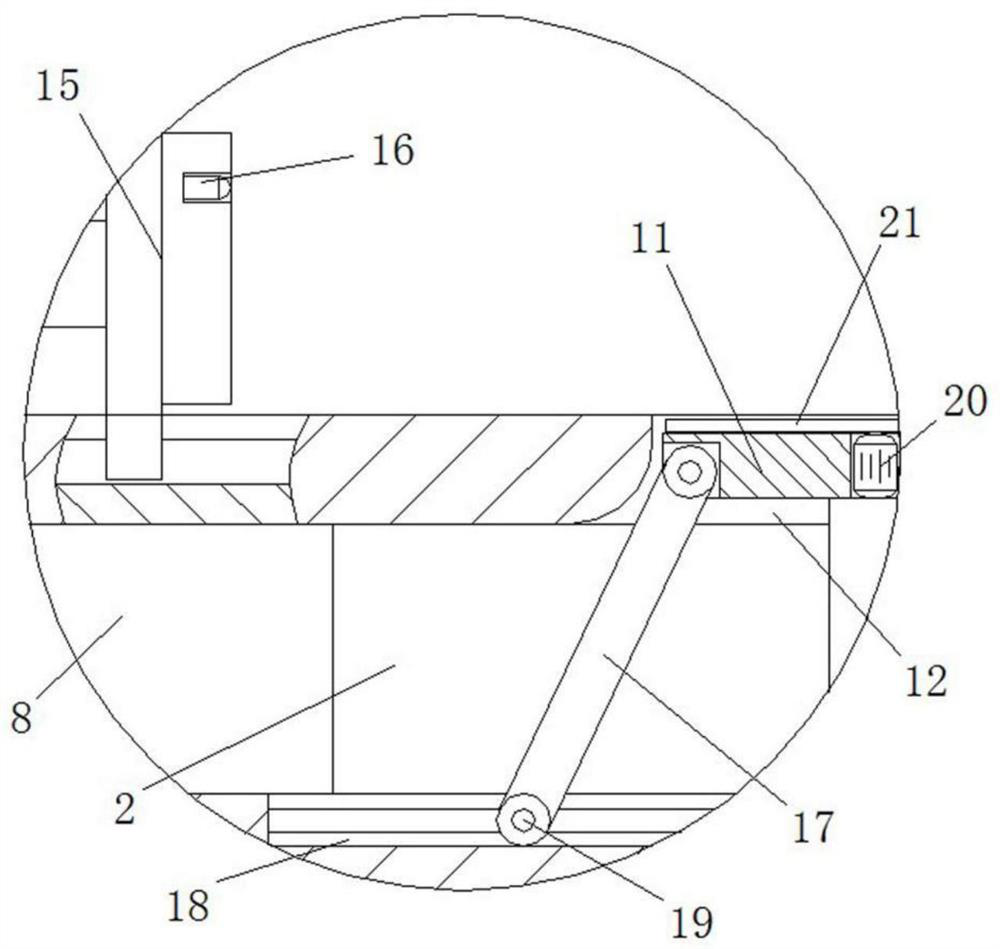

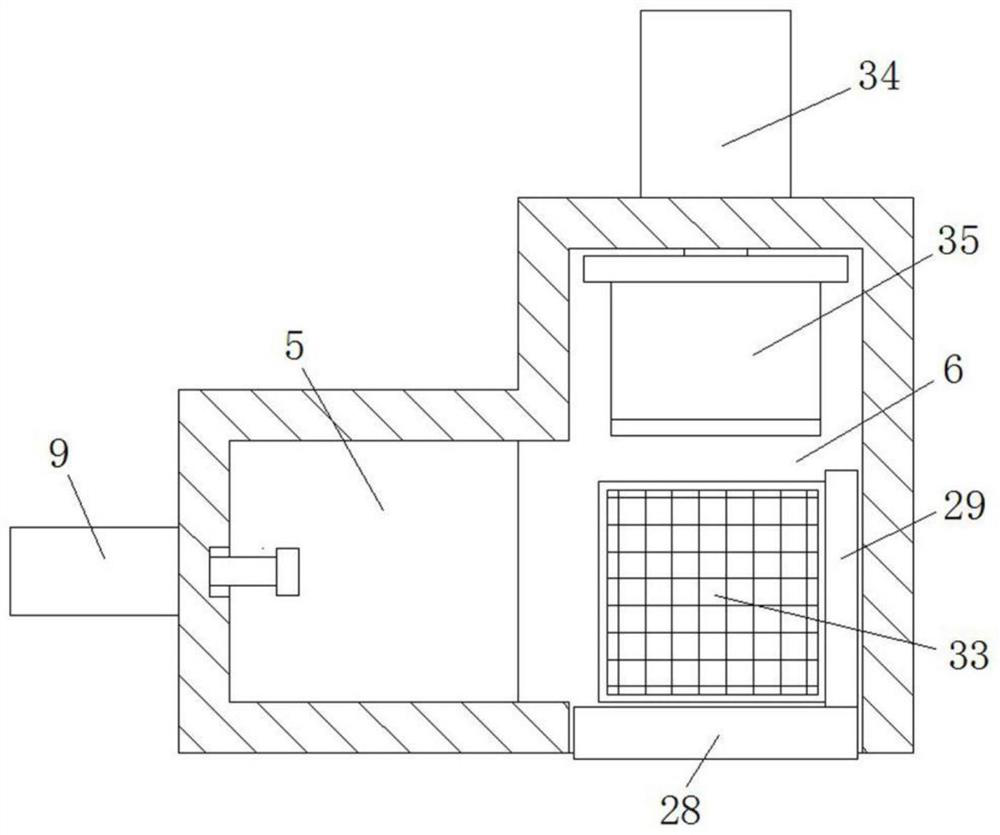

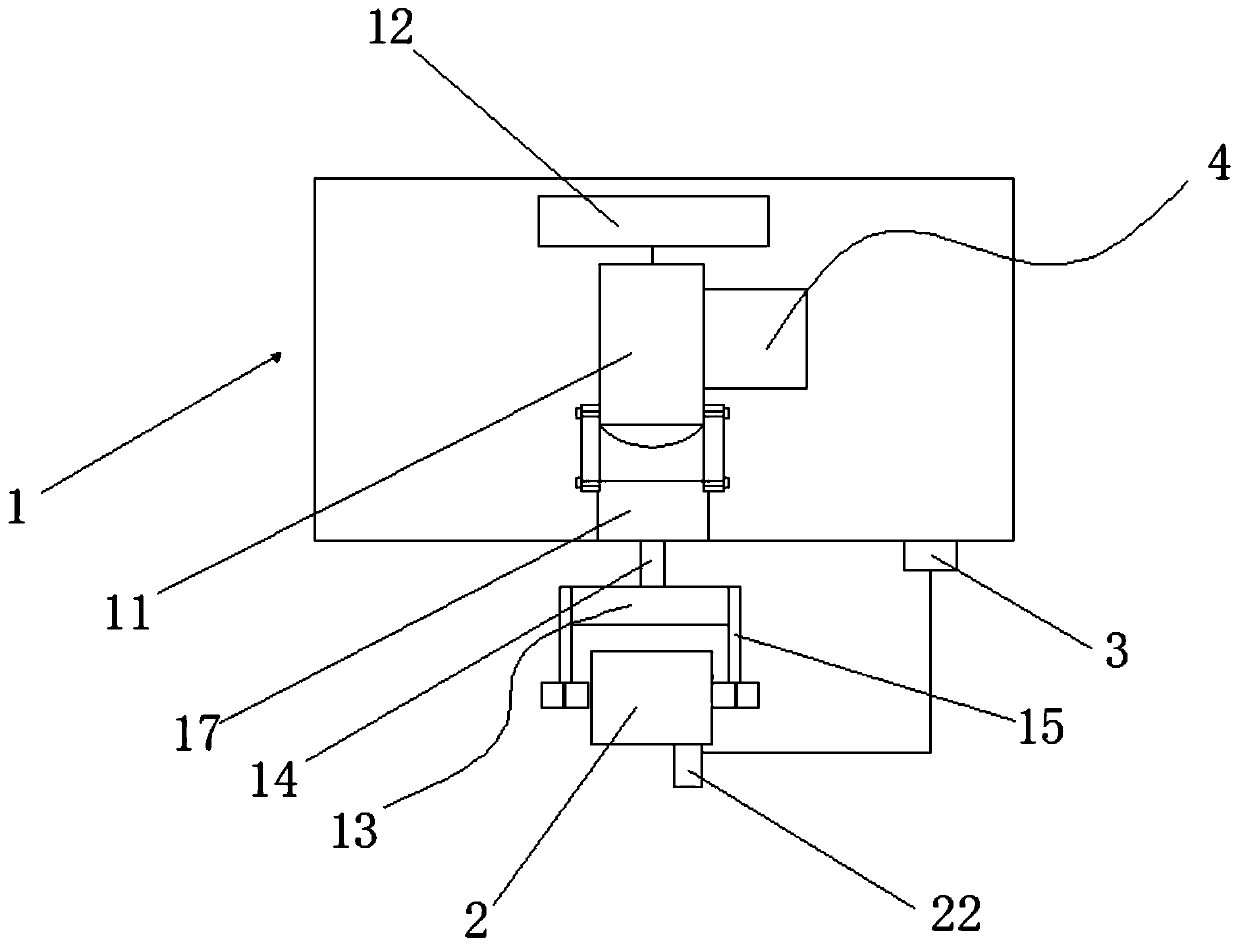

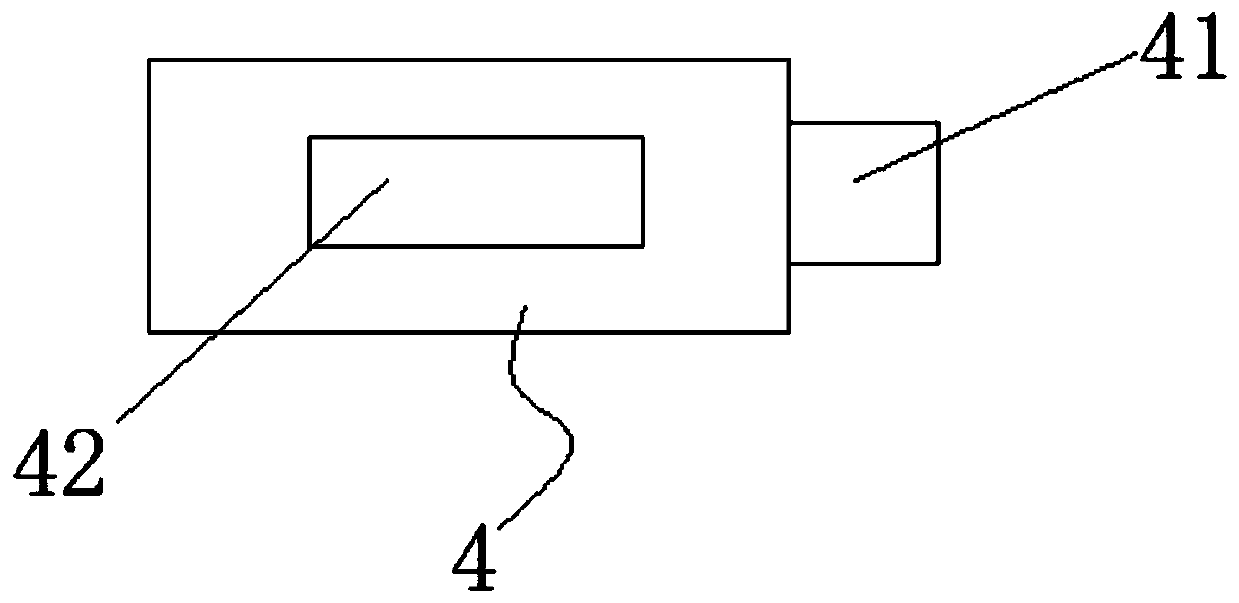

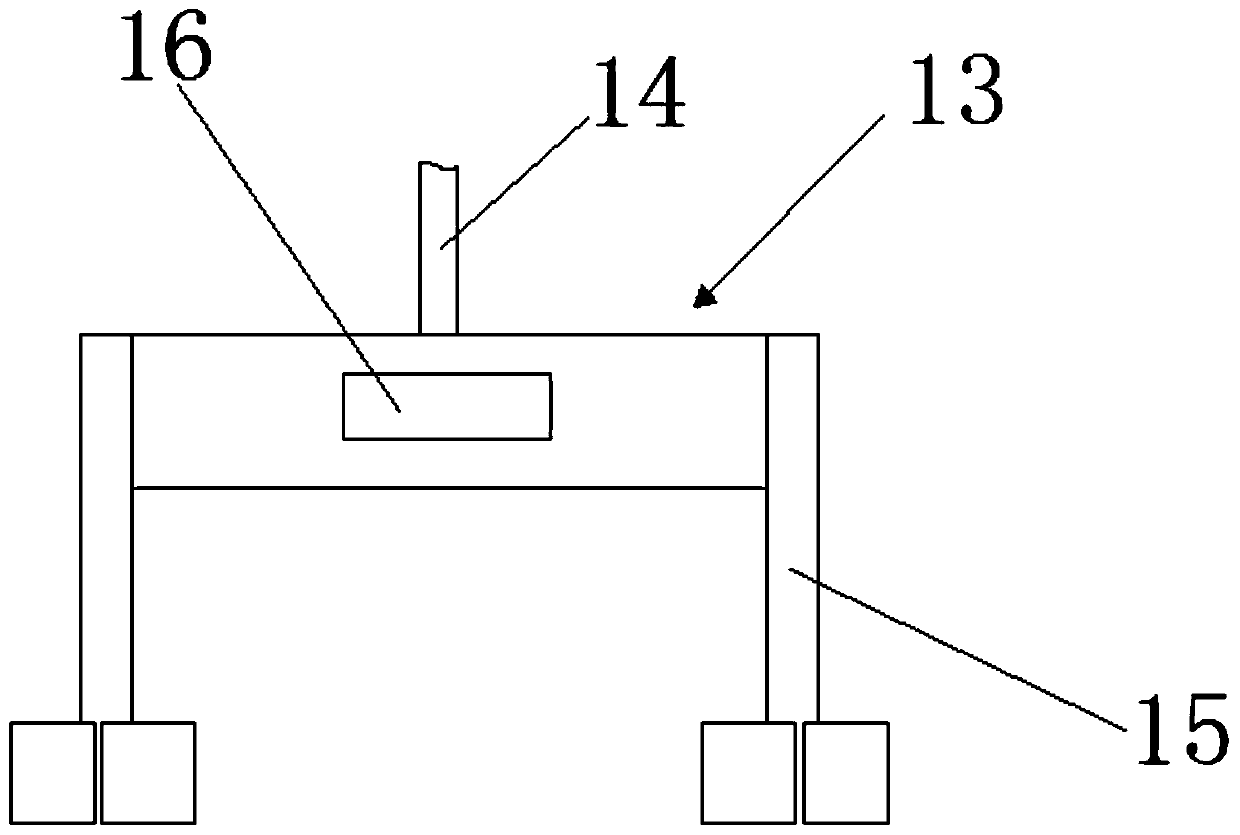

Novel pneumatic hydraulic synchronous clamp device

InactiveCN109420908AReduce processing wasteImprove processing pass rateWork clamping meansPositioning apparatusEngineeringMechanical engineering

The invention provides a novel pneumatic hydraulic synchronous clamp device which comprises clamping blocks, sliding blocks, a clamp base, triangle levers, a horizontal pressing plate, a pin shaft, apressure cylinder, a piston, a horizontal dustproof plate and a fixing shaft sleeve. A containing cavity is formed in the clamp base. A piston capable of moving up and down along the shaft in a reciprocating manner is coaxially installed in the containing cavity of the clamp base. The lower portion of the piston is in transmission connection with the pressure cylinder installed below the clamp base. The triangle levers are connected to the left side and the right side of the piston correspondingly. The sliding blocks capable of moving left and right in a reciprocating manner are connected above the triangle levers. One clamping block is fixed to each sliding block. The horizontal pressing plate connected with the clamp base is further arranged between the sliding blocks and the clamping blocks. According to the lever principle, the pressure cylinder is utilized for moving up and down to pull the levers to control the left sliding block and the right sliding block to move in the same direction or the opposite directions, and it is ensured that the center is located automatically for clamping a workpiece.

Owner:泉州市创佳自动化设备有限公司

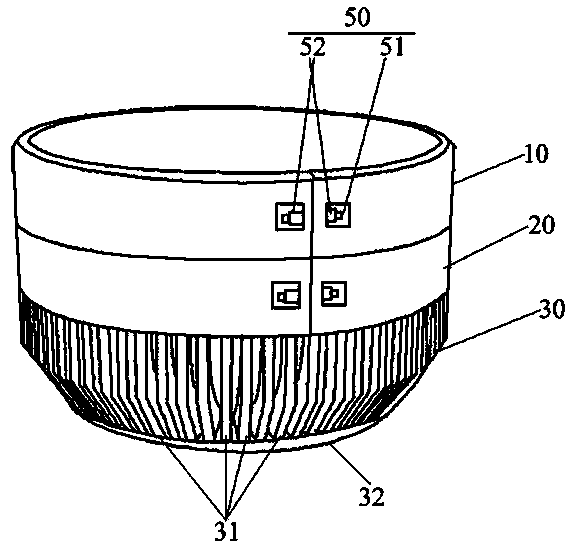

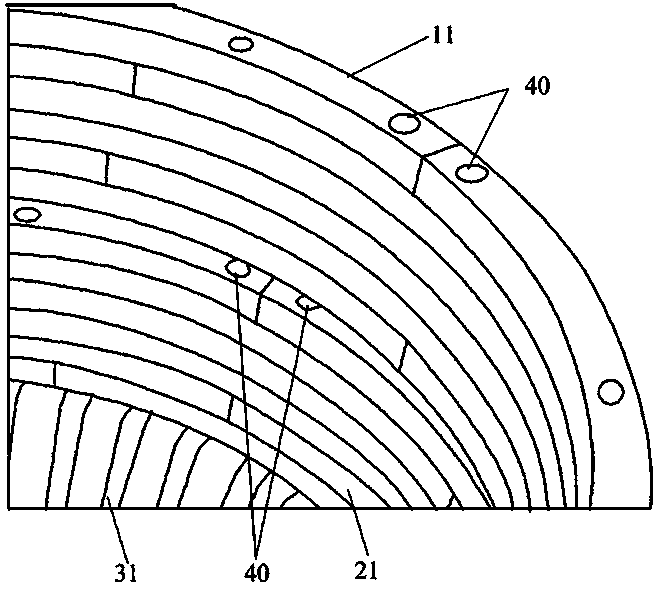

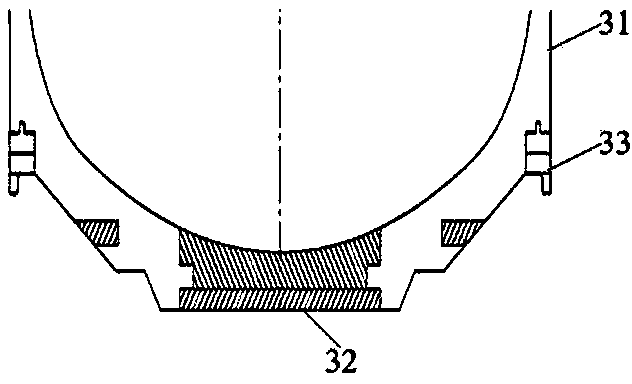

Novel crucible and manufacturing method thereof

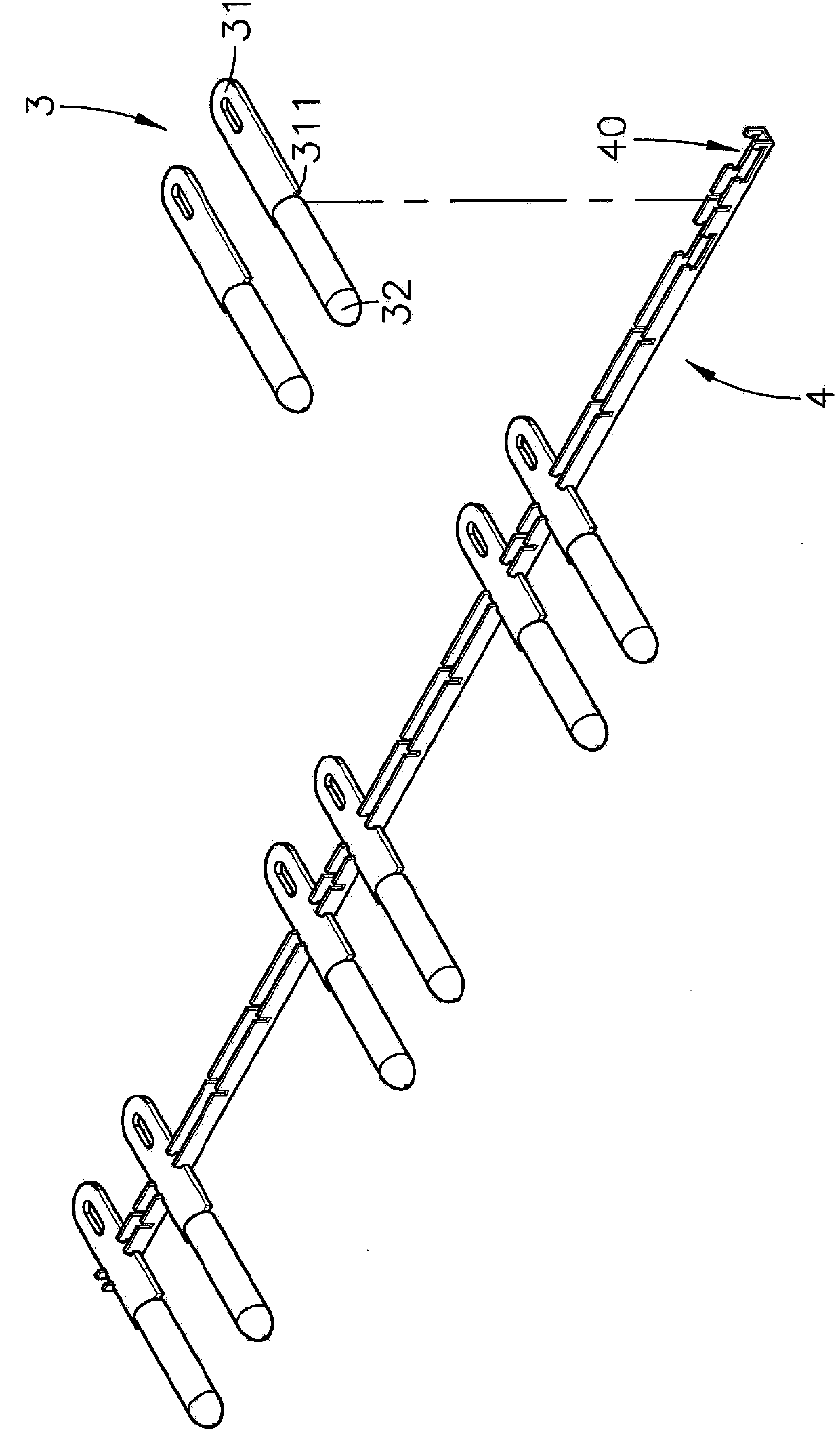

InactiveCN103469294AOvercome thermal stressImprove reliabilityPolycrystalline material growthBy pulling from meltMonocrystalline siliconCorrosion

The invention provides a novel crucible, which is applied in a manufacturing process of monocrystalline silicon or polysilicon. The novel crucible comprises an upper ring part, a middle ring part and a lower bowl mounting part, which are connected in sequence, wherein the upper ring part is an annular hollow body and is formed in such a manner that a plurality of first arc-shaped combination pieces are arranged and stacked in parallel to the circumferential direction of the bottom part and are assembled through pins vertical to the bottom parts, the side face of the upper ring part is provided with a gap parallel to the axial direction, and a connecting mechanism is arranged on the gap; the middle ring part is an annular hollow body and is formed in such a manner that a plurality of second arc-shaped combination pieces are arranged and stacked in parallel to the circumferential direction of the bottom part and are assembled through pins vertical to the bottom parts, the side face of the middle ring part is provided with a gap parallel to the axial direction, and a connecting mechanism is arranged on the gap; the lower bowl mounting part is an arc-shaped bowl body and comprises a plurality of third combination pieces and a bowl bottom, and the third combination pieces are vertically connected with the bowl bottom to form a bowl wall. The crucible provided by the invention is high in cost performance, strong in corrosion resistance, capable of effectively resisting against erosion of silicon vapor and long in service life.

Owner:SHANGHAI QI JIE CARBON MATERIALS

A post-extraction process for antimicrobial peptides produced by Bacillus subtilis

ActiveCN104130318BDry fastHigh activityPeptide preparation methodsDepsipeptidesBiotechnologyAntimicrobial peptides

The invention relates to a post-extraction process for producing antibacterial peptide through bacillus subtilis and belongs to the technical field of biology. The process comprises the following steps: by taking bacillus subtilis as a production strain, preparing a finished antibacterial peptide product through centrifugation, membrane separation and spray drying treatment of fermentation liquor, centrifuging by adopting two continuous centrifugal machines, performing classification and membrane separation, removing the thallus and hybrid proteins to the greatest degree, thus obtaining the antibacterial peptide with high activity. By utilizing heat resistance of the antibacterial peptide, the antibacterial peptide is rapidly dried through a spray drying technology, the preparation efficiency of the antibacterial peptide is improved, and maltodextrin serving as an auxiliary material has the advantages of high solubility and high stability, is unsuitable for moisture absorption and deterioration and contains rich trace elements and mineral substances. The separated and purified antibacterial peptide is high in activity, low in cost, simple in process and low in post-treatment loss.

Owner:山东仙普爱瑞科技股份有限公司

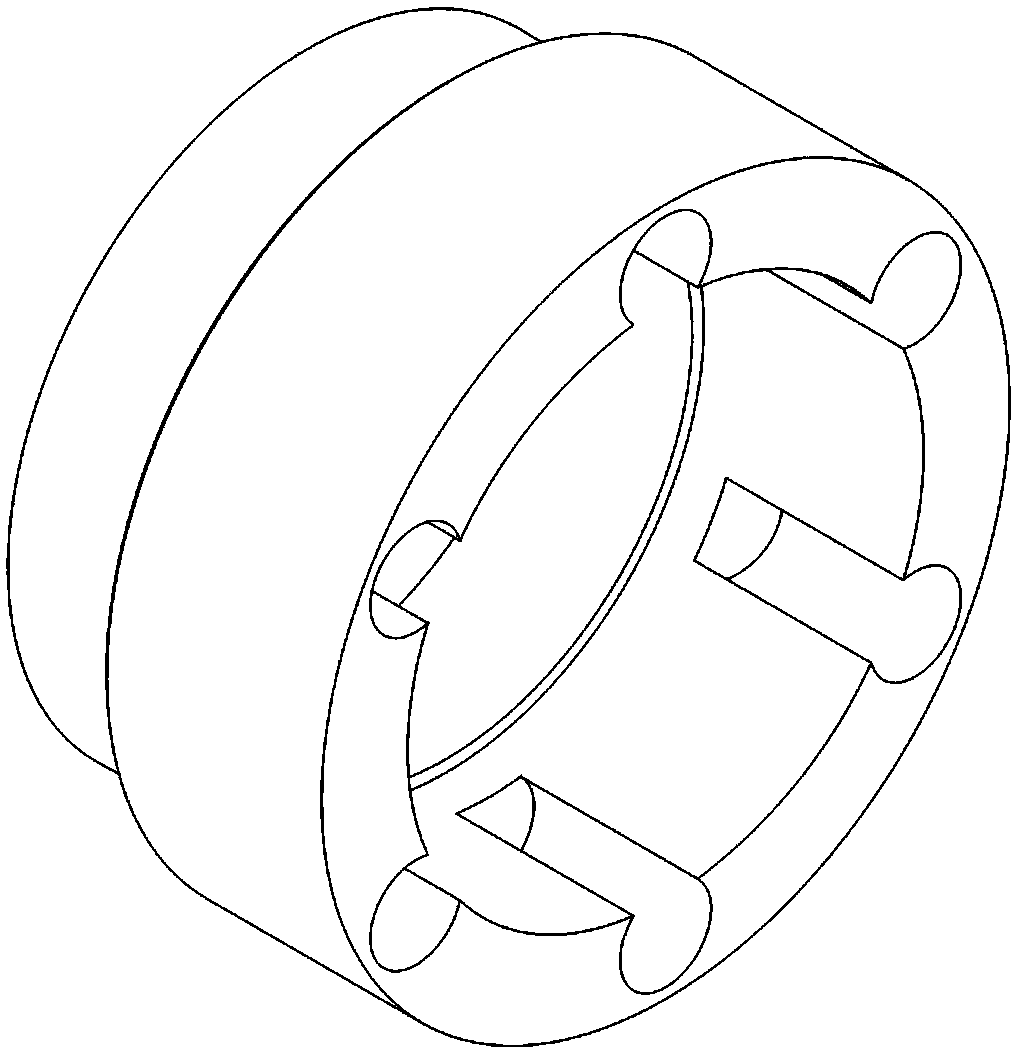

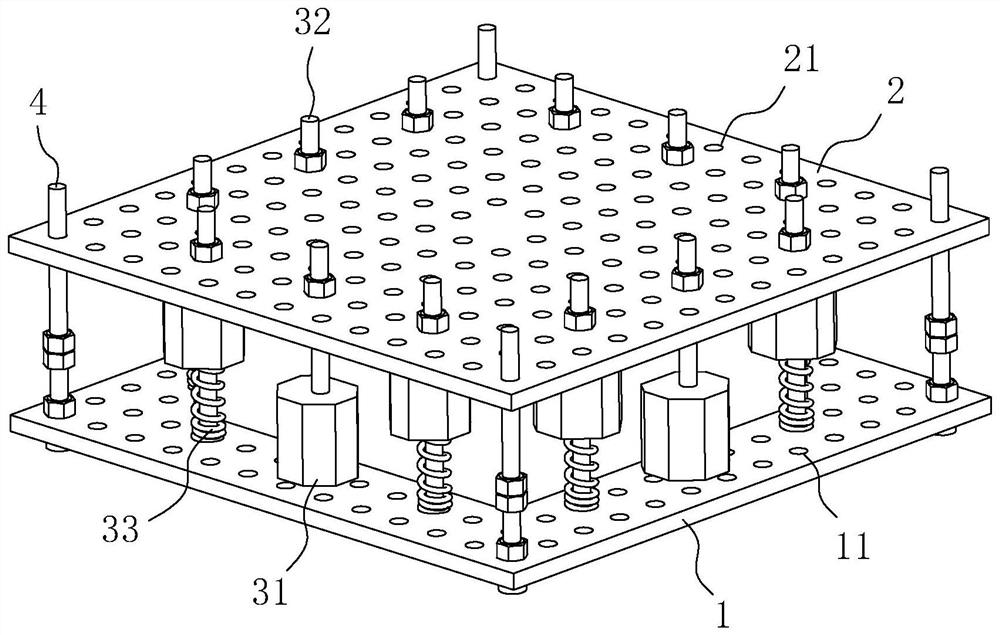

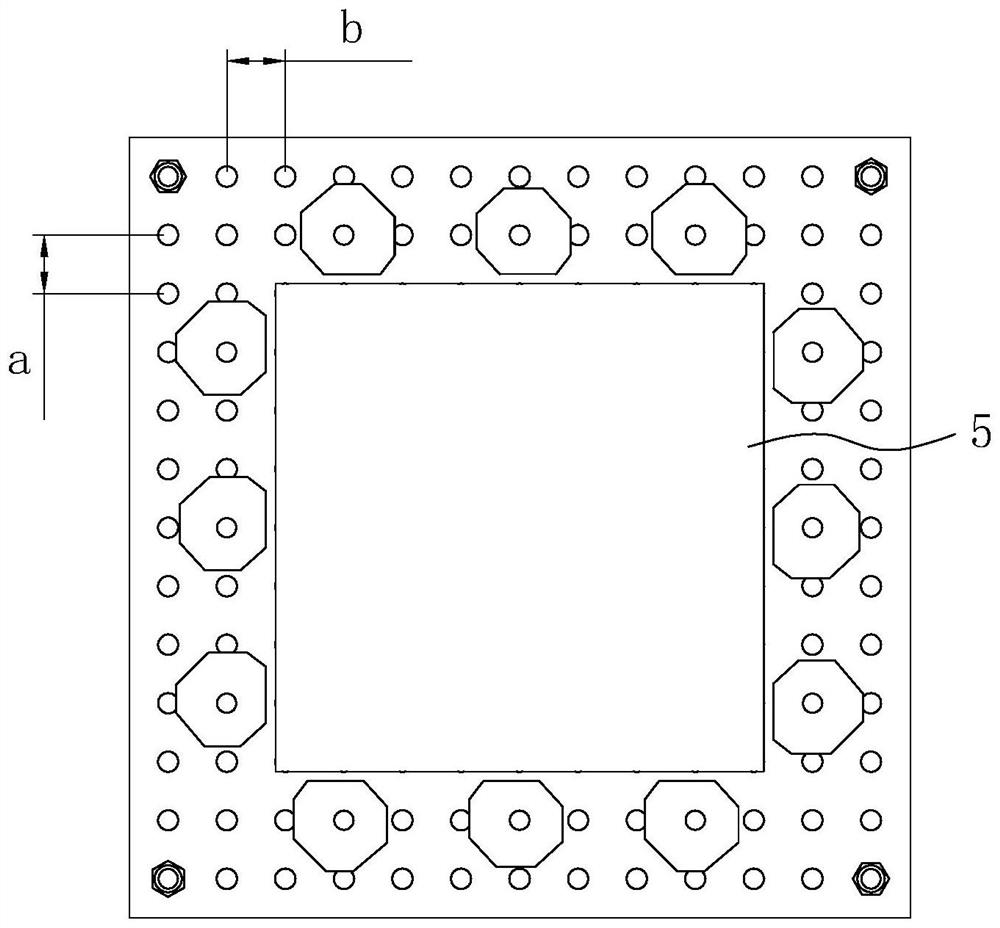

Silicon steel sheet press fitting tooling

ActiveCN113664759AControl slide offsetReduce processing wasteWork holdersMetal-working hand toolsElectric machineryEngineering

The invention discloses a silicon steel sheet press fitting tooling, and relates to the technical field of motor production. According to the technical scheme, the silicon steel sheet press fitting tooling is characterized by comprising a lower pressing plate, and a limiting structure is arranged on the lower pressing plate and used for limiting a silicon steel sheet in the silicon steel sheet press fitting process; and the limiting structure comprises a limiting check block capable of being rotatably adjusted, the limiting check block comprises a plurality of limiting faces used for limiting silicon steel sheets of different dimensions, and the minimum distances between the limiting faces and the rotating axis of the limiting check block are different. The silicon steel sheet press fitting tooling provided by the invention can be suitable for silicon steel sheets of various specifications, and is convenient to operate and good in stability.

Owner:苏州英磁新能源科技有限公司

Reducing rotary forging method for internal thread copper pipe

InactiveCN102000755BImproves exterior surface finishIncrease productivityForging/hammering/pressing machinesForging press drivesControl lineScrew thread

The invention discloses a reducing rotary forging method for an internal thread copper pipe, in particular a method for machining the internal thread copper pipe by reducing spinning and the extrusion of rotating roller cores. In the machining method, the rotating roller cores with threads are adopted while the reducing spinning is performed, and the inner wall of the cooper pipe is subjected extrusion molding under the action of friction force to ensure that continuous and uniform threads exist on the inner surfaces of copper pipes, and the inner surfaces have the distinct threads, controlled lines and few residues.

Owner:HEFEI GREAT WALL REFRIGERATION TECH

Sewing machine providing convenience for needle threading

InactiveCN108823845AShorten the timeImprove work efficiencyNeedle-threading devicesLaser transmitterEngineering

The invention discloses a sewing machine providing convenience for needle threading. The sewing machine comprises a supporting table, a machine body is installed at the top of the supporting table, and a fixing column is arranged at the top of one side of the machine body; a machine head and a sewing needle are arranged at the bottom of one side of the machine body in sequence, sliding rails, first sliding blocks, second sliding blocks, a first fixing plate and a second fixing plate are arranged at the top of the supporting table in sequence, and a guide needle is arranged at one side of the first fixing plate; a groove opening is formed in one end of the guide needle, a laser emitter is arranged at one side of the first fixing plate, a reflection mirror is installed on one side wall of the second fixing plate, and a flexible ruler is installed at one side of the top of the supporting table; a ruler strip and a fixing clamp are connected to one side of the flexible ruler in sequence, and a ruler is installed at the top of the supporting table. According to the sewing machine, the sewing needle can be conveniently used for needle threading, the time required by needle threading is shortened, the working efficiency is improved, the length of sewed cloth can be measured, the accurate length of the cloth is obtained accordingly, processing waste is reduced, and the cloth cost is lowered.

Owner:邓瑞英

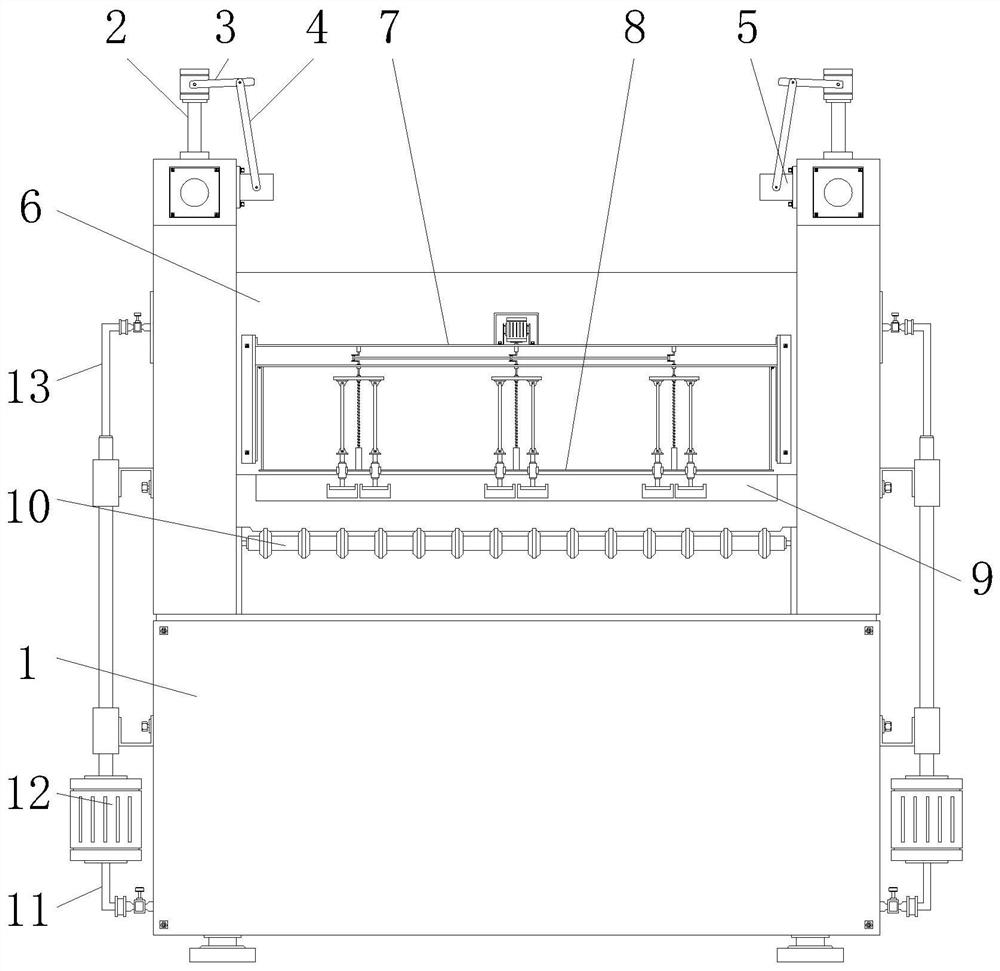

Backlash compensation method for laser welding and device implementing same

InactiveCN102107296BMeet straightness requirementsGood cross sectionPlaning/slotting machinesButt jointEngineering

The invention belongs to the field of laser welding, and particularly relates to a backlash compensation method for laser welding and a device implementing the method. The method comprises the following steps: planning the side to be welded of the welding base metal, and planning a butt joint end surface with high straightness and flatness, and reducing the inter-plate backlash when the base metal is in butt joint; the device comprises a supporting platform as well as a frame, a compressing mechanism, a transmission mechanism, a locating mechanism and a cutter arranged on the supporting platform; the frame is positioned above the supporting platform, and the compressing mechanism capable of reciprocating up and down is arranged on the frame; the transmission mechanism is arranged at the outer side of the supporting platform and moves back and forth by driving a cutter rest provided with the cutter so as to plane the side to be welded of the base metal; and the inner side of the transmission mechanism is provided with the locating mechanism on the supporting platform. The method has good straightness and flatness in the whole process, and can meet the requirement of laser welding on the straightness and flatness of the side to be welded of the base metal; and the device has the advantages of simple structure, strong reliability, high efficiency, safe operation, and the like.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Low-waste sulfur-free processing device and method for poria cocos dices

ActiveCN112405689AHigh yieldReduce processing wasteClimate change adaptationMetal working apparatusBiotechnologyAgricultural science

The invention discloses a low-waste sulfur-free processing device and method for poria cocos dices. The low-waste sulfur-free processing device comprises a shell. A preprocessing device is arranged ona processing track, and the preprocessing device comprises a pushing device arranged in the processing track and an end face cutter arranged above the pushing device. A driving assembly used for controlling the end face cutter is arranged on a fixed transverse plate. A blanking track is arranged at the end, away from a feeding device, of the processing track, and the end of the blanking track communicates with a discharging chamber. A first cutting assembly and a second cutting assembly are arranged on the side wall of the discharging chamber. According to the scheme, by arranging the pushingdevice and the feeding device in the preprocessing device, poria cocos can be conveyed to the end face cutter one by one through the pushing device to cut the end face, and the poria cocos is cut tothe proper size in advance. Therefore, the yield of the poria cocos dices is greatly increased, processing waste is reduced, and practicability is high.

Owner:靖州康源苓业科技股份有限公司

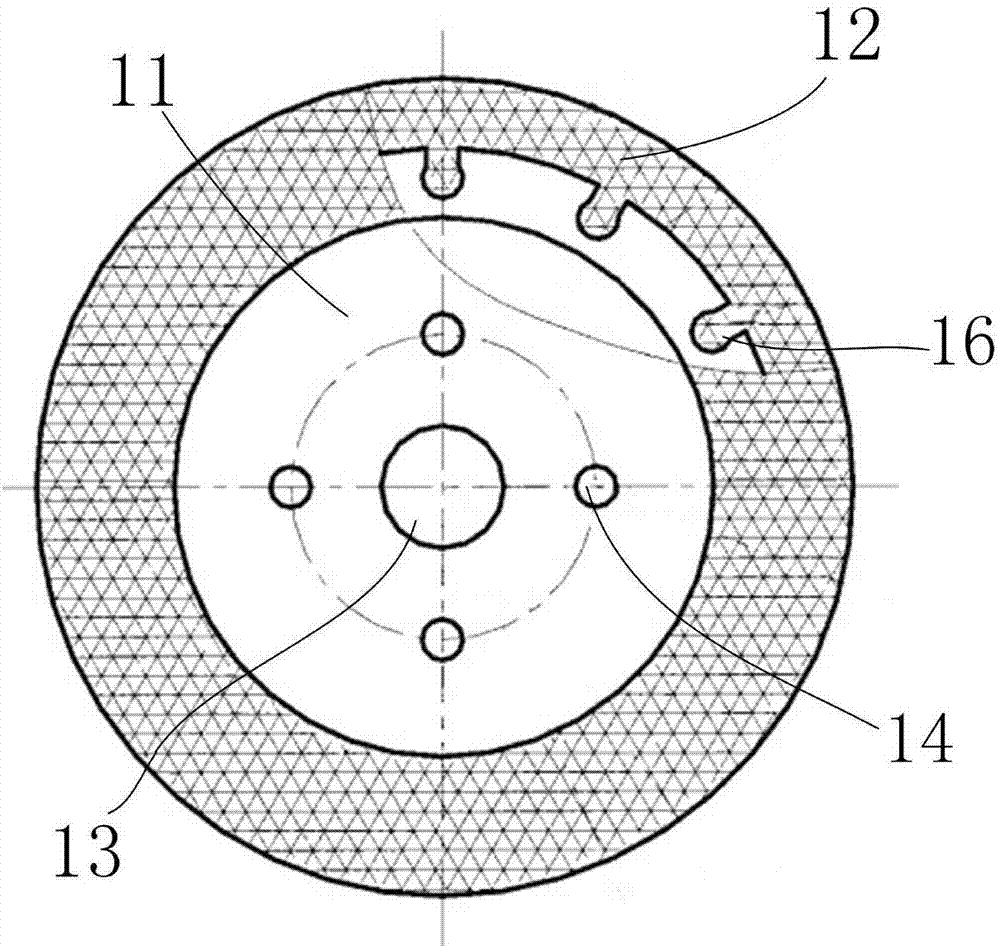

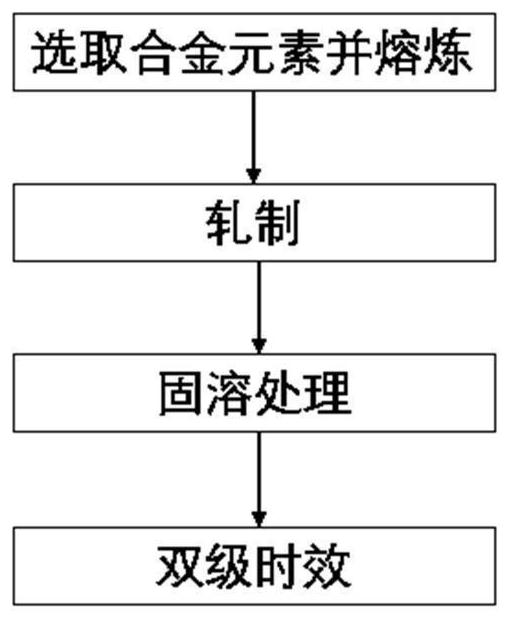

Reinforcing steel bar cutting machine

The invention discloses a reinforcing steel bar cutting machine comprising a machine seat, a support, a detachable machine cover, a center shaft, a cutter, a handle, a drive motor, four supporting legs and a moving mechanism. The support is installed at the back end of the machine seat. The detachable machine cover is installed on the support. The center shaft is arranged at the center of the detachable machine cover. The cutter is installed inside the detachable machine cover. The handle is installed on the left side of the detachable machine cover. The drive motor is installed at the lower end of the handle and connected with the center shaft. The four supporting legs are installed at the bottom end of the machine seat. The moving mechanism is installed at the lower ends of the supporting legs. The machine seat is longitudinally provided with a cutting groove. The machine seat is provided with multiple round through holes arranged in a reversed-trapezoid shape, wherein the round through holes transversely penetrate through the machine seat. The cutting groove is matched with the cutter. The cutter comprises a round-disk-shaped cutter body and a grinding wheel, wherein the round-disk-shaped cutter body is made of alloy steel, the grinding wheel is arranged on the edge of the cutter body, and the grinding wheel and the cutter body are connected into a whole through sintering. The outer circumference of the cutter body is provided with convex portions and connection grooves. The grinding wheel is provided with concave-convex structures matched with the convex portions and the connection grooves.

Owner:CHENGDU HANDAO TECH CO LTD

A kind of shell material of electronic product and its manufacturing method

Owner:SOUTHEAST UNIV

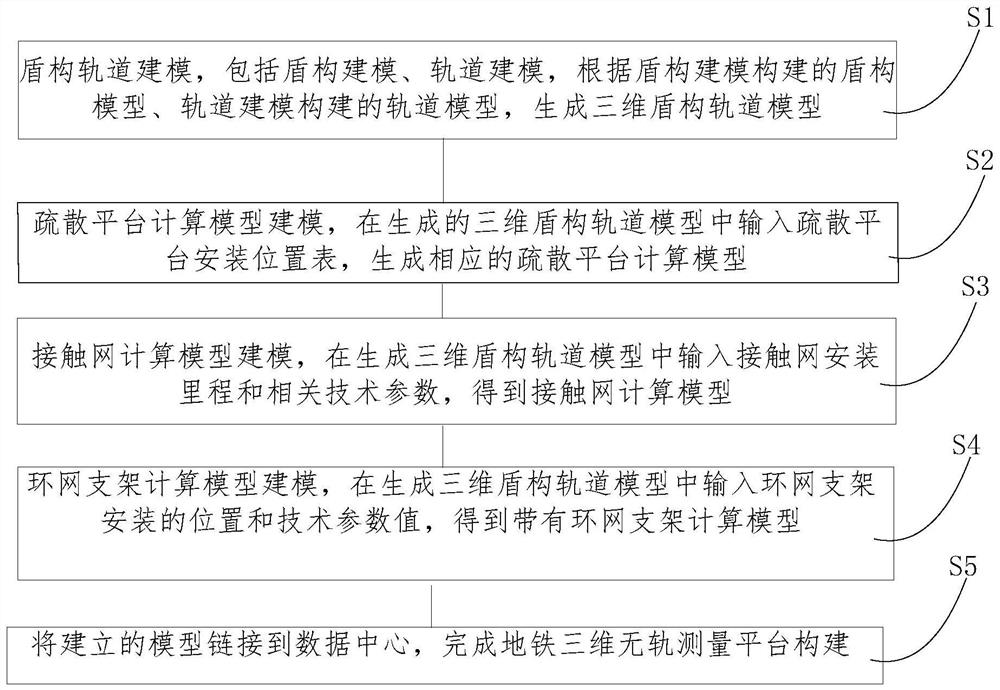

Construction method of subway three-dimensional trackless measurement platform

ActiveCN114818288AShorten the construction periodReduce processing wasteGeometric CADDesign optimisation/simulationTrackwayTracking model

The invention relates to a subway three-dimensional trackless measurement platform construction method which comprises the following specific steps: generating a three-dimensional shield track model according to a shield model constructed by a shield construction model and a track model constructed by a track modeling model; an evacuation platform installation position table is input into the generated three-dimensional shield track model, and a corresponding evacuation platform calculation model is generated; a contact network installation mileage and related technical parameters are input in the process of generating the three-dimensional shield track model, and a contact network calculation model is obtained; inputting the installation position and the technical parameter value of the looped network bracket in the generation of the three-dimensional shield track model to obtain a calculation model with the looped network bracket; and linking the established model to a data center to complete construction of the subway three-dimensional trackless measurement platform. By constructing the subway three-dimensional trackless measuring platform, ordering of an evacuation platform, a contact network and a ring network support can be completed before on-track communication, so that the construction period is shortened, and machining waste is reduced.

Owner:中铁建电气化局集团南方工程有限公司

Rolling outlet real-time monitoring rolling quality device

ActiveCN108746217BEasy to installImprove yieldMeasuring devicesMetal rolling arrangementsProduct inspectionEngineering

Owner:韩亚半导体材料(贵溪)有限公司

A low-waste tuckahoe fang ding sulfur-free processing device and method

ActiveCN112405689BHigh yieldReduce processing wasteClimate change adaptationMetal working apparatusProcess engineeringWolfiporia extensa

The invention discloses a sulfur-free processing device and method for low-waste tuckahoe fang ding. The drive assembly for controlling the end cutter is set on the fixed horizontal plate above the end face cutter above the pushing device; the end of the processing track away from the feeding device is provided with a blanking track, and the end of the blanking track is connected to a discharge chamber ; The side wall of the discharge chamber is provided with a first cutting assembly and a second cutting assembly. Through the setting of the pusher and feeding device in the pretreatment device, this program can transport the Poria cocos one by one to the end face cutter through the pusher device, cut the end face, and cut the Poria cocos to a suitable size in advance, thereby greatly improving the quality of the Poria cocos recipe. The output rate of Ding is high, the processing waste is reduced, and the practicability is strong.

Owner:靖州康源苓业科技股份有限公司

Anti-clogging grinding machine for circuit board processing

ActiveCN112589559BAvoid cloggingEasy to grindGrinding carriagesGrinding feedersStructural engineeringScreen filter

The invention discloses an anti-clogging grinder for circuit board processing, which comprises a device casing, a protective cover, a lower grinding plate cylinder and a screw rod, the upper end of the device casing is penetrated and connected with a positioning rod, and the protective cover is movably installed. Inside the equipment casing, a transmission rod is installed on the front side of the equipment casing, the outlet pipe is connected to one end of the water pump, the lower grinding plate tube is rotatably installed on the inside of the protective cover, and the inside of the equipment casing A filter screen plate is installed, the screw mandrel is rotatably installed inside the installation frame, the slider is movably connected to the outside of the slide bar, and the inside of the installation frame is rotatably installed with a side rotating shaft. The anti-clogging grinding machine for circuit board processing adopts a new structural design, so that the device can clean up the impurities blocked in the equipment through the high-frequency vibration structure after processing, and maintain the effect of continuous processing of the equipment, and the device is equipped with a circuit Board pretreatment structure, improve the effect of circuit board processing.

Owner:江西遂川光速电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com